Benefits of 4 Head Embroidery Machine

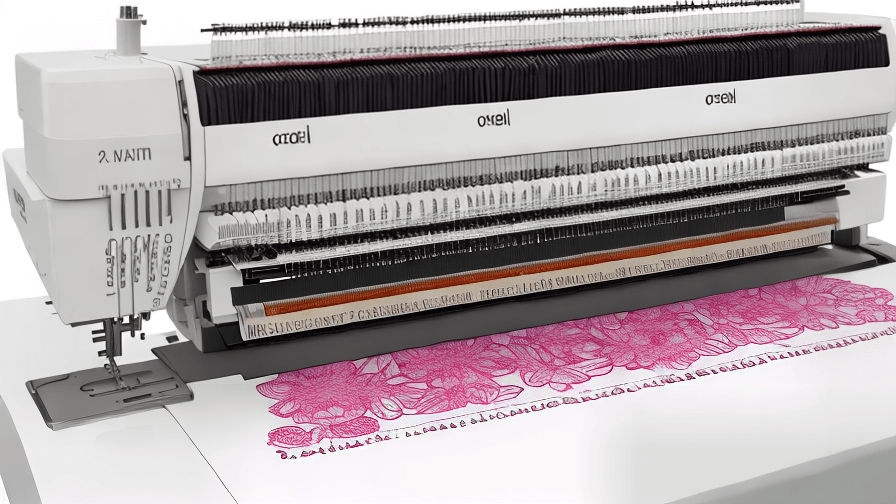

The art of embroidery has been around for centuries and is still alive today. With advancements in technology, the use of embroidery machines has increased in popularity. One such machine is the 4 head embroidery machine.

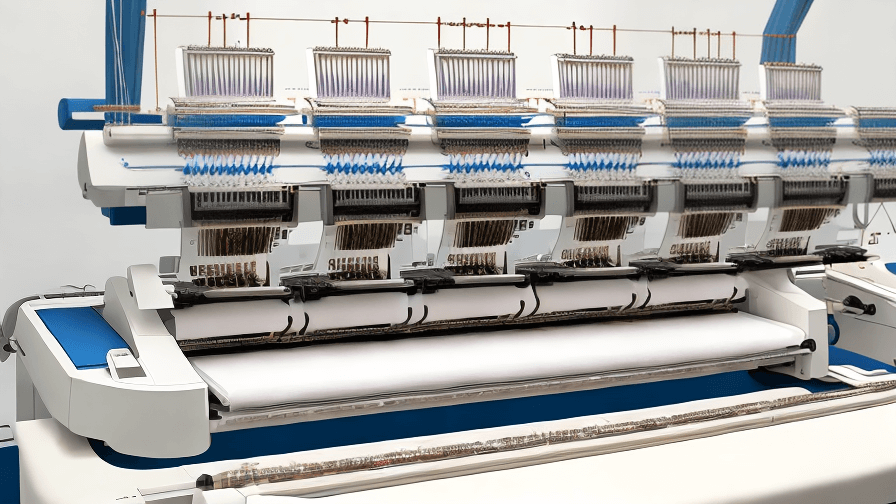

A 4 head embroidery machine is a multi-needle machine that has 4 sewing heads. This machine allows for quick and efficient embroidery work, saving time and effort for the user. Here are some of the benefits of using a 4 head embroidery machine:

1. Increased production: With four sewing heads, the machine can produce multiple designs at the same time, increasing productivity. This is especially advantageous for businesses that require mass production of embroidered items.

2. Versatility: The 4 head embroidery machine can be used to create a wide range of designs, from simple text to intricate designs. The large embroidery area also allows for bigger designs to be embroidered onto fabrics.

3. Consistency: The machine’s computerized system ensures that each stitch is consistent, eliminating the possibility of human error. This results in high-quality embroidery work that appears uniform and professional.

4. Cost-effective: Although the initial investment may be higher compared to single-head embroidery machines, the 4 head embroidery machine pays off in the long run. With increased production and decreased labor cost, the machines prove to be cost-effective.

