Benefits of Bearings China

Bearings are essential components in various machines and equipment, and with the increasing demand for bearings worldwide, China has emerged as the leading supplier of bearings in the world. The benefits of bearings from China are multiple and significant compared to those from other countries.

One of the significant benefits of bearings from China is their affordability. Bearings from China are relatively affordable, making them the go-to for many consumers globally. This is because China has an efficient production system, and the cost of producing bearings is generally lower than in other countries. Despite being affordable, the quality of bearings from China is excellent, with many companies adhering to rigorous quality control measures.

Another benefit of bearings from China is their availability. China is home to many bearing manufacturers and suppliers, which ensures a steady supply of bearings for consumers. This makes replacements and repairs more accessible, reducing machine downtime and improving productivity for businesses and industries that rely heavily on bearings.

China is also home to skilled and experienced engineers that design and develop bearings that meet specific industrial needs. These engineers work with the latest technology and production processes to ensure that the bearings meet the required standards and are of high quality.

In recent years, many bearing manufacturers in China have adopted environmentally friendly practices that reduce the impact of industrial activities on the environment. This has led to the production of eco-friendly bearings that are more sustainable and reduce the carbon footprint of companies that use them.

In conclusion, the benefits of bearings from China include affordability, availability, high-quality standards, and eco-friendliness. These benefits make bearings from China an attractive option for consumers and industries worldwide. With China continuously improving its production processes and adhering to strict quality control measures, it is no surprise that the country is the leading supplier of bearings in the world.

Features of Bearings China

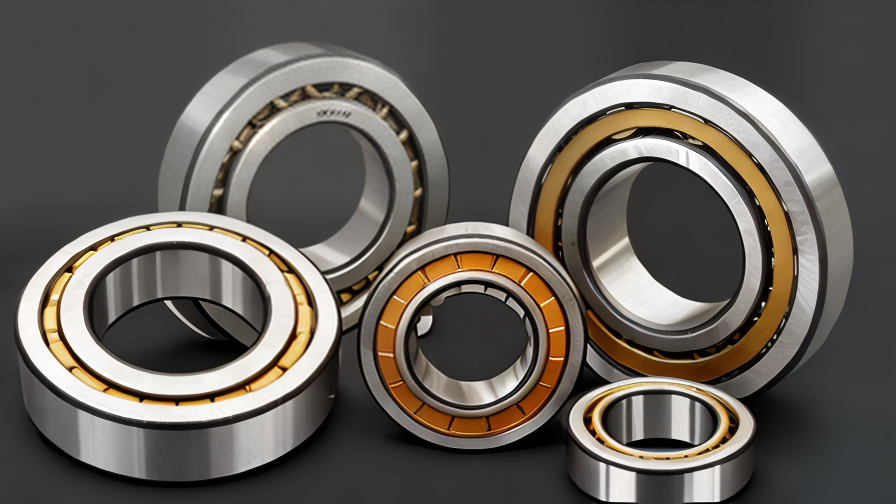

Bearings are an essential component of modern machinery, and China has become a global center for manufacturing quality bearings. The features of bearings made in China are renowned for their high quality and excellent performance.

One of the primary features of bearings made in China is their durability. These bearings are made from high-quality materials and undergo rigorous testing to ensure that they can withstand the demands of heavy-duty machinery.

Another significant feature of bearings made in China is their precision. The manufacturing process is highly automated, and advanced technologies are used to produce bearings with precise dimensions and shapes to ensure their optimal performance.

Bearings made in China also offer enhanced resistance to wear and tear. Various advanced techniques are employed in the production process to create bearings that can withstand high temperatures and extreme pressures without breaking down or wearing out.

Additionally, the bearings made in China are designed for efficient operation, ensuring that they minimize friction and reduce energy consumption. This feature makes them highly energy-efficient, contributing to cost savings in the long run.

Furthermore, the bearings made in China are environmentally friendly. The production process is designed to minimize negative environmental impacts, and the materials used are recyclable and biodegradable.

Lastly, the bearings made in China are cost-effective. The advanced technologies and efficient manufacturing practices employed in the production process keep the costs low, making them an ideal option for those seeking high-quality bearings at affordable prices.

In conclusion, the bearings made in China offer an impressive array of features that make them stand out from products made elsewhere. From durability to precision, wear resistance, energy efficiency, and cost-effectiveness, bearings made in China are reliable, versatile, and high-performing equipment components.

