Benefits of Bottling Machine Manufacturers

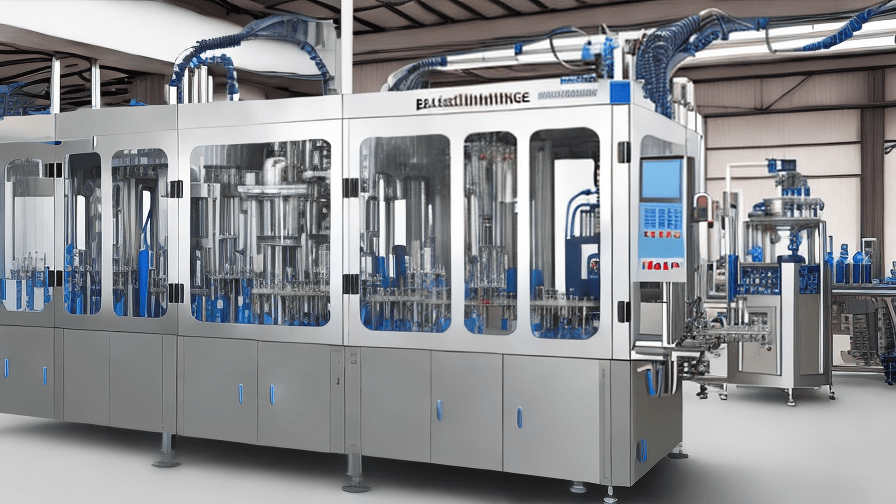

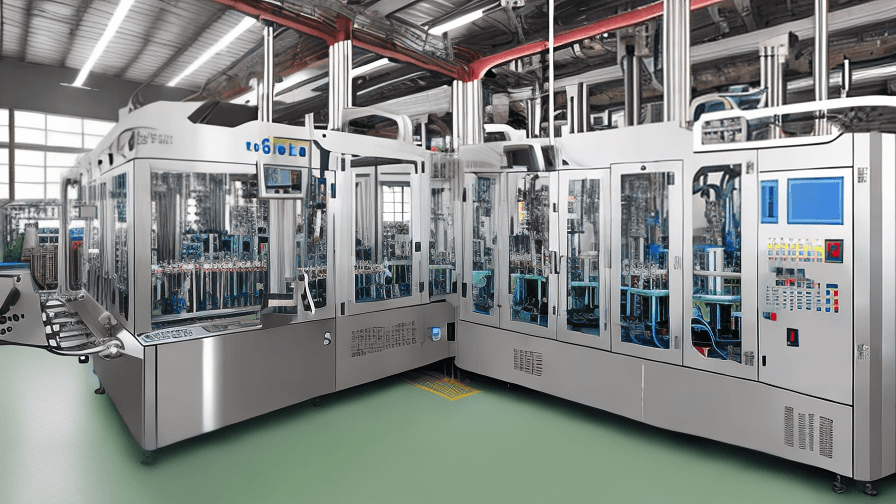

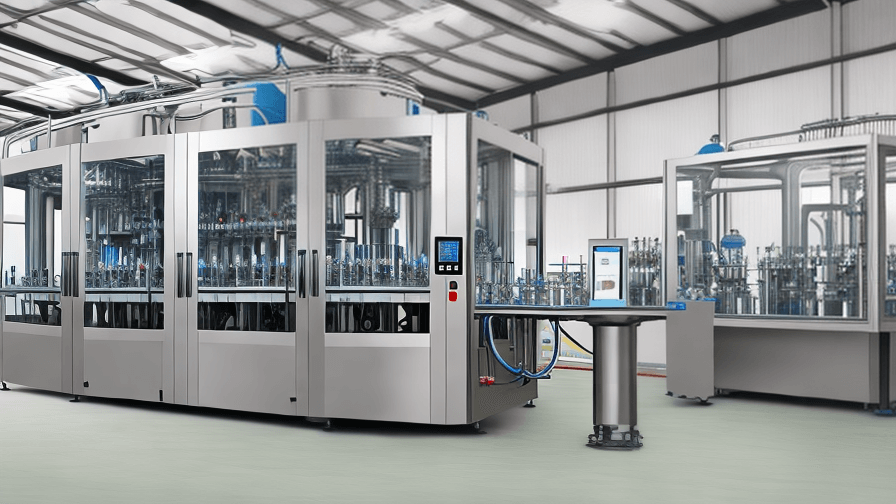

Bottling Machine manufacturers are a key component in the success of businesses that require automated bottling processes. These machines have revolutionized the bottling process by offering fast, efficient, and accurate filling, capping, and labeling.