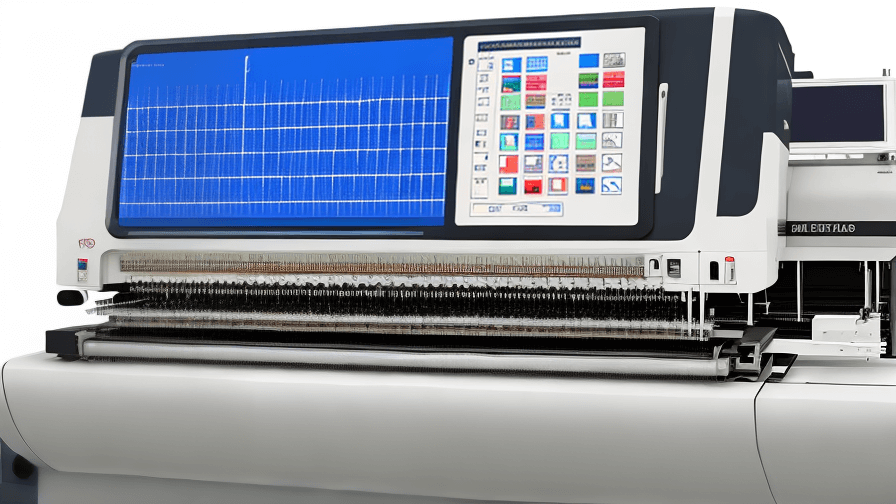

5. Easy to use: The 4 head embroidery machine is user-friendly, with an intuitive interface that allows even beginners to operate it with ease. The machine also comes with training and technical support.

In conclusion, a 4 head embroidery machine is an excellent investment for businesses and individuals who require high-quality embroidery work. With increased production, consistency, versatility, and cost-effectiveness, it is a machine worth considering.

Features of 4 Head Embroidery Machine

A four-head embroidery machine is a multi-needle embroidery machine that has four embroidery heads. These machines are designed for commercial purposes and have become a go-to choice for businesses that require high-volume embroidery production. The following are some of the features that make a 4 head embroidery machine a great choice.

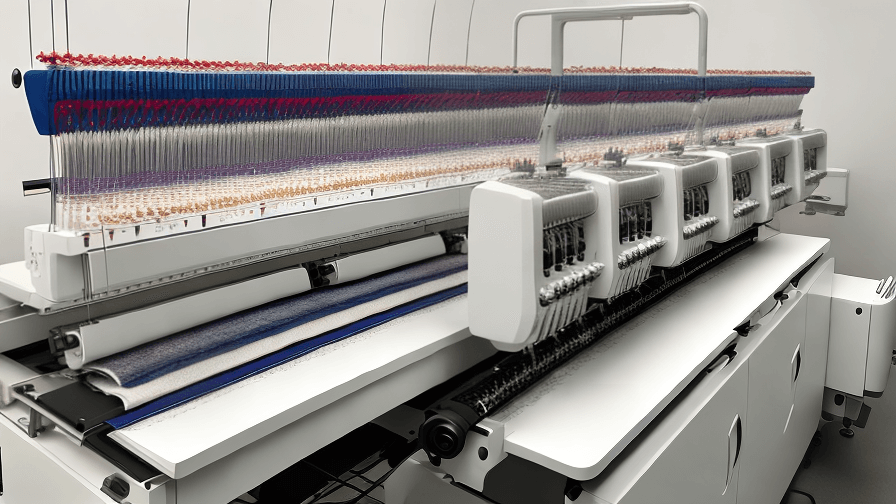

1. Speed: A 4 head embroidery machine can produce up to four times the amount of embroidery in the same amount of time that it would take a single-head machine to produce. The speed of the machine is crucial in meeting customer demands and increasing production efficiency.

2. Versatility: These machines allow for the creation of intricate embroidery designs using multiple colors and stitch patterns. The versatility of the 4 head embroidery machine allows for the production of a wide range of embroidery designs, including hats, shirts, jackets, bags, and more.

3. Automatic color changes: Unlike typical embroidery machines, a 4 head embroidery machine allows automatic color changes. This feature eliminates the need to manually change the thread color during the embroidery process, saving time and effort.