Various Types of Bearings China

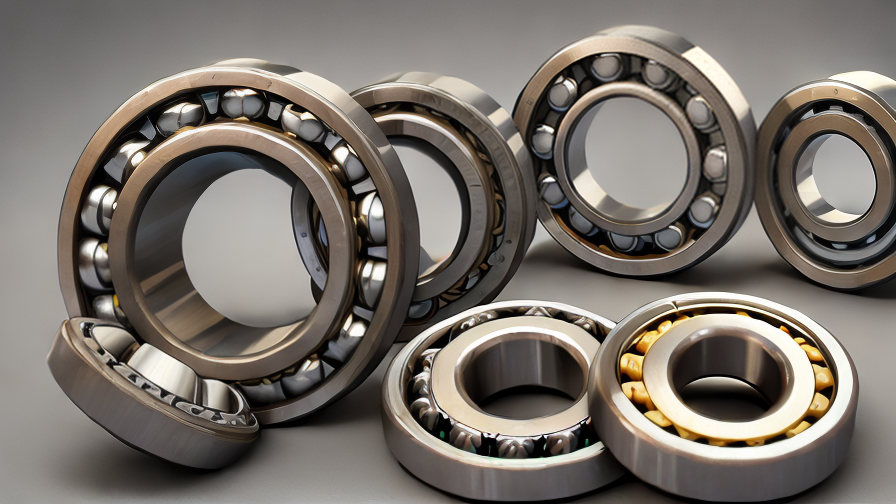

Bearings are one of the most critical components in various machines and tools. They facilitate smooth motion and reduce friction, thus enhancing the lifespan and performance of machines. China is one of the leading manufacturers of bearings globally, offering a wide range of products for different industrial needs.

The different types of bearings available in China include ball bearings, roller bearings, plain bearings, and thrust bearings. Ball bearings are the most common type and operate by rotating a ball around its axis. Roller bearings, on the other hand, work by using cylindrical or tapered rollers to provide support and reduce friction.

Plain bearings are simple, rigid bearings that rely on lubrication between the bearing surface and the shaft to reduce friction. They are suitable for low-speed and high-load applications. Thrust bearings are designed to support axial loads and work with either balls or rollers.

Other specialty bearings available in China include ceramic bearings, needle bearings, and spherical bearings. Ceramic bearings have high thermal conductivity and are ideal for applications in high-temperature environments. Needle bearings are designed for use in applications with limited space and low weight. Spherical bearings can accommodate misalignment, making them suitable for applications where shafts are not aligned correctly.

In summary, China offers a vast range of bearings to cater to various industrial needs. Depending on the specific application, one can choose from ball bearings, roller bearings, plain bearings, thrust bearings, and other specialty bearings. The availability of these bearings in China makes it an ideal destination for machines and tools that require reliable and efficient bearing solutions.

Applications of Bearings China

Bearings are essential components of many machines and equipment. They are small but critical parts that help machines to operate efficiently and smoothly. Bearings facilitate the rotary motion between two surfaces by reducing friction while supporting radial and axial loads. Bearings are commonly used in many industries, including automotive, aerospace, construction, marine, and manufacturing. China, being a global manufacturing powerhouse, is home to many bearing manufacturers, supplying both domestic and foreign markets.

One of the significant applications of bearings is in the automotive industry. Bearings in modern automobiles are used in different parts of the car, such as brakes, wheels, engine, and transmission. The use of bearings in these parts ensures that cars run smoothly and efficiently, reducing wear and tear while preventing frequent replacements.

Another application of bearings is in the aerospace industry. With the advent of high-tech machinery and equipment that operate at high speeds and loads, bearings play a crucial role in maintaining precise performance and reducing friction between the rotating parts. Aerospace applications include turbines, engines, and control systems.

The construction industry is yet another essential area where bearings find their use. The significant component of construction machinery is bearings that support the weight of bridges, towers, and cranes. Bearings allow for safe and smooth operation of these machines, which minimize the risk of accidents that can cause significant damage.

The manufacturing industry is another critical field where bearings have a tremendous impact. They are used in production lines, machine tools, and robots, among other industrial applications. Bearings are known for their durability and reliability, making them particularly useful in industrial environments, where machines operate for long periods.

In conclusion, bearings are essential components in many different industries, and their applications are endless. The reliability and durability of the bearings have made them an essential component to ensure smooth and safe operation of the machines. Bearins China is a global supplier of high-quality bearings, offering a range of products to meet different industrial needs. Their products have a proven track record of quality and reliability, which reinforces the confidence customers have in them.

