Benefits of Baler Net

Baler net is a material used to wrap and secure baled products such as hay, straw, and silage. The net has several benefits that make it a popular choice for farmers and agricultural businesses.

One of the major benefits of baler net is that it provides better protection for baled products. The net is made of durable and strong materials that can withstand external pressures and damage. This helps to keep the baled products secure during transport and storage, keeping them fresh and protected from pests and weather conditions.

Another advantage of baler net is that it facilitates faster baling and wrapping of hay and other products. The net is designed to be easily placed over the bales and tightly secured using specialized baling machines, which ensures that the baled products are well-packaged and less prone to damage.

Baler net is also very cost-effective and environmentally friendly. Compared to traditional materials like twine and baling wire, the net requires less time and resources to apply, which results in cost savings for farmers and businesses. Moreover, the net is recyclable and does not produce waste that can harm the environment.

Finally, baler net is easy to handle and store due to its lightweight and compact nature. This makes it convenient for farmers and businesses with limited storage space, and allows for easy handling and transportation of baled products.

In conclusion, baler net provides numerous benefits for farmers and agricultural businesses. It offers better protection for baled products, facilitates faster baling and wrapping, is cost-effective and environmentally friendly, and is easy to handle and store. As such, it is no wonder that baler net has become an indispensable tool for modern agriculture.

Features of Baler Net

Baler nets are commonly used for baling hay, straw and other agricultural produce. The use of these nets offers a number of benefits, especially when it comes to reducing wastage. Here are some of the features of baling nets that make them an essential tool for farmers.

Strength and Durability

Baler nets are specially designed to be strong and durable. These nets are constructed from high quality materials that are capable of withstanding the harsh conditions of the farm environment. They are engineered to securely hold bales together, even under extreme pressure, ensuring minimal wastage and maximum yield.

UV Stabilization

Exposure to sunlight can easily damage bales, leading to loss of quality and value. Baler nets are usually treated with UV stabilizers, ensuring that the bales remain well protected against the harmful effects of sunlight, allowing farmers to store their products for longer periods of time.

Ease of Use

Bale nets are incredibly easy to use, making them an ideal tool for farmers and agricultural workers. They can be easily installed and removed as needed, and their lightweight design makes handling them a breeze.

Cost-effective

Baler nets are more cost-effective than traditional baling methods. Using bale nets can result in minimal wastage, which ultimately means that farmers get more value for their investment. This makes it an ideal tool for farmers who are looking to improve their bottom line.

Versatility

Bale nets are versatile and can be used in a wide range of applications. They can be used to secure hay bales, straw bales, and other types of agricultural produce. They are also available in a variety of widths and lengths, making them suitable for use with different types of balers.

In conclusion, the use of bale nets has become increasingly popular among farmers due to their strength, durability, ease of use, cost-effectiveness, and versatility. They offer farmers an economical and efficient way to secure their bales, reducing wastage and improving yields.

Various Types of Baler Net

Baler net is a type of twine that is used to hold hay or straw together in bales. There are various types of baler net available in the market that are designed for different purposes and conditions. In this article, we will discuss some of the most common types of baler nets.

1. Standard Baler Net: This is the most common type of baler net that is used for general baling purposes. It is made of high-density, UV-stabilized polyethylene that makes it durable and resistant to weather conditions. It comes in different sizes and can be used with both square and round balers.

2. Heavy-Duty Baler Net: As the name suggests, this type of baler net is designed to handle heavy-duty baling tasks. It is made of thicker and stronger twine that can withstand high pressure and tension. It is ideal for baling silage, high-moisture hay, and other heavy-duty crops.

3. Ultra-Heavy-Duty Baler Net: This type of baler net is designed for extreme baling conditions. It is made of ultra-thick and strong twine that can handle the most challenging baling tasks. It is perfect for baling wet crops, such as rice straw or millet, and for use in extreme weather conditions.

4. Biodegradable Baler Net: This type of baler net is made of natural materials, such as sisal or hemp, and is designed to decompose over time. It is a popular option for eco-conscious farmers who want to reduce their environmental footprint.

5. Colored Baler Net: This type of baler net comes in a range of colors and is mainly used for branding or marketing purposes. It can be used to match the color of the bales with a particular brand or for promotion purposes.

In conclusion, there are different types of baler nets available in the market, each with its own unique features and benefits. Choosing the right kind of baler net depends on the type of crop, baling conditions, and personal preferences. It is essential to consider the quality, durability, and efficiency of the baler net before making a purchase decision.

