Benefits of Nitrile Glove Manufacturer

Nitrile gloves have become increasingly popular in recent years, and their demand has increased rapidly, especially during the ongoing pandemic. These gloves are made from synthetic rubber and are known for their strength and durability. With their excellent quality, nitrile gloves are the preferred choice of many industries and healthcare professionals globally. Therefore, it is no surprise that the importance of nitrile glove manufacturers continues to grow.

One of the key benefits of working with nitrile glove manufacturers is the quality of their products. Manufacturers use innovative technology to produce high-quality gloves that are tested to meet strict industry standards. The gloves are designed to fit perfectly and provide excellent protection from harmful contaminants, chemicals, and bloodborne pathogens. As a result, these gloves are widely used in the healthcare and food industry where hygiene is of utmost importance.

Furthermore, nitrile glove manufacturers offer a wide range of colors, sizes, and styles to meet the needs of different customers. Whether you need gloves for small hands or you want to choose a color that matches your company’s branding, manufacturers have got you covered. They also produce gloves that are powder-free to prevent allergic reactions and skin irritations, providing maximum comfort and safety.

Another benefit of working with nitrile manufacturers is the cost-effectiveness of their products. With their long-lasting durability, nitrile gloves offer value for money and can be used for extended periods. As such, companies can save money by reducing glove consumption and related expenses.

Lastly, nitrile glove manufacturers have a strong commitment to sustainability and environmental protection. Many companies use eco-friendly materials and processes to minimize waste and reduce their carbon footprint. With the growing concern about environmental conservation, working with manufacturers that prioritize sustainability is a significant advantage for businesses.

In conclusion, nitrile glove manufacturers offer numerous benefits, including high-quality products, customization options, cost-effectiveness, and sustainability. Businesses can take advantage of these benefits by partnering with reliable manufacturers to meet their needs. In the current pandemic, nitrile gloves are indispensable in ensuring health and safety, making it crucial to work with manufacturers that produce top-quality gloves that meet industry standards.

Features of Nitrile Glove Manufacturer

Nitrile gloves have become a popular choice in various industries, including healthcare, food, and automotive, among others. However, not all nitrile glove manufacturers are created equal. Here are some features to look for in a reliable nitrile glove manufacturer.

1. Quality certifications

A trustworthy nitrile glove manufacturer should have quality certifications, such as ISO 9001 and CE. These certifications guarantee that the gloves are produced under strict quality control standards.

2. Range of products

A good nitrile glove manufacturer should offer a wide range of products to meet various customer needs. This includes different sizes, colors, and textures of gloves.

3. Customization options

Sometimes, customers may require specialized gloves that meet specific requirements. A reputable nitrile glove manufacturer should be able to offer customization options to cater to such needs.

4. Testing capabilities

To ensure that the gloves meet the required standards, reliable nitrile glove manufacturers should have in-house testing capabilities. This includes conducting tests for puncture resistance, tensile strength, and chemical resistance.

5. Sustainability practices

Sustainability is becoming an essential aspect of manufacturing, and nitrile glove production is no exception. A responsible nitrile glove manufacturer should have sustainability practices, such as using eco-friendly materials and reducing carbon footprints.

6. Customer service

Good customer service is crucial in any industry, and nitrile glove manufacturing is no different. Reliable manufacturers should have efficient and responsive customer service to handle inquiries, complaints, and ensure customer satisfaction.

In conclusion, the above features are critical when choosing a reliable nitrile glove manufacturer. It is essential to do research and choose a manufacturer that meets all the required standards and offers quality products.

Various Types of Nitrile Glove Manufacturer

When it comes to choosing a nitrile glove manufacturer, having a variety of options to choose from can be a great advantage. Here are some of the different types of nitrile glove manufacturers in the market.

1. Medical-Grade Nitrile Glove Manufacturers

These are manufacturers that specialize in producing high-quality, durable, and comfortable nitrile gloves that are specifically designed for medical purposes. They adhere to strict quality control standards to ensure that their gloves perform optimally in medical settings.

2. Industrial Nitrile Glove Manufacturers

Industrial nitrile glove manufacturers focus on producing sturdy and durable gloves that are ideal for tough industrial applications. Their gloves are designed to provide maximum protection to workers who face heavy physical labor or exposure to hazardous materials.

