Benefits of Small Water Jet Cutter

A small water jet cutter is a versatile tool that can be used in a variety of applications. It uses high-pressure water mixed with an abrasive material to cut through a wide range of materials, including metal, glass, and ceramics. There are many benefits to using a small water jet cutter, including:

1. Precision cutting: Unlike other cutting methods, a water jet cutter provides precise cuts with clean edges. It can create intricate shapes and designs with high accuracy, making it ideal for industries that require precise cuts, such as aerospace and engineering.

2. Versatility: A small water jet cutter can cut through a variety of materials, including thick metals, without causing damage or distortion. It can cut through materials that are sensitive to heat, such as plastic and foam, without melting or warping the material.

3. Environmentally friendly: A water jet cutter uses water and an abrasive material to cut, which means it does not produce any harmful by-products or emissions. It is a clean cutting method that does not produce any hazardous waste, making it an eco-friendly solution to cutting.

4. Time-saving: A water jet cutter is a fast cutting method that can cut through materials quickly and efficiently. It reduces setup and programming time, which allows for faster production times and increased productivity.

5. Cost-effective: A small water jet cutter can reduce material waste by creating precise cuts. It can also eliminate the need for secondary finishing operations, such as grinding and polishing, which can reduce production costs.

Overall, a small water jet cutter is a versatile and valuable tool that provides many benefits over other cutting methods. From precision cutting to environmental sustainability and cost savings, a water jet cutter is an excellent investment for any industry that requires cutting.