Applications of Baler Net

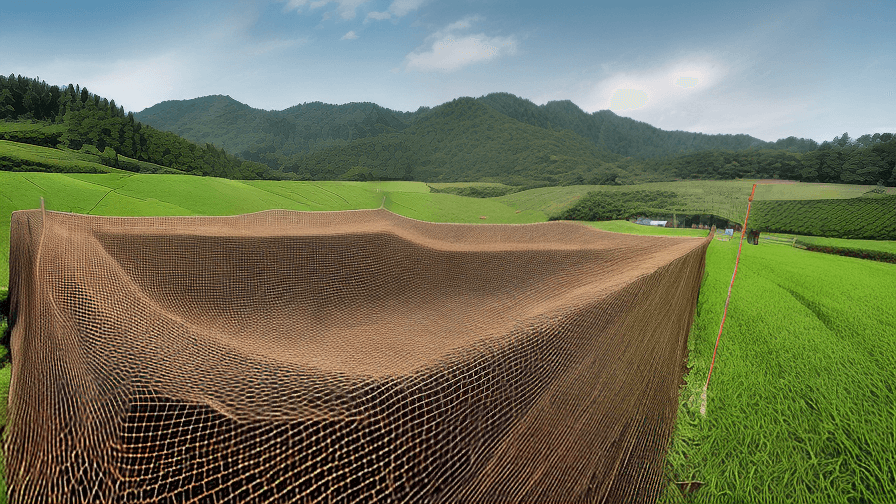

Baler net is a high-strength material that is used to wrap bales of hay, straw, and other crops. It is commonly made of polypropylene, a strong and durable plastic that can withstand the weight and pressure of the bales. Baler net has a wide range of applications, from agriculture to construction, and even to household use.

One of the most common applications of baler net is in agriculture. Farmers use it to wrap bales of hay and straw to keep them dry and protected from the elements. Baler net also helps to keep bales in shape and prevents them from falling apart, making them easier to handle and transport. Additionally, it reduces the risk of mold and moisture damage, ensuring that quality feed is available for livestock all year round.

In the construction industry, baler net is used as a safety netting material. It can be attached to scaffolding to prevent debris from falling and causing injury to workers or the public below. Baler net is also used to cover materials being transported on trucks or in trailers, ensuring that they do not fly out and cause accidents on the road.

Baler net has also found its way into household use. It can be used as a temporary fence for pets or to secure a garden patch. Additionally, it can be used to cover outdoor furniture or equipment during the winter months, protecting them from the harsh elements.

In conclusion, baler net is a versatile material that has found its way into various industries. Its durability and resistance to wear and tear make it an essential component in agriculture, construction, and even household applications. With the growing demand for reliable and sustainable materials, baler net is set to continue playing a vital role in shaping the future.

The Process of Baler Net

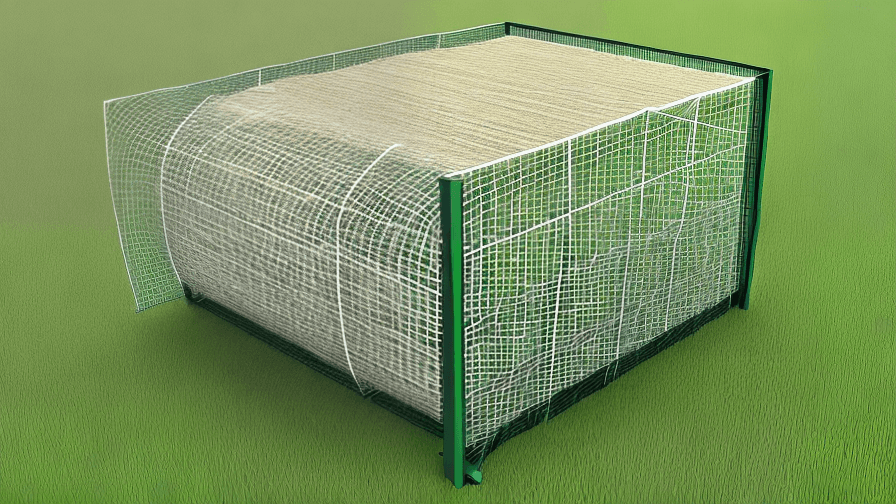

Baler netting is the process of enveloping crops, hay, and straw to be used for grazing, feeding or exporting. The process of baler netting involves the use of specialized netting material that is wrapped around a bale of hay or straw, providing a secure holding mechanism. The process is crucial in maintaining the quality of the crops, preventing losses, and reducing wastage.

