Introduce about encapsulator machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

The encapsulator machine guide is an essential tool for those involved in the pharmaceutical and nutraceutical industries. It allows for the efficient and precise encapsulation of various substances, ensuring high-quality production.

Quality is of utmost importance when it comes to encapsulation. These machines are designed to deliver consistent results, with accurate dosing and reliable capsule formation. They are equipped with advanced features like automatic filling, separation, and sealing mechanisms to maintain optimal quality standards.

Cost considerations play a crucial role in the decision-making process. The encapsulator machine’s price may vary based on factors such as its capacity, speed, and additional features. It is essential to assess the budget limitations and production volume requirements to find the perfect match.

There are several reliable suppliers of encapsulator machines in the market. Buyers should carefully evaluate their reputation, customer reviews, and after-sales support. Some well-known manufacturers include Bosch, Korsch, and IMA. Additionally, it is advisable to compare prices and negotiate for the best deal.

Certification is a critical aspect when purchasing encapsulator machines. Buyers should ensure that the supplier offers machines that comply with international quality and safety standards, such as ISO and CE certifications. These certifications guarantee that the equipment meets the necessary regulations and ensures product safety.

The market for encapsulator machines is growing steadily due to the increasing demand for encapsulated products, such as dietary supplements and pharmaceuticals. With the rising popularity of these industries, the need for efficient encapsulation equipment has also expanded.

Here are a few tips for selecting the right encapsulator machine: consider the required capacity and speed, evaluate the machine’s accuracy and precision, assess the ease of use and maintenance, and explore available technical support.

Frequently Asked Questions (FAQ) about encapsulator machines include queries related to machine operation, maintenance, troubleshooting, and warranty coverage. Buyers can consult the supplier or manufacturer’s website or contact their customer support for instant clarification on these common concerns.

In conclusion, the encapsulator machine guide provides valuable insights into the quality, cost, suppliers, certifications, market trends, tips, and frequently asked questions related to these machines. By considering these factors, buyers can make informed decisions to optimize their encapsulation processes and achieve high-quality production.

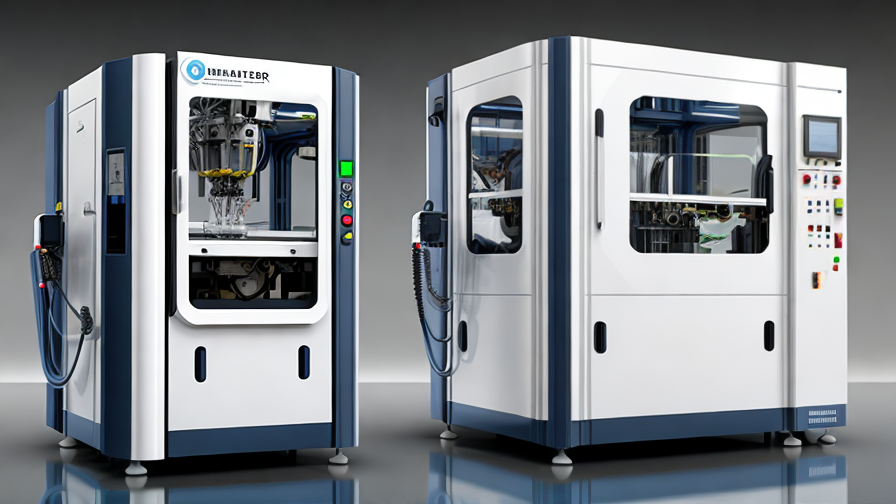

Types of encapsulator machine

Encapsulator machines are a vital component in the pharmaceutical and nutraceutical industries. These machines are used to create capsules that hold active ingredients, ensuring proper dosage and ease of administration. There are several types of encapsulator machines, each with its own unique features and advantages.

1. Manual Capsule Filling Machine:

This type of encapsulator is a simple, hand-operated device used for small-scale production. It consists of a capsule holder, a dosing tray, and a tamping tool. Manual capsule filling machines are affordable, easy to use, and suitable for filling a limited number of capsules at a time.

2. Semi-automatic Capsule Filling Machine:

Semi-automatic encapsulators are designed for medium-scale production. These machines automate the capsule filling process, reducing manual labor. They feature a capsule loading system, a dosing station, and a closing mechanism. Semi-automatic machines offer increased speed and accuracy compared to manual machines.

3. Automatic Capsule Filling Machine:

Automatic encapsulators are the most advanced and efficient option. These machines have a high production capacity, capable of filling hundreds of thousands of capsules per hour. They include multiple modules for different processes like capsule separation, filling, and closing. Automatic machines offer precise dosing, reduced human intervention, and enhanced productivity.

4. Softgel Encapsulation Machine:

Softgel encapsulators are specialized machines used for manufacturing soft gelatin capsules. These capsules have a gelatin-based shell filled with a liquid or semi-liquid active ingredient. Softgel machines automate the entire encapsulation process, including gelatin preparation, filling, sealing, and drying. They offer high production rates, excellent product quality, and are commonly used in the supplement industry.

5. Powder Capsule Filling Machine:

Powder capsule filling machines are designed specifically for filling capsules with powdered substances. These machines ensure accurate dosing and uniform filling of the capsules. They come with features such as a vacuum system to eliminate air, a powder spreader to achieve consistent filling, and a tamping mechanism to compress the powder. Powder capsule fillers are suitable for industries where precise dosage is critical.

Choosing the right encapsulator machine depends on the production requirements, budget, and specific needs of the manufacturer. Manual machines are suitable for small-scale operations, while semi-automatic and automatic machines offer increased efficiency and productivity. Softgel encapsulators are ideal for producing liquid-filled capsules, and powder capsule fillers are tailored for powdered substances. Ultimately, selecting the most appropriate encapsulator will optimize the encapsulation process and contribute to the overall success of the product manufacturing.

Pros and Cons of Using encapsulator machine

Pros:

1. Time Efficiency: Encapsulator machines are designed to automate the process of encapsulating products, such as pills or powders. This significantly reduces the time required for manual encapsulation, increasing overall productivity.

2. Accuracy: These machines are programmed to dispense specific amounts of product into each capsule, ensuring precise dosing. This eliminates human error common in manual encapsulation, leading to more consistent and accurate results.

3. Cost-saving: While the initial investment in an encapsulator machine can be significant, it can save money in the long run. The accuracy and efficiency of the machine reduce the amount of wasted product, minimizing material costs.

4. Increased capacity: Encapsulator machines have higher output capabilities than manual encapsulation, allowing for larger production volumes. This is particularly advantageous for businesses experiencing growth or catering to high demand.

5. Quality control: Encapsulator machines are equipped with built-in quality control features, such as weight verification and defect detection. This ensures that all capsules meet the required standards, reducing the risk of product recalls and customer dissatisfaction.

