Benefits of Custom Aluminum Fabrication

Custom aluminum fabrication is a process of creating a unique product for specific uses and requirements of an individual or organization. Whether it is creating a customized tool, part or a product, aluminum fabrication has numerous benefits. Here are some of the benefits of custom aluminum fabrication:

1. Versatility: Custom aluminum fabrication is versatile and can be used for a wide range of applications. From automotive parts to architectural designs, the adaptability of aluminum allows it to be used in various industries.

2. Durability: Aluminum is a strong, durable and long-lasting material that can withstand harsh weather conditions and environments. Customized aluminum products are built to last, and they require minimal maintenance.

3. Lightweight: Compared to other metals, aluminum is incredibly lightweight, which makes it an ideal material for creating products that require mobility, such as equipment enclosures, transportation vehicles and aircraft.

4. Corrosion-resistant: Aluminum has natural corrosion-resistant properties that make it suitable for products and structures that are exposed to the elements. These properties make it a low-maintenance option that can save money in the long run.

5. Cost-effective: Custom aluminum fabrication can often be done at a lower cost than other construction materials, such as steel or copper. This makes it a more affordable alternative for producing customized products.

6. Aesthetic appeal: Custom aluminum fabrication allows for endless possibilities in design, finishes, and color choices. This allows organizations to create a unique product that looks great and performs well.

In conclusion, custom aluminum fabrication provides an array of benefits, including versatility, durability, lightweight, corrosion-resistance, cost-effectiveness, and aesthetic appeal. These benefits allow individuals and organizations to produce customized products that meet their unique needs and requirements.

Features of Custom Aluminum Fabrication

Custom aluminum fabrication is the process of creating unique and specialized products from aluminum materials to meet specific customer needs. The innovation and customization involved in aluminum fabrication ensures that products are designed to fit specific requirements.

One of the key features of custom aluminum fabrication is the ability to produce products with exceptional strength and durability. Aluminum is a highly durable element that can withstand harsh weather conditions, extreme temperatures, and corrosive environments. This makes it an ideal material for products that require a high level of strength and durability, such as industrial equipment, aerospace components, and automotive parts.

Another feature of custom aluminum fabrication is its versatility. It can be used to create a variety of products, including large structures like bridges and buildings, and small intricate components used in medical devices and electronics. With custom aluminum fabrication, the possibilities are endless, and customers have the freedom to create unique designs that best suit their requirements.

Custom aluminum fabrication also offers excellent aesthetic appeal, with the ability to create products with smooth, sleek surfaces and intricate designs. The material can be easily shaped and manipulated, providing customers with the opportunity to create visually appealing products that are not only functional but also aesthetically pleasing.

In summary, custom aluminum fabrication is a highly versatile and unique process that offers superior strength, durability, and aesthetic appeal. It is perfect for customers who desire products that are tailored to their specific needs and requirements. With custom aluminum fabrication, and the unique features it offers, customers can enjoy not only highly functional products but also visually appealing and durable ones.

Various Types of Custom Aluminum Fabrication

Custom aluminum fabrication is the process of designing and manufacturing aluminum products based on the specific requirements and specifications of a client. Aluminum is a versatile and lightweight material that is widely used in different industries, such as aerospace, transportation, construction, and consumer goods, among others.

There are various types of custom aluminum fabrication, and they include:

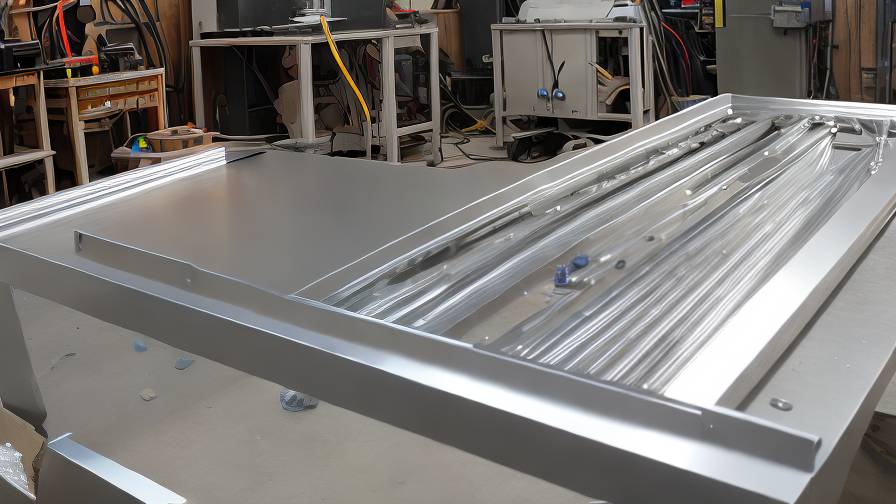

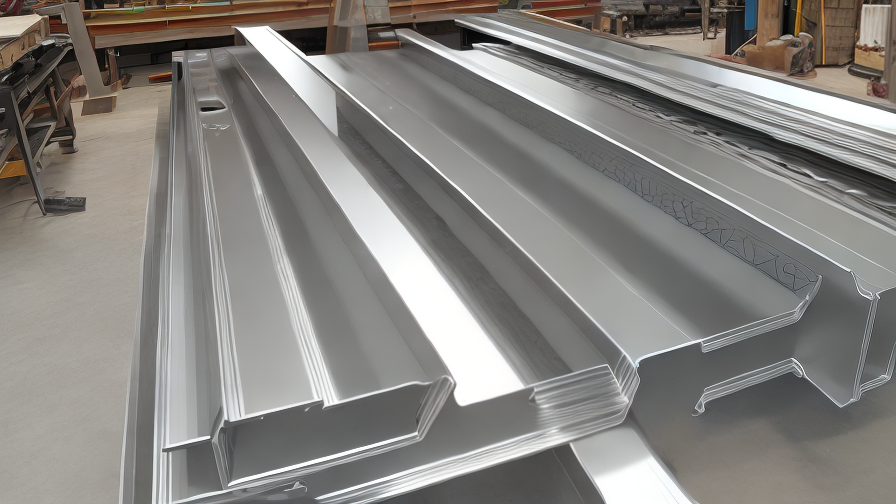

1. Sheet Metal Fabrication: This involves the creation of aluminum sheets and plates of different sizes and shapes, using various techniques like cutting, bending, welding, and finishing.

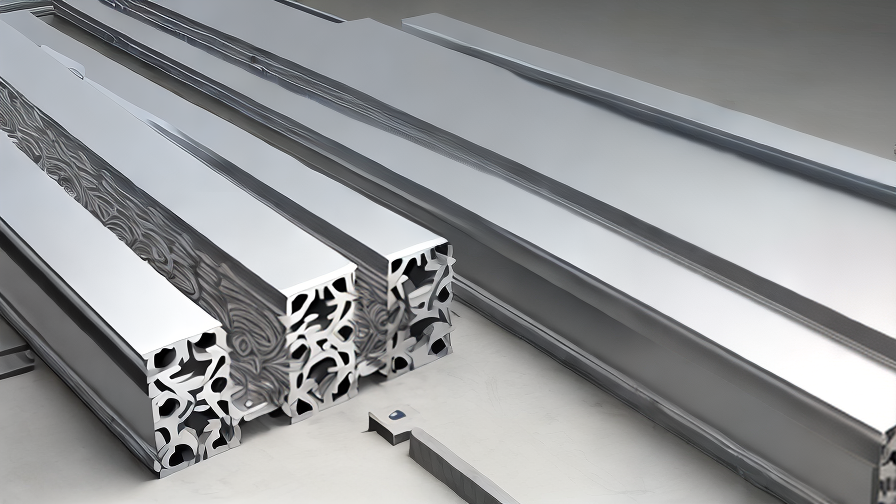

2. Extrusion Fabrication: This involves the creation of complex aluminum profiles by forcing the material through a die of the desired shape, resulting in a uniform cross-section.