One of the benefits of bottling machine manufacturers is that they offer customized machines that can fit the unique needs of businesses. With the ability to tailor these machines to specific requirements, bottling machine manufacturers have eliminated the need for businesses to settle for off-the-shelf solutions that may not meet their precise needs. This customization option offers businesses the chance to increase their productivity, reduce downtime, and ensure customer satisfaction with the quality of their products.

Another benefit of bottling machine manufacturers is that they provide businesses with machines that are energy-efficient and eco-friendly. These machines are designed to reduce the amount of energy used during the bottling process, resulting in lower operating costs and reduced carbon emissions. This eco-friendly approach to manufacturing helps businesses maintain a sustainable production process while meeting their production targets.

Bottling machine manufacturers also offer support services such as maintenance, repair, and training to businesses. Maintenance services ensure that the machines continue to operate at optimal performance levels, resulting in higher productivity levels and reduced downtime. Training services provide businesses with the necessary skills to operate and maintain the machines, reducing the likelihood of costly mistakes and increasing the lifespan of the machines.

In conclusion, bottling machine manufacturers offer businesses a range of benefits, including customized solutions, energy efficiency, and comprehensive support services. Investing in these machines is an investment in the success and productivity of a business, and can help businesses maintain a competitive edge in their industry.

Features of Bottling Machine Manufacturers

Bottling machines are used to fill and seal bottles of various types of products such as water, carbonated beverages, wine, and more. As an essential component of the packaging industry, bottling machines have become increasingly sophisticated and efficient over the years. The features of bottling machine manufacturers can greatly impact the quality, speed, and reliability of these machines.

One of the most important features of bottling machine manufacturers is their expertise in the production of high-quality machines. They must have extensive knowledge of the materials and components required to ensure the durability and reliability of the machines. They must also incorporate the latest technology and innovations to meet the changing demands of the industry.

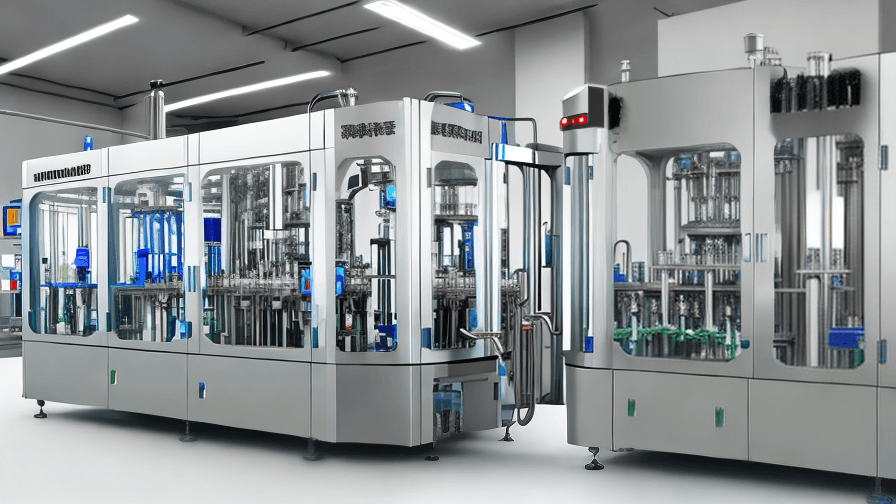

Another important feature is the ability to provide customization options tailored to the specific needs of their clients. Bottling machines are used in various industries, which means that different products require different bottling machines. A good manufacturer should be able to offer customized solutions to fit the unique requirements of each application.