Cons:

1. High initial cost: The purchase of an encapsulator machine can be a significant upfront investment, especially for smaller businesses or startups. This cost may limit accessibility for companies with limited funds.

2. Maintenance requirements: Encapsulator machines require regular maintenance and calibration to ensure optimal performance. This may involve additional costs and the need for specialized technical expertise.

3. Limited flexibility: Encapsulator machines are designed to encapsulate specific types and sizes of products. Switching between different formulations or capsule sizes may require additional equipment or adjustments, limiting flexibility for product diversification.

4. Dependency on a single machine: Relying solely on an encapsulator machine for production creates a vulnerability to breakdowns or malfunctions. This can halt production until the machine is repaired, potentially leading to delays and loss of revenue.

5. Skill requirements: Operating an encapsulator machine requires trained personnel with technical skills. This may require additional training or hiring specialized staff, which can add to the overall cost of using the machine.

It is important to carefully consider these pros and cons before making a decision about incorporating an encapsulator machine into a production process.

encapsulator machine Reference Specifications (varies for different product)

The encapsulator machine is a versatile and efficient piece of equipment used in various manufacturing industries. It is designed to encapsulate different products, ranging from pharmaceuticals to food supplements, in a seamless and controlled manner. The machine’s reference specifications may vary depending on the specific product being encapsulated.

One of the key features of the encapsulator machine is its high-speed capability. It can encapsulate a large number of products per minute, reducing production time and increasing overall efficiency. The machine is equipped with advanced technology that ensures precise encapsulation, minimizing product wastage and maximizing yield.

The encapsulator machine incorporates a state-of-the-art filling system. It is capable of accurately depositing the desired amount of product into each capsule, ensuring uniformity and consistency. The filling system is adjustable and customizable, allowing for the encapsulation of different product sizes and dosages.

In terms of product handling, the encapsulator machine offers exceptional flexibility. It can accommodate a wide range of product formulations, including powders, granules, and even liquids. The machine’s design incorporates a dedicated feeding system and transfer mechanisms, ensuring smooth and seamless product flow throughout the encapsulation process.

Furthermore, the encapsulator machine features an easy-to-use interface, facilitating user-friendly operation. It is equipped with an intuitive control panel that allows operators to set and monitor critical process parameters, such as fill weight, capsule size, and production speed. The machine also incorporates advanced safety features to ensure operator protection and prevent potential accidents.

The encapsulator machine is built to meet the highest industry standards. It is constructed using high-quality materials and components, guaranteeing durability and reliability. Regular maintenance and servicing ensure optimal performance and prolonged machine lifespan.

In conclusion, the encapsulator machine is a versatile and efficient solution for encapsulating various products. Its reference specifications may vary depending on the specific product requirements. With its high-speed capability, precise filling system, flexible product handling, user-friendly interface, and robust construction, the encapsulator machine is an essential asset for companies aiming to streamline their encapsulation processes and enhance overall productivity.

Applications of encapsulator machine

Encapsulator machines have diverse applications in various industries due to their ability to efficiently encapsulate or coat a wide range of materials. Here are some notable applications of encapsulator machines:

1. Pharmaceutical Industry: Encapsulator machines are extensively used in the pharmaceutical industry to produce capsules for oral drug delivery. These machines can accurately fill capsules with precise doses of active pharmaceutical ingredients (APIs), enabling convenient and consistent dosing for patients.

2. Nutraceutical Industry: Encapsulator machines are commonly employed in the nutraceutical industry to manufacture encapsulated dietary supplements. These machines enable the encapsulation of vitamins, minerals, herbal extracts, and other nutraceutical ingredients, facilitating controlled-release formulations and improving product stability.

3. Food and Beverage Industry: Encapsulator machines are utilized in the food and beverage industry for encapsulating various ingredients. They can encapsulate flavors, oils, vitamins, and additives to enhance the taste, texture, and nutritional value of food products. Encapsulation helps in protecting sensitive ingredients from degradation and extends their shelf life.

4. Cosmetics Industry: Encapsulator machines find applications in the cosmetics industry for the production of encapsulated active ingredients in skincare and personal care products. Encapsulation enhances the stability and efficacy of ingredients such as vitamins, peptides, and antioxidants, ensuring their controlled release for optimal skin benefits.

5. Agricultural Industry: Encapsulator machines are utilized in the agricultural industry for the encapsulation of fertilizers, pesticides, and herbicides. Encapsulating these agrochemicals improves their controlled release, decreases environmental impact, and enhances their efficacy by protecting them from moisture and degradation.

6. Chemical Industry: Encapsulator machines play a vital role in the chemical industry for encapsulating and controlling the release of various chemicals, such as fragrances, dyes, and catalysts. Controlled release encapsulation enables prolonged action, improved safety, and efficient utilization of these chemicals in various applications.

7. Research and Development: Encapsulator machines are essential tools in research and development laboratories, enabling scientists to encapsulate and study various substances. These machines assist in the development of new drug formulations, controlled-release systems, and innovative materials with enhanced properties.

In conclusion, encapsulator machines find wide-ranging applications across industries. From pharmaceuticals to food and cosmetic industries, these machines are invaluable for encapsulating ingredients, protecting them, improving stability, enhancing efficacy, and facilitating controlled release in diverse products. Their contributions to product innovation, improved performance, and better customer experiences make encapsulator machines crucial tools for many industries.

The Work Process and how to use encapsulator machine

The work process of an encapsulator machine involves encapsulating or coating small-sized objects such as pills, tablets, or capsules with a protective layer. This process helps in enhancing the stability and appearance of the encapsulated product. Encapsulator machines are commonly used in pharmaceutical and food industries.

To use an encapsulator machine, the following steps should be followed:

1. Preparation: Gather all the necessary materials including the encapsulant material, the core material to be encapsulated, and any additives or colors required for the process. Ensure that the machine is clean and free from any residual materials.

2. Setup: Install the necessary parts and adjust the machine according to the desired capsule size. This includes adjusting the filling and sealing mechanisms, as well as the speed and pressure controls.

3. Loading: Load the core material into the machine’s hopper, which is the reservoir for the material to be encapsulated. The hopper should be filled carefully without overloading to ensure smooth operation.

4. Encapsulation: Start the machine and monitor the process closely. The encapsulator machine will automatically fill the capsules with the core material, seal them, and release the final product. Adjustments may be needed during the process to ensure the desired encapsulation quality and consistency.

5. Cleaning and maintenance: After completing the encapsulation process, clean the machine thoroughly to remove any leftover materials or residues. Regular maintenance should be performed according to the manufacturer’s guidelines to ensure the longevity and efficiency of the machine.

6. Quality control: Once the encapsulation process is complete, perform quality checks on a sample of the finished products. This includes visual inspection for defects or irregularities and testing for attributes such as hardness, dissolution rate, or stability.