The first step in the baler netting process is the preparation of the crops. Crops need to be cut and dried to the optimal moisture content to ensure that the quality is maintained throughout the process. Once the crops are ready, they are compressed into bales using a cylindrical baler. This compression process helps to reduce the volume of the crops, making it easier to transport and store them safely.

After the crops have been compressed, the next step is to wrap them with the baler netting material. The netting material used in this process should be of high quality, strong enough to hold the crops securely without breaking, and easily removable when the bales are required for use.

The bales are moved through a baler netting machine, which wraps the netting material around them, providing an extra layer of protection to the crops. The machine pulls the netting material from a spool, ensuring that the bales are evenly covered, increasing the stability of the structure.

Once the bales are wrapped, they are ready for transport or storage. Baler netting helps to secure the bales, protecting them from moisture, sunlight, and pests. The netting material also prevents the bales from deteriorating when they are stored outside, ensuring that the crops remain fresh until they are required for use.

In conclusion, baler netting is a crucial process that helps to maintain the quality of crops, prevent wastage, and increase efficiency. Crops that are baler netted are easy to transport, store, and use, making them an essential ingredient in animal feed. Grains, fodder, hay and straw are all baled together, and the netting process ensures that they remain healthy and fresh for usage as animal feed. A proper understanding of the baler netting process is essential to ensure that the best quality crops are obtained.

How to use Baler Net

Baler net is an essential tool to use when baling hay or any other agricultural product. Baler nets offer many benefits such as reduced hay loss, quicker baling time, and better protection against moisture. Using baler net can also help you save money in the long run since it reduces the amount of hay wasted. In this article, we’ll go through the steps you need to follow to use baler net effectively.

Before we start, make sure that your baler is in good condition and that the net you are using is the correct size for your baler. Always wear protective gear when handling baler net and follow these steps below:

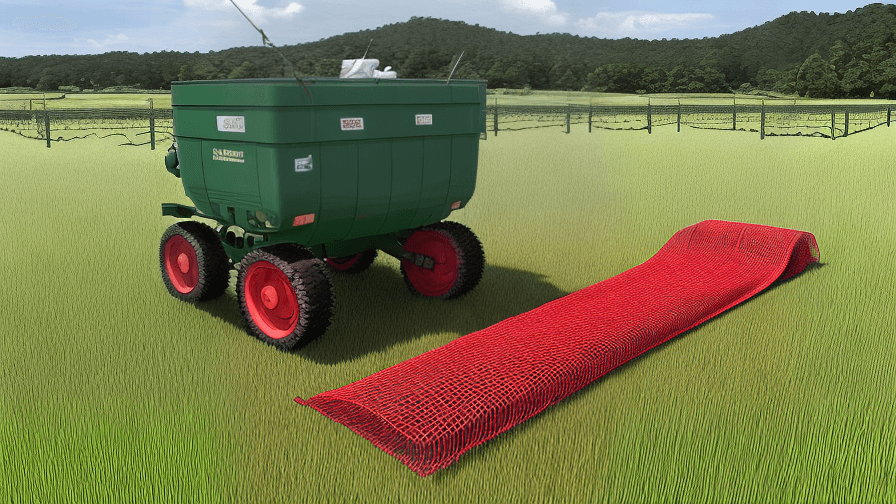

Step 1: After you have baled your hay, ensure that the bale chamber is clear and ready for the netting process. It’s important to note that the baler must have an appropriate net wrap mechanism installed.

Step 2: Once the baler is ready, insert the baler net roll into the baler’s net wrap mechanism. Ensure the roll is installed correctly and that the end of the net is left hanging out in a convenient location for easy access.

Step 3: Start the baler and watch as the net wrap system starts to wrap the bale. As the bale chamber fills up, the net will start to wrap the bale.

Step 4: When the net has finished wrapping the bale, cut the net using a knife or scissors. Ensure a safe distance is kept between you and the spinning baler, thereby avoiding the risk of injury resulting from the machine’s moving parts.

Step 5: When the net has been cut, close the door of the baler, and continue baling, repeating the process.

Using baler netting is as easy as that. It’s an efficient and reliable way of baling hay or any other agricultural product. With the proper use and maintenance, baler net can last for years and be a valuable investment. Remember, your safety is of utmost importance when handling any form of machinery. Follow the outlined steps carefully, take things gradually and most importantly, stay safe.

Selecting the Ideal Manufacturer Baler Net

Selecting the Ideal Manufacturer Baler Net

A baler net is a necessary component for packaging hay, straw, and other agricultural products. Choosing the right type and manufacturer of the baler net is essential since it affects the efficiency and effectiveness of baling operations.

