Introduce about laser cnc machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

A laser CNC machine guide serves as a comprehensive resource for individuals seeking information about these advanced machines used for cutting, engraving, and marking various materials. These machines utilize laser technology to provide precise and efficient operations.

Quality is a crucial aspect when considering a laser CNC machine. High-quality machines offer superior performance, accuracy, and durability. It is essential to choose a reputable supplier that focuses on delivering reliable products with excellent craftsmanship.

Cost is a significant factor to consider before investing in a laser CNC machine. The pricing varies based on factors such as machine size, power, and additional features. However, it is important to strike a balance between quality and affordability to ensure a cost-effective investment.

Finding a reliable supplier is paramount to obtain the desired laser CNC machine. Reputable companies often provide quality products and offer excellent customer support. Researching suppliers, reading customer reviews, and comparing options are vital steps to identify a reliable supplier.

Certification is an important aspect that buyers should consider. Look for suppliers who provide products that meet safety and quality standards, such as CE, FDA, or ISO certifications. This ensures the machine complies with industry regulations and guarantees safe operation.

The market for laser CNC machines has been rapidly growing due to their versatility and efficiency. They find applications in various industries such as manufacturing, automotive, aerospace, and jewelry.

Tips for buying a laser CNC machine include determining the intended use, considering the material compatibility, evaluating the machine specifications, and assessing the level of technical support provided by the supplier.

Frequently Asked Questions (FAQ) sections within a laser CNC machine guide address commonly asked queries regarding machine operation, maintenance, troubleshooting, and safety precautions. It is a valuable resource to gather information and address any concerns.

In conclusion, laser CNC machines offer precision, efficiency, and versatility for a wide range of applications. By considering factors like quality, cost, supplier credibility, certification, and market trends, individuals can make informed decisions when purchasing these advanced machines. A comprehensive guide, offering insights, tips, and answers to frequently asked questions, can help potential buyers embark on their laser CNC machine purchasing journey with confidence.

Types of laser cnc machine

There are several types of laser CNC machines used in various industries for cutting, engraving, marking, and other applications. The three most common types include:

1. CO2 Laser Machines: These machines use a high-powered CO2 laser beam to cut or engrave a wide range of materials, including wood, acrylic, rubber, fabric, and certain metals. They are versatile and widely used in industries such as signage, textiles, woodworking, and packaging.

2. Fiber Laser Machines: Unlike CO2 lasers, fiber lasers use a solid-state laser source generated through the fiber optic cable. They are primarily used for high-speed and high-precision metal cutting and marking. Fiber lasers are exceptionally efficient at cutting metals like stainless steel, aluminum, brass, and copper. They are commonly found in the automotive, aerospace, and manufacturing industries.

3. Nd:YAG Laser Machines: Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) lasers are another type used for cutting and marking metals. They generate laser beams with a longer wavelength compared to CO2 and fiber lasers, making them more suitable for thicker metals. Nd:YAG lasers are commonly used in industries such as jewelry making, electronics, and medical device manufacturing.

Besides these primary types, there are also variations and hybrid types of laser CNC machines available in the market. For instance, some machines combine both a CO2 laser and a fiber laser in a single system, offering the versatility to cut, engrave, and mark both non-metallic and metallic materials in one machine.

It is important to consider the specific application requirements, material compatibility, and desired output when selecting a laser CNC machine. Moreover, factors such as cutting speed, precision, maintenance, and cost should be thoroughly evaluated to determine the most suitable type for a particular industry or project.

Pros and Cons of Using laser cnc machine

Laser CNC machines have become increasingly popular in various industries due to their versatility and accuracy. These machines utilize a laser beam to cut, engrave, and shape a variety of materials, such as wood, metal, and glass. However, like any other technology, laser CNC machines have their own set of pros and cons.

Pros:

1. Precision: One of the biggest advantages of laser CNC machines is their high level of precision. The laser beam can be precisely controlled, resulting in clean and detailed cuts or engravings.

