Analysis of Manufacturing Expenses for oil pan cost

The cost of manufacturing an oil pan involves a range of expenses that include material, labor, and overhead expenses. The material expenses include the cost of the raw materials needed to make the oil pan, such as steel or aluminum. Additionally, labor expenses are incurred from the wages paid to the workers engaged in manufacturing the oil pan. The overhead expenses are the indirect expenses incurred during the manufacturing process such as rent, insurance, and utilities.

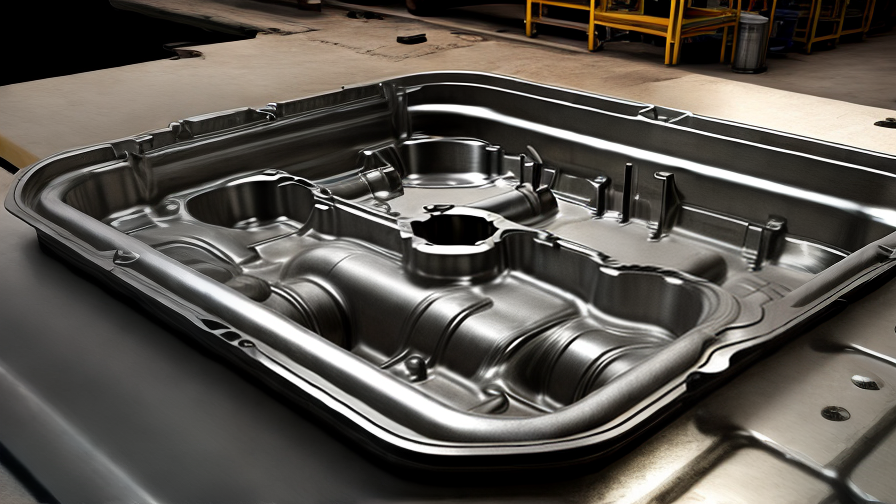

In manufacturing an oil pan, the material expense would be significant due to the type of raw material chosen and its quality. For instance, aluminum is preferred over steel due to its lightweight, corrosion-resistant properties, which increases the material cost. Additionally, the manufacturing process may require specialized equipment, which would increase overhead expenses and the total manufacturing cost.

Labor expense would depend on the number of workers required in the manufacturing process and the hourly wage paid to the workers. The cost of labor would be higher if the manufacturing process requires specialized skills or advanced machinery. Moreover, additional labor cost would be incurred when assembling the oil pan and inspecting its quality to ensure compliance with quality standards.

In conclusion, the cost of manufacturing an oil pan is a function of various expenses, including material, labor, and overhead expenses. The choice of material and the manufacturing process would significantly influence the total cost. Moreover, labor costs are also significant, based on the number of workers required in the manufacturing process. Reducing manufacturing costs would require an efficient manufacturing process, reducing overhead expenses, and sourcing affordable but quality raw materials.

Understanding the Components that Contribute to the Price of oil pan cost

The price of an oil pan is determined by several factors. Firstly, the materials used to manufacture the oil pan can significantly influence its cost. The cost of the aluminum or steel material used can vary depending on the quality and source. More expensive materials will result in higher costs for the final product.

Secondly, the complexity and design of the oil pan can also contribute to its cost. An oil pan with a complex design and more intricate shapes will require higher manufacturing costs. The manufacturing process of such oil pans may also require specialized equipment and skilled labor, which will further drive up its price.

Thirdly, the brand name and reputation of the manufacturer can also play a role in the price of an oil pan. Established brands with a reputation for quality will often charge a premium for their products.

Lastly, any additional features or functionalities that come with the oil pan can also impact its price. For instance, some oil pans come with additional drainage capabilities, oil level sensors, or magnetic drain plugs, which will increase the overall cost of the oil pan.

In conclusion, the cost of an oil pan is determined by various factors, including the material used, the complexity and design of the oil pan, the brand and reputation of the manufacturer, and the additional features that come with the product. Understanding these factors can help consumers make informed decisions when purchasing an oil pan.

Comparing the Wholesale and Retail Prices of oil pan cost in China

The wholesale and retail prices of oil pan cost in China vary significantly. The wholesale price is usually lower than the retail price, and this is because wholesalers buy in bulk directly from the manufacturer, whereas retailers buy in smaller quantities from the wholesalers and seek to make a profit by marking up the price.

The wholesale price of oil pan cost in China is affected by various factors such as the cost of raw materials, labor, and transportation costs. The manufacturer determines the wholesale price of the oil pan based on these factors. The wholesale price is usually lower because the manufacturer makes a reasonable profit by selling in large quantities to the wholesaler.

On the other hand, the retail price of oil pan cost in China is higher and varies from one retailer to another. Retailers consider various factors such as competition, demand, and quality when setting the retail price of oil pans. Retailers aim to make a profit by buying in bulk from the wholesaler and marking up the price to cover their overheads and make a profit.

The retail price of the oil pan may also be affected by the location of the retailer. Retailers located in high-end areas and shopping malls may sell the product at a higher price due to higher rent and overhead costs. Moreover, retailers who offer additional services such as installation, warranties, or aftersales support may also charge higher prices for an oil pan.

In conclusion, the wholesale and retail prices of oil pan cost in China vary significantly. Wholesalers sell the product at a lower price than retailers who aim to make a profit by marking up the cost. The retail price may be affected by various factors such as competition, overhead costs, and location.