3. Casting Fabrication: This involves the pouring of molten aluminum into a mold to create intricate shapes and designs, suitable for a wide range of applications.

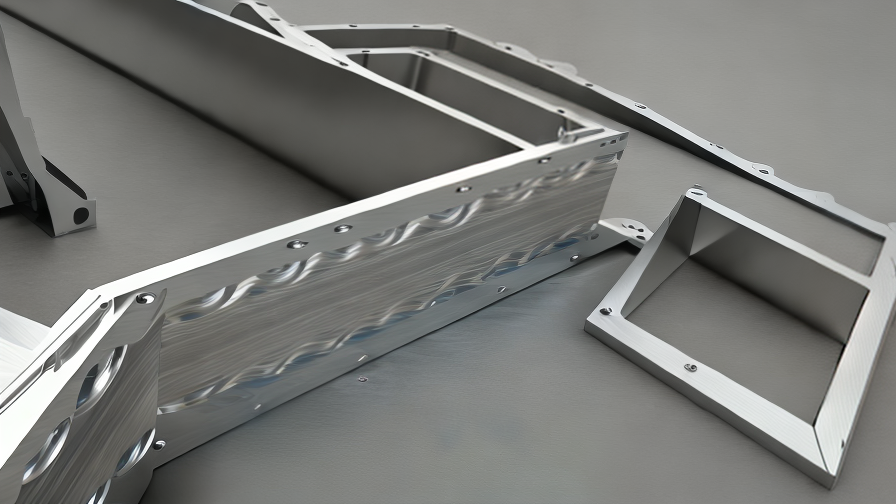

4. Welding Fabrication: This involves the joining of two or more aluminum pieces using specialized welding techniques, such as TIG or MIG welding, to create a durable and strong structure.

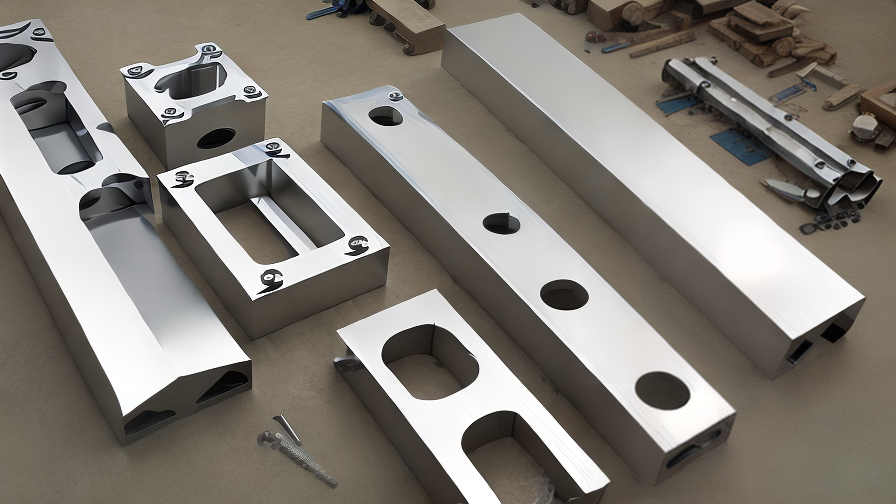

5. Machining Fabrication: This involves the cutting of aluminum materials using precision tools and machines, such as CNC routers and lathes, to create accurate and symmetrical shapes.

6. Custom Finishing: This involves the application of various finishing techniques, such as anodizing, painting, or polishing, to enhance the appearance and durability of aluminum products.

Additionally, custom aluminum fabrication can also involve the creation of custom accessories like brackets, hinges, and clamps, which are essential for the stability and functionality of aluminum products.

In conclusion, custom aluminum fabrication is a valuable service that offers endless possibilities to different industries. By understanding the various types of fabrication techniques available, clients can work with fabricators to create products that meet their specific needs and requirements.