3. Food-Grade Nitrile Glove Manufacturers

These manufacturers produce gloves that are used in the food industry. Their gloves are designed not to contaminate the food being handled with hazardous chemicals or foreign objects. They are tested to ensure that they are free from any toxic substances and are suitable for handling food products.

4. Fashion Nitrile Glove Manufacturers

Fashion nitrile glove manufacturers produce gloves that are stylish and trendy. These gloves may feature unique designs or patterns that make them stand out from traditional nitrile gloves. They are suitable for use in the fashion industry, such as photo shoots, runway shows, and events.

5. Specialty Nitrile Glove Manufacturers

Specialty nitrile glove manufacturers produce gloves that serve specific purposes. For example, they may produce gloves for use in cleanrooms, laboratories, and research facilities. These gloves are designed to provide maximum protection against particulates, contaminants, and other harmful substances found in these environments.

In conclusion, choosing a nitrile glove manufacturer that specializes in producing the ideal gloves for your situation or application is essential. By understanding the various types of nitrile glove manufacturers, you can make a more informed decision to select the one that best suits your needs.

Applications of Nitrile Glove Manufacturer

Nitrile gloves are one of the most popular types of gloves in the market today. They are highly durable and resistant to punctures, making them ideal for use in various industries and applications. As a result, the demand for nitrile gloves has been increasing steadily, and so has the number of nitrile glove manufacturers in the market. Here are some of the applications of nitrile glove manufacturer in various industries.

Firstly, nitrile glove manufacturers are used in the healthcare industry. Hospitals, clinics, and other medical facilities require gloves that are durable, comfortable, and provide an effective barrier against infections. Nitrile gloves are the preferred choice for many healthcare workers as they are latex-free, reducing the risk of allergic reactions. They are also resistant to chemicals and blood-borne pathogens, making them ideal for use in laboratories and during surgical procedures.

Secondly, nitrile glove manufacturers are used in the food industry. Foodservice professionals need gloves that are resistant to punctures, cuts, and abrasions. They also need gloves that are safe for handling food and do not contain any harmful chemicals. Nitrile gloves are resistant to fats and oils, making them ideal for use in food preparation and handling.

Thirdly, nitrile glove manufacturers are used in the automotive industry. Automotive workers need gloves that can protect them from oil, grease, and other car fluids. They also need gloves that are comfortable and flexible, allowing them to work efficiently with their hands. Nitrile gloves are the perfect solution as they are resistant to oils and chemicals, making them ideal for use in auto repair shops.

In conclusion, nitrile glove manufacturers are used in various industries and applications where durability, resistance to chemical and punctures, comfort, and safety are significant factors. As demand for nitrile gloves continues to rise, the importance of nitrile glove manufacturers in various industries cannot be overstated. With technological innovations and advancements, manufacturers have been able to produce quality gloves that meet the needs of various industries.

The Process of Nitrile Glove Manufacturer

Nitrile gloves are widely used in many industries such as healthcare, chemical, and food processing due to their durability, puncture resistance, and chemical resistance. The process of manufacturing nitrile gloves involves several stages, including compounding, mixing, dipping, curing, and stripping.

Firstly, the compounding stage involves the mixing of raw materials such as nitrile latex, accelerators, antioxidants, and other additives. The mixture is then homogenized and filtered to remove any impurities.

Next, the mixing stage involves the addition of other components such as pigments and scents. The mixture is then heated and stirred to ensure that the ingredients are uniformly distributed.

Afterward, the dipping process begins where a former or mold is dipped into the mixture. The mold is then removed from the mixture, and excess material is drained off, leaving a thin layer of nitrile on the mold. The mold is then dipped again several times until the desired thickness is achieved.

Once the dipping process is complete, the gloves are transferred to the curing stage. The gloves are placed in an oven where heat is added, and the nitrile undergoes a chemical reaction, cross-linking the molecules and solidifying the gloves.

Lastly, the stripping process involves removing the gloves from the mold and turning them inside out. The gloves are then subjected to quality control tests to ensure that they meet industry standards.

All in all, the process of nitrile glove manufacturing is highly technical and requires specialized machinery and trained operators. With proper quality control measures in place, manufacturers can produce high-quality nitrile gloves that offer superior hand protection.