Features of Small Water Jet Cutter

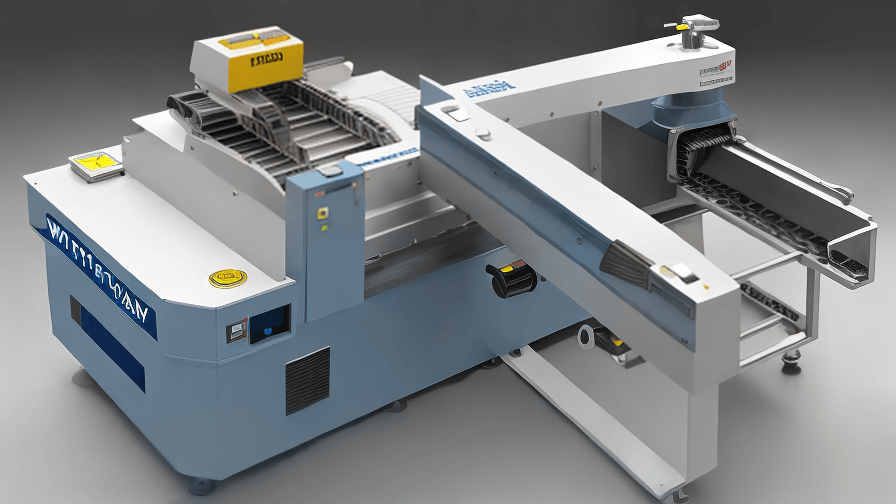

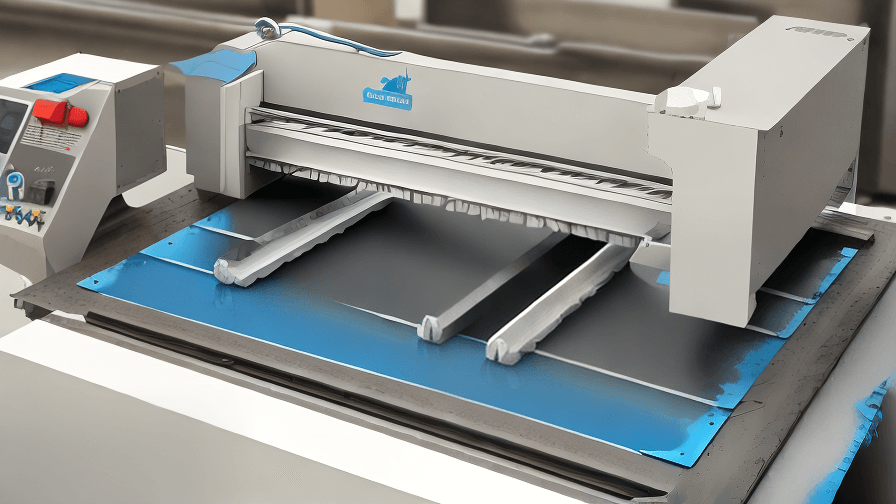

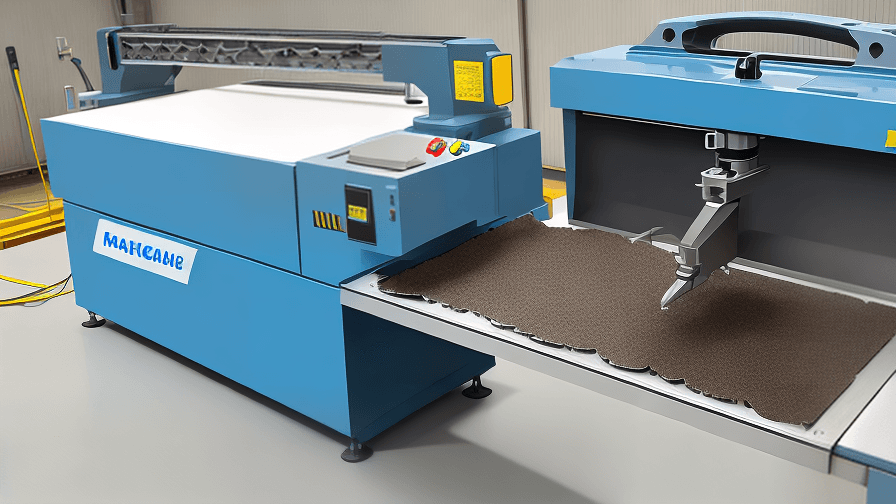

A small water jet cutter, also known as a mini water jet cutter, is a versatile, cost-effective, and efficient cutting tool that can be used in a wide range of cutting applications. Despite its small size, it is capable of cutting through a variety of materials with precision and accuracy. Here are some of the features of small water jet cutters:

1. Compact and Portable

One of the main advantages of small water jet cutters is their compact size, making them easy to move around and store. They are also portable, which means they can be used in different locations without any hassle.

2. Precise Cutting

Small water jet cutters are capable of making precise and accurate cuts, even in the most complex shapes and intricate designs. With the use of computer-controlled systems, the cutting process can be automated, further enhancing accuracy and speed.

3. Versatile

Small water jet cutters can cut through a wide range of materials, including metals, plastics, glass, ceramics, and composites. This versatility makes them an ideal tool for many industries, including aerospace, automotive, and medical.

4. Cost-Effective

Small water jet cutters are cost-effective compared to other cutting tools, such as lasers and plasma cutters. They require less maintenance and consumables, making them economical to operate.

5. Environmentally Friendly

Small water jet cutters do not produce any hazardous fumes or dust, making them environmentally friendly. They also use less water than traditional water jet cutting, making them a more sustainable cutting solution.

In conclusion, small water jet cutters are an excellent choice for cutting small parts or intricate designs. They are compact, portable, and versatile, allowing them to be used in a wide range of applications. With their precise cutting, cost-effectiveness, and environmental friendliness, small water jet cutters are a valuable addition to any cutting operation.