By following these steps, the encapsulator machine can be effectively used to encapsulate various products. It is crucial to adhere to safety guidelines and ensure proper calibration and maintenance of the machine for optimal results.

Quality Testing Methods for encapsulator machine and how to control the quality

The encapsulator machine is a critical component in the manufacturing process of encapsulated products such as pharmaceuticals, food supplements, and other small solid items. Ensuring the quality of the encapsulator machine is of utmost importance to maintain the overall product quality. Here are some quality testing methods for the encapsulator machine and how to control the quality:

1. Visual Inspection: Conduct a visual inspection of the machine to check for any visible defects, damages, or wear and tear that may affect its performance. This can be done regularly or after a specific number of production cycles.

2. Performance Testing: Test the machine’s performance by encapsulating a sample product and evaluating the encapsulation process. This includes checking for accurate filling, correct sealing, proper capsule formation, and consistent output.

3. Time and Speed Testing: Measure the time taken by the machine to complete encapsulation cycles and verify if it meets the designated time requirements. Also, test the speed of the machine to ensure it operates within the specified speed range.

4. Fill Weight Control: Verify the accuracy of fill weight by randomly selecting capsules and measuring the weight of the product inside. Compare the results with the desired fill weight and set tolerance limits to control the quality.

5. Regular Maintenance: Implement a preventive maintenance schedule to keep the encapsulator machine in optimal condition. This includes lubrication, cleaning, replacing worn-out parts, and calibration of the machine.

6. Process Validation: Periodically validate the encapsulation process by collecting and analyzing data such as fill weight, capsule uniformity, and sealing integrity. This helps in identifying any variations or deviations from the desired quality standards.

7. Training and Documentation: Ensure that operators and technicians are trained on the proper operation and maintenance of the encapsulator machine. Maintain proper documentation of training records, maintenance activities, and quality test results for future reference and traceability.

To control the quality of the encapsulator machine, establish specific quality standards and performance criteria. Regularly monitor and analyze the testing data to identify patterns, trends, or anomalies that may indicate potential issues. Implement corrective actions promptly in case of any quality deviations. Conduct internal audits to assess compliance with quality control measures and regulatory requirements. Collaborate with suppliers or manufacturers of the encapsulator machine to address any concerns or issues regarding machine quality or performance.

By following these quality testing methods and control measures, manufacturers can ensure the encapsulator machine’s reliability, accuracy, and efficiency, ultimately leading to high-quality encapsulated products.

encapsulator machine Sample Policy and Post-Purchase Considerations for encapsulator machine from China

Encapsulator machines play a crucial role in the pharmaceutical and nutraceutical industries by automatically filling and sealing capsules. When considering purchasing an encapsulator machine from China, it is essential to have a well-defined sample policy and post-purchase considerations in place to ensure a successful purchase and subsequent operations. Here’s a concise overview with a limit of 300 words:

Sample Policy:

1. Request samples: Before finalizing any purchase, it is crucial to request samples of the encapsulator machine from Chinese suppliers. Evaluate the machine’s build quality, efficiency, accuracy, and suitability for your specific requirements.

2. Sample testing: Conduct thorough testing of the samples provided, including capsule filling speed, size range, and machine compatibility with different capsules. Ensure that the samples meet your production standards and comply with any regulatory requirements.

3. Client references: Seek references from existing clients of the Chinese supplier to gather insights about the machine’s performance and after-sales support.

Post-Purchase Considerations:

1. Documentation and certification: Ensure that the encapsulator machine meets international quality and safety standards. Request the necessary certifications, such as ISO and CE, as well as detailed documentation for troubleshooting and maintenance.

2. Training and technical support: Seek assistance from the supplier for operator training and installation guidance. Clarify the extent of technical support provided, warranty duration, and availability of spare parts.

3. Customs duties and shipping: Understand the import regulations, customs duties, and shipping arrangements involved when importing the encapsulator machine from China. Plan logistics and budget accordingly.

4. After-sales service: Clarify the availability and terms of after-sales service offered by the Chinese supplier. Prompt technical support and efficient maintenance services ensure uninterrupted production.

5. Communication and language: Establish effective communication channels with the supplier, considering the language barrier. Ensure the supplier has a proficient English-speaking representative on their team to facilitate smooth correspondence.

By implementing a comprehensive sample policy and post-purchase considerations, you can mitigate potential risks and select a reliable encapsulator machine supplier from China. Conducting thorough due diligence will enable you to make an informed purchase decision and maintain a productive and sustainable operation.

Sourcing encapsulator machine from China: Opportunities, Risks, and Key Players

Sourcing encapsulator machines from China can provide various opportunities for businesses. Chinese manufacturers offer competitive prices due to their low labor costs and economies of scale. This allows companies to save on production costs and potentially increase profit margins. Moreover, China has a well-developed manufacturing infrastructure and extensive supply chain networks that can efficiently produce and deliver encapsulator machines.

However, there are also risks associated with sourcing from China. The quality control of products can be a concern, as some manufacturers may prioritize price over quality. It is crucial for businesses to thoroughly research and vet potential suppliers to ensure they meet international quality standards and certifications. Intellectual property risks are another consideration, as China has been criticized for intellectual property violations in the past. Businesses should take appropriate steps to protect their designs and intellectual property when dealing with Chinese suppliers.

When sourcing encapsulator machines from China, key players in the market should be identified. Some prominent Chinese companies include Shanghai Royal Pharmaceutical Machinery, Liaoyang Pharmaceutical Machinery Co., Ltd., and Beijing Decoction Machinery Co., Ltd. These companies are recognized for their expertise and experience in manufacturing encapsulator machines. Companies should carefully evaluate and compare different suppliers to determine the most suitable option for their specific requirements, considering factors such as quality, price, delivery time, and after-sales service.

In conclusion, sourcing encapsulator machines from China presents opportunities to save on production costs and benefit from the country’s manufacturing infrastructure. Nevertheless, businesses should be aware of the risks associated with quality control and intellectual property protection. By conducting thorough research and partnering with reputable suppliers, companies can mitigate these risks and leverage the benefits offered by the Chinese market.

How to find and select reliable encapsulator machine manufacturers in China,use google search manufacturers and suppliers

Finding and selecting reliable encapsulator machine manufacturers in China can be a daunting task, but by utilizing Google search to look for manufacturers and suppliers, you can streamline the process. Here is a step-by-step guide on how to do so in less than 300 words:

1. Start by conducting a Google search using keywords like “encapsulator machine manufacturers in China” or “encapsulator machine suppliers.”

2. You will get numerous search results, so begin by visiting the websites of the top-ranked manufacturers or suppliers. Pay attention to their website design, layout, and overall professionalism.