4. Large hoop sizes: 4 head embroidery machines have large embroidery hoops that can accommodate multiple items simultaneously, including larger garments like jackets and sweatshirts.

5. Easy to use: With the flip of a switch or the push of a button, the machine can be programmed and set up for embroidery design. The user-friendly interface allows for quick set up and operation, making it easy for anyone to use, even without years of experience.

These are just a few of the many features that make the 4 head embroidery machine an excellent investment for businesses in the embroidery industry. From speed and versatility to automatic color changes and large hoop sizes, these machines provide both efficiency and productivity to ensure accurate and high-quality embroidery designs.

Various Types of 4 Head Embroidery Machine

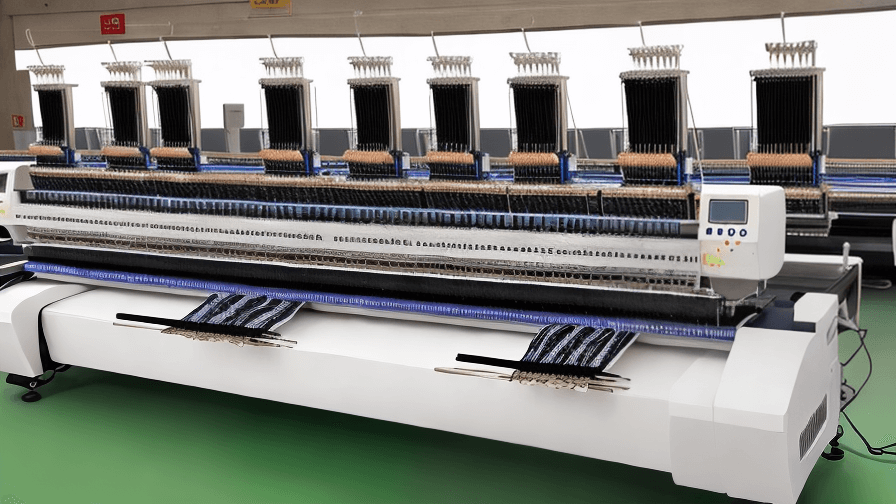

Embroidery machines come in many different types, each with their unique features and capabilities. One such type is 4 head embroidery machines, which can simultaneously embroider four different items at once, making them an excellent choice for businesses with high production demands. Here are some of the various types of 4 head embroidery machines:

1. Commercial 4 Head Embroidery Machines: These machines are designed for high-volume, commercial use and can produce up to 1200 stitches per minute. They have many features that make them ideal for businesses, such as automatic thread trimmers and large embroidery fields.

2. Home 4 Head Embroidery Machines: These machines are designed for home use and have a lower production capacity than commercial machines. However, they still offer a variety of features such as built-in designs and automatic needle threading.

3. Portable 4 Head Embroidery Machines: As the name suggests, these machines are portable, making them ideal for businesses that need to move their machines from one location to another. They are lightweight and compact, but still, offer many of the features found in commercial machines.

4. Multi-Needle 4 Head Embroidery Machines: These machines have multiple needles, which means that they can embroider several colors at once without the need to change threads constantly. This makes them ideal for businesses that require multiple colors in their designs.

Overall, 4 head embroidery machines offer a wide range of features and capabilities that make them versatile and useful for both commercial and home use. With so many different types available, businesses and individuals can easily find a machine that meets their specific needs and requirements.

Applications of 4 Head Embroidery Machine

Embroidery has been a traditional method of decorating fabrics and textiles for centuries. With the advent of technology, embroidery machines have been developed, providing faster and more efficient methods of producing elaborate designs on fabrics. One popular type of embroidery machine is the 4 head embroidery machine.

A 4 head embroidery machine is a textile machine that allows for the simultaneous embroidering of four different embroidery designs on the same fabric. These machines are widely used in textile and garment manufacturing industries due to their speed and accuracy.