Understanding Shipping and Logistics for oil pan cost from China

Shipping and logistics are crucial components in the transportation of goods, including the oil pan cost from China. The oil pan industry relies on efficient and cost-effective shipping and logistics to ensure timely delivery to its customers. The process starts with the manufacturers in China, who package and label the oil pans for export.

To ship the oil pans, freight forwarders are engaged to organize the transportation of the goods. They help with the documentation, bookings, and shipping arrangements to ensure a smooth and hassle-free delivery. The most common method of shipping for oil pans is the use of ocean freight, either in full container loads (FCL) or less-than-container loads (LCL).

FCL means that the entire container is used for one shipment, while LCL means that the container is shared by several shippers. The choice between FCL and LCL depends on the quantity of the oil pans being shipped and the cost-effectiveness of each option. Other factors such as destination, transit time, and reliability of the carrier are also taken into account.

Once the oil pans arrive at the destination port, customs clearance is required before the goods can continue their journey. This involves paying import taxes and duties, presenting the necessary documentation, and complying with any customs regulations. From the port, the oil pans are transported to the warehouse or distribution center where they will be stored before being delivered to the end customers.

In summary, shipping and logistics play a crucial role in the transportation of oil pan cost from China. By engaging the services of freight forwarders, manufacturers can ensure cost-effective and efficient delivery of their products to customers. Understanding the shipping and logistics process helps businesses to make informed decisions and manage their supply chain effectively.

Potential Tariffs or Import Taxes on oil pan cost Purchased from China

The recent trade tensions between the US and China have led to the threat of potential tariffs or import taxes on various goods, including oil pan cost purchased from China. To protect domestic manufacturing in the US, the government may impose a tariff or import tax on Chinese oil pan cost, thereby increasing the cost of import for Chinese manufacturers and potentially reducing the profit margins of importers in the US.

The imposition of tariffs or import taxes could have a significant impact on the oil pan market. Firstly, it could lead to an increase in the cost of oil pan cost purchased from China for US buyers, which would reduce demand for these products in the domestic market. This could result in a shift in consumer preference towards alternative products or a reduction in overall consumption of the product.

Secondly, Chinese manufacturers may also choose to pass on the additional costs from tariffs or import taxes to US importers, which could lead to higher prices for the product in the US market. As a result, US importers may look for alternative sources of oil pan cost, such as domestic manufacturers or those based in other countries, which could ultimately hurt Chinese manufacturers.

In conclusion, the potential imposition of tariffs or import taxes on oil pan cost purchased from China could have a significant impact on the US market for this product. It could lead to higher costs for consumers, a shift in demand towards alternative products, and hurt Chinese manufacturers.

Impact of Market Demand and Competitive Environment on oil pan cost

The cost of oil pans is impacted by market demand and competitive environment. If there is high demand for oil pans, the cost of production will go up due to the increased cost of raw materials and labor, as manufacturers try to meet market demands. Conversely, if the demand is low, the production cost may go down as manufacturers try to maintain profitability and remain competitive.

Competitive environment also plays a significant role in oil pan cost. If there are many competitors in the market producing oil pans, prices are likely to remain low due to the intense competition. On the other hand, if there are few players in the market, manufacturers may be able to charge premium prices for their products, contributing to higher production costs.

Additionally, regulatory requirements and environmental standards may also impact the cost of producing oil pans. Compliance with regulations may require manufacturers to use specific materials or engage in certain production practices, resulting in added costs.

In conclusion, the cost of oil pans is influenced by various factors, including market demand, competitive environment, and regulatory requirements. Manufacturers need to take these factors into account when pricing their products to ensure that they remain profitable while meeting market demands.

FAQ about oil pan cost with multiple answers

Q: How much does it cost to replace an oil pan?

A: The cost to replace an oil pan can vary depending on the make and model of the vehicle, as well as the labor costs at the auto repair shop. On average, the cost can range from $100 to $500.

Q: Why do I need to replace my oil pan?

A: You may need to replace your oil pan if it is damaged or corroded, causing oil leaks. This can lead to engine damage if not addressed promptly.

Q: Can I temporarily fix a damaged oil pan?

A: You may be able to use a temporary fix, such as an epoxy or sealant, to patch a small crack or hole in your oil pan. However, it is recommended to replace the oil pan for a permanent solution.

Q: How long does it take to replace an oil pan?

A: The replacement time can vary depending on the make and model of the vehicle, as well as the extent of damage to the oil pan. On average, it can take anywhere from 2 to 4 hours to replace an oil pan.

Q: Can I replace an oil pan myself?

A: It is possible to replace an oil pan yourself if you have the proper tools and knowledge. However, it is recommended to have a professional mechanic perform the replacement for safety and to ensure it is done correctly.

Q: What can cause a damaged oil pan?

A: There are several reasons why an oil pan can become damaged, including hitting a curb or speed bump, driving over debris on the road, or corrosion due to exposure to salt and moisture.

In conclusion, the cost of oil pan replacement can vary depending on several factors. While a temporary fix may be possible for small cracks or holes, it is recommended to replace the oil pan for a permanent solution. The time it takes to replace an oil pan can depend on the vehicle and the extent of the damage, and it is recommended to have a professional mechanic perform the replacement.