3. Look for important information on their website, such as their experience in the industry, product range, manufacturing capabilities, certifications, and quality control processes. This will give you an idea of their expertise and dedication to producing reliable encapsulator machines.

4. Check for any customer testimonials or reviews on their website or other platforms. These reviews can provide insights into the manufacturer’s reputation and the satisfaction levels of their customers.

5. In addition to customer reviews, look for any industry certifications or awards that the manufacturer has received. This can further validate their credibility and reliability.

6. Contact the selected manufacturers or suppliers directly via email or phone. Inquire about their product specifications, production capacity, delivery times, and after-sales service. Prompt and informative responses indicate a manufacturer’s professionalism and commitment to customer satisfaction.

7. Request product samples or visit their factory if feasible. This will allow you to evaluate the quality and performance of their encapsulator machines firsthand.

8. Finally, compare the information gathered from different manufacturers and suppliers. Consider factors such as product quality, price, lead time, after-sales service, and reputation before making a decision.

Remember, due diligence is crucial when selecting a reliable encapsulator machine manufacturer in China. By utilizing Google search, thoroughly researching potential suppliers, and following the steps outlined above, you can increase your chances of finding a trustworthy and reputable manufacturer.

How to check encapsulator machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

When checking the reliability of an encapsulator machine manufacturer’s website, you can follow a simple approach using SEOquake, a Google Chrome extension. SEOquake provides a variety of metrics that can help you evaluate the website’s ranking and authority. Here’s a step-by-step guide on how to analyze a website’s reliability using SEOquake:

1. Install SEOquake: Go to the Google Chrome Web Store and search for “SEOquake.” Click on “Add to Chrome” to install the extension.

2. Open the manufacturer’s website: Visit the encapsulator machine manufacturer’s website you want to evaluate.

3. Analyze the website: Once the website loads, locate the SEOquake extension in your browser’s toolbar. Click on the SEOquake icon to activate it.

4. Check Ranking Metrics: In the SEOquake pop-up, navigate to the “Rank” section. Look for the metric called “Alexa Rank.” Alexa Rank provides an estimate of a website’s popularity based on their traffic data. A lower number indicates higher popularity.

5. Verify Alexa Rank: If the manufacturer’s website has an Alexa Rank within the top 10 million websites, it generally signifies a reliable site. However, keep in mind that the lower the Alexa Rank is, the more popular the website is considered.

6. Verify Other Metrics: Additionally, SEOquake provides various other metrics like SEMrush Rank, Domain Score, and Backlinks, which can further help to evaluate a website’s reliability. Consider these metrics as well to get a more comprehensive understanding.

7. Research further if needed: If the encapsulator machine manufacturer’s website doesn’t rank within the top 10 million or if you have any doubts about its reliability, it’s best to conduct further research. Look for customer reviews, testimonials, or references to gain a better understanding of the company’s reputation.

Remember, while SEOquake provides useful metrics, it’s essential to consider other factors like customer feedback, industry reputation, and testimonials as well. A combination of various sources will provide you with a more reliable assessment of the encapsulator machine manufacturer’s website.

Top 10 encapsulator machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

**Top 10 Encapsulator Machine Manufacturers in China:**

1. **Changsheng:** Changsheng Machinery specializes in the production of pharmaceutical and food encapsulator machines. Their products provide precise and efficient encapsulation solutions for various industries.

2. **SaintyCo:** SaintyCo offers a wide range of encapsulator machines, including automatic and semi-automatic models. Their machines are known for their advanced technology, high-speed production capability, and ease of maintenance.

3. **Shanghai Tianhe:** Shanghai Tianhe Pharmaceutical Machinery Co., Ltd. manufactures encapsulator machines for the pharmaceutical industry. Their products are designed to meet GMP standards and ensure accurate dosing and sealing.

4. **Ruian Trustar:** Ruian Trustar Pharmaceutical Machinery is a renowned manufacturer of encapsulator machines. Their products are suitable for encapsulating tablets, capsules, and soft gels, providing reliable and consistent results.

5. **Korican Machinery:** Korican Machinery offers encapsulator machines with various production capacities and customization options. Their machines are highly efficient, with a user-friendly interface and durable construction.

6. **Shanghai Universal:** Shanghai Universal Pharmaceutical Machinery Co., Ltd. specializes in the production of high-quality encapsulator machines. Their products feature advanced technology, high-speed production, and precise dosing.

7. **Bosch Packaging Technology:** Bosch Packaging Technology manufactures encapsulator machines for the pharmaceutical and nutraceutical industries. Their products ensure accurate dosing, reliable sealing, and efficient production.

8. **Pharmaland Technologies:** Pharmaland Technologies provides encapsulator machines that are widely used in the pharmaceutical, food, and cosmetic industries. Their machines are known for their user-friendly operation and consistent performance.

9. **Nanjing Careal Automation Equipment:** Nanjing Careal produces encapsulator machines for the pharmaceutical industry. Their products incorporate advanced technology, ensuring high-speed production, accurate dosing, and efficient sealing.

10. **Shanghai Aligned Machinery:** Shanghai Aligned Machinery specializes in encapsulator machines for various industries. Their products are designed to handle different materials, providing reliable encapsulation and optimal productivity.

| Manufacturer | Key Features |

|—————————|—————————————————————-|

| Changsheng | Precise and efficient encapsulation solutions |

| SaintyCo | Advanced technology, high-speed production, easy maintenance |

| Shanghai Tianhe | GMP-compliant, accurate dosing and sealing |

| Ruian Trustar | Reliable and consistent results, suitable for various forms |

| Korican Machinery | Customizable options, user-friendly interface, high efficiency |

| Shanghai Universal | Advanced technology, high-speed production, precise dosing |

| Bosch Packaging Technology| Accurate dosing, reliable sealing, efficient production |

| Pharmaland Technologies | User-friendly operation, consistent performance |

| Nanjing Careal | Advanced technology, high-speed production, accurate dosing |

| Shanghai Aligned Machinery| Reliable encapsulation, compatibility with various materials |

These top Chinese encapsulator machine manufacturers offer a wide range of products to cater to the needs of different industries, providing highly efficient encapsulation solutions. Whether it’s pharmaceuticals, food, or cosmetics, their machines ensure precision, reliability, and productivity. By comparing their key features, customers can make informed decisions based on their specific requirements.

Background Research for encapsulator machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to encapsulator machine manufacturers in China, several notable companies can be found through platforms such as qcc.com, archive.org, and importyeti.com. These platforms provide information on various manufacturers, their products, and services. Here are some key findings on encapsulator machine manufacturers in China:

1. Shanghai Tian He Machinery Equipment Co., Ltd: This company specializes in the production of capsule filler machines, including encapsulator machines. They offer a wide range of machines, from semi-automatic to fully automatic models, suitable for different production capacities.

