Knowledge about Industrial Laminator Machine

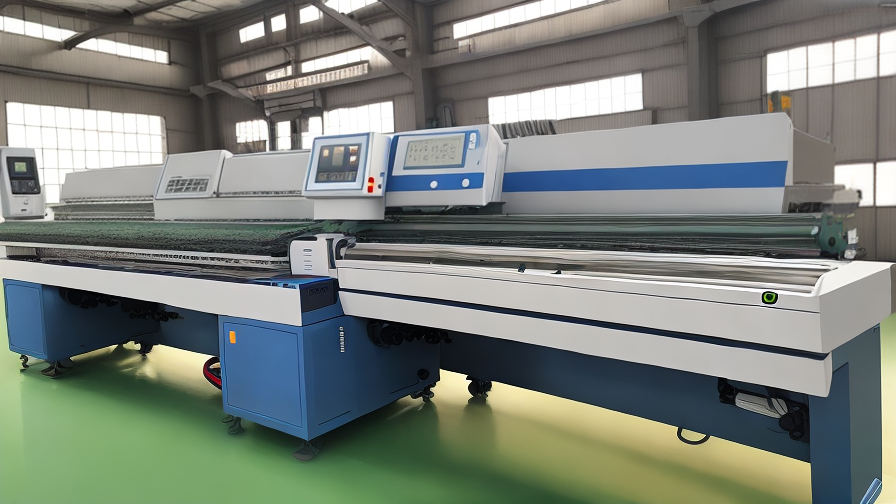

Industrial laminator machines are used to produce thermoplastic laminates for various applications. These machines are widely used in industries such as packaging, printing, and automotive.

To operate the machine, the operator needs to load the thermoplastic material into the laminator. The material passes through a pair of rollers which are heated. The heat softens the material, making it malleable.

The two layers of material are then pressed together between the rollers. The pressure created by the rollers helps to bond the layers together, creating a strong and durable laminated product.

The speed of the machine can vary, and the operator can adjust the temperature of the rollers to achieve the desired results. The laminator machine can handle materials with varying thicknesses and widths.

There are several types of industrial laminator machines available in the market, each designed for specific applications. For example, some machines are designed to laminate only one side of the material, while others can laminate both sides simultaneously.

When selecting an industrial laminator machine, it is crucial to consider the type of product being produced, the width of the material, the thickness of the material, and the required output speed.

In conclusion, industrial laminator machines are essential for producing high-quality laminated products in many industries. Knowledge of how to operate and select the correct machine can help businesses produce laminated products efficiently and effectively.

Various Types of Industrial Laminator Machine

Industrial laminator machines have become an essential component in various industries due to their ability to enhance the durability, quality, and aesthetic appeal of a wide range of products. Lamination involves the application of a thin layer of plastic or adhesive film to paper, cardboards, textiles, or other materials to improve their appearance, stiffness, waterproofing, or resistance to wear and tear. There are several types of industrial laminator machines available in the market, each with unique features and specifications.

Roll Laminator

The roll laminator is a type of industrial laminator machine used to laminate paper, cards, and photos. It comes with a roller attached to a heat-activated adhesive film that is used to bond the layers together. The machine consists of two heated rollers that apply heat and pressure to the laminating material, providing an airtight seal. The roll laminator is available in both hot and cold models.

Pouch Laminator

Pouch laminators are smaller tabletop machines that use laminating pouches to laminate documents. It is the most common type of laminator machine used in homes and small offices. The machine has two heated rollers that apply heat and pressure on the pouch to seal the lamination.

Cold Laminator

Cold laminator works without the need for heat or electricity, which makes them suitable for laminating heat-sensitive materials. They use self-adhesive laminating films, which stick to the materials’ surfaces without the need for heat. Cold laminators are ideal for lamination processes that don’t require heat curing.

Hot Laminator

As the name suggests, hot laminators use heated rollers to seal the lamination. They are used in industrial settings and are capable of laminating large items such as banners, posters and signs. The machine can also laminate a variety of materials, including metal, wood, and plastic.

Multifunctional Laminator

Multifunctional laminator machines have the capabilities to perform multiple functions such as laminating, cutting

FAQ sourcing Industrial Laminator Machine manufacturer from China

If you are in search of an Industrial Laminator Machine manufacturer from China, you must have a lot of questions in your mind. To offer you more clarity, here are some of the frequently asked questions and their answers:

Q1. What are the qualities to look for in an industrial laminator machine?

A: The qualities that you should keep in mind are its durability, efficiency, versatility, and safety features. You should ensure that the machine can handle the materials and the workload you expect from it.