How to use Nitrile Glove Manufacturer

Nitrile gloves are a type of disposable gloves made from synthetic rubber. They are commonly used in healthcare, cleaning, food service, and other industries. If you are looking for a Nitrile Glove Manufacturer, there are some important things to consider.

First, choose a reliable manufacturer that uses high-quality materials and has a good reputation for producing durable gloves. Check their certifications and ensure they meet the necessary standards for quality.

Next, consider the type and size of gloves you need. Nitrile gloves come in different sizes and thicknesses to meet different needs. Some manufacturers offer customizable options to fit the specific needs of your business.

Proper storage is also important. Keep the gloves in a cool, dry place away from direct sunlight. Exposure to heat and light can cause the gloves to weaken and degrade.

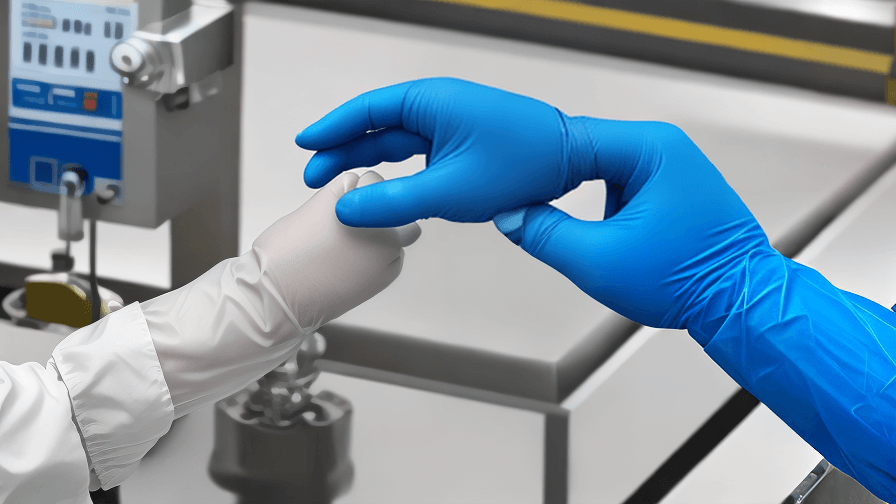

When using Nitrile gloves, be sure to follow proper procedures for donning and removing the gloves. Never reuse gloves, as this can cause contamination and the risk of infection. Also, remove gloves carefully to avoid tearing or puncturing the gloves.

Finally, dispose of used gloves properly. Place them in a designated waste container to avoid cross-contamination. Proper disposal helps prevent the spread of germs and keeps the environment clean and safe.

In conclusion, using Nitrile gloves from a reliable manufacturer is essential for maintaining hygiene and safety standards in various industries. Follow proper procedures for storage, usage, and disposal to ensure optimal protection for yourself and others.

Selecting the Ideal Manufacturer Nitrile Glove Manufacturer

When selecting a nitrile glove manufacturer, there are several factors to consider in order to ensure that you choose the ideal manufacturer. Below are some key factors to consider.

Quality of the gloves

It is important to choose a manufacturer that produces high-quality nitrile gloves. Ensure that the manufacturer uses top-quality materials in their production process to guarantee strong, durable gloves. The manufacturer’s gloves should be highly resistant to chemicals, punctures, and tears, ensuring that they offer the appropriate level of protection.

Pricing

When selecting a nitrile glove manufacturer, you want to ensure that they offer competitive pricing. Doing due diligence to find a manufacturer that offers good quality gloves but still at a lower cost, will give you an edge over other buyers.

Customization

If your company has unique needs or requires a specific type of nitrile glove, it is essential to find a manufacturer that is willing and capable of producing customized gloves. This involves ensuring you have your brand or any distinctive specification on the gloves.

Minimum Order Quantities

If you are a small business or require small quantities of nitrile gloves, you may need to find a manufacturer with low minimum order quantities. This allows you to purchase smaller quantities of gloves without having to purchase excess amounts that you may not need.

Customer Service

It is important to work with a manufacturer that offers excellent customer service. A manufacturer that is receptive to your questions and concerns and provides timely feedback is important. Good communication with the manufacturer and the ability to negotiate on your terms is also of great importance.

Certification

It is important to ensure that the manufacturer is verified or has certification from regulatory agencies. This ensures that they meet the regulatory and quality standards in producing nitrile gloves.