2. Ruian Hanwas Machinery Co., Ltd: With a focus on pharmaceutical packaging equipment, this company offers encapsulator machines capable of filling capsules with precise dosages. Their machines are designed for various capsule sizes, such as 00, 0, 1, and 2.

3. Ruian Trustar Pharma & Packing Equipment Co., Ltd: This manufacturer produces encapsulator machines that provide high accuracy and efficiency in encapsulating pharmaceutical and nutraceutical products. Their machines feature advanced technology, adjustable speed, and easy operation.

4. Sino Pharmaceutical Equipment Development (Liaoyang) Co., Ltd: Specializing in pharmaceutical machinery, this company manufactures encapsulator machines that ensure high productivity and low noise levels. Their machines also have a stable performance and are suitable for various capsule sizes.

5. Guangdong Rich Packing Machinery Co., Ltd: This company offers a wide range of packaging machinery, including encapsulator machines. They provide both standard and customized solutions to meet different customer requirements.

Overall, these encapsulator machine manufacturers in China demonstrate a commitment to providing advanced, efficient, and reliable machines for capsule filling processes. Additionally, they are capable of catering to different production capacities and offering customized solutions.

Leveraging Trade Shows and Expos for encapsulator machine Sourcing in China

Trade shows and expos play a significant role in sourcing encapsulator machines from China. These events provide a platform for businesses to connect with manufacturers, gather industry knowledge, and explore new opportunities. Leveraging trade shows and expos for encapsulator machine sourcing can be advantageous in several ways.

Firstly, trade shows and expos offer a concentrated marketplace where numerous manufacturers and suppliers exhibit their products and services. This allows buyers to compare different encapsulator machine models, features, and prices all under one roof. By attending these events, businesses can efficiently evaluate multiple suppliers and make informed decisions based on their specific requirements.

Secondly, trade shows provide an opportunity for face-to-face interactions with potential Chinese manufacturers. This direct contact allows buyers to establish relationships, discuss specifications, negotiate pricing, and assess the supplier’s capabilities. Meeting with manufacturers in person can provide a deeper understanding of their expertise, production processes, and quality control measures, helping businesses ensure that they are partnering with a reliable source.

Furthermore, trade shows and expos often host seminars, conferences, and workshops where industry experts share valuable insights and trends. Attending these sessions can equip buyers with knowledge about the latest advancements, innovations, and best practices in encapsulator machine manufacturing. Understanding the industry landscape and staying up-to-date with technological advancements can be instrumental in making well-informed sourcing decisions.

To maximize the benefits of trade shows and expos, businesses should thoroughly research and identify the relevant events in China focusing on encapsulator machine manufacturing. Preparing a detailed list of questions, brochures, and specifications beforehand can help streamline conversations with potential suppliers. Additionally, businesses should allocate sufficient time to thoroughly explore the exhibition area, engage with various manufacturers, and collect relevant information for future reference.

In conclusion, leveraging trade shows and expos for encapsulator machine sourcing in China offers businesses a consolidated platform to connect with manufacturers, compare products, establish relationships, and gain industry knowledge. By utilizing these events effectively, businesses can streamline their sourcing process, find the right manufacturers, and secure cost-effective and high-quality encapsulator machines.

The Role of Agents and Sourcing Companies in Facilitating encapsulator machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating encapsulator machine purchases from China. These intermediaries act as a bridge between buyers and manufacturers, providing various services to streamline the procurement process.

One key function of agents and sourcing companies is to locate suitable suppliers in China. They have an extensive network of connections and deep industry knowledge, enabling them to identify reliable manufacturers capable of producing encapsulator machines that meet the buyer’s requirements. By conducting thorough supplier assessments and due diligence, agents and sourcing companies mitigate risks associated with quality, delivery, and compliance.

In addition to supplier discovery, these intermediaries assist buyers in negotiating favorable terms and conditions. They leverage their expertise in Chinese business practices, negotiation tactics, and knowledge of local market dynamics to secure the best possible pricing and contractual arrangements. This often involves conducting price comparisons, obtaining multiple quotations, and negotiating favorable payment terms such as deposit and installment payments.

Agents and sourcing companies also handle the logistics and shipping aspects of the purchase. They coordinate the transportation from the manufacturer’s facility in China to the buyer’s location, ensuring efficient and secure delivery. These intermediaries can also provide assistance in customs clearance and navigating import regulations, minimizing any potential challenges or delays.

Furthermore, agents and sourcing companies act as quality controllers during the manufacturing process. They conduct factory inspections and audits to ensure that the encapsulator machines adhere to the buyer’s specifications and quality standards. This helps buyers mitigate the risk of receiving substandard or non-compliant products.

Overall, agents and sourcing companies in China play an integral role in facilitating encapsulator machine purchases. Their expertise in supplier identification, negotiation, logistics, and quality control provides significant value to buyers, ensuring a smooth and successful procurement process.

Price Cost Research for encapsulator machine manufacturers Companies in China, use temu.com and 1688.com

When it comes to researching the price cost of encapsulator machine manufacturers in China, two popular online platforms that can be utilized are temu.com and 1688.com.

Temu.com is a comprehensive B2B platform that specializes in connecting international buyers with Chinese suppliers. It offers various tools and services to streamline the sourcing process. By utilizing temu.com, buyers can easily search for encapsulator machine manufacturers in China. The platform provides information about each manufacturer, including their location, certifications, and capabilities. Additionally, temu.com enables buyers to request quotes directly from the manufacturers, allowing them to compare prices and negotiate.

1688.com, on the other hand, is a prominent wholesale marketplace operated by Alibaba Group. It is specifically designed for domestic buyers and suppliers within the Chinese market. Although the website is primarily in Chinese, buyers can utilize translation tools available through web browsers for easier navigation. 1688.com provides a wide range of products, including encapsulator machines. The platform also allows buyers to contact manufacturers directly, discuss pricing details, and negotiate deals.

When conducting price cost research on these platforms, it is recommended to follow these steps:

1. Start by searching for encapsulator machine manufacturers based on specific requirements such as machine specifications, certifications, and production capacity.

2. Collect information about each manufacturer, including their location, years of experience, and customer reviews.

3. Evaluate the manufacturers’ capabilities and ensure they meet quality standards and relevant certifications.

4. Contact the manufacturers directly to inquire about the price cost of encapsulator machines. Provide detailed specifications and quantities required for accurate quotations.

5. Compare the prices, delivery time, and after-sales services offered by different manufacturers.

6. Engage in negotiation to potentially obtain better pricing or additional benefits.

7. Consider factors like payment terms, shipping options, and warranties before finalizing a deal.

By utilizing temu.com and 1688.com, buyers can easily access a vast database of encapsulator machine manufacturers in China, compare prices, and make informed purchasing decisions.