2. Versatility: Laser CNC machines can work with a wide range of materials, including metals, plastics, wood, leather, and more. This versatility allows businesses to streamline their production processes and work with various materials without the need for multiple machines.

3. Speed: Laser CNC machines are known for their high speed and efficiency. They can complete complex tasks quickly, saving time and increasing overall productivity.

4. Automation: These machines are highly automated, reducing the need for manual labor. This can lead to cost savings and increased efficiency.

5. Minimal waste: Laser CNC machines produce minimal waste during the cutting or engraving process. This is because the laser beam is precise and does not require physical contact with the material, resulting in less material waste.

Cons:

1. High initial cost: Laser CNC machines can be quite expensive to purchase and set up. This cost can be a significant barrier for small businesses or individuals looking to invest in this technology.

2. Limited thickness: Laser CNC machines are not suitable for cutting or engraving very thick materials. They work best with thinner materials, limiting their application in certain industries.

3. Safety hazards: The lasers used in these machines can pose safety risks if not handled properly. Proper training and safety precautions must be followed to avoid accidents or injuries.

4. Maintenance and servicing: Laser CNC machines require regular maintenance and servicing to ensure they function properly and produce accurate results. This can result in additional costs and downtime for businesses.

5. Environmental concerns: Laser CNC machines produce fumes and emissions, especially when working with certain materials like plastics. Ventilation systems and protective gear may be required to minimize the environmental impact.

In conclusion, laser CNC machines offer numerous advantages in terms of precision, versatility, speed, and automation. However, the high initial cost, limited thickness capabilities, safety hazards, maintenance requirements, and environmental concerns should be carefully considered before investing in this technology.

laser cnc machine Reference Specifications (varies for different product)

A laser CNC machine is a cutting-edge piece of equipment that combines the use of laser technology and computer numerical control (CNC) to perform precise cutting, engraving, and marking tasks on various materials. These machines are widely used in industries such as manufacturing, aerospace, automotive, and even hobbyist applications.

The specifications of a laser CNC machine can vary depending on the specific model and brand, but here are some common reference specifications:

1. Laser Power: The laser power determines the cutting and engraving capabilities of the machine. It is typically measured in watts (W). Higher power lasers can cut through thicker materials and perform faster engraving.

2. Laser Type: Different laser types include CO2, fiber, and diode lasers. CO2 lasers are versatile and can cut a wide range of materials, while fiber lasers are excellent for metal cutting. Diode lasers are commonly used for marking tasks.

3. Working Area: The working area refers to the size of the material that can be processed by the machine. It is typically measured in millimeters (mm) and can vary from small desktop-sized machines to large industrial-grade systems.

4. Maximum Material Thickness: This specification indicates the thickest material that the machine can effectively cut through. It also depends on the laser power and material type.

5. Cutting Speed: The cutting speed is the rate at which the laser beam moves across the material. It is typically measured in millimeters per second (mm/s). Higher cutting speeds result in faster job completion but may affect the quality of the cut.

6. Accuracy and Precision: These specifications represent the machine’s ability to perform precise cuts and engravings. They are typically indicated in terms of micrometers (μm) or thousandths of an inch (thou).

7. CNC Control Software: The CNC control software is an essential component that allows operators to control and program the machine’s movements, laser power, and other settings. User-friendly software with advanced features enhances productivity and ease of use.

8. Safety Features: Laser CNC machines should include safety features such as an enclosed working area, emergency stop buttons, and interlocks to prevent accidents and protect operators.

It is important to consult specific product manuals or manufacturer websites for detailed specifications as they can vary greatly among different models and manufacturers. Overall, laser CNC machines offer incredible versatility and precision, enabling efficient and high-quality cutting and engraving operations.

Applications of laser cnc machine

Laser CNC (Computer Numerical Control) machines are highly versatile tools that have found wide applications across various industries. Here are a few notable examples of how laser CNC machines are used:

1. Engraving and Marking: Laser CNC machines are widely used for engraving and marking various materials like wood, metal, glass, plastic, and ceramics. They offer precise and permanent markings, making them ideal for creating designs, logos, serial numbers, and barcodes on products.