In conclusion, selecting the ideal nitrile glove manufacturer involves consideration of the quality of the gloves, pricing, customization, minimum order quantities, customer service, and certification. By taking these factors into account, you can confidently choose a manufacturer that meets your company’s needs while also providing top-quality gloves.

list FAQ with answer about Nitrile Glove Manufacturer

Nitrile gloves are essential personal protective equipment that healthcare providers, laboratory technicians, and many others need. However, not all nitrile glove manufacturers provide quality and reliable gloves. To help you select a reliable supplier, we have compiled a list of frequently asked questions with answers.

Q: What are nitrile gloves?

A: Nitrile gloves are made from synthetic rubber and provide resistance to punctures, tears, and chemicals.

Q: Why are nitrile gloves desirable for the healthcare industry?

A: Nitrile gloves are resistant to punctures and chemicals, non-allergenic and provide a good grip.

Q: What are the popular nitrile glove colours?

A: The most common colours include blue, purple, and black.

Q: What are the available sizes for nitrile gloves?

A: Nitrile gloves are available in a range of sizes, typically ranging from small to extra-large.

Q: How long can nitrile gloves last?

A: Nitrile gloves have a shelf life of three to five years, but it also depends on the manufacturer’s specifications.

Q: Are all nitrile gloves created equal?

A: No, not all nitrile gloves are created equal. Some manufacturers compromise on quality to keep the price down, which may lead to poor quality gloves.

Q: What standards should I look for in a nitrile glove manufacturer?

A: Look for manufacturers that comply with the relevant standards, such as CE, FDA, ISO 9001, and ISO 13485.

Q: What are some red flags to watch out for when selecting a nitrile glove manufacturer?

A: Be wary of manufacturers with poor quality control, low-grade materials, and those without the necessary certifications.

In conclusion, selecting a reliable nitrile glove manufacturer requires careful consideration and research. By asking the right questions and looking for the appropriate certifications, you can ensure that you get quality gloves that meet the necessary standards.

Things to Consider When Purchasing Nitrile Glove Manufacturer

Nitrile gloves have become a popular choice for healthcare professionals due to its puncture-resistant and chemical-resistant properties. However, not all nitrile gloves are created equal, which is why it is important to consider a manufacturer’s reputation before making a purchase. Here are some things to keep in mind when purchasing nitrile gloves:

1. Quality Standards: A reputable nitrile glove manufacturer follows strict quality standards to ensure that their products meet the required standards and are of high quality. Accreditation from recognized organizations such as the FDA, CE, and ISO is a good indication of a manufacturer’s commitment to quality.

2. Glove thickness: The thickness of nitrile gloves can vary significantly and choosing the right thickness can greatly affect the level of protection needed for specific tasks. Therefore, it is important to consider the intended use of the gloves and consult with the manufacturer to determine the appropriate thickness.

3. Durability and Comfort: The gloves must be durable enough to withstand punctures and tears during use while also providing comfort for the wearer. A good nitrile glove manufacturer will use high-quality materials and state-of-the-art technology to ensure their gloves are both durable and comfortable.

4. Sustainability: Environmental sustainability is increasingly becoming a key consideration in the manufacturing process. A good nitrile glove manufacturer should be committed to environmental sustainability and integrate eco-friendly materials and sustainable practices into their production process.

5. Customer Service: Good customer service is essential in any business, and nitrile glove manufacturing is no exception. Choose a manufacturer that is responsive to your needs and can provide fast and reliable delivery of orders.

In summary, when choosing a nitrile glove manufacturer, consider the quality standards, glove thickness, durability and comfort, sustainability, and customer service. By choosing a reputable manufacturer that meets these factors, healthcare professionals and other users can ensure they are getting the best possible protection and comfort from their nitrile gloves.

Properties of Nitrile Glove Manufacturer

Nitrile gloves are becoming increasingly popular in the medical and industrial industries, and as a result, there are numerous manufacturers in the market. There are a few key properties that differentiate high-quality nitrile glove manufacturers from lower-quality ones.

Firstly, a good nitrile glove manufacturer should use high-quality materials in the production of their gloves. Nitrile gloves are made from synthetic rubber, and a reputable manufacturer will ensure that their gloves are made using only the best quality raw materials to ensure that the gloves are durable and provide the necessary levels of protection.