Shipping Cost for encapsulator machine import from China

The shipping cost for importing an encapsulator machine from China can vary depending on various factors. Generally, there are two primary methods of shipping: air freight and sea freight.

Air freight is typically faster but more expensive. The cost can be determined by the weight and dimensions of the machine. As an estimate, the air freight charges for a standard encapsulator machine weighing around 500 kg could range from $1,500 to $3,000. This cost includes documentation fees, customs clearance charges, and delivery to the destination airport.

On the other hand, sea freight is a more cost-effective alternative but has a longer transit time. The charges for sea freight depend on the volume or size of the machine and the destination. As an estimation, the sea freight charges for a standard encapsulator machine could range from $800 to $1,800. This cost includes sea freight charges, customs clearance fees, and delivery to the destination port.

It is essential to note that these estimates are indicative and can vary depending on the specific location of the buyer, the shipping company, the current market conditions, and other additional services required.

Moreover, additional costs such as import duties, customs taxes, and local handling charges may apply and should be considered. It is advisable to consult with a freight forwarder or shipping agent to get an accurate shipping quotation and assistance with the import process.

In conclusion, the shipping cost for importing an encapsulator machine from China can be estimated based on the chosen shipping method, weight, dimensions, and destination. It is crucial to obtain accurate quotations and consider additional costs to ensure a smooth and cost-effective import process.

Compare China and Other encapsulator machine Markets: Products Quality and Price,Visible and Hidden Costs

China, with its vast manufacturing capabilities, is a major player in the encapsulator machine market. The country offers a wide range of options in terms of product quality and price, catering to various customer needs.

In comparison to other encapsulator machine markets, China’s products generally offer competitive quality. Many manufacturers in China have invested heavily in research and development, allowing them to produce machines that meet international standards. However, it is important for buyers to carefully evaluate the reputation and credentials of Chinese suppliers to ensure quality assurance.

When it comes to price, China often has an advantage. The country’s lower labor and manufacturing costs contribute to more affordable options for encapsulator machines. This affordability makes China an attractive market for buyers looking to optimize their budgets without compromising on quality. However, it is essential to note that price should not be the sole determining factor, as quality and reliability are equally important considerations.

When evaluating the costs associated with purchasing encapsulator machines from China, both visible and hidden costs need to be considered. Visible costs include the purchase price, shipping, and import duties, while hidden costs may include quality control inspections, product customization, and potential language and cultural barriers. It is advisable for buyers to have a clear understanding of all potential costs involved before making a purchase decision.

Despite these advantages, it is crucial to highlight that China is not the only viable option in the encapsulator machine market. Other countries, such as Germany, Italy, and the United States, also offer high-quality machines, often at a premium price. Additionally, these markets may provide superior customer service and after-sales support, which could be a crucial consideration for some buyers.

In conclusion, China’s encapsulator machine market offers a wide range of products with competitive quality and affordable prices. However, buyers should carefully evaluate the reputation and credentials of suppliers and consider visible and hidden costs associated with purchasing from China. Other markets may also provide high-quality options but may come at a higher price point. Ultimately, buyers should weigh their specific requirements and budget constraints when making a decision.

Understanding Pricing and Payment Terms for encapsulator machine: A Comparative Guide to Get the Best Deal

When it comes to purchasing an encapsulator machine, understanding the pricing and payment terms is crucial in order to get the best deal. This guide aims to provide a comparative overview of pricing and payment terms for encapsulator machines.

Pricing for encapsulator machines can vary depending on various factors such as the brand, model, features, and capabilities of the machine. It is important to compare prices from different suppliers or manufacturers to ensure that you are getting the best value for your investment. Some suppliers may offer discounts or promotions, so it is recommended to inquire about any ongoing deals.

Additionally, payment terms can also differ between suppliers. The most common payment options include upfront payment, installment plans, or leasing agreements. Upfront payment typically requires paying the full amount upon purchase, while installment plans allow for spreading the cost over a period of time. Leasing agreements involve paying a monthly fee for a specified duration, after which you may have the option to purchase the machine at a discounted rate.

It’s important to consider your budget and financial capabilities when deciding on the payment terms. While upfront payment may require a larger initial investment, it eliminates any ongoing payments. Installment plans may be a more feasible option for businesses with limited budgets, as they allow for spreading out the cost. Leasing agreements provide flexibility and the ability to upgrade to newer models in the future.

Before finalizing a purchase, it is advisable to thoroughly review and understand the warranty terms and after-sales support provided by the supplier. A comprehensive warranty can provide peace of mind and protect you from unexpected expenses in case of machine malfunction or breakdown.

In conclusion, understanding the pricing and payment terms for encapsulator machines is essential to make an informed decision. By comparing prices, considering payment options, and reviewing warranty terms, you can ensure that you get the best deal and invest in a high-quality encapsulator machine that meets your needs.

Chinese Regulations and Industry Standards Certifications for encapsulator machine,Import Regulations and Customs for encapsulator machine from China

China has implemented various regulations and industry standards certifications for encapsulator machines. One of the significant certifications is the China Compulsory Certification (CCC) mark. This certification ensures that the encapsulator machines meet the safety requirements set by the government. The CCC mark is mandatory for many products, including encapsulator machines, before they can be sold in the Chinese market.

In addition to the CCC mark, there are industry-specific standards that encapsulator machines need to comply with. For example, the Pharmaceutical Equipment GMP Certification ensures that the machines meet Good Manufacturing Practices (GMP) standards specifically for pharmaceutical industry applications. This certification is important for companies involved in manufacturing pharmaceutical products using encapsulator machines.

When importing encapsulator machines from China, businesses must also adhere to import regulations and customs procedures. First, the machines need to comply with the regulations and standards of the destination country. It is crucial to ensure that the machines meet the required safety and quality standards to avoid potential issues during customs clearance.

Importers must also provide necessary documentation, such as commercial invoices, packing lists, and certificates of origin. These documents help customs authorities to identify the products and determine the appropriate customs duty and taxes to be applied. It is essential to accurately declare the value of the encapsulator machines to avoid any customs penalties or delays.

Furthermore, importers might need to obtain additional certifications or conformity assessments required by their home country’s regulations. These may include safety certifications, electromagnetic compatibility (EMC) certifications, or other specific certifications relevant to the industry.

In summary, encapsulator machines imported from China must comply with the Chinese regulations and industry standards certifications. Additionally, importers need to follow the import regulations and customs procedures of their destination country. It is crucial to ensure the machines meet safety and quality standards and provide all necessary documentation for smooth customs clearance.

Sustainability and Environmental Considerations in encapsulator machine Manufacturing

Sustainability and environmental considerations are becoming increasingly important in the manufacturing industry, including encapsulator machine manufacturing. As the global focus on climate change and the depletion of natural resources intensifies, manufacturers are recognizing the need to reduce their environmental impact and adopt sustainable practices.