Applications of Custom Aluminum Fabrication

Custom aluminum fabrication has a variety of applications across different industries. It involves the process of designing and manufacturing aluminum products that are tailored to meet specific needs and requirements of customers. Some of the most common applications of custom aluminum fabrication include:

1. Aerospace: In the aerospace industry, custom aluminum fabrication is utilized in the manufacture of aircraft parts such as panels, brackets, and structural components. Aluminum is preferred due to its lightweight, corrosion resistance, and durability.

2. Automotive: Custom aluminum fabrication is used in the production of racing car parts such as brake calipers, suspension parts, and body panels. Aluminum is also used in mass-produced cars due to its weight reduction and fuel economy benefits.

3. Architecture: Custom aluminum fabrication is utilized in the construction of modern buildings and structures. Aluminum is preferred due to its versatility, durability, and lightweight property that enables easy transportation and installation.

4. Marine: In the marine industry, custom aluminum fabrication is used in the manufacture of boat parts such as hulls, masts, and outriggers. Aluminum is preferred due to its corrosion resistance and lightweight property.

5. Industrial: In the manufacturing industry, custom aluminum fabrication is utilized in the production of machines and other industrial equipment. Aluminum is preferred due to its high strength-to-weight ratio, which makes it ideal for machines that require stability and maneuverability.

In conclusion, custom aluminum fabrication has a variety of applications across different industries, from aerospace to industrial manufacturing. It offers numerous benefits such as lightweight, durability, and versatility, making it a preferred choice for many. As technology advances, more applications of custom aluminum fabrication are expected to emerge, making it a critical aspect of modern industry.

The Process of Custom Aluminum Fabrication

Custom aluminum fabrication is a process where aluminum materials are expertly fashioned into unique designs, shapes, and sizes that match the specifications of a client or project. The process of custom aluminum fabrication involves several stages that ensure the production of high-quality and durable aluminum products.

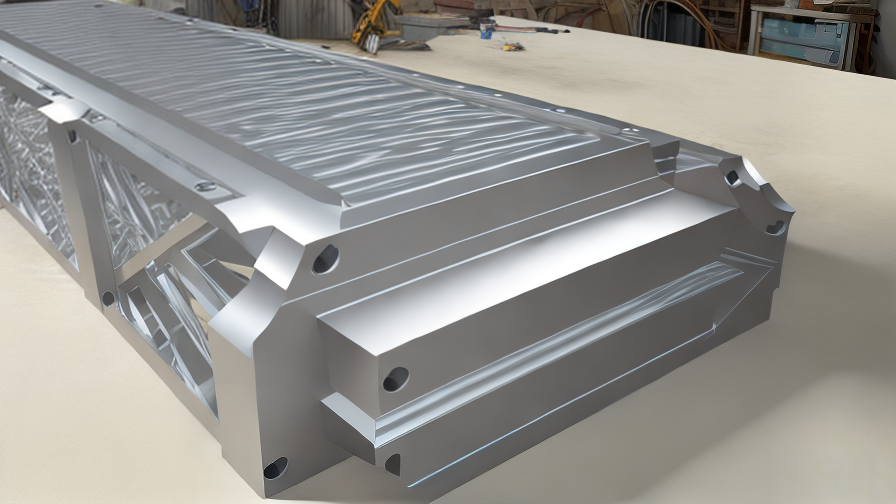

The first stage of custom aluminum fabrication is the design phase. During this stage, the client’s requirements and specifications are gathered alongside the intended purpose of the aluminum product. Skilled designers then utilize advanced software to create 3D models that illustrate how the product will look, function, and integrate into the client’s project. The design phase is critical to ensuring the production of functional, high-quality, and aesthetically pleasing products.

Next is the fabrication stage. A skilled team of fabricators then works with the design created in stage one to bring the product to life. This stage involves cutting, drilling, bending, and welding aluminum sheets as per product design specifications. The process requires attention to detail since the slightest margin of error can result in a non-functional product. It is, therefore, typically performed by a team of experts who utilize advanced machinery, including laser cutters and CNC machines, to ensure precision and consistency.