Various Types of Small Water Jet Cutter

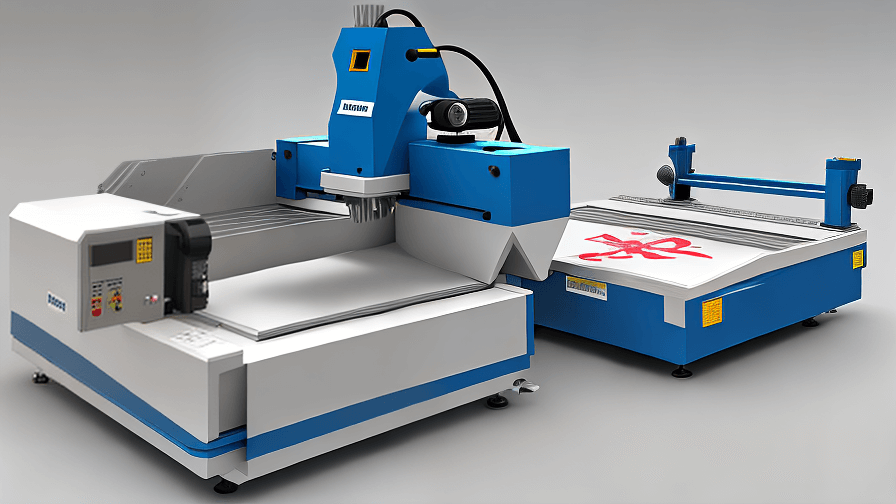

Water jet cutting is one of the most popular technologies used for precision cutting in various industries. Small water jet cutters are highly efficient and can be utilized in various applications from DIY projects to industrial cutting processes.

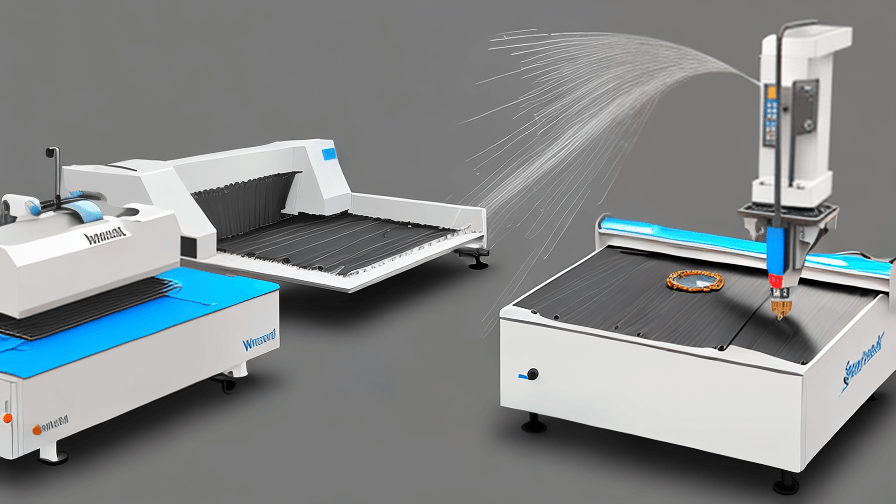

There are various types of small water jet cutters available in the market, including desktop water jet cutters, handheld water jet cutters, and portable water jet cutters. Desktop water jet cutters are small machines that are capable of precise cutting and are typically used by hobbyists to produce intricate designs. They are affordable, easy to install, and user-friendly, making them an excellent option for beginners.

Handheld water jet cutters are designed for more complex and heavy-duty applications, and they are efficient in cutting through materials ranging from metals to composites. They are lightweight, easy to use, and can be quickly maneuvered to make precise cuts. They are also suitable for fieldwork and outdoor projects.

Portable water jet cutters are a step up from handheld options, and they are suitable for industries that require accurate cutting on-site. They are equipped with state-of-the-art technology that offers precise and fast cutting operations. They can be used in various industries, like aerospace, mining, and automotive, and can cut through materials up to five inches thick.

Water jet cutters come in different sizes, and the power output varies from one machine to another. Small water jet cutters are perfect for small shops, DIY enthusiasts, and small businesses that require precision cutting without breaking the bank. They are versatile, can cut through various materials, and are environmentally friendly.

In conclusion, small water jet cutters have revolutionized precision cutting processes. They are cost-effective, user-friendly, and versatile, making them an excellent choice for DIY enthusiasts, small shops, and industrial applications. With their many options available in the market, businesses can easily find a small water jet cutter that suits their needs and budget.

Applications of Small Water Jet Cutter

Small water jet cutters are a powerful tool that can be used for various applications. Their small size makes them more portable and easier to use compared to larger water jet cutters. Here are some of the applications of small water jet cutters.

1. Arts and crafts: Small water jets cutters are perfect for creating intricate designs on a variety of materials such as paper, plastic, and wood. This tool is especially useful for artists who need to make detailed cuts in their work.