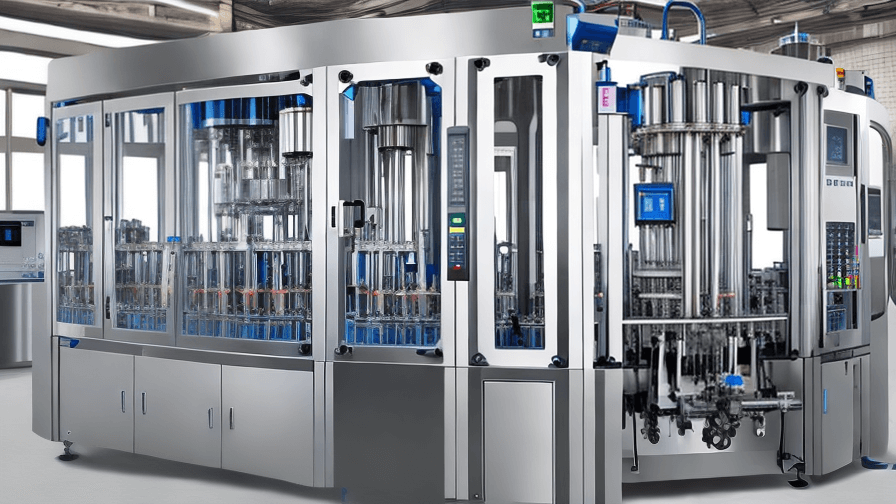

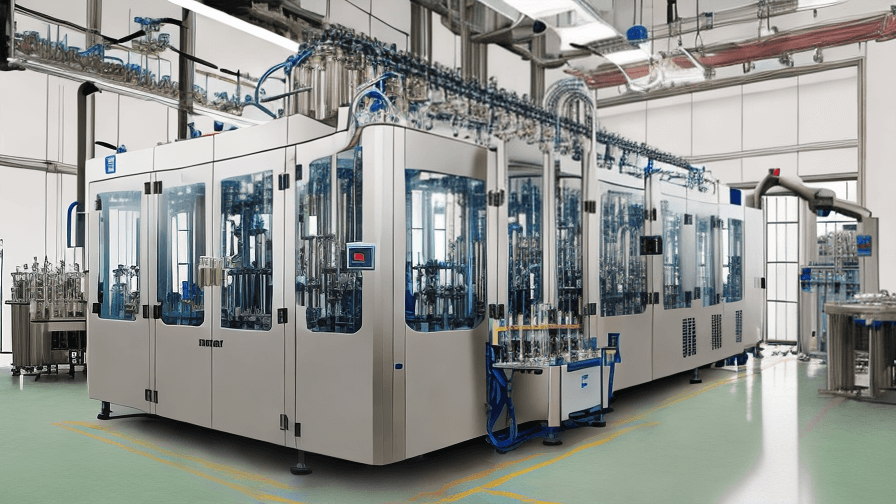

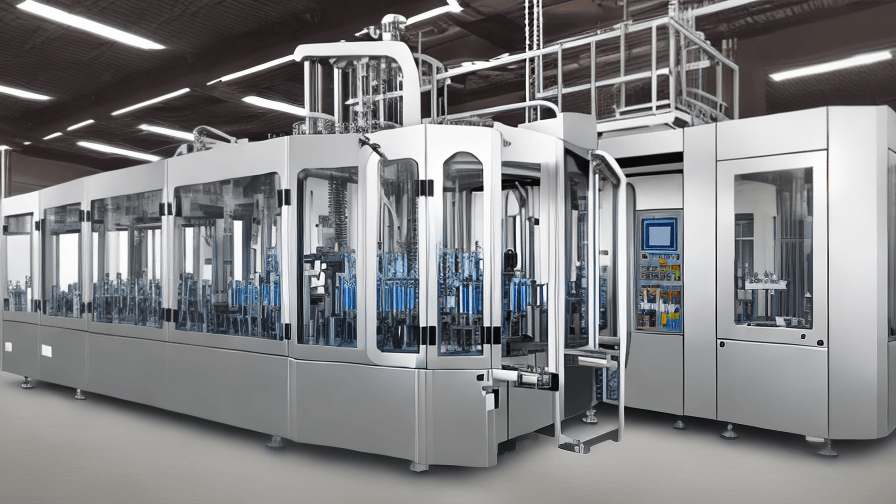

Speed and efficiency are also critical features that bottling machine manufacturers must consider. Machines that can fill and seal bottles quickly and accurately are essential in ensuring optimal productivity and profitability. Manufacturers should invest in high-speed filling and capping equipment that can help clients increase their output and profits.

Safety features are also a critical consideration for bottling machine manufacturers. They must ensure that their machines meet industry safety standards and regulations to ensure the health and safety of users and the end consumer. This includes the use of materials and components that promote hygiene and minimize contamination risks.

In conclusion, bottling machine manufacturers play a crucial role in the packaging industry. Their expertise, customization options, speed, efficiency, and safety features all impact the quality and success of the machines they manufacture. Clients should seek out manufacturers that prioritize these features to ensure that they are investing in quality and reliable equipment.