The Process of Bearings China

Bearings are essential components that support rotating equipment and reduce friction in machines. China, known as the world’s manufacturing hub, is a significant player in the bearing industry. The process of bearings in China mainly involves three steps: design, manufacturing, and testing.

The first step in the process is designing the bearings. The design process starts with the selection of the right material to ensure durability and reliability, followed by determining the type of bearings needed for the specific application. Computer-aided design (CAD) software is used to create precise models that can be used to manufacture the bearings.

Once the design is completed, the manufacturing process begins. There are various bearing manufacturing methods in China, such as rolling, forging, and machining. Rolling is the most common method used in China, which involves forming the bearing’s outer and inner rings by using a rolling machine. Forging method, on the other hand, uses high-pressure and heat to form the bearings. Machining involves producing bearings through removal of material using a machine tool.

After the manufacturing process, bearings undergo extensive testing to ensure quality and durability. Bearings are tested for their fatigue resistance, ability to handle extreme pressure, vibration, and noise. The testing involves subjecting the bearings to simulated working conditions and measuring their performance.

In conclusion, China’s bearing industry is robust and continuously growing, thanks to its ability to provide a vast range of high-quality bearings at competitive prices. The process of manufacturing bearings involves skilled design, manufacturing techniques, and testing to ensure optimal performance in various applications. As a result, China will continue to be a global leader in the bearing industry for years to come.

How to use Bearings China

Bearings are an essential component of many machines and equipment. They help reduce friction, prevent wear and tear, and ensure smooth operation. If you want to use bearings from China, there are several things you need to know. Here is a simple guide on how to use bearings China.

1. Identify the right bearing type- First, determine the type of bearing you need. China produces different types of bearings, including ball bearings, roller bearings, spherical bearings, and others. Make sure you know the exact specifications of your machine and choose the right type of bearing for it.

2. Choose a reliable supplier- The supplier you choose will determine the quality of the bearings you get. Look for reputable companies that have a history of supplying high-quality bearings. Ensure the supplier meets all the relevant standards such as ISO and has a good track record of delivering orders on time.

3. Proper installation- When you receive the bearings, make sure you install them correctly. Follow the manufacturer’s instructions and use the proper tools to avoid damaging the bearings.

4. Regular maintenance- To get the most out of your bearings, perform regular maintenance. Regularly clean the bearings and ensure they are properly lubricated. Check for any signs of damage or wear, and replace the bearings if necessary.

5. Proper storage- If you’re not using the bearings immediately, ensure you store them correctly. Keep them in a dry and clean environment to prevent rust and corrosion.

In conclusion, using bearings from China can be cost-effective and efficient if you follow the right procedures. Identify the right bearing type, choose a reliable supplier, properly install the bearings, do regular maintenance, and store them correctly.

Selecting the Ideal Manufacturer Bearings China

When it comes to selecting bearings in China, it is essential to choose the right manufacturer. The manufacturer’s reputation is vital because they produce quality products that have met the required standards. Bearings are vital components in different machines, and the manufacturer’s quality guarantees the machine’s durability.

The first step in choosing an ideal manufacturer in China is to research thoroughly. Look at the manufacturer’s website and the products they offer. You can compare the prices of the different manufacturers and ensure they have a variety of bearings. A reliable manufacturer should be able to provide technical details on their products to ensure that you know the product specifications that you are buying.

The manufacturer should have a good track record in producing quality products. Check the feedback and reviews from customers who have had experience with the manufacturers’ products. This will give you an idea of the manufacturer’s reputation and quality of their products. A good manufacturer should also have good customer service, and they should be able to handle any complaints raised by customers.

The experience of the manufacturer is also an essential factor to consider. The manufacturer should have a proper understanding of the bearings’ production process and the materials required to manufacture them. An experienced manufacturer will have the necessary expertise to produce quality products.

Lastly, the manufacturer should comply with the required standards in producing their products. The bearings should be compliant with ISO standards and other regulations in the country. This helps ensure that the bearings have undergone the necessary tests to determine their quality.

In conclusion, selecting the ideal manufacturer bearings China depends on thorough research, the manufacturer’s reputation, experience, customer service, and compliance with the required standards. With the right manufacturer, you can be assured of quality products that will perform efficiently and have a long lifespan.

list FAQ with answer about Bearings China

List FAQ with Answers about Bearings China

1. What is Bearings China?

Bearings China is a country that produces different kinds of Bearings. Bearings are devices that help machines move and rotate smoothly.