2. Jewelry making: Water jet cutters can be used to cut through precious stones and metals to make precise cuts that are essential in creating high-end jewelry.

3. Foam cutting: Small water jet cutters are the perfect tool for cutting foam sheets that are used in the production of various items such as mattresses, furniture, and packaging materials.

4. Prototyping: Small water jet cutters can be used to create prototypes and samples of different products. This is especially useful for small businesses that need to test their designs before proceeding to mass production.

5. Automotive industry: Small water jet cutters are used to cut through metal components such as gears, engine parts, and suspension systems.

6. Aerospace industry: The aerospace industry has found numerous uses for water jet cutters as they can be used to cut through composite materials used in the aircraft’s construction.

7. Signage and lettering: Small water jet cutters can be used for creating custom signs and lettering from a variety of materials such as metal, plastic, and wood.

In conclusion, small water jet cutters have numerous applications, ranging from simple arts and crafts to complex cutting tasks in the aerospace and automotive industries. With their precision and ease of use, small water jet cutters are an essential tool for any business or individual looking to create high-quality products.

The Process of Small Water Jet Cutter

Small water jet cutters have revolutionized the way precision cutting is done. They are fast, efficient, and versatile for cutting different types of materials. The process of small water jet cutting is relatively simple, and it involves the following steps.