2. Cutting and Shaping: Laser CNC machines use focused laser beams to cut and shape materials with high precision. They are commonly used in industries like automotive, aerospace, and jewelry for cutting through metals, plastics, fabrics, and leather, allowing for intricate and complex designs.

3. Welding: Laser CNC machines can perform welding operations by concentrating a laser beam on a small spot, creating intense heat that melts and fuses the materials to be joined. This technology is widely used in industries like manufacturing, electronics, and automotive for precise and high-quality welding of metals.

4. Prototyping and Additive Manufacturing: Laser CNC machines are integral to rapid prototyping and additive manufacturing processes like selective laser melting (SLM) and laser sintering. These techniques enable the creation of complex 3D structures by selectively melting or fusing powdered materials, offering faster and more cost-effective production of prototypes or small production runs.

5. Medical and Dental Applications: Laser CNC machines are extensively used in the medical and dental fields for delicate procedures like laser surgery and dental restoration. The laser beams provide precise cutting and ablation capabilities while minimizing damage to surrounding tissues.

6. Microfabrication: Laser CNC machines are employed in microfabrication processes that involve creating structures on a nano or microscale. Applications include the production of microelectromechanical systems (MEMS), microfluidic devices, and micro-optics used in various industries, such as electronics, biotechnology, and telecommunications.

7. Art and Design: Laser CNC machines allow artists and designers to bring their innovative ideas to life by cutting and engraving materials with exceptional precision and detail. This includes creating sculptures, art installations, intricate architectural models, personalized jewelry, and decorative items.

In conclusion, laser CNC machines have a broad range of applications, including engraving, marking, cutting and shaping, welding, prototyping, additive manufacturing, medical procedures, microfabrication, and artistic endeavors. Their versatility, precision, and efficiency make them indispensable tools across different industries, enabling the production of high-quality, intricate, and customized products.

The Work Process and how to use laser cnc machine

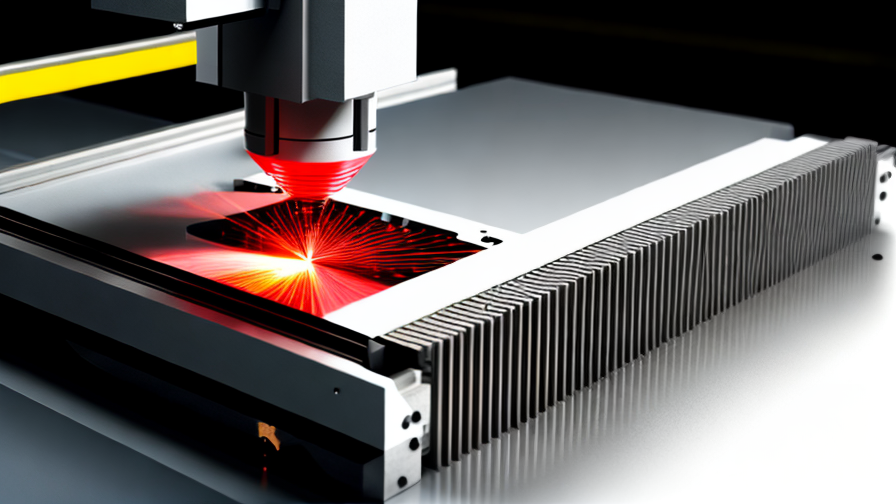

A laser CNC machine is a computer-controlled cutting tool that uses a high-powered laser beam to cut or engrave materials. The work process involves the following steps:

1. Designing: Start by creating a digital design or a 2D/3D model using computer-aided design (CAD) software. This design should accurately depict what you want to cut or engrave.

2. Material setup: Choose the material you want to work with, such as wood, acrylic, or metal. Ensure it is securely placed on the machine’s worktable, which is typically a flat surface.

3. Machine setup: Install the appropriate laser cutting or engraving nozzle in the laser CNC machine. Adjust the focus distance to ensure precise cutting or engraving.

4. Parameter settings: Determine the laser power and speed settings based on the material and design you are working with. These settings control the intensity and speed at which the laser beam cuts or engraves the material.