2. What is the quality of Bearings from China?

China produces both low-quality and high-quality bearings. It is highly recommended to buy bearings from a reputable manufacturer in China to ensure quality and reliability.

3. How can I find a reputable bearing manufacturer in China?

You can find a reputable bearing manufacturer in China by checking their certifications, researching their company history, reading customer reviews, and asking for samples.

4. What types of bearings does China produce?

China produces a wide range of bearings including ball bearings, roller bearings, spherical plain bearings, and tapered roller bearings.

5. How long does it take to produce bearings in China?

The production time for bearings in China varies depending on the type of bearing and the quantity. Generally, it takes 20 to 30 days to produce bearings in China.

6. What is the minimum order quantity for bearings in China?

The minimum order quantity for bearings in China varies depending on the manufacturer. Some manufacturers require a minimum order of 500 to 1000 units, while others may have no MOQ.

7. What is the payment method for bearings from China?

The payment method for bearings from China varies depending on the manufacturer. Generally, manufacturers accept payment through wire transfer, PayPal, or credit card.

8. What is the warranty for bearings from China?

The warranty for bearings from China varies depending on the manufacturer. However, most manufacturers offer a one-year warranty for their bearings.

9. What is the shipping method for bearings from China?

The shipping method for bearings from China varies depending on the manufacturer and the quantity. Generally, manufacturers use air, sea or rail transportation to ship bearings.

10. How can I ensure the quality of the bearings from China?

To ensure the quality of the bearings from China, it is highly recommended to buy from a reputable manufacturer, request samples, and conduct product testing before making a bulk purchase.

Things to Consider When Purchasing Bearings China

When it comes to purchasing bearings, China has become a popular destination for buyers around the world due to its high quality products and affordable prices. However, there are several important factors that need to be considered to ensure a successful purchase.

Firstly, it is vital to select a reliable supplier. When buying bearings from China, it is important to work with a reputable supplier who has a track record of delivering quality products. Double-check their certifications and perform a thorough background check before making any purchases.

Another thing to consider is the type of bearing required. There are a variety of bearing types such as roller, ball, ceramic, or thrust bearings. Each type of bearing has its own benefits and limitations, so it is important to choose the type of bearing that is best suited to your specific needs.

Next, it is essential to factor in the cost. When searching for bearings in China, always consider the cost per unit, shipping charges, and additional taxes or import duties. Don’t forget to also take into consideration any additional costs, such as inspection or testing fees.

Furthermore, quality control is crucial when sourcing bearings from China. Before shipment, it is necessary to inspect the bearings thoroughly to ensure that they meet the required standards. Additionally, manufacturers must provide the necessary documentation and certificates to certify that their products meet international standards.

Finally, don’t forget about communication. Communication is key when dealing with suppliers from China. Always ensure that the communication process is smooth and effective, so that all your concerns and requirements can be addressed comprehensively.

In conclusion, purchasing bearings from China can be very advantageous, but buyers must do their research and take the necessary precautions to ensure a satisfactory outcome. By considering factors such as supplier reputation, bearing type, cost, quality control, and communication, buyers can find the right supplier and make a successful purchase that meets their needs.

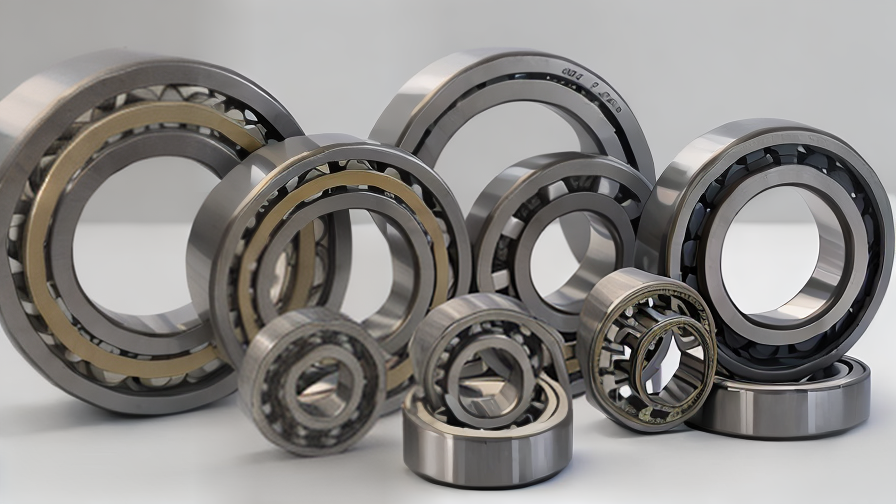

Properties of Bearings China

Bearings are critical components of almost all machinery, from automobiles and airplanes to cutting edge factory machines. Bearings China is a global leader in the production and distribution of high-quality bearings designed to suit the needs of various industries. The manufacturing process involves the use of high-tech machinery and skilled personnel to create high-quality bearings. These bearings vary in design, size, and specifications to cater to the diverse needs of industries.