Q2. What are the different types of industrial laminator machines?

A: There are mainly two types of industrial laminator machines- hot roller laminators and cold laminators. Hot laminators require heat to seal the materials, whereas cold laminators use pressure to bond the materials.

Q3. How much does an industrial laminator machine cost?

A: The cost of an industrial laminator machine varies based on its specifications and features. The price can range anywhere from a few hundred dollars to a few thousand dollars.

Q4. Can I get customized industrial laminator machines from China?

A: Yes, most manufacturers in China offer customized industrial laminator machines according to their client’s specifications.

Q5. What is the lead time to receive an industrial laminator machine?

A: The lead time depends on the manufacturer and the order size. However, it typically takes around 20-30 days to receive an industrial laminator machine from China.

With these FAQs, you can confidently source an industrial laminator machine manufacturer from China. Make sure to do your research and choose a reliable and reputable manufacturer that can cater to your needs.

Applications of Industrial Laminator Machine

Industrial laminator machines have become a crucial piece of equipment in several industries. These machines are primarily used for laminating or applying a protective covering to various documents, photos, and even fabrics.

One of the most common applications of industrial laminator machines is in the printing and publishing industry. Printed materials such as posters, flyers, and brochures require a protective covering to increase their lifespan and protect them from moisture, stains, or fading. Laminated prints also have a more professional look and feel, which enhances the overall appeal of the printed material.

Another industry that benefits from the use of industrial laminator machines is the manufacturing industry. Industrial laminators are used to produce lightweight and durable packaging materials. These include protective covers like vinyl and polyester, cardboard sleeves, and plastic pouches for electronics and other sensitive equipment.

Industrial laminator machines have also seen use in the healthcare industry. Medical materials such as charts, x-rays, and patient identification cards require laminating to protect them from spills and tears. Laminated medical materials are more durable and easier to clean, making them more hygienic and safer for patients and healthcare providers.

The use of industrial laminator machines has also expanded to the automotive industry. Many car owners choose to have their cars fitted with protective films or laminating films to protect the paint from scratches and damage. These films can also be used for window tinting and treatment to reduce heat and glare.

In conclusion, the applications of industrial laminator machines are numerous and diverse. They have become an essential piece of equipment in several industries, including printing and publishing, manufacturing, healthcare, and the automotive industry. With advancements in technology, industrial laminator machines will continue to provide solutions to ensure durability, longevity, and protection for various materials.

Manufactured Products made of Industrial Laminator Machine

Industrial lamination machines have become an integral part of modern manufacturing processes today. These machines are used to produce various types of manufactured products. The laminating process involves bonding two different materials together, typically by using heat, pressure, or adhesives. The result is a finished product that is stronger, more durable, and has better resistance to wear and tear.

One of the most common applications of industrial lamination machines is the production of laminated flooring, which is made by bonding multiple layers of wood or other materials together. This process creates a stable, high-quality flooring product that is better able to withstand the stresses of daily use.

Another commonly produced manufactured product made using industrial laminator machine is laminated glass. In this case, thin sheets of glass are bonded to a layer of polyvinyl butyral (PVB) to create a strong and durable material that is resistant to impact and breakage. Laminated glass is frequently used in buildings and vehicles where strength, durability, and safety are important.

Textiles are also popular products that are made using laminating machines. Fabrics of all kinds can be laminated together to create a range of products, including waterproof jackets and pants, heat-resistant fabrics, and even fire-resistant materials.

Laminating machines can also be used to produce a wide range of durable and protective packaging materials. For example, laminated paper and plastic bags are often used to protect sensitive products from moisture, dust, and other contaminants during shipping and storage.

In conclusion, industrial lamination machines are essential tools for producing strong, durable manufactured products. From laminated flooring to safety glass, laminated textiles to protective packaging materials, a wide range of products benefit from the lamination process. As technology advances and new materials continue to be developed, the potential applications for industrial lamination machines are only growing.

The Evolution history of Industrial Laminator Machine

The industrial laminator machine has undergone a significant evolution over the years. From being a manual machine in earlier years to automated machines, the industrial laminator has come a long way.

The first laminator was invented in the 1940s and was used to laminate documents. The machine required manual effort, and the documents had to be fed through it individually. Over time, this technology was improved, and in the 1960s, a heat-assisted laminator was invented, which provided much faster lamination.

In the 1970s, with the growth in the printing industry, the need for high-speed lamination machines increased. This led to the creation of industrial laminators that could laminate large volumes of papers in a short time. Automated machines that could load and feed materials on their own soon followed.