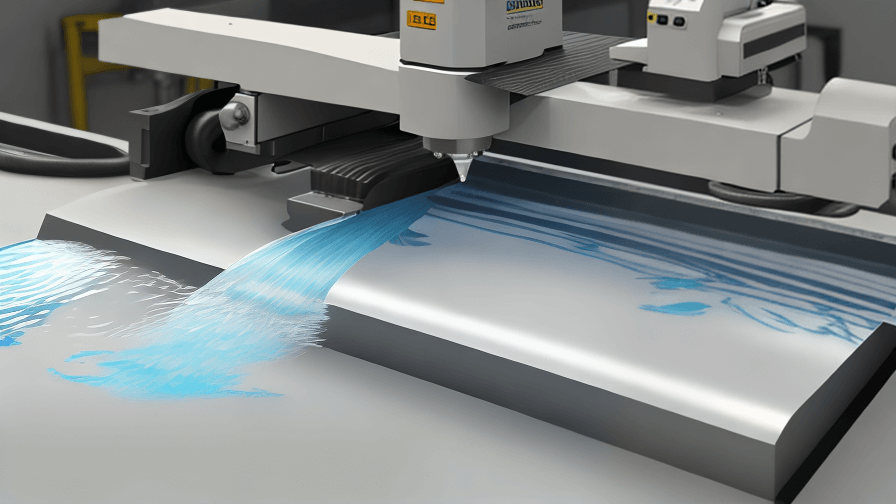

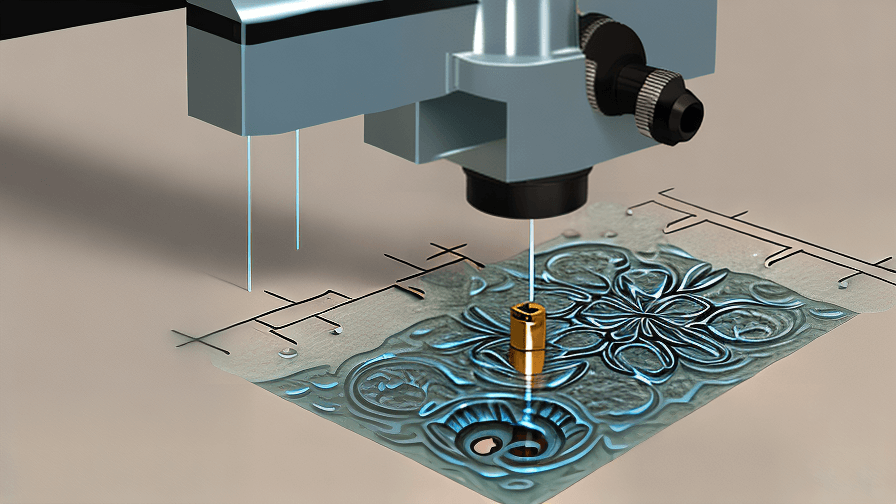

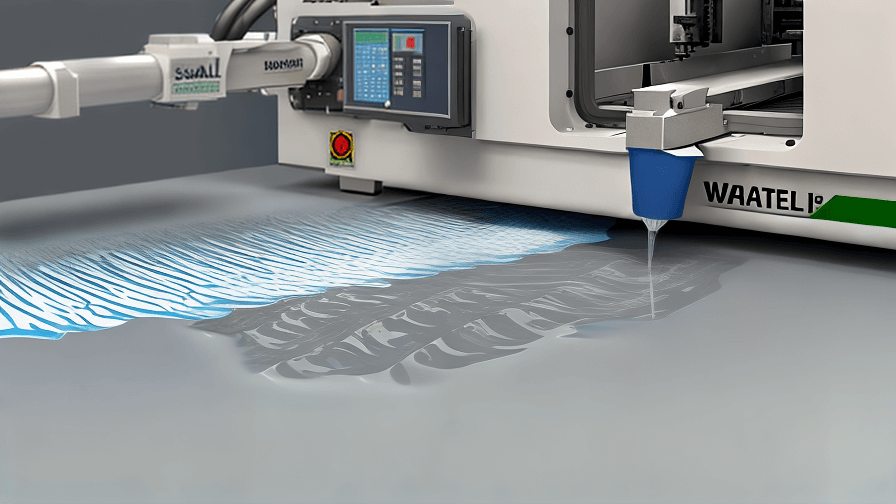

Firstly, the material to be cut is fixed to a bed or platform. This bed moves the material back and forth under the water jet’s nozzle, which is controlled by a computer program. The computer program controls the position and pressure of the water jet.

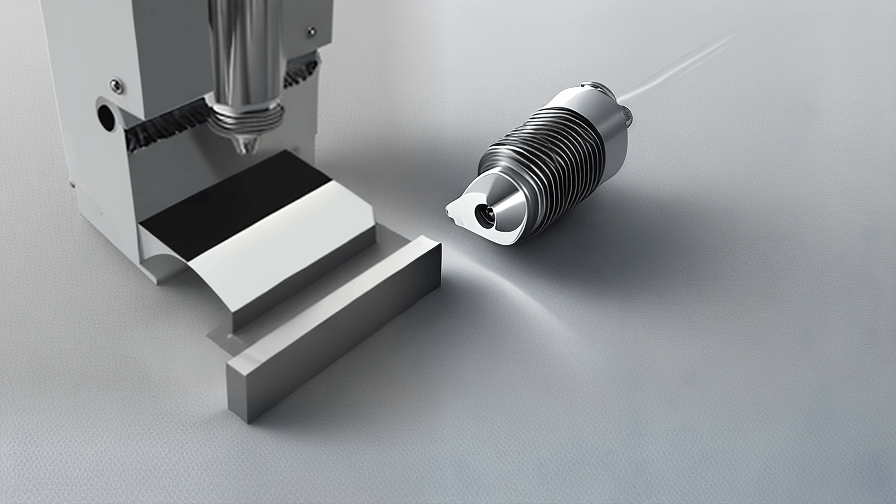

Secondly, a high-pressure water pump forces water through a small orifice, creating a water jet that travels at speeds of up to 900 meters per second. The pressure of the water jet can be as high as 100,000 pounds per square inch, depending on the thickness and hardness of the material being cut.

Thirdly, if the material being cut is too thick, abrasive particles are added to the water, creating an abrasive water jet. The abrasive particles, typically garnet, are mixed with the water and forced through the nozzle, where they cut through the material with the water jet. The abrasive particles act like tiny knives, slicing through the material.

Lastly, the precision of small water jet cutters is outstanding. The computer program controls the nozzle’s position and pressure, ensuring that the cut is accurate and precise. Small water jet cutters can cut through a variety of materials, including metals, composites, plastics, and ceramics.

In conclusion, small water jet cutters have become an indispensable tool for precision cutting. The process of small water jet cutting is relatively simple, using high-pressure water combined with abrasive particles if necessary to achieve precise cuts. The computer program controls the nozzle’s position and helps in producing an accurate and precise cut of various materials.