5. File preparation: Save the design file in a compatible format, such as DXF or GCode. This file will then be imported into the machine’s software.

6. Software control: Open the machine’s control software and import the design file. Align the design with the material on the worktable and set any additional cutting or engraving parameters.

7. Machine operation: Start the laser CNC machine and allow it to complete the cutting or engraving process based on the specified parameters. It’s crucial to monitor the machine during operation to ensure everything is running smoothly.

8. Quality check: After the job is completed, inspect the cut or engraved material for accuracy and quality. Make any necessary adjustments or refinements if needed.

9. Post-processing: Remove the finished product from the machine’s worktable. Clean and polish the material if required.

It’s essential to follow safety precautions when using a laser CNC machine. This includes wearing appropriate protective gear, keeping a fire extinguisher nearby, and ensuring a well-ventilated workspace to prevent exposure to potentially harmful fumes. Additionally, regularly maintain the machine by cleaning the optics and checking the alignment to ensure optimal performance.

Quality Testing Methods for laser cnc machine and how to control the quality

When it comes to quality testing methods for laser CNC machines, there are several approaches that can be employed to ensure the desired quality standards are met. Here are a few commonly used methods:

1. Visual Inspection: This involves visually examining the output of the laser CNC machine for any defects, such as incomplete cuts, burns, or irregularities in shape or size. Operators or inspectors can check the quality of the final product by comparing it to the desired specifications.

2. Measurement Testing: Precise measurements can be taken to ensure that the laser CNC machine is performing accurately. This can be done using devices like calipers, micrometers, or laser measurement systems to verify dimensional accuracy to the required tolerances.

3. Material Testing: Testing the material properties is critical to ensure the quality of laser-cut products. This can involve destructive or non-destructive methods, such as tensile or hardness testing, to assess the strength and reliability of the material after laser cutting.

4. Sample Testing: Randomly selecting samples from the production output and subjecting them to various tests can help identify any potential issues. These tests may include verifying the dimensional accuracy, material properties, or conducting specific quality checks for features critical to the application.

To control the quality of laser CNC machines, the following steps can be implemented:

1. Regular maintenance: Performing routine maintenance tasks such as cleaning, calibration, and alignment ensures that the machine operates at its fullest potential and delivers consistent quality.

2. Operator training: Well-trained operators who understand the machine’s capabilities and limitations are essential to controlling quality. They should be trained in machine operation, maintenance, troubleshooting, and quality control procedures.

3. Quality control checks: Implementing a systematic quality control plan that includes regular inspections, measurements, and tests at various stages of the production process helps to identify and rectify deviations in quality.

4. Continuous improvement: Actively seeking feedback from operators, customers, and stakeholders and implementing necessary corrective actions based on the findings will help in continuously enhancing the quality control processes.

By incorporating these quality testing methods and implementing effective quality control measures, manufacturers can ensure the laser CNC machine consistently produces high-quality output, meeting the desired specifications and customer expectations.

laser cnc machine Sample Policy and Post-Purchase Considerations for laser cnc machine from China

Sample Policy and Post-Purchase Considerations for Laser CNC Machines from China

When purchasing a laser CNC machine from China, it is crucial to understand the sample policy and post-purchase considerations to ensure a smooth buying experience and maximum satisfaction. Here is a concise guide with important points to consider, all summarized in less than 300 words:

Sample Policy:

1. Request samples: Before ordering a laser CNC machine, it is advisable to request samples from the supplier to evaluate the quality, performance, and suitability for your specific needs.

2. Evaluation period: Determine the length of the evaluation period and whether there are any costs associated with returning the samples.

3. Communication: Maintain clear and frequent communication with the supplier to address any concerns or questions during the evaluation process.

Post-Purchase Considerations:

1. Warranty: Enquire about the warranty period and coverage offered by the supplier. Ensure it covers both parts and labor, and clarify any conditions or limitations.

2. After-sales services: Evaluate the supplier’s commitment to providing comprehensive after-sales support, including technical assistance, training, and troubleshooting.