Since then, the industrial laminator machine has continued to evolve, with the advent of digital laminating, which allows for more precision and accuracy. Today’s digital laminators are designed to integrate with other printing equipment to streamline the production process and reduce the time taken to complete jobs.

Another notable advancement in recent years is the eco-friendly laminating solutions that are becoming increasingly popular. These machines use film made of biodegradable materials that maintain the same quality standards while reducing environmental impact.

In conclusion, the industrial laminator machine has come a long way from a manual device to an automated, digital and eco-friendly machine. Today’s laminators are much faster, efficient, and produce higher quality laminated documents than their predecessors. As industries continue to grow, we can expect to see further advancements in laminating technology.

The Process of Industrial Laminator Machine

An industrial laminator machine is a specialized piece of equipment that is used to laminate materials together. It is used in many industries, including packaging, printing, and manufacturing.

The process of industrial laminating involves feeding two or more layers of material into the machine, which then uses heat and pressure to fuse them together. The resulting product is a strong, durable, and protective composite material.

The first step in the process is to choose the right type of laminating machine for the job. There are many different types of machines available, each designed for specific materials and applications.

Once the machine has been chosen, the next step is to prepare the materials for lamination. This may involve cutting them to the correct size and shape, and applying any necessary coatings or adhesives.

Once the materials are prepared, they are fed into the laminating machine. The machine uses rollers to apply pressure and heat to the materials, which causes them to bond together.

During the laminating process, it is important to monitor the temperature and pressure carefully. If the temperature is too high or the pressure too low, the materials may not bond properly.

After the lamination is complete, the composite material is cooled and trimmed to the desired size and shape. It is now ready for use in a wide variety of applications.

In conclusion, the process of industrial laminating is a complex but essential part of many industries. With the right equipment and careful attention to detail, it is possible to create strong, durable, and protective composite materials that can be used in a wide range of applications.

Benefits Advantages of Utilizing Industrial Laminator Machine

The utilization of an industrial laminator machine offers a wide array of benefits and advantages for businesses, manufacturers, and various industries. An industrial laminator machine is a highly specialized equipment used to apply a protective layer to a printed or unprinted material, guaranteeing sturdiness, longevity, and permanence.

One of the key benefits of using an industrial laminator machine is that it provides a protective cover against wear and tear, dust, scratches, and moisture. Protecting the printed material from these elements ensures that the content is durable and presentable to customers and clients.

Another benefit is that the material can be customized by adding a finishing coat of gloss, matte, or texture. This provides diverse aesthetics that give end products a professional and unique feel. What’s more, laminated materials are resistant to fading or discoloration, thus ensuring the longevity of vibrant colors.

Industrial laminator machines also increase the efficiency of printing and manufacturing processes. The machines can laminate large volumes of material in a short amount of time, therefore reducing production time and increasing productivity.

Moreover, lamination can improve the safety of printed materials. For instance, caution signs, fire exit maps, and other safety indicators are best protected and can be seen clearly when they are laminated. This not only ensures the safety of the employees but also protects the companies themselves from liability in case of accidents.

Industrial laminator machines also have financial benefits. The use of laminating improves the durability of products, reducing the frequency of replacements or repairs. This, in turn, saves businesses money that would have been spent on replacements and repairs.

In conclusion, investing in an industrial laminator machine is a wise decision for businesses and companies looking to enhance the presentation, durability, and safety of their products. These machines guarantee efficiency, cost savings, customization, and longevity of printed and unprinted materials.

Disadvantages Industrial Laminator Machine

Industrial laminator machines are incredibly useful tools to protect and preserve important documents, photographs, and posters. However, like any mechanical device, they have their own disadvantages that can affect the quality and productivity of their outputs.

One of the most significant drawbacks of industrial laminator machines is their price tag. These machines often come with a high price, especially those that are designed to cater to industrial or commercial needs. Plus, they consume a lot of energy, which can significantly raise the electricity bills. Therefore, purchasing, installing, and maintaining an industrial laminator machine can be quite expensive for small and medium-sized businesses.

Another significant disadvantage is the complexity of the machine. Industrial laminator machines are designed to be used by professionals who have extensive knowledge of the lamination process. This means that novice users may have a difficult time operating the machine, leading to errors and wasting time and resources. Additionally, the machine may require technical maintenance from time to time, which can only be provided by qualified and experienced technicians, thereby causing downtime that can affect productivity.

The size and weight of industrial laminators are also a disadvantage, particularly for businesses with limited spaces. These machines can consume a lot of floor space, and users may need to dedicate a separate room for the equipment. Additionally, moving these machines can be challenging, as they can weigh several hundred pounds. Therefore, users must carefully decide on the location of the machine before installing it.