One crucial aspect of sustainability in encapsulator machine manufacturing is energy efficiency. Designing and engineering these machines to operate with lower energy consumption can significantly reduce their carbon footprint. This can be achieved through the use of advanced technology, such as energy-efficient motors and sensors, and optimizing the overall system to minimize unnecessary energy usage.

Another critical consideration is the responsible sourcing and use of materials. Encapsulator machines are complex systems made up of various components. Manufacturers can prioritize the use of sustainable materials, such as recycled or bio-based plastics, in the production of these machines. Additionally, implementing efficient material management practices, such as recycling and waste reduction programs, can help minimize the environmental impact of the manufacturing process.

Water usage is another significant environmental concern. Encapsulator machines require water for cooling and cleaning purposes. Implementing water-saving measures, such as using closed-loop systems or incorporating water recycling technologies, can help conserve this valuable resource.

To further enhance sustainability, manufacturers can also focus on the end-of-life management of encapsulator machines. Designing these machines with ease of disassembly and recyclability in mind can facilitate their proper disposal or recycling when they reach their end of life. Implementing take-back programs or partnering with recycling facilities can ensure that these machines are disposed of in an environmentally responsible manner.

Lastly, incorporating eco-friendly manufacturing practices, such as lean manufacturing principles, can help reduce waste, increase efficiency, and lower overall environmental impact. Streamlining production processes, optimizing supply chain logistics, and reducing packaging waste can all contribute to a more sustainable manufacturing approach.

In conclusion, sustainability and environmental considerations in encapsulator machine manufacturing are imperative for reducing the industry’s overall environmental impact. By enhancing energy efficiency, sourcing sustainable materials, managing water usage, improving end-of-life management, and embracing eco-friendly manufacturing practices, manufacturers can contribute to a greener and more sustainable future.

List The Evolution history of “encapsulator machine”

The encapsulator machine has a rich history that spans over several decades, witnessing various advancements and innovations. Here, we briefly outline its evolution:

1950s-1960s: The earliest development of the encapsulator machine occurred during this period. It involved manual encapsulation processes where gelatin capsules were filled by hand, which was a tedious and time-consuming task.

1970s-1980s: Automatic encapsulation machines emerged, replacing the manual labor-intensive process. These early models utilized a single dosing station and a rotating disc system to fill and seal capsules. Although more efficient, these machines were limited in terms of speed and precision.

1990s: With the advancement of technology, encapsulator machines underwent significant improvements. Computerized controls were introduced, allowing for better accuracy and control in the encapsulation process. These machines became more versatile and could handle a variety of capsule sizes and materials.

Early 2000s: The demand for efficient production led to the development of high-speed encapsulator machines. These machines incorporated multiple dosing stations with improved filling mechanisms, enabling them to achieve higher production rates. They also featured advanced sensors and monitoring systems to ensure product quality.

Mid-2000s: Encapsulator machines became more adaptable to changing industry needs. Manufacturers began incorporating innovative features like automatic capsule sorting, electronic monitoring of dosage weight, and enhanced safety mechanisms. The introduction of servo motors increased precision, consistency, and reduced downtime.

Present: The latest encapsulator machines continue to evolve with cutting-edge technology. They employ advanced control systems to ensure accurate dosing and precise capsule filling. The use of artificial intelligence and machine learning algorithms enables error detection, predictive maintenance, and automatic adjustment of various parameters. The machines are designed to have a smaller footprint, enhanced operator interface, and increased automation for higher productivity.

In conclusion, from the early manual processes to the current technologically advanced systems, the evolution of encapsulator machines has greatly improved the efficiency, speed, and precision of capsule production. This continuous development ensures the pharmaceutical industry can meet the increasing demands of consumers worldwide.

The Evolution and Market Trends in encapsulator machine Industry

The encapsulator machine industry has witnessed significant evolution and market trends in recent years. These machines are widely used in the pharmaceutical and nutraceutical industries for encapsulating active ingredients into capsules, ensuring accurate dosing and easy consumption. In line with increasing demand for health supplements and medications, the encapsulator machine market has experienced rapid growth.

One key evolution in this industry is the development of advanced technologies in encapsulator machines. Manufacturers are now incorporating features such as automated dosing, in-line quality control, and high-speed production capabilities. These advancements have enabled pharmaceutical and nutraceutical companies to meet the growing demand for their products and streamline their manufacturing processes. Additionally, integration of digital interfaces and smart systems has enhanced efficiency and reduced human errors in operation.

Market trends in the encapsulator machine industry reflect the changing needs and preferences of pharmaceutical and nutraceutical manufacturers. Firstly, there is a growing demand for versatile encapsulator machines that can handle different capsule sizes and materials. This allows companies to diversify their product offerings and cater to various customer requirements. Furthermore, the industry has observed an increasing preference for machines that offer higher production capacity, ensuring faster turnaround times and meeting high-volume orders.

Another trend is the demand for encapsulator machines with easy-to-clean and maintenance-friendly designs. Manufacturers are now investing in machines that minimize downtime for cleaning and maintenance processes, optimizing overall productivity. This trend is also driven by the need for strict adherence to hygiene and cGMP (current Good Manufacturing Practice) regulations.

Moreover, the industry is witnessing a shift towards sustainable practices and technologies. Encapsulator machine manufacturers are now focusing on developing machines that consume less energy, produce minimal waste, and adopt eco-friendly materials. This aligns with the growing awareness and commitment of pharmaceutical and nutraceutical companies towards sustainability and environmental responsibility.

In conclusion, the encapsulator machine industry has evolved significantly to meet the changing demands of the pharmaceutical and nutraceutical sectors. Advanced technologies, versatile capabilities, and sustainable practices are shaping the market trends in this industry. Manufacturers are continuously striving to improve efficiencies, enhance product quality, and offer innovative solutions, driving the growth and expansion of the encapsulator machine market.

Custom Private Labeling and Branding Opportunities with Chinese encapsulator machine Manufacturers

Chinese encapsulator machine manufacturers offer excellent opportunities for custom private labeling and branding. These manufacturers specialize in producing encapsulator machines, which are widely used in the pharmaceutical, nutraceutical, and food industries.

Custom private labeling allows businesses to have their own branding and logo on the encapsulator machines they purchase. This branding creates a unique identity for the product, helping businesses establish their presence in the market and differentiate themselves from competitors. Chinese manufacturers understand the importance of branding and can provide customized options to meet specific requirements.

Chinese encapsulator machine manufacturers are known for their advanced technology and cost-effective production. They can offer competitive prices without compromising quality, making them an attractive option for businesses looking to expand their product range or enter new markets. With their vast manufacturing capabilities, these manufacturers can handle large-scale production as well as smaller orders, providing businesses with flexibility and convenience.