First and foremost, one should consider the material and construction of the baler net. Baler nets are typically made of different materials, including polypropylene or polyester, and come in various thicknesses. For instance, thin nets can rip quickly, which can lead to significant losses. Therefore, one should choose baler nets with a higher tensile strength as they can withstand different weather conditions, such as UV rays and moisture.

Another factor to consider when selecting a baler net manufacturer is their reputation in the market. Choosing a reputable manufacturer ensures that one gets high-quality nets that meet the industry standards. Moreover, a reputable manufacturer offers customer service and technical support, ensuring that clients don’t experience problems with their products.

Pricing is also a critical factor when choosing a manufacturer for baler nets. One should consider the type of net required, the quantity, and the budget available. While it might be tempting to opt for cheaper options, it is vital to ensure that quality is not compromised. For example, cheap nets may not have adequate durability, causing significant losses to farmers.

Lastly, it is essential to consider the manufacturer’s delivery system, particularly in terms of orders, lead times, and shipping times. A good manufacturer should deliver orders promptly and meet clients’ schedules, even in short notice.

In conclusion, selecting the ideal manufacturer for baler nets requires careful consideration of various factors. A reputable manufacturer offers quality products, reliability, and excellent customer service. pris, on the other hand, one should consider product quality, pricing, and delivery system when selecting a baler net manufacturer.

list FAQ with answer about Baler Net

Baler net is a necessary component for every baler machine. It is used to wrap around the bales of hay, straw, or other material, so that they can be easily transported, stored, or sold. However, many people have questions about baler net, its features, advantages, and usage. Here is a list of frequently asked questions (FAQ) and their answers, which will help you understand baler net better.

Q1. What is baler net made of?

Baler net is made of high-quality, UV-resistant polyethylene material, which makes it strong, durable, and long-lasting.

Q2. What is the width and length of the baler net?

Baler net is available in various widths from 48 inches to 67 inches, and lengths from 7000 feet to 9000 feet. The exact dimensions depend on the manufacturer and the model you choose.

Q3. Does baler net come in different colors?

Yes, some manufacturers offer baler net in different colors, such as green, white, or orange. However, the color does not affect the quality or performance of the net.

Q4. How is baler net applied to the bales?

Baler net is applied by the baler machine itself, which uses a net wrap dispenser to wrap the net around the bales automatically as they are being formed. There is no need for manual application.

Q5. What are the benefits of using baler net?

Baler net offers several benefits, such as reducing hay waste, preventing bale spoilage, improving the bale quality and appearance, and making bales easier to handle and transport.

Q6. Is baler net compatible with all types of baler machines?

Most baler machines are designed to work with baler net, but you should always check the specifications of your baler model to ensure compatibility. Some manufacturers may also offer customized nets for specific baler models.

In summary, baler net is an essential accessory for your baler machine, and it is available in various sizes, colors, and materials. By using baler net, you can save time, money, and resources, and get the best results from your baling operations.

Things to Consider When Purchasing Baler Net

When it comes to baling hay, one important factor to consider is the quality of the baling net. A good baler net ensures that your hay is tightly packed and stays protected from the elements. However, finding the right baling net can be a challenging task. Here are some things to consider when purchasing baling net.

1. QUALITY – the quality of the baling net is crucial in ensuring that your hay is properly packed. Choose a net that is high in quality and tear-resistant. This guarantees that the netting will hold its shape under pressure during the baling process.

2. SIZE – Consider the size of the netting. Choose a size that fits your bale size, so you don’t need to adjust the netting much. Be sure to know the proper size of your bale before purchasing your baler net.

3. UV RESISTANCE – Consider a net that is UV resistant. An exposure to the sun’s harmful UV rays can cause degradation and breakage of the fibers of the net, leading to reduced service life.

4. MATERIAL – There are different materials that make up a baler net. Make sure the material is durable and can withstand harsh weather conditions when stored outside.

5. COST – Balers nets vary in price, and some of the more expensive options may not always be the best fit for your agricultural needs. The cost of the netting should be the last thing on the list. It is essential to find a net that is affordable and of high quality that lasts long and saves you money on necessary replacements.

In conclusion, a good baler net plays an essential role in ensuring that your hay is tightly packed and preserved from the elements. By considering these factors when purchasing your next baler net, you’ll be able to find the perfect product and efficiently store your hay.

Properties of Baler Net

Baler net is a versatile product that is mainly used in the agricultural industry. It is a durable and reliable product that is utilized to tie bales of hay, straw, or any other agricultural commodity. The netting is made of high-density polyethylene, which is known for its strength, chemical resistance, and durability.