Lastly, industrial laminator machines can be dangerous if not used correctly. The machine has several moving parts that could cause injury if not handled correctly. Therefore, companies must train their employees on the safe operation of the machine to avoid accidents and reduce workers’ compensation claims.

In conclusion, industrial laminator machines are essential to businesses that require document protection and preservation. However, their high cost, complex operation, low portability, and potential danger can be significant disadvantages. Companies should carefully evaluate their needs before deciding to invest in an industrial laminator machine.

Selecting the Ideal Manufacturer Industrial Laminator Machine

When it comes to choosing an industrial laminator machine, there are various factors that you must consider. Selecting the right model can help you increase productivity and efficiency, along with ensuring product quality. Therefore, here are a few key factors that can help you in selecting the ideal manufacturer industrial laminator machine.

The first thing to consider is the type of lamination you require. There are various options like hot, cold, and pressure-sensitive lamination. Depending on your product, you must choose the right machine for optimal results.

Next, the speed of the machine is another essential factor that cannot be overlooked. The right speed can help you get more laminated products in a specified time, enhancing productivity. Also, consider the thickness of the materials you intend to laminate as it determines the speed and pressure required to get the desired outcome.

The size of the machine will also significantly impact your productivity. Choose an industrial laminator machine that can cater to the dimensions of your products. Similarly, the durability of the machine should also be considered. Some laminators come with strong metal frames while others with a plastic frame. Choose wisely based on your product’s size and weight.

Finally, check the reputation of the manufacturer or supplier. A reliable and reputable manufacturer will offer quality machines and ensure exceptional customer service. Look for a manufacturer that has a good track record in the industry, with positive reviews, and no history of quality issues.

In conclusion, the process of selecting the right industrial laminator machine requires careful consideration of several crucial factors. Your ideal machine should cater to your specific needs, with an optimal laminating speed, size, and durability. Also, the reputation of the manufacturer should not be overlooked as it plays a crucial role in ensuring a quality machine that will serve you for years to come.

Things to Consider When Purchasing Industrial Laminator Machine

When it comes to purchasing an industrial laminator machine, there are several factors to consider that can impact the efficiency and effectiveness of the device. Here are a few things to think about before making your purchase:

1. Size: The first thing to consider is the size of the laminator machine that you need for your business. Industrial laminators can vary in size from small desktop models to large floor-standing machines. You need to know the maximum size of the materials you will be laminating and determine how much space you have in your facility for the laminator.

2. Lamination thickness: Different laminators have different capacities when it comes to thickness. You should consider the type of materials you will be laminating and choose a machine that can handle that thickness.

3. Speed: Speed is an essential factor when considering an industrial laminator machine. Laminators come with different speeds, each meant for specific applications. You should choose a machine with the appropriate speed for your business.

4. Film type: There are different types of films or laminate materials you can choose from. Some laminators are designed for a specific type of laminate film, so you need to be sure to select the right one for your application.

5. Ease of use: A machine with complicated controls or settings can be frustrating for you and your employees to use. You should choose a machine with easy-to-use controls and features that can reduce downtime and improve productivity.

6. Durability: An industrial laminator machine is an investment, and it is essential to choose a durable and reliable model that you can count on for years to come. Look for a well-manufactured machine that is designed to last, even under heavy use.

In conclusion, choosing the right industrial laminator machine for your business requires careful consideration of all the necessary factors. By choosing a machine that meets your specific needs, you can improve your workflow, increase productivity, and achieve better results.

Properties of Industrial Laminator Machine

An industrial laminator machine is a versatile piece of equipment used for a variety of purposes such as laminating, encapsulating, and mounting various prints and documents. Laminating is an important process used by various industries such as printing, packaging, education, and healthcare. Here are some of the key properties of an industrial laminator machine.

Speed: Industrial laminator machines operate at high speeds, making them ideal for high-volume laminating. These machines can handle large volumes of documents in a short period of time, making them efficient and productive.

Versatility: Industrial laminator machines can work with different materials such as paper, vinyl, and plastic, and can handle various thicknesses depending on the specific needs of the user. They are also capable of laminating varying sizes, ranging from small documents like ID cards to large photos and posters.

Ease of use: Modern industrial laminator machines are designed to be easy to operate, even for first-time users. They come with user-friendly interfaces, clear instructions, and can be controlled through user-friendly touchscreens.

Safety: Industrial laminator machines feature safety mechanisms that protect the operator and the machine during operation. These safety features include sensors that prevent the machine from overheating and shutting down when it reaches a certain temperature.