The final stage of custom aluminum fabrication involves finishing the product. This stage includes powder-coating, painting, or anodizing the aluminum to enhance its aesthetics, extend its lifespan, and protect it from adverse weather conditions, scratching, and discoloration. The finishing stage is crucial to the durability and longevity of the product, and thus, it is typically performed with utmost care.

In conclusion, custom aluminum fabrication is a highly intricate and technical process that requires expertise, experience, and specialized equipment to produce high-quality and durable products. It involves three main stages, including design, fabrication, and finishing. Therefore, ensure that you engage with reputable and experienced fabricators to bring your design concepts into reality.

How to use Custom Aluminum Fabrication

Custom aluminum fabrication is a process of producing aluminum products that meet your specific requirements. It involves the use of specialized tools and techniques to create unique designs that can be used in different applications. If you want to take advantage of custom aluminum fabrication, here is how to go about it:

1. Identify your requirements: Before you can start the custom aluminum fabrication process, you need to know what you want. You should have a clear idea of the design, size, and shape of the product that you need. This information will help the fabricator to create an accurate blueprint of your product.

2. Find a reliable fabricator: The success of your custom aluminum fabrication project depends on the expertise and experience of the fabricator. You should select a reputable fabricator who has a proven track record of delivering quality products. Look for a fabricator who has experience in working with similar materials and in the same industry as yours.

3. Discuss the project requirements: After identifying a reliable fabricator, you should schedule a meeting to discuss your project requirements in detail. The fabricator will ask you questions to understand your needs and expectations, and also offer suggestions on how to improve the design or functionality of your product.

4. Review the blueprint: After the fabricator has created a blueprint of your product, it is essential to review it to ensure that it meets your requirements. You should carefully examine every aspect of the blueprint and make necessary adjustments if required.

5. Fabrication and delivery: Once you have approved the blueprint, the fabricator will start the fabrication process. After completing the product, it will be delivered to your site, ready for use.

In conclusion, custom aluminum fabrication is an excellent way of getting products that meet your unique requirements. However, it requires careful planning and collaboration with experienced fabricators to achieve the desired outcome. By following the above steps, you can ensure that your custom aluminum fabrication project is successful.

Selecting the Ideal Manufacturer Custom Aluminum Fabrication

Selecting the ideal manufacturer for custom aluminum fabrication can be a challenging task, but it is also essential to ensure the quality of your finished product.

When choosing a manufacturer, look for a company with experience and a proven track record in custom aluminum fabrication. Look for certifications and qualifications that indicate their capability and expertise in the field.

Consider the manufacturer’s capacity to handle the size and scope of your project. Can they accommodate your volume and timeline requirements? Do they have the necessary equipment and personnel to complete the job adequately?

Ask for references and reviews from prior clients. Check out the manufacturer’s website and social media pages to see examples of their previous work.

Customer service is also critical when selecting a manufacturer. Choose a company that values communication and collaboration, with a project manager readily available to answer questions and address concerns.

Moreover, ensure that the manufacturer has a rigorous quality control system in place to guarantee the final product meets your exact specifications. Ask about the types of testing and inspection techniques they utilize to ensure accuracy and quality.

Lastly, choose a manufacturer that is dedicated to sustainability and environmental practices. Look for companies that prioritize recyclable materials and green processes, and have eco-friendly certifications.

In conclusion, choosing the right manufacturer for custom aluminum fabrication is crucial for a successful project. Consider experience, capacity, customer service, quality control, and sustainability when making your decision. Remember to check references, reviews, and credentials before choosing a manufacturer to ensure the best outcome for your project.

list FAQ with answer about Custom Aluminum Fabrication

Here is a list of frequently asked questions with their answers about custom aluminum fabrication:

Q: What is custom aluminum fabrication?

A: Custom aluminum fabrication is the process of creating or altering a product made of aluminum to satisfy a specific customer requirement or design.

Q: What type of products can be custom fabricated from aluminum?