One of the most critical properties of bearings in China is that they are highly durable, with a prolonged lifespan. This attribute makes them ideal for applications that require frequent and prolonged use, such as in the automotive and aerospace industries. The bearings are designed to withstand extreme temperatures, pressures, and heavy loads, thanks to their high-quality materials, such as stainless steel and ceramic.

Another critical property of bearings in China is that they exhibit a low coefficient of friction. They possess highly polished surfaces that allow for smooth, seamless motion between components in motion. This low coefficient of friction results in reduced wear and tear, ensuring minimal maintenance needs and reduced downtime.

The bearings’ precise dimensions and tolerances also make them ideal for applications where accuracy is key, such as in the medical and robotics industries. The bearings are manufactured with a high level of precision to ensure that they fit perfectly into the specified components, reducing any possibilities of instability or failure.

In conclusion, the properties of bearings in China make them a valuable component for various industries. They are highly durable, exhibit a low coefficient of friction, and are precise, making them ideal for applications where accuracy and reliability are key. With the rapidly advancing technology and high demand for precision components, bearings China is poised to play a vital role in the world’s machinery industry.

Technical Parameters Terms for Bearings China

Technical Parameters Terms for Bearings China

Bearings are critical components in various industries, ranging from automotive and aerospace to power generation and medical equipment. China is one of the leading countries that manufacture bearings, and it’s essential to understand the technical parameter terms for bearings to ensure their optimal performance. Here are some of the commonly used technical parameter terms for bearings in China:

1. Radial Load: This refers to the load that acts perpendicular to the axis of rotation. It’s a critical parameter that determines the bearing’s ability to support weight and withstand pressure.

2. Axial Load: This refers to the load that acts parallel to the axis of rotation. In most cases, the axial load is much smaller than the radial load, but it’s still an important parameter to consider when designing or selecting bearings.

3. Contact Angle: This refers to the angle between the bearing’s axis and the line connecting the contact points between the rolling elements and the raceway. The contact angle determines the ability of the bearing to support axial and radial loads.

4. Dynamic Load Rating: This refers to the maximum load that a bearing can support before failure occurs. It’s usually specified in terms of the maximum load capacity in Newtons or pounds.

5. Static Load Rating: This refers to the load that a bearing can support without fail when it’s stationary or not rotating. It’s usually specified in terms of the maximum load capacity in Newtons or pounds.

6. Speed Rating: This refers to the maximum rotational speed that a bearing can sustain without failure. It’s usually specified in terms of revolutions per minute (RPM).

In conclusion, understanding the technical parameter terms for bearings in China is crucial for ensuring the optimal performance and longevity of the bearings. Manufacturers and end-users should always consider these parameters when selecting or designing bearings for various applications.

Bearings China Price

Bearings China Price

Bearings are essential components of machinery and tools as they reduce friction between moving parts and facilitate smooth rotational movement. China has emerged as a major producer and exporter of bearings, offering a wide range of options at competitive prices.

The price of bearings in China varies depending on factors such as material, size, type, and application. Generally, Chinese bearings are cheaper compared to those made in Western countries without compromising on quality. This is mainly due to lower labor costs and favorable government policies to support the manufacturing industry.

China produces top-quality bearings that meet or exceed international standards such as ISO and ANSI. Many Chinese bearing manufacturers have obtained quality certifications such as ISO 9001, TS16949, and CE certification. They use advanced production technologies and invest heavily in research and development to improve the performance and durability of their products.

The most common types of bearings produced in China include ball bearings, roller bearings, tapered roller bearings, and linear bearings. These bearings find application in various industries such as automotive, machinery, aerospace, and construction.

When buying bearings from China, it is essential to choose a trustworthy supplier that meets your specific requirements. Consider factors such as the company’s reputation, quality of products, delivery time, and after-sales service. You can also opt for third-party testing and inspection to ensure that the bearings meet your desired specifications.

In conclusion, China offers a wide range of quality bearings at affordable prices. However, it is essential to conduct proper research and due diligence to find a reliable supplier and ensure that the products meet your specific needs.