Accuracy: Industrial laminator machines are designed for precision and accuracy, ensuring the final product is of high quality. They are equipped with advanced sensors that detect any issues or malfunctions and alert the operator to take corrective measures.

Maintenance: Industrial laminator machines require regular maintenance to ensure they remain in good working condition. Routine maintenance such as cleaning and oiling helps prolong the lifespan of the machine and prevent mechanical breakdowns.

In conclusion, an industrial laminator machine is an essential piece of equipment for any business or industry that requires laminating, encapsulating or mounting. With their speed, versatility, ease of use, safety, accuracy, and maintenance features, these machines offer an efficient, safe, and convenient way to laminate various documents and materials.

How to use Industrial Laminator Machine

An industrial laminator machine is a heavy-duty device used to laminate various materials in industries. The machine works by sandwiching the material between two layers of adhesive film, which is then put through heated rollers to create a tight seal.

To use an industrial laminator machine, you need to make sure you follow these simple steps:

1. Prepare the material: Before laminating, make sure the material is clean and flat. If you need to laminate multiple layers, make sure they are well-aligned.

2. Choose the appropriate film: Choose the film that best suits the material you’re laminating. The thickness and type of film you choose will depend on the nature and intended use of the laminated material.

3. Set the heat and speed settings: Set the laminator’s heat and speed settings according to the manufacturer’s instructions. It’s important to use the correct settings to ensure the material is laminated correctly.

4. Feed the material into the machine: Feed the prepared material into the laminator and ensure that it is evenly aligned within the rollers.

5. Wait for the process to complete: Once the material has been fed into the machine, allow the laminator to run and do the rest. The laminator will take the material through the heated rollers, creating a tight seal between the layers of adhesive film.

6. Remove the laminated material: Once the process is completed, remove the laminated material from the machine and trim any excess film.

Industrial laminator machines are useful for laminating materials that need an extra layer of protection from wear and tear. With proper use and maintenance, they can last for many years to provide a valuable service. By following these simple steps, you can laminate your materials effortlessly and ensure they are protected for longer.

Glossary Terminology Terms for Industrial Laminator Machine

If you are new to the world of industrial laminator machines, the terminology used can often seem overwhelming. Here is a list of glossary terminology terms that will help you navigate the world of industrial laminators.

1. Feed Table – The area where the un-laminated material is loaded into the machine.

2. Heat Roller – A roller responsible for applying heat to the top layer of the lamination film, causing it to adhere to the material below.

3. Pressure Roller – A roller responsible for applying pressure to the lamination film, ensuring that it adheres correctly to the material below.

4. Cooling Roller – A roller responsible for cooling the laminated material, allowing it to set.

5. Tension Control – An adjustable mechanism that maintains the proper tension of the lamination film as it moves through the machine.

6. Core Diameter – The size of the core on which the lamination film is wound.

7. Webbing – Strips of plastic that are embedded within the film to promote even tension throughout the lamination process.

8. Speed Adjuster – A mechanism that allows you to control the speed at which the material passes through the machine.

9. Side Guides – Adjustable guides that help ensure that the material enters the machine correctly.

10. Auto-Cut – A feature that automatically cuts the laminated material into the desired length.

Understanding these terms will help you choose the right machine for your needs, and make the laminating process smoother and more efficient. With the right equipment and a basic understanding of glossary terminology terms, you can achieve professional-grade lamination every time.

Industrial Laminator Machine Price

An industrial laminator machine is an essential tool for businesses that require the lamination of large volumes of paper. These machines are used in a variety of industries such as printing, packaging, and document management. The price of an industrial laminator machine can vary depending on various factors such as the brand, size, features, and overall quality of the machine.

The price range for industrial laminator machines can start from a few hundred dollars to tens of thousands of dollars. The cheapest laminator machines are usually manual and have limited features. These are best suited for small businesses or home-based offices that have a low-volume lamination requirement. More advanced and automated machines can cost considerably more but offer greater speed, accuracy, and efficiency in laminating large volumes of paper.

Other factors that can affect the price of an industrial laminator machine include the width of the machine, heating time, laminating film thickness, and speed of operation. Generally, machines with a higher capacity and speed will cost more, as will those with advanced features such as pre-set temperature controls, adjustable speed, and automatic paper feeders.

When shopping for an industrial laminator machine, it’s important to consider the specific needs of your business. Determine the volume of paper that needs to be laminated, the size of the paper, and the thickness of the laminating film required. This will help in selecting the appropriate machine for your business needs.

In conclusion, the price of an industrial laminator machine can vary significantly depending on the features and specifications of the machine. Before purchasing a machine, it is important to evaluate your business requirements and select a machine that provides the necessary features and quality within a reasonable budget range.