A: Aluminum can be custom fabricated into a wide range of products such as enclosures, panels, brackets, mounts, guards, and frames.

Q: What are the advantages of custom aluminum fabrication?

A: Custom aluminum fabrication offers several advantages, including increased strength, corrosion resistance, light weight, and versatility. Aluminum is also a more cost-effective material compared to other metals such as steel.

Q: What are the common methods of custom aluminum fabrication?

A: The common methods of custom aluminum fabrication include welding, bending, cutting, drilling, punching, and stamping.

Q: What type of finishes can be applied to custom aluminum products?

A: The common finishes that can be applied to custom aluminum products include powder coating, anodizing, polishing, and painting.

Q: What is the lead time for custom aluminum fabrication?

A: The lead time for custom aluminum fabrication varies based on the complexity of the project and the quantity of products required. It usually ranges from a few days to several weeks.

Q: How can I find a reliable custom aluminum fabrication supplier?

A: You can find a reliable custom aluminum fabrication supplier by searching online, asking for referrals from other businesses, or attending metal fabrication trade shows.

Q: Can I provide my own design for custom aluminum fabrication?

A: Yes, you can provide your own design for custom aluminum fabrication. The supplier will work with you to ensure the design is feasible and can be fabricated within the required timeframe.

Q: What is the cost of custom aluminum fabrication?

A: The cost of custom aluminum fabrication varies based on several factors such as the complexity of the project, the quantity of products required, and the selected finish. It is best to request a quote from the supplier to get an accurate cost estimate.

In conclusion, custom aluminum fabrication is a versatile and cost-effective way to create or modify products made of aluminum. It is important to work with a reliable supplier who can ensure a high-quality end product that meets your specific requirements.

Things to Consider When Purchasing Custom Aluminum Fabrication

When you are looking for custom aluminum fabrication, it is important to consider a few factors before making your final decision. The following are some things that you should consider before purchasing:

1. Quality – The quality of the aluminum fabrication is something that you should not overlook. You want to ensure that the fabrication is of high quality, and that it will withstand the test of time.

2. Price – The price of custom aluminum fabrication is also a factor that you should consider. You want to make sure that you are getting a good deal for the money you are spending.

3. Design – The design of the fabrication is also important. You want to make sure that the design meets your exact requirements and specifications.

4. Materials – It is important to consider the materials that are being used in the fabrication. You want to make sure that the materials are of high quality and that they will not deteriorate over time.

5. Customization – Custom aluminum fabrication is often done to meet specific requirements. Therefore, you want to ensure that the fabrication can be customized to meet your specific needs.

6. Delivery – You want to ensure that the custom aluminum fabrication will be delivered on time, and that it will be installed properly.

In conclusion, custom aluminum fabrication is a great way to get a product that meets your specific requirements. However, before you make your final decision, it is important to consider the factors listed above. By doing so, you can ensure that you get a product that meets your needs and that will last for many years to come.

Properties of Custom Aluminum Fabrication

Custom aluminum fabrication is one of the most commonly utilized fabrication techniques in the modern manufacturing industry. It enables manufacturers to design, create, and produce unique and intricate parts and components for various industrial applications and consumer goods. Custom aluminum fabrication offers a range of properties that make it an ideal choice for manufacturing high-quality, durable, and reliable products.

One of the most important properties of custom aluminum fabrication is its versatility. Aluminum is a highly malleable and ductile material, which means that it can be bent, shaped, and formed into a wide range of different shapes and configurations. It is also lightweight and corrosion-resistant, making it ideal for use in a variety of different industrial and consumer applications.

Another key property of custom aluminum fabrication is its strength and durability. Aluminum is a strong and durable material that can withstand harsh environments and temperature fluctuations. It has excellent thermal and electrical conductivity properties, making it ideal for use in automotive, aerospace, and electronics industries.

Custom aluminum fabrication also offers excellent weldability and machinability. This makes it easy to work with and enables manufacturers to produce complex and intricate parts and components quickly and efficiently. It also allows for easy repairs and modifications, which can save time and money in the long run.