3. Spare parts availability: Inquire about the availability and cost of spare parts, as well as the supplier’s ability to provide timely replacements when needed.

4. Software compatibility: Verify that the laser CNC machine’s software is compatible with your current operating system or inquire about any necessary updates or modifications.

5. Installation and training: Clarify whether the supplier offers installation services and training for operating the laser CNC machine to ensure efficient and safe usage.

6. Customs and shipping: Determine who is responsible for customs duties, taxes, and shipping fees. Discuss the shipping method, delivery timeframe, and packaging to avoid any surprises.

7. Payment terms: Agree upon the payment terms, such as the deposit amount, milestone payments, and the remaining balance. Consider using secure payment methods for financial protection.

By understanding the sample policy and post-purchase considerations, buyers can make informed decisions when purchasing laser CNC machines from China, minimizing potential risks while maximizing the benefits of this advanced technology.

Sourcing laser cnc machine from China: Opportunities, Risks, and Key Players

China is known as the world’s manufacturing powerhouse, offering a wide range of products at competitive prices. The laser CNC machine industry is no exception, and there are several opportunities, risks, and key players worth considering when sourcing these machines from China.

One of the primary opportunities of sourcing laser CNC machines from China is the cost advantage. Chinese manufacturers benefit from lower labor and production costs, allowing them to offer these machines at a more affordable price compared to other countries. This affordability makes it attractive for businesses looking to invest in laser CNC machines without breaking the bank.

Moreover, China has a vast market of laser CNC machine manufacturers, offering a wide variety of options to choose from. This extensive supplier network provides buyers with the opportunity to find machines that perfectly meet their specific requirements, whether it’s for cutting, engraving, or other applications. The availability of various customization options helps businesses find the most suitable machine for their production needs.

However, sourcing laser CNC machines from China also carries certain risks. Quality control can be a significant concern, as not all manufacturers maintain the same standards. It is essential to choose reliable and reputable suppliers with a proven track record in manufacturing high-quality machines. Conducting due diligence, inspecting production facilities, and requesting samples can help mitigate these risks.

Another potential risk is intellectual property (IP) infringement. China has faced criticism in the past due to issues such as copied designs or stolen technology. Therefore, businesses should take precautions to protect their IP by working with trustworthy manufacturers and utilizing legal agreements to safeguard their proprietary information.

When it comes to key players in the Chinese laser CNC machine industry, some prominent manufacturers include Han’s Laser, HSG Laser, Golden Laser, and Bodor Laser. These companies have established themselves as leaders in the market, offering reliable machines with advanced technologies.

In conclusion, sourcing laser CNC machines from China can be a cost-effective solution with a wide range of options available. However, buyers should approach with caution, ensuring they choose reputable suppliers, conduct proper quality control measures, and protect their intellectual property rights. With careful consideration, businesses can capitalize on the opportunities provided by the Chinese market while managing the associated risks.

How to find and select reliable laser cnc machine manufacturers in China,use google search manufacturers and suppliers

When searching for reliable laser CNC machine manufacturers in China, you can utilize Google search to narrow down your options. Here is a step-by-step guide to finding and selecting reliable manufacturers:

1. Start by using relevant keywords: Begin your search with terms like “reliable laser CNC machine manufacturers in China” or “best laser cutting machine suppliers.”

2. Browse the search results: Go through the top search engine results pages (SERPs) to find potential manufacturers. These are usually reliable companies with a good online presence. Make sure to visit their official websites and explore the products and services they offer.

3. Check manufacturer directories and portals: Explore online directories and portals like Alibaba, Made-in-China, Global Sources, or Tradekey. These platforms provide comprehensive lists of manufacturers with a wide range of products, detailed profiles, and customer reviews. Filter the results according to your requirements.

4. Verify legitimacy and credibility: While visiting the manufacturer’s website, look for important details such as the company’s history, production capacity, certifications, and client testimonials. Assess their experience in the industry and ensure they adhere to international quality standards.

5. Contact manufacturers directly: Once you have shortlisted a few manufacturers