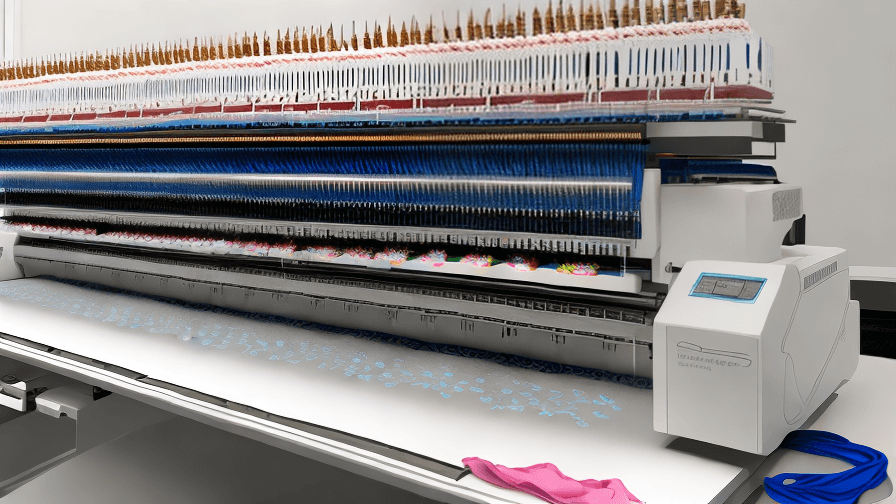

The applications of 4 head embroidery machines are vast. One popular application is in the production of sportswear where logos and team names can be embroidered onto uniforms. This makes the production process faster and more efficient while allowing for intricate designs to be embroidered.

Another application of 4 head embroidery machines is in the production of industrial textiles such as curtains, bed linens, and tablecloths. With this machine, intricate designs can be embroidered quickly on these textiles, increasing productivity in the production process.

Fashion designers and clothing manufacturers also use 4 head embroidery machines to produce high-quality embroidered designs on their clothing. These machines are especially useful in the production of haute couture fashion where intricate and ornate details are required.

4 head embroidery machines are also used in the production of custom-made embroidery and personalized gifts. These machines allow for unique designs to be embroidered on items such as hats, bags, and towels. This has increased the availability of personalized gifts and merchandise at a faster pace.

In conclusion, 4 head embroidery machines have numerous applications in the textile and garment manufacturing industries. These machines have increased productivity while allowing for intricate and unique designs to be embroidered on fabrics and clothing. The use of these machines has revolutionized the embroidery industry, and their popularity is only expected to grow in the future.

The Process of 4 Head Embroidery Machine

The Process of 4 Head Embroidery Machine

A 4 head embroidery machine is a large industrial machine used to embroider multiple designs on fabric. The process of 4 head embroidery machine involves several steps that ensure the desired design is achieved.

The first step is to select the design to be embroidered. The design is created using specialized embroidery software and saved in a digital format that can be read by the 4 head embroidery machine. Once the design is selected, it is loaded into the machine.

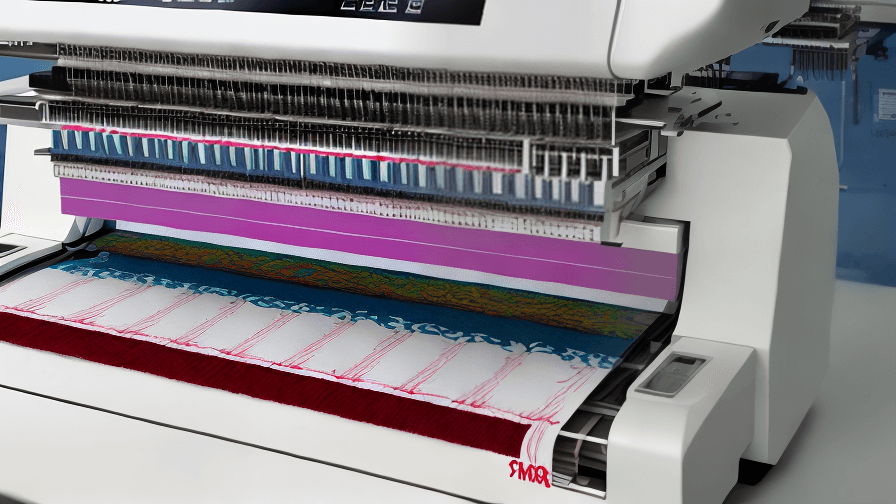

The next step involves selecting the thread color. The 4 head embroidery machine has a wide range of thread colors to choose from. The thread is then loaded onto the machine, and the color sequence is set.