Finally, custom aluminum fabrication is a cost-effective solution for many manufacturing applications. Aluminum is abundant and readily available, which makes it more cost-effective than other materials such as steel or titanium. It is also easy to recycle, making it an environmentally friendly choice for manufacturers looking to reduce their carbon footprint.

In conclusion, custom aluminum fabrication offers a range of properties that make it an ideal choice for modern manufacturing applications. Its versatility, strength, durability, weldability, machinability, and cost-effectiveness make it a popular choice for a wide range of industrial and consumer products. As the demand for high-quality, reliable, and innovative products continues to grow, custom aluminum fabrication will undoubtedly continue to play a vital role in the manufacturing industry.

Technical Parameters Terms for Custom Aluminum Fabrication

Custom aluminum fabrication involves the manufacture of various products using aluminum material as the primary material. Before commencing with any custom aluminum fabrication, it is essential to understand the technical parameters used in the industry to achieve the desired product. The following is an outline of technical terms used in custom aluminum fabrication.

Tensile Strength – Tensile Strength refers to the maximum stress a material can take under loading before it fails. When choosing the right material for custom aluminum fabrication, it is important to consider the tensile strength as it determines the durability of the final product.

Yield Strength – Yield Strength is the stress point at which the material begins to deform permanently beyond its elastic deformation limit. Choosing a material with a high yield strength is important as it resists structural deformation.

Elongation – Elongation is the percentage of deformation the material experiences after it is stretched to its breaking point. It is essential to consider this factor as it helps design and manufacture products that can withstand elongation stress without losing functionality.

Hardness -Hardness defines how resistant a material is to indenter penetration, wear, or abrasion. Knowing the hardness of the material being used in custom aluminum fabrication is important as it determines the suitability of the material for the intended application.

Density -Density refers to the weight of a material per unit volume. The density of aluminum affects the ease of fabrication, transportation, and storage of the final product.

Conductivity -The conductivity of aluminum refers to the ability of the material to conduct electricity. It is important to consider the conductivity of the material used in custom aluminum fabrication, especially when designing products that need to transmit electricity.

In conclusion, technical parameters are essential when it comes to custom aluminum fabrication. They help determine the suitable material for the intended purpose, the manufacturing process, and the product’s durability. For this reason, it is important to work with a professional fabricator who has the knowledge and experience of using these parameters to deliver high-quality, durable custom aluminum products.

Custom Aluminum Fabrication Price

Custom aluminum fabrication involves designing unique items made of aluminum materials to fit a customer’s specifications. The fabrication process is tailored to meet the customer’s specific needs and requirements. Due to the uniqueness of each project, the price of custom aluminum fabrication varies widely. The price of each project is influenced by various factors, including the design of the product, the complexity of the fabrication process, and the size of the product.

The design of the product is the most significant factor that affects the price of custom aluminum fabrication. A more complex design will require more labor and materials, leading to a higher price. The shape, size, and detail of the design also play a crucial role in determining the cost of the project. A complex design with intricate details will require more time, effort, and materials, increasing the price of the project.

The complexity of the fabrication process is another significant factor that influences the price of custom aluminum fabrication. Some projects may require unique cutting, bending, joining, or welding techniques, leading to additional expenses. The fabrication process also depends on the type and thickness of the aluminum materials used. Thicker and stronger aluminum materials will require more time and effort to fabricate, increasing the cost of the project.

Lastly, the size of the product is an essential factor that affects the custom aluminum fabrication price. Large projects require more materials, labor, and time, leading to higher costs. The transportation costs may also increase due to the size of the product.

In conclusion, the price of custom aluminum fabrication varies significantly depending on various factors such as the design, complexity of the fabrication process, and size of the product. However, despite the high cost of custom aluminum fabrication, its benefits outweigh the expenses. Custom aluminum fabrication offers excellent strength, durability, and versatility, making it an attractive choice for various projects. In addition, customized products fit the customer’s specific needs and requirements, ensuring that they get value for their money.