Furthermore, Chinese manufacturers are experienced in exporting products worldwide and understand the regulatory requirements of different markets. They can provide necessary certifications and documentation to ensure compliance with international standards and regulations, facilitating a smooth import process for businesses.

In conclusion, Chinese encapsulator machine manufacturers present lucrative opportunities for custom private labeling and branding. With their advanced technology, competitive pricing, and expertise in international exporting, businesses can leverage these manufacturers to create their unique identity and expand their product offerings in a cost-effective manner.

Tips for Procurement and Considerations when Purchasing encapsulator machine

When purchasing an encapsulator machine for procurement, there are several considerations that should be taken into account. Here are some tips and considerations to help you make an informed decision:

1. Determine your needs: Assess your production requirements, the volume of capsules you need to produce, and the type of capsules you plan to manufacture. Understanding your needs will help you choose the right machine with the appropriate capacity.

2. Quality and reliability: Look for a reputable manufacturer with a proven track record in producing high-quality encapsulator machines. Read reviews and seek recommendations from trusted sources to ensure reliability and durability of the machine.

3. Cost-effectiveness: Consider the price of the machine, but also evaluate the long-term costs associated with its operation and maintenance. Look for a machine that provides good value for money and offers a reasonable return on investment.

4. Ease of use and versatility: Opt for a machine that is user-friendly, easy to operate, and offers flexibility in terms of capsule sizes and materials. This will allow you to adapt to changing market demands and increase your production capabilities.

5. After-sales support and warranty: Ensure that the manufacturer offers comprehensive after-sales support, including training, technical assistance, and spare parts availability. A warranty should also be provided to protect you against any defects or malfunctions.

6. Safety and compliance: Check if the machine meets all necessary safety standards and regulatory requirements. It should be designed to prevent accidents and comply with industry regulations to ensure the safety of operators and consumers.

7. Efficiency and productivity: Look for features that enhance the efficiency of the machine, such as automated capsule filling processes, high-capacity hoppers, and advanced control systems. These features can significantly increase productivity and reduce downtime.

8. Maintenance requirements: Consider the maintenance needs of the machine and evaluate if your team has the necessary expertise and resources to handle it. Regular maintenance is crucial to ensure optimal performance and longevity of the encapsulator machine.

9. Future growth: Assess the scalability of the machine and its ability to accommodate your future business growth. You may want to choose a machine that can be easily upgraded or expanded to match your evolving needs.

10. Consider customer reviews and testimonials: Research and read reviews or testimonials from existing customers to get a better understanding of their experience with the machine and the manufacturer.

By taking these considerations into account, you can make an informed decision when purchasing an encapsulator machine that best fits your requirements, budget, and future business goals.

FAQs on Sourcing and Manufacturing encapsulator machine in China

Q: What is an encapsulator machine?

A: An encapsulator machine is a device used in the pharmaceutical and nutraceutical industries to encapsulate powders or liquids into capsules.

Q: Why source and manufacture encapsulator machines in China?

A: China is known as the world’s manufacturing hub, offering cost-effective solutions for various industries. It has a well-established infrastructure, skilled labor force, and numerous factories specializing in machinery manufacturing.

Q: How can I find a reliable encapsulator machine manufacturer in China?

A: There are several ways to find reliable manufacturers in China. Some options include attending trade shows, searching online B2B platforms, using sourcing agents, or seeking recommendations from industry professionals.

Q: What factors should I consider when sourcing an encapsulator machine from China?

A: Some key factors to consider include the manufacturer’s reputation, quality control measures, compliance with international standards, customization options, pricing, after-sales service, and lead times.

Q: Can I customize an encapsulator machine according to my specific requirements?

A: Yes, most Chinese manufacturers offer customization services to tailor the encapsulator machine to your specific needs. Ensure clear communication with the manufacturer regarding your requirements and specifications.

Q: Are Chinese encapsulator machines of good quality?

A: While quality can vary, there are many reputable Chinese manufacturers producing high-quality encapsulator machines that meet international standards. Conduct thorough research, request product samples or visit the manufacturer’s facility to assess the quality standards.

Q: What is the typical lead time for manufacturing an encapsulator machine in China?

A: Lead times can vary depending on the manufacturer and machine complexity. Generally, it takes around 4-6 weeks for production, while larger orders or customized machines may take longer.

Q: Can I visit the manufacturing facility in China before placing an order?

A: Yes, it is advisable to visit the manufacturing facility to inspect the manufacturer’s capabilities, quality control procedures, and to ensure their legitimacy. This will help build trust and establish a stronger supplier relationship.

Q: What are the payment terms when sourcing encapsulator machines from China?

A: Payment terms can vary between manufacturers, but common options include a down payment (30-50% of the total amount) upon order confirmation, with the remaining balance paid before shipment or upon receipt.

In conclusion, China offers a wide range of reliable encapsulator machine manufacturers. Thorough research, due diligence, and effective communication are crucial during the sourcing process to ensure the best possible outcome in terms of quality, customization, pricing, and lead times.

Why contact sourcifychina.com get free quota from reliable encapsulator machine suppliers?

Sourcifychina.com offers a platform for businesses to connect with reliable encapsulator machine suppliers in China. By partnering with these suppliers, sourcifychina.com is able to secure exclusive benefits such as free quota. There are a few reasons why contact sourcifychina.com receives this free quota from reliable encapsulator machine suppliers.

Firstly, sourcifychina.com acts as a trusted intermediary between the suppliers and businesses looking to source encapsulator machines. By consolidating the sourcing process, sourcifychina.com provides a reliable platform for suppliers to showcase their products and services. This reduces the suppliers’ marketing efforts and costs, making it beneficial for them to provide free quota as an incentive.

Additionally, sourcifychina.com has built strong relationships and partnerships with various encapsulator machine suppliers over time. By consistently bringing in high-quality leads and potential customers, sourcifychina.com proves their value and importance to the suppliers. As a result, the suppliers are more willing to offer free quota as a way to maintain and strengthen their partnership with sourcifychina.com.

Moreover, providing free quota to contact sourcifychina.com helps encapsulator machine suppliers to expand their customer base and generate more sales. Sourcifychina.com offers a large database of businesses looking to source encapsulator machines, and by offering free quota, the suppliers can reach a wider range of potential customers. This not only benefits the suppliers but also ensures a diverse range of options for businesses, fostering a competitive market.

In conclusion, sourcifychina.com obtains free quota from reliable encapsulator machine suppliers due to its role as a trusted intermediary, its established partnerships, and its ability to bring in potential customers. This mutually beneficial arrangement allows businesses to source encapsulator machines efficiently while suppliers can expand their reach and generate more sales.