How to use Small Water Jet Cutter

A water jet cutter uses high-pressure water mixed with an abrasive to cut through various materials. This technology has been in use for decades in large industrial operations, but recently, smaller, more affordable machines have become available for small businesses and hobbyists.

Here are some tips on how to use a small water jet cutter:

1. Safety first. Always wear safety glasses and gloves while operating a water jet cutter. The high-pressure water can be dangerous, and the abrasive particles can cause harm if ingested or inhaled.

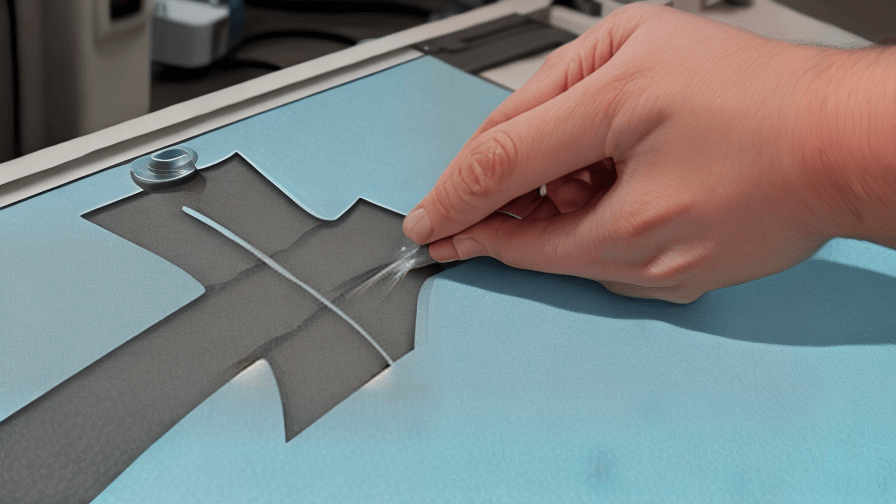

2. Prepare your materials. The water jet cutter can cut through a range of materials, including metal, plastic, wood, and stone. Choose the appropriate abrasive for your material and make sure it is secure on the cutting bed.

3. Set up the machine. Fill the water tank with clean water, and add the appropriate amount of abrasive to the hopper. Connect the nozzle to the machine and test it to make sure water is flowing properly.

4. Adjust the pressure and speed. The water jet cutter comes with a control panel where you can adjust the water pressure and the speed of the nozzle. Different materials require different settings, so consult the machine’s instruction manual or do some experimenting to find the optimal settings for your material.

5. Cut your material. Once the machine is set up and your material is ready, you can begin cutting. Use the control panel to move the nozzle along the cutting bed, following your design. Take your time and make sure the nozzle is making smooth, continuous cuts.

6. Clean up. When you’re finished cutting, turn off the machine and dispose of any waste material properly. Clean up the cutting bed and nozzle to ensure they’re ready for the next use.

A small water jet cutter can be a valuable tool for small businesses and DIY enthusiasts. With proper setup and safety precautions, you can achieve accurate, high-quality cuts on a range of materials.

Selecting the Ideal Manufacturer Small Water Jet Cutter

When selecting the ideal manufacturer for a small water jet cutter, there are several factors to consider. First, you should look at the reputation of the manufacturer. Since the water jet cutter is a high-end machine that requires precision and accuracy, it is essential to choose a manufacturer who has a good reputation in the market.

Secondly, you should consider the features of the water jet cutter. Each manufacturer offers unique features to their machines, making each machine different from the other. Features to be evaluated include the cutting speed, accuracy, size of the machine, and the ability to cut different materials.

The third factor to consider is the price of the water jet cutter. The price range for these machines varies from manufacturer to manufacturer. It would help if you compared the prices of different manufacturers before choosing one. Keep in mind that shopping for the lowest price isn’t always the best option, as you don’t want to sacrifice quality for price.

Fourthly, the level of customer support and after-sales service that a manufacturer provides should be considered. Manufacturers vary in their customer service policies and the warranties they provide for their products. Therefore, you should choose a manufacturer that offers excellent customer support before and after purchasing the product.