One of the significant properties of baler net is its resistance to ultraviolet rays. This type of netting is designed to withstand the harshest weather conditions, including exposure to the sun. As a result, the netting retains its strength and flexibility, thereby serving the intended purpose effectively.

Another crucial property of baler net is its high tensile strength. Baler nets are known for their excellent strength, which ensures that the bales are compact and efficiently compressed. This property helps in maintaining the integrity of the bales, which reduces the risk of spoilage and loss of feed value.

Baler net is also known for its flexibility. It is designed to stretch during the baling process and then contract once the bale is tied. This property ensures that the bale is tight and compact, thereby preventing air from entering. Ensuring that the bale is dense and free from air leads to reduced spoilage, better-quality feed, and reduced wastage.

Lastly, baler netting is available in different sizes and shapes. It comes in different widths, lengths, and thicknesses, making it easy to choose a product that meets the specific needs of the user. The different sizes of baler netting also make it easy to handle, transport, and use during the baling process.

In conclusion, baler netting is an essential product for the agricultural industry. Its unique properties, high tensile strength, and resistance to ultraviolet rays make it ideal for tying bales of hay and straw. The flexibility and availability of different sizes and shapes make it easy to use and handle. Industrial users, farmers, and individuals in the agricultural industry are guaranteed to find baler netting a reliable product that delivers quality and value.

Technical Parameters Terms for Baler Net

Technical Parameters Terms for Baler Net

Baler netting, also known as bale net wrap, is a crucial component of baling machines. It controls the expansion and collapsing of the bale while being transported and eventually stored. The technical parameters of a netting material are vital in ensuring that it fulfills its functions to the maximum. This article will delve into some of the key technical parameters of baler netting.

Tensile Strength – This is a measure of the resistance of the netting to breakage. The tensile strength of the netting is the maximum amount of force that the netting can withstand before breaking. It is essential to consider the tensile strength of the netting material when selecting the right netting for your needs.

UV Resistance – The durability of the netting material is another critical technical parameter. The ability to resist degradation caused by UV radiation is essential, given that the baler netting is almost always exposed to sunlight. With UV-resistant netting, the lifespan of the baling equipment is increased, reducing the frequency of replacement and maintenance.

Width and Length – The length and width of the baler netting are vital factors that determine its compatibility with different baling machines. It is essential to select the netting that works optimally with your machinery. Length and width also play a significant role in determining the strength and effectiveness of the netting.

Knot Strength – Knot strength refers to the strength of the knot used to join two ends of the netting. It is imperative to consider the knot strength of the netting material to ensure that it can maintain the bale’s shape during handling and transport.

Elongation – The ability of the baling netting to stretch without breaking is the elongation. It is essential to consider this technical parameter to ensure that the netting can accommodate the expansion of the bale during transportation, without disintegrating or causing damage to the bale.

In conclusion, the technical parameters of baling netting are essential to its effectiveness and durability. By choosing the right size and strength of netting, the baling process can be made smoother, more efficient, and more cost-effective in the long run.

Baler Net Price

Baler net price is a term that refers to the price of a baler machine and the accompanying netting material used to wrap bales. The price of baler netting can vary depending on the type and quality of material used.

When it comes to purchasing a baler machine, it’s important to consider the cost of netting material as well. The netting material is used to wrap the bales, keep them together, and protect them from the elements. Without proper netting, bales can easily become untied or damaged, reducing their value.

The cost of baler netting will depend largely on the type of material used. Traditional netting is made from polypropylene, but newer, more durable materials such as co-extruded netting are becoming increasingly popular. Co-extruded netting is made by extruding two different materials at the same time, resulting in a stronger and more resilient material.

The quality of the netting material will also affect the price. Higher quality netting may be more expensive, but it can also provide better protection for bales and reduce the risk of damage during transportation or storage.

In addition to the cost of the netting material, the price of a baler machine can also vary depending on its features and capabilities. Some balers are designed for specific types of materials, while others may have advanced features such as automatic tying or bale labeling.

When shopping for a baler machine and netting material, it’s important to consider both the immediate cost as well as the long-term benefits. Investing in higher quality netting and a more advanced baler machine can lead to greater efficiency and reduced costs over time.

In conclusion, baler net price is an important consideration when purchasing a baler machine. The type and quality of netting material can affect the cost, as can the features and capabilities of the machine itself. By carefully considering these factors, you can make an informed decision when choosing a baler machine and avoid unnecessary expenses in the long run.