Various Types of Bottling Machine Manufacturers

Bottling is a crucial process in the manufacturing of beverages and other liquid products. It is a process that involves filling and capping of bottles with specific quantities of liquid for final packaging. The efficiency of the bottling process is largely dependent on the type of bottling machine used. In today’s market, there are various types of bottling machine manufacturers, and each offers distinct features and benefits to their customers.

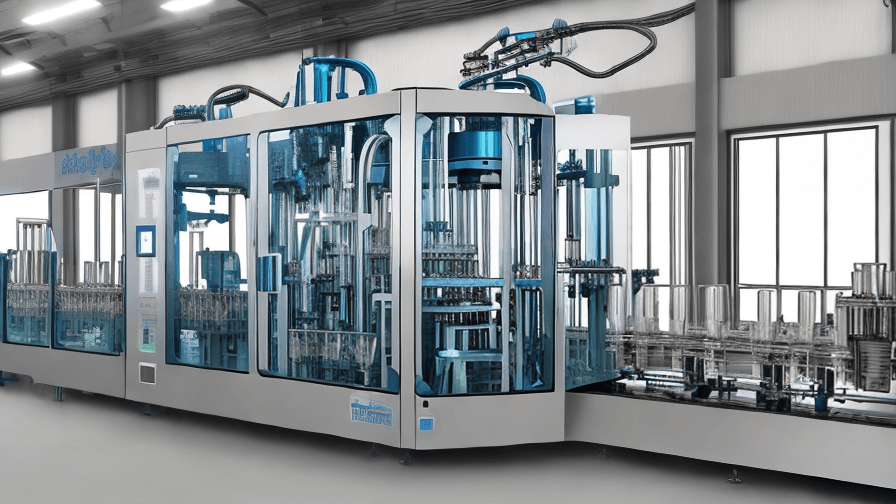

The first type of bottling machine manufacturer is the automatic bottling machine manufacturer. As the name suggests, this type of manufacturer produces machines that use an automatic system to fill, cap, and label bottles. The advantage of using an automatic bottling machine is that it saves time and reduces labor costs. In addition, it reduces the risk of error and contamination, therefore improves the quality of the product.

The second type of bottling machine manufacturer is the semi-automatic bottling machine manufacturer. This type of manufacturer produces machines that require minimal manual input, and they still require the operator to perform the filling, capping, and labeling. Semi-automatic bottling machines are ideal for small-scale manufacturers who cannot invest in fully automated machines.

The third type of bottling machine manufacturer is the manual bottling machine manufacturer. This type of manufacturer produces machines that are operated entirely by hand. Manual machines are most suitable for small businesses that cannot afford to purchase automated or semi-automated machines.

Another type of bottling machine manufacturer is the rotary bottling machine manufacturer. This type of machine uses a rotating wheel that holds the bottles in place as they are filled and capped. The rotary design offers high-speed operation, and it is most suitable for large-scale manufacturing.

In conclusion, each type of bottling machine manufacturer offers distinct features that cater to different manufacturing needs. It is crucial to consider the volume of production, labor costs, and quality of the product before choosing a bottling machine manufacturer.

Applications of Bottling Machine Manufacturers

Bottling machine manufacturers play a critical role in the production of various beverages and liquids. These machines are designed to fill and seal bottles, jars and other containers with liquids, including water, juice, soft drinks, beer, wine, spirits, oil and many other types of liquids.

One of the primary applications of bottling machines is in the beverage industry. Manufacturers use these machines to fill and package different types of drinks, including soda, juice, and water. These machines come in various sizes depending on the production capacity, ranging from small scale machines to large industrial machines that can fill up to thousands of bottles per minute.

Another application of bottling machines is in the pharmaceutical industry. These machines are used to fill and package different types of medicinal liquids such as syrups, cough mixtures, and medical oils. They are designed to maintain cleanliness, accuracy, and speed, ensuring that the drugs meet all industry regulations.

Bottling machines are also used in the oil industry. These machines are used to fill and package cooking oils, vegetable oils, and other types of oil products. They are designed to fill various container sizes, ranging from small bottles used in cooking to large drums used in industrial applications.

In the cosmetics industry, bottling machines are used to fill and package various liquids such as perfumes, lotions, and other cosmetic oils. These machines are designed to maintain the quality and texture of the cosmetics, ensuring that the final product is of the highest quality.

In conclusion, bottling machine manufacturers play a critical role in the manufacturing process of various liquids. They design and manufacture machines that are used in different applications, including the beverage, pharmaceutical, oil, and cosmetics industries. Bottling machines help to ensure efficiency, accuracy, and speed in the production process while maintaining the quality of the liquids being packaged.