Lastly, you should evaluate the technical expertise required to operate and maintain the machine. The ideal manufacturer should provide sufficient technical support and training to guarantee that the machine is operated safely.

In conclusion, the ideal manufacturer for a small water jet cutter is the one that offers a machine with the features and capabilities you need, quality and reliable products, excellent customer service and technical support, and comprehensive training to ensure that the machine is operated safely.

list FAQ with answer about Small Water Jet Cutter

Small water jet cutters are becoming increasingly popular in various industries due to their precision, versatility, and ease of use. Here are some frequently asked questions about small water jet cutters and their corresponding answers.

Q: What is a small water jet cutter?

A: A small water jet cutter is a tool that uses a high-pressure stream of water mixed with abrasive particles to cut various materials, such as metals, plastic, and stone.

Q: What are the advantages of using a small water jet cutter?

A: The primary advantage of using a small water jet cutter is its ability to provide precise cuts, even on materials that are difficult to cut with other types of tools. Additionally, water jet cutting is a cold-cutting process, which means that it doesn’t produce heat-affected zones, and it doesn’t leave any hazardous fumes or waste.

Q: What types of materials can be cut using a small water jet cutter?

A: Small water jet cutters can cut a wide variety of materials, such as metals, plastic, rubber, glass, ceramic, stone, and composites.

Q: How thick of a material can a small water jet cutter cut?

A: Small water jet cutters can cut materials up to several inches thick, depending on the type of material and the power of the water jet cutter.

Q: How fast can a small water jet cutter cut?

A: The cutting speed of a small water jet cutter depends on several factors, such as the type of material, the thickness of the material, and the power of the water jet cutter. However, small water jet cutters can generally cut at speeds ranging from a few inches per minute to several inches per second.

Q: How much does a small water jet cutter cost?

A: The cost of a small water jet cutter varies depending on the size, power, and features of the machine. Prices can range from a few thousand dollars to tens of thousands of dollars.

In conclusion, a small water jet cutter is a versatile and precise cutting tool that can be used in various industries. Its ability to cut a wide range of materials and thicknesses makes it a popular choice among manufacturers, artisans, and hobbyists alike.

Things to Consider When Purchasing Small Water Jet Cutter

Small water jet cutters are great tools for cutting a variety of materials, including metal and plastics. However, choosing the right one can be a daunting task, especially if you’re new to the technology. Here are some things to consider when purchasing a small water jet cutter.

1. Cutting area – Small water jet cutters come in different sizes, so it’s important to consider the cutting area you’ll need for your projects. If you have large pieces to cut, you may need a larger cutter.

2. Type of materials – Not all water jet cutters can cut all materials. Some are designed to cut soft materials like foam and rubber, while others can cut metals and hard plastics. Be sure to choose a cutter that is capable of cutting the materials you’ll be working with.

3. Pump type – The pump is one of the most critical components of a water jet cutter. There are two types of pumps: intensifier pumps and direct-drive pumps. Intensifier pumps are more common and can produce higher pressure, but they require more maintenance. Direct-drive pumps are simpler and more reliable, but they have lower pressure capabilities.

4. Operating costs – In addition to the initial cost of the cutter, you should also consider the operating costs. These include the cost of electricity, water, abrasives, and maintenance. Some cutters are more efficient and require less maintenance than others.

5. Control software – Most water jet cutters come with control software that allows you to design and cut your parts. Be sure to choose a cutter with software that is easy to use and has the features you need.

In conclusion, when purchasing a small water jet cutter, it’s important to consider the cutting area, the type of materials you’ll be cutting, the pump type, operating costs, and control software. By taking these factors into account, you’ll be able to choose a cutter that is best suited for your needs, budget, and skill level.

Properties of Small Water Jet Cutter

Small water jet cutters are precision cutting machines that have been developed for use in small-scale industries. These tools are becoming increasingly popular as they offer accurate, clean and fast cutting operations. Despite their small size, they offer an unmatched cutting capability that can be adjusted according to the user’s needs.