Once the design and thread are selected, the fabric is loaded onto the machine. The fabric is secured to the embroidery hoop, which is attached to the 4 head embroidery machine.

The next step is to set the machine’s speed and needle depth. The speed and needle depth are adjusted to ensure that the embroidery is done accurately and efficiently.

The machine then begins to embroider the design on the fabric. The machine moves the hoop in different directions, while the needles work together to create the design. The machine can embroider the same design on multiple pieces of fabric simultaneously.

Once the embroidery is complete, the fabric is removed from the machine and the embroidery hoop. Any excess thread is trimmed, and the fabric is inspected for any errors or inconsistencies.

In conclusion, a 4 head embroidery machine is an essential tool for producing high-quality embroidery designs on different fabrics. The process of 4 head embroidery machine involves several steps that ensure the desired design is achieved with accuracy and efficiency. From selecting the design to trimming the excess thread, the machines’ features make the embroidery process fast and efficient, reducing the process timeline.

How to use 4 Head Embroidery Machine

Embroidery is a fun and creative way to add personal touches to clothing, accessories, and home décor. The process can be made even more efficient and enjoyable with the use of a 4-head embroidery machine. Here are some tips on how to make the most of your machine:

1. Prepare your design: Before you begin embroidering, you will need to have your design ready. This can be done using embroidery software or by purchasing pre-made designs. Once you have your design, you will need to load it into the machine’s computer.

2. Set up your machine: Next, you will need to set up your machine according to the specifications of your design. This will include selecting the thread colors, needle type, and stitching speed.

3. Choose your fabric: It is important to choose the right fabric for your embroidery project. Heavier fabrics such as denim or canvas will require a larger needle and slower stitching speed than lighter fabrics such as cotton or silk.

4. Hoop your fabric: Once you have your design and fabric prepared, you will need to hoop your fabric. This involves placing your fabric in the embroidery hoop and tightening the clamps to keep it in place.

5. Start embroidering: Once everything is set up, it’s time to start embroidering! Check that your machine is threading correctly and that the design is centered on your fabric. Then, press the start button and watch as your machine creates your design.

6. Care for your machine: After your embroidery project is complete, be sure to properly care for your machine. This includes regular maintenance and cleaning.

Using a 4-head embroidery machine can streamline your embroidery process and produce high-quality results. By following these tips, you can enjoy a fun and successful embroidery project.

Selecting the Ideal Manufacturer 4 Head Embroidery Machine

When it comes to selecting the ideal manufacturer for a 4 head embroidery machine, there are several factors that need to be considered. These factors will not only determine the quality of the machine but also its efficiency and performance.

One of the most important factors to consider is the manufacturer’s reputation and experience in producing embroidery machines. You need to look for a manufacturer that has a good track record in the industry and has been producing high-quality embroidery machines for a long time.

The quality of the components used in the machine is also important. You want to make sure that the machine is made with high-quality materials that are durable and long-lasting. This will ensure that the machine can withstand the constant wear and tear of daily use.

Another important factor to consider is the machine’s efficiency and speed. Look for a manufacturer that produces machines that can run at high speeds without compromising the quality of the embroidery. Additionally, make sure that the machine comes with easy-to-use controls that are user-friendly and intuitive.

Finally, consider the manufacturer’s customer support and after-sales service. A good manufacturer should have a strong customer service team that can provide you with support and assistance whenever you need it. This includes providing you with training and support materials as well as servicing and repairing the machine when necessary.