The Process of Bottling Machine Manufacturers

Bottling machine manufacturers are a critical part of the modern manufacturing process. They design, build, and install machines that aid in the production of bottled products. Several steps are involved in the process of bottling machine manufacturing.

The first step is idea generation, which involves identifying a need in the market and developing a product concept that meets that need. Design engineers then develop the product specifications, including the size, shape, and capacity of the machine.

The next step is the prototyping phase where the design specifications are used to create a mockup of the machine. This allows the engineers to test the design, identify potential issues, and refine the product.

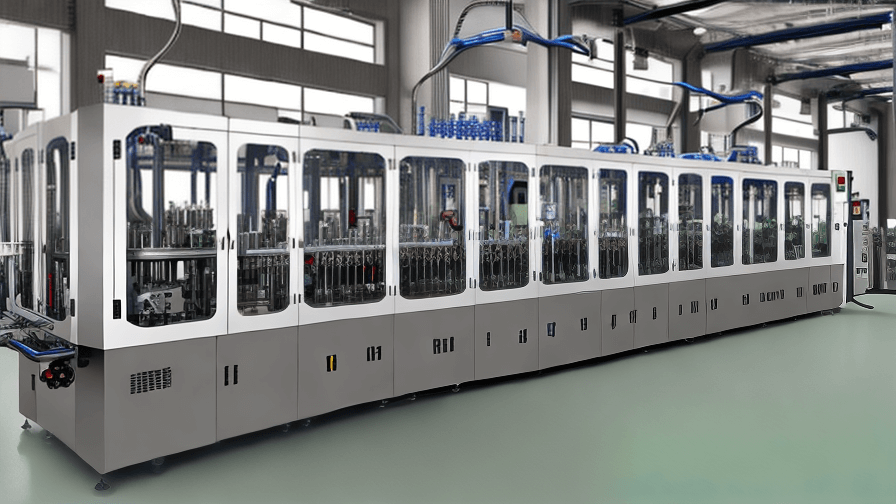

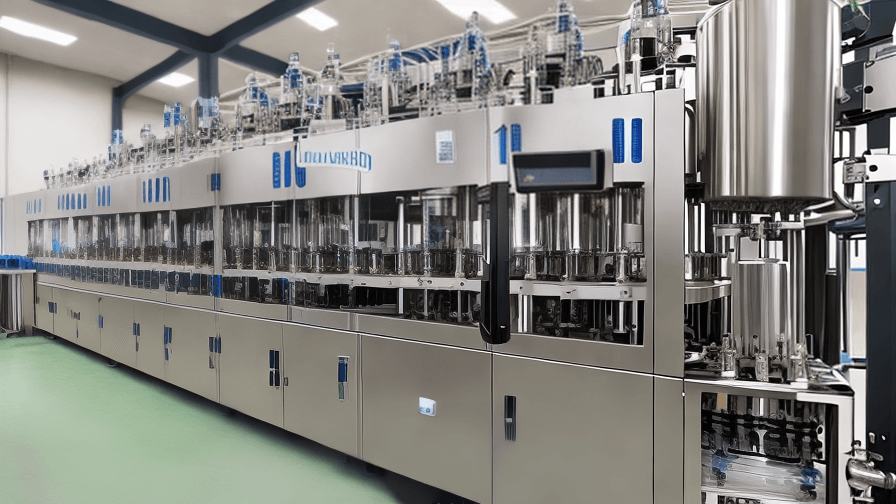

Once the design is finalized, the production of the machine can begin. The manufacturing process involves the use of various machines, tools, and materials to construct the final product. These machines are built to exacting standards to ensure their precision and durability.

After the production phase, quality control testing ensures that the machine meets the highest standards of safety and performance. This includes safety checks, leak testing, and other quality assurance measures.

Once the bottling machine has passed all quality control testing, it is transported to the customer’s site, where it is installed and tested. Bottling machine manufacturers typically offer ongoing training and support to their customers to ensure proper functionality, maintenance, and repair.

In conclusion, the process of bottling machine manufacturing is a complex series of steps that requires skilled engineers, quality materials, and precision manufacturing techniques. The result is state-of-the-art machinery that can efficiently produce high-quality, bottled products for consumers around the world.