Properties of Small Water Jet Cutter:

1. Speed: Small water jet cutters can deliver high cutting speeds, depending on their power output. These cutters can be used to perform rapid cuts on various materials, including glass, metal, plastic, and ceramics.

2. Accuracy: Small water jet cutters are exceptionally precise, ensuring that the cutting process is clean and cuts are accurate. This feature is essential in industries where precision is vital for the end product’s quality and efficiency.

3. Versatility: Small water jet cutters are versatile, meaning they can be used to cut multiple materials, including composites, metals, and plastics.

4. Portability: These cutters are relatively small and portable, making them a suitable choice for those who require a cutting tool that they can move from one job site to another with ease.

5. Safety: Small water jet cutters are safe to use since they use water as the cutting medium, eliminating the need for chemicals in the cutting process, which can be hazardous to the user.

6. Easy Maintenance: With simple and easy-to-use design, maintenance of these machines is straightforward. Users can quickly troubleshoot and repair the machines if they identify any faults.

In conclusion, small water jet cutters are some of the most versatile and efficient cutting tools available. Their ability to deliver excellent cutting quality while still being portable, accurate, and safe make them a popular choice for those looking for high-quality cutting in their small-scale industries. The fact that they are user-friendly and maintenance-free makes them a profitable investment, worth considering.

Technical Parameters Terms for Small Water Jet Cutter

A small water jet cutter is a powerful tool often used in many industrial and manufacturing processes. However, for those who are unfamiliar with the technical aspects of this machine, the terms used in its specification may be quite confusing. Here are some of the important technical parameters terms that one must know when dealing with a small water jet cutter.

1. Cutting bed size: This term refers to the maximum size of the material that the water jet cutter can cut. It’s important to choose the cutting bed size depending on the material you are planning to use.

2. Cutting speed: This term mentions how fast the machine can cut through the material. The cutting speed is usually measured in inches per minute (IPM).

3. Accuracy: This refers to the level of precision with which the small water jet cutter can cut the material. It’s measured in microns or thousandths of an inch.

4. Operating pressure: This term refers to the pressure of the water that is used to cut the material. The operating pressure can vary depending on the type of material being cut.

5. Pump Type: This term refers to the type of hydraulic pump that is used to generate high-pressure water. The most common types are hydraulic intensifier pumps and direct drive pumps.

6. Nozzle size: This term refers to the size of the orifice through which the water jet flows. The nozzle size can impact the quality and accuracy of the cut.

7. Abrasive and water consumption: This term refers to the amount of abrasive and water used during the cutting process. It’s essential to manage the consumption of abrasive and water to ensure a cost-effective operation.

In conclusion, understanding the technical parameters terms for a small water jet cutter is crucial for selecting the appropriate machine for your specific application. It will help you determine the suitability of the machine for your work process based on its cutting bed size, cutting speed, accuracy, operating pressure, pump type, nozzle size, and abrasive and water consumption.

Small Water Jet Cutter Price

Small water jet cutters are an essential and versatile tool used in many industries, and the cost of purchasing one can be expensive. However, a small water jet cutter price can be quite affordable, depending on the purpose and specific uses.

Typically, small water jet cutters are used for simple and straightforward cutting tasks. The size of the machine allows for faster production and considerably less expensive compared to larger and more robust water jet cutters. There are different brands and models that come with different features and capabilities, which will determine the price. Factors such as power, applications, features, and technology used affect the price of water jet cutters.

The most common small water jet cutters range in price between $10,000 and $50,000, while some models can cost up to $100,000. These prices are still more affordable compared to larger water jet cutters, which can cost up to a million dollars.

Purchasing a small water jet cutter can help businesses save money long-term. One reason is they don’t require any expensive tooling or fixtures, making them more economical. Also, they are more environmentally friendly as they decrease material waste with precise cutting, and the use of water as a cutting agent does not emit harmful fumes in the air. Additionally, maintaining a small water jet cutter is relatively inexpensive as users can replace parts as needed instead of having to replace the entire machine, which can be costly.

In conclusion, the price of small water jet cutters is dependent on various factors, including the specifications and applications needed. However, it remains a relatively affordable option compared to larger water jet cutters and can offer cost savings for businesses that require precise cutting solutions.