In conclusion, choosing the ideal manufacturer for a 4 head embroidery machine requires careful consideration of several factors. By looking for a reputable manufacturer that produces high-quality machines with durable components, efficient speed, user-friendly controls, and excellent customer service, you can be assured of getting a reliable and efficient machine that can help you grow your embroidery business.

list FAQ with answer about 4 Head Embroidery Machine

A 4-head embroidery machine is an excellent and effective tool for those who run an embroidery business or are interested in embroidery as a hobby. It is a machine that consists of four heads or stations that allow the user to embroider four items at once. Here are some frequently asked questions about 4-head embroidery machines and their answers.

1. How many hoops come with a 4-head embroidery machine?

A 4-head embroidery machine typically comes with four hoops that allow for multiple items to be embroidered at once. The size of the hoops may vary, but they are usually between 9-12 inches.

2. How fast does a 4-head embroidery machine embroider?

The speed of a 4-head embroidery machine varies from model to model, but most can embroider at a rate of 1000 stitches per minute per head. Therefore, a 4-head machine can embroider up to 4000 stitches per minute.

3. Can you embroider different designs on each head?

Yes, a 4-head embroidery machine allows you to embroider different designs on each head simultaneously. This feature makes the machine more efficient and versatile.

4. Are 4-head embroidery machines only for commercial use?

No, 4-head embroidery machines can be used for personal use as well. However, they are more expensive than smaller embroidery machines, so they are more suitable for those who plan on embroidering frequently and in larger quantities.

5. What is the maintenance required for a 4-head embroidery machine?

4-head embroidery machines require regular maintenance, such as oiling, cleaning, and changing needles. It is also important to make sure all the threads are properly threaded and that the machine is dust-free to ensure optimal performance.

In conclusion, a 4-head embroidery machine is a powerful tool that can help you get more done in less time. It is important to know the answers to these frequently asked questions before investing in one. With proper care and maintenance, a 4-head embroidery machine can last for many years and help you create beautiful embroidered items.

Things to Consider When Purchasing 4 Head Embroidery Machine

Embroidery machines are a must-have for any aspiring embroidery artist. The 4-head embroidery machine is the perfect machine for those who wish to create multiple designs at once. However, selecting the right 4-head embroidery machine can be a daunting task. Therefore, it is essential to consider some factors before purchasing a 4 head embroidery machine.

Firstly, purpose and size of machine should be considered. The size of the machine should be large enough to accommodate your embroidery needs. If you are considering this machine for commercial use, then it should be large enough to cater for large volume orders.The purpose of the machine should also be considered. Some machines are built for home use while others are built for industrial use.

Secondly, Brand and stability of machine should be explored. Some brands are more reputable than others and have a better build quality. Ensure that you research the brands and models of the 4 head embroidery machines you are considering before making a purchase. Stability of the machine is also an important concern. This is because the machine needs to withstand high speeds and tensions when embroidering. Therefore, the machine should be structurally sound to avoid damages.

Lastly, but not least, the price of the machine should also be taken into consideration. The price should be reasonable and within the budget of the buyer. However, this does not mean to compromise quality for a lower price. It is important to strike a balance between cost and quality.

In conclusion, purchasing a 4 head embroidery machine can be a complicated and overwhelming process. However, with proper research and consideration, buyers can find a quality machine that meets their embroidery needs. Therefore, buyers should consider the size and purpose of the machine, the brand and stability of the machine, and the price of the machine before making a purchase.

Properties of 4 Head Embroidery Machine

A 4 head embroidery machine is an excellent investment for businesses that need to produce a high volume of embroidered products. This machine has four embroidery heads, which means that it can embroider up to four items at once, making it ideal for large orders.

One of the primary benefits of a 4 head embroidery machine is its efficiency. With four heads, it can complete multiple jobs at once, increasing productivity and output. This machine can embroider multiple items simultaneously, reducing the amount of time it would take a single head machine to complete the same number of items.

Another significant advantage of a 4 head embroidery machine is its versatility. It can handle different types of embroidery projects, from hats to t-shirts to bags. This flexibility means that businesses can use this machine to cater to a wider range of clients and projects.