How to use Bottling Machine Manufacturers

Bottling machines are the backbone of any beverage production line. They handle the process of filling, capping, and labeling bottles quickly and consistently. If you’ve invested in a bottling machine for your business, it’s important to know how to use it correctly to maximize its potential. Here are the steps to follow:

1. Set up the machine – Make sure the machine is properly assembled and positioned in a location that can support its weight. The machine should be stable and level to avoid tipping over while in operation.

2. Clean the machine – Before using the machine, clean and sanitize all its components, including the filling valves, conveyor belts, and bottle holders. This helps to eliminate any bacteria or contaminants that might affect the quality of your product.

3. Adjust the settings – Depending on the bottle size and volume, you need to adjust the filling and capping settings accordingly. This ensures that the machine fills the bottles accurately and seals them properly.

4. Connect the bottles – Load the empty bottles onto the conveyor belt and make sure they’re properly aligned and spaced apart to avoid jamming. The machine will automatically detect and fill each bottle as it passes through the filling station.

5. Add labels – Once the bottles are filled and capped, attach labels to them using the labeling mechanism integrated into the machine. You can customize the labels to include information such as brand name, ingredients, and product code.

6. Inspect the bottles – Finally, inspect the filled and labeled bottles to ensure they meet your quality standards. If you come across any defective bottles, remove them from the production line immediately.

In conclusion, the process of using a bottling machine can be simple and straightforward if you follow the steps mentioned above. It’s important to remember to clean and adjust the machine before use and inspect the bottles after production to ensure high-quality output. By following these steps, you can maximize the efficiency of your bottling machine and produce high-quality bottled products consistently.

Selecting the Ideal Manufacturer Bottling Machine Manufacturers

When it comes to choosing a bottling machine manufacturer, there are a variety of factors to consider. Some of the most important considerations include the type of product being bottled, the desired level of automation, and the budget available for the investment.

One key factor to consider when choosing a bottling machine manufacturer is the company’s reputation for quality and reliability. A manufacturer with a track record of producing durable and effective machines is likely to be a good choice, since these machines are often a significant investment.

Another important factor to consider is the specific needs of the production facility. For example, if the facility processes a high volume of products, a fully automated machine may be the best choice. Alternatively, if the products being bottled require careful handling or special packaging, a specialized machine may be necessary.

The budget available for the investment is also an important consideration. While a high-end, fully automated bottling machine may be ideal for some facilities, it may not be feasible for others. By carefully considering all of the factors involved, it is possible to select a bottling machine manufacturer that can provide an ideal solution at a price that the facility can afford.

Ultimately, selecting the ideal manufacturer for a bottling machine requires careful consideration of a variety of factors. By taking the time to research different manufacturers and carefully assessing the needs of the production facility, it is possible to make an informed investment in a high-quality machine that meets all of the necessary requirements.

list FAQ with answer about Bottling Machine Manufacturers

List of FAQs with Answers about Bottling Machine Manufacturers

1. What is a bottling machine?

A bottling machine is a piece of equipment that is used to fill, cap, label, and package liquids into bottles.

2. Why do I need a bottling machine?

If you are producing a large quantity of bottled products, a bottling machine can save time and resources while increasing efficiency and productivity.

3. What types of bottling machines are available?

There are various types of bottling machines available, including automatic, semi-automatic, rotary, and linear machines.

4. What factors should I consider when choosing a bottling machine manufacturer?

You should consider factors such as the manufacturer’s reputation, their experience in the industry, the types of machines they offer, their customer service and support, and their pricing.

5. How can I ensure the bottling machine I purchase meets my specific needs?

Talk to the manufacturer about your production needs and requirements to ensure that the machine you purchase meets your specific needs. You can also ask for a demonstration or trial run to test the machine before making a purchase.

6. What maintenance does a bottling machine require?

Regular maintenance is essential to ensure optimal performance and extend the life of the machine. The manufacturer should provide guidelines and instructions on how to properly maintain and service the machine.

7. Are bottling machines customizable?

Yes, many manufacturers offer customizable options to meet specific production needs and requirements. Customizations can include bottle size, labeling options, and filling speed.

8. What safety features should a bottling machine have?

Safety features should include emergency stop buttons, safety doors, and guards to prevent accidents and ensure operator safety.

In conclusion, choosing the right bottling machine manufacturer is essential to ensure that you get a machine that meets your specific production needs. Keep these FAQs in mind when searching for a bottling machine manufacturer to ensure that you make an informed decision.