Another important property of a good nitrile glove manufacturer is their commitment to quality control. The manufacturer should have rigorous quality control processes in place, from sourcing raw materials to the finished product. This will help to ensure that the gloves meet the necessary standards and are free from defects.

A good manufacturer should also be able to offer a variety of glove styles and sizes to cater to different needs. This includes gloves with different thicknesses, textures, and lengths, as well as gloves designed for specific uses, such as medical or industrial applications.

Finally, a reputable nitrile glove manufacturer should provide excellent customer service and support. This includes providing information about their products, answering any questions or concerns, and providing timely and efficient delivery.

In conclusion, the properties of a nitrile glove manufacturer are crucial in ensuring that the gloves provided are of high quality, meet the necessary standards, and provide the necessary protection to the wearer. A reputable manufacturer will use high-quality materials, have rigorous quality control processes, offer a variety of gloves, and provide excellent customer service and support.

Technical Parameters Terms for Nitrile Glove Manufacturer

As a nitrile glove manufacturer, it is important to understand the technical parameters associated with producing high-quality gloves. These parameters can help in determining the overall performance of the gloves, durability, and protection levels that they offer.

The thickness of a glove is the first parameter to consider and is usually measured in mils or millimeters. A thicker glove offers better protection against chemicals, punctures, and abrasions. It is important to ensure that the thickness of the gloves meet international standards such as ASTM International Standards.

The second parameter is the glove’s tensile strength. This is the amount of stress a glove can take before it breaks. A glove with high tensile strength can withstand more stress and is more durable. This is especially important for gloves used in heavy-duty tasks.

Elongation is another important parameter and refers to how much a glove can stretch before breaking. When a glove has a higher elongation rate, it can withstand more extensive movements without breaking. This is especially important for gloves used in medical scenarios where there is a need for frequent hand movements.

The fourth parameter to consider is puncture resistance. This takes into consideration the amount of force needed to puncture the glove. Gloves with higher puncture resistance levels offer more protection against sharp objects and chemical splashes.

Lastly, chemical resistance is another important technical parameter for nitrile glove manufacturers. Nitrile gloves are known for their exceptional resistance to chemicals, and it is important to ensure that the gloves are tested against various chemicals to ensure they meet the necessary standards.

In conclusion, nitrile glove manufacturers should consider technical parameters such as thickness, tensile strength, elongation, puncture resistance, and chemical resistance when producing high-quality gloves. Meeting international standards for these parameters is essential in ensuring that the gloves offer adequate protection to the users.

Nitrile Glove Manufacturer Price

Nitrile gloves have become a staple in medical and industrial settings, due to their durability, resistance to chemicals and punctures, and overall protection. With the ongoing COVID-19 pandemic, the demand for nitrile gloves has surged further, leading to an increase in prices from the manufacturers.

The price of nitrile gloves can vary depending on various factors, including the quality of the gloves, the quantity purchased, and the location of the manufacturer. Generally, nitrile gloves from well-established brands with certifications and necessary quality standards tend to cost more than those produced by new or uncertified manufacturers.

Moreover, a buyer can also negotiate the price with the manufacturer if they are purchasing in bulk. They can also check out different online stores in the market to compare the price of a specific manufacturer. Generally, it’s always wise to go for a trustworthy manufacturer to get a good quality nitrile glove, even if it costs a bit more.

However, the COVID-19 pandemic has severely impacted the supply of nitrile gloves, leading to a shortage of raw materials and a spike in production costs. With increased demand and limited supply, manufacturers have been forced to increase the prices of nitrile gloves, making it harder for medical professionals, first responders, and industrial workers to access the essential protective gear.

Furthermore, the distribution process also adds up to the cost as manufacturing companies have to share their profits with wholesalers and retailers. The transportation and delivery costs also add to the nitrile glove manufacturing price, making it a bit more expensive for the end-user.

In conclusion, nitrile gloves are a vital part of personal protective equipment, and their importance in the present COVID-19 pandemic cannot be overstated. While the manufacturing price of nitrile gloves may vary based on several factors, it is recommended to choose a reputable manufacturer offering high-quality gloves, even if they come at a higher price. The industry needs to work towards controlling the manufacturing price to ensure wider access to protective gear without burning holes in the pockets of end-users.