The quality of embroidery produced by a 4 head embroidery machine is also noteworthy. The four heads work together to ensure that the embroidery is precise and accurate, resulting in high-quality products. When compared to a single head machine, the 4 head machine produces cleaner, crisper, and more detailed embroidery, making it an invaluable investment for businesses that require high-quality embroidered products.

Lastly, this machine is user-friendly and straightforward to use, making it easy for beginners and experts alike to operate. With its intuitive interface and simple setup, users can begin embroidering almost immediately, saving time and reducing the learning curve.

In conclusion, a 4 head embroidery machine is a valuable investment for businesses that need to produce high-quality embroidered products efficiently. Its ability to handle multiple projects at once, versatility, high-quality output, and user-friendly interface make it a worthwhile investment for businesses of all sizes.

Technical Parameters Terms for 4 Head Embroidery Machine

A 4-head embroidery machine is a piece of equipment that is ideal for commercial embroidery projects. It is capable of producing intricate designs on a large scale and with great speed. Understanding the technical parameters for a 4-head embroidery machine is essential for making the most of this investment.

The first parameter to consider is the number of needles. A four-head embroidery machine will have sixteen needles in total. This allows the machine to use sixteen different colors without requiring a thread change. This feature is essential for embroidering complex designs and saving time while embroidering multiple garments.

Another important parameter is the embroidery area. The embroidery area of a 4-head embroidery machine is typically 450 x 360mm. This large embroidery area enables the machine to produce large designs effortlessly. To further enhance the sewing capability, the machine incorporates a high-speed motor that can move the hoop quickly and seamlessly.

Stitch speed is another critical parameter to consider when purchasing a 4-head embroidery machine. On average, a 4-head embroidery machine can produce up to 1000 stitches per minute. This speed is crucial for achieving high-volume production and reducing the time it takes to complete a project.

In addition to stitch speed, the embroidery machine’s thread tension should be considered. When the tension is too high or too low, stitching problems may arise. A 4-head embroidery machine has automatic thread tension that can be adjusted to the specific thread being used.

One final critical parameter to consider is the software that comes with the machine. The software enables the user to design and digitize embroidery files and transfer them to the machine. The software also allows users to edit designs, resize designs, and change thread colors.

In conclusion, understanding the technical parameters of a 4-head embroidery machine is essential for maximizing its potential. The number of needles, embroidery area, stitch speed, thread tension, and software are all key features to consider when purchasing a 4-head embroidery machine. A well-equipped machine will give users endless possibilities for creating beautiful embroidery designs with precision and speed.

4 Head Embroidery Machine Price

Embroidery has been a popular art form across different cultures, and it has been made easier with the use of embroidery machines. The 4 head embroidery machine is one such machine that has been gaining popularity over time in the market.

The 4 head embroidery machine is designed to perform embroidery on multiple garments at the same time. It is ideal for commercial and industrial embroidery businesses that require high production rates. The machine operates by using four needles and four embroidery heads to create intricate designs on various materials such as t-shirts, caps, bags, and jackets.

The price of the 4 head embroidery machine varies depending on the brand, features, and model. Several brands offer 4 head embroidery machines, including Tajima, Barudan, and Happy. The Tajima TFMX-IIC-480 is a popular option in the market, retailing at approximately $75,000. The machine has features such as a touch screen control panel, automatic thread trimming, and a large embroidery area.

Another popular option is the Barudan BEKY-SC1504, retailing at approximately $65,000. The machine features four embroidery heads, 15 needles, and a 20.5″ x 18.75″ embroidery area. It also has a memory capacity of up to 20 million stitches.

The Happy HCR3-1504 is another 4 head embroidery machine with a price tag of approximately $50,000. It has features such as a large embroidery area of 15.7″ x 23.6″, auto-color change, and a touch screen display.

In conclusion, the 4 head embroidery machine is an excellent investment for businesses that require bulk embroidery production. The price may seem steep, but the machine will pay for itself with increased production rates and efficiency. When purchasing a 4 head embroidery machine, it is essential to consider features such as the embroidery area, number of needles, and control panel. With the right machine, businesses can create intricate and beautiful designs on a variety of garments in a shorter amount of time.