Things to Consider When Purchasing Bottling Machine Manufacturers

When starting a new business that involves bottling products, choosing the right bottling machine manufacturer is crucial. While there are many manufacturers to choose from, not all of them will be suitable for your business needs. Here are some important things to consider when purchasing bottling machine manufacturers.

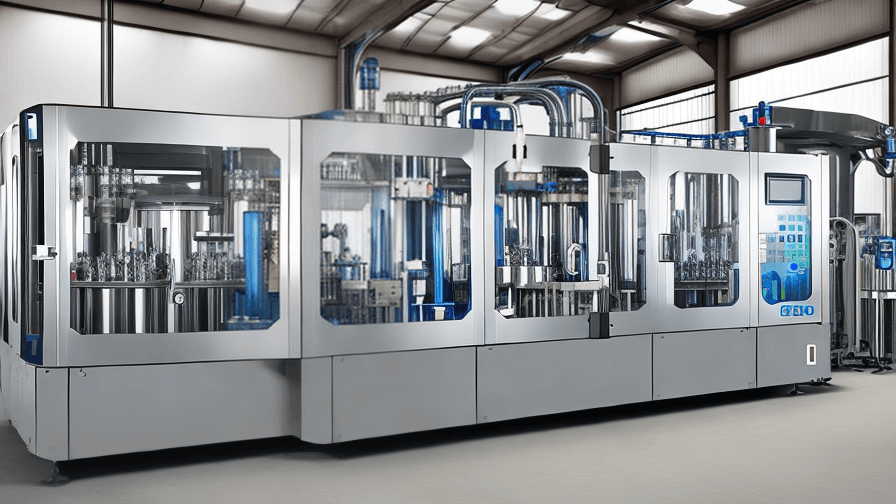

Type of Bottling Machine: The first thing to consider is the type of bottling machine you need. There are different types of machines available such as semi-automatic, automatic, and multi-head fillers. Choosing the right type of machine will depend on the size of your business, the type of products you are bottling and your production needs.

Customization: Another important thing to consider is whether the manufacturer can customize the bottling machine to meet your specific business needs. Customization can include features such as different sized bottles, label placement, and capping options.

Quality and Reliability: The quality and reliability of the bottling machine is also important. You want to choose a manufacturer that produces machines that are durable and can handle your production needs. Additionally, the manufacturer should have a good reputation and provide good customer service.

Cost: The cost of the bottling machine is also an important consideration. While you want to choose a quality machine, you also need to consider the cost and whether it fits within your budget. You should get quotes from different manufacturers and compare the prices before making a decision.

Maintenance: Finally, you should consider the maintenance requirements of the bottling machine. You want to choose a manufacturer that provides maintenance services and has replacement parts available. This will ensure that your machine stays in good condition and reduces downtime.

In conclusion, when choosing a bottling machine manufacturer, it’s important to consider the type of machine, customization options, quality and reliability, cost and maintenance requirements. By taking these factors into consideration, you will be able to choose a manufacturer that meets your business needs and helps you to grow your business.

Properties of Bottling Machine Manufacturers

Bottling machine manufacturers are responsible for designing and producing the machines that are used in the bottling industry. These machines fill containers with various liquids and are essential for the production of drinks, pharmaceuticals, and other liquids that require packaging. There are several properties that distinguish one bottling machine manufacturer from another, and we will discuss some of them below.

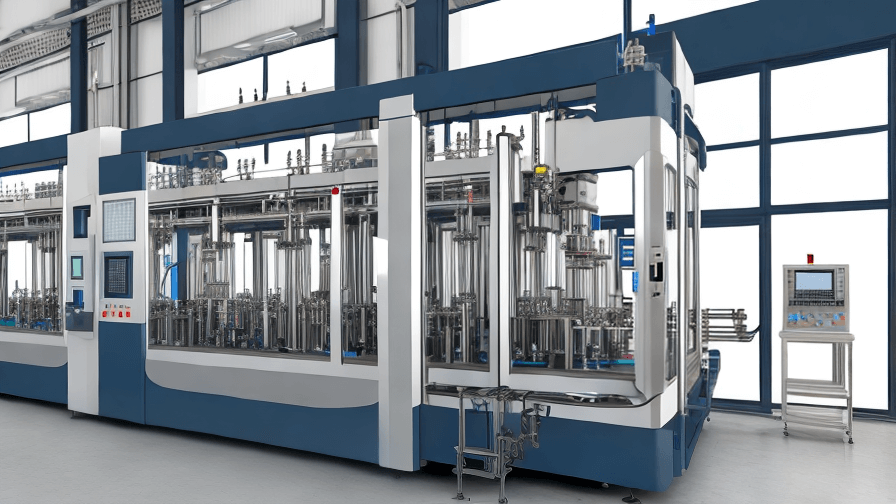

One of the most important properties of a bottling machine manufacturer is their ability to create high-quality machines that are efficient and reliable. These machines must be able to fill containers accurately and at a consistent speed, while also minimizing waste. Quality control is extremely important in the bottling industry since the end product will ultimately be consumed by customers. Therefore, the machines must be able to meet strict quality standards. An experienced and reputable bottling machine manufacturer will take this into consideration and produce high-quality machines that are designed to last.

Another property of bottling machine manufacturers is their ability to customize their machines according to the customer’s needs. The bottling industry is diverse, and therefore, customers will have different requirements depending on the type of liquid they are packaging, the volume they need to fill, and the packaging materials they are using. A good bottling machine manufacturer will be able to tailor their machines to meet the specific needs of each customer, providing them with the perfect solution to their packaging requirements.

Lastly, bottling machine manufacturers should be able to provide excellent customer service and support. Since these machines are an investment for their customers, it is important for the manufacturer to be available to help their customers with any technical issues that may arise. A good bottling machine manufacturer will have a support system in place that can help their customers troubleshoot problems and provide solutions to keep their machines running efficiently.

In conclusion, the properties of bottling machine manufacturers are crucial in determining the quality and reliability of their machines. Quality, customization, and customer support should be the top priorities for a bottling machine manufacturer. With these properties, manufacturers can produce machines that will meet the needs of their customers and provide them with an efficient and reliable packaging solution.

Technical Parameters Terms for Bottling Machine Manufacturers

Bottling machines are vital equipment for beverage production facilities. These machines come with various specifications and technical parameters. This article delves into technical parameters terms for bottling machine manufacturers.

First on the list is speed. This parameter refers to the number of bottles a machine can fill within a given period. Bottling machines come with varying speeds depending on the intended use.

Another critical parameter is accuracy. Accurate filling is vital in beverage production. Machine manufacturers specify the accuracy of their machines to ensure uniformity in volume and quality.

The filling volume is a crucial parameter. Bottling machines can fill bottles from a few millimeters to several litres. Machine manufacturers have specifications for filling volume, which clients can choose based on their requirements.

The type of bottles a machine can fill is essential. Machines come with specifications on bottle size, shape, and material. Machine manufacturers can customize the machine to fill specific bottle types depending on clients’ needs.

The type of product that a bottling machine can fill is also an essential parameter. Some machines fill water, while others fill carbonated drinks, juices, and alcoholic beverages. As such, it is critical to specify the product type when selecting a machine.

The last parameter is the machine’s automation level. Machines vary in automation levels depending on the manufacturer’s specifications. Fully automated machines are preferred as they reduce manual labor and boost production speed.

In conclusion, technical parameters terms for bottling machines are essential when it comes to selection. Manufacturers specify speed, accuracy, filling volume, bottle type, product type, and automation level. With this information, clients can choose the most suitable bottling machines for their beverage production processes.

Bottling Machine Manufacturers Price

Bottling machine manufacturers offer a wide range of products that cater to the needs of different industries. The price of these machines varies depending on their size, capacity, features, and the materials used in their construction.

The most basic bottling machines for small businesses usually cost around $5,000 to $10,000. These machines are designed to handle low-volume production, with a capacity of up to 1,000 bottles per hour. They are usually semi-automatic and require manual labor for some of the operations.

For larger businesses, the price of bottling machines can range from $15,000 to $50,000 or more. These machines are capable of handling high-volume production, with a capacity of up to 12,000 bottles per hour. They are usually fully automatic and require minimum human intervention.

The price of bottling machines can also vary depending on the type of bottles they are designed to handle. Machines that can handle different sizes and shapes of bottles are usually more expensive than those that are designed for specific bottle types.

Factors such as the type of filling mechanism, the type of capping mechanism, and the level of automation also influence the price of bottling machines. Machines with more advanced features such as automatic bottle transfer, precise dosing, and real-time monitoring are usually more expensive.

In conclusion, the price of bottling machine manufacturers varies widely depending on the specific needs of the business. It is essential to carry out a thorough analysis of the requirements of the business before choosing a bottling machine. This will help to ensure that the investment is cost-effective and that the machine can meet the production needs of the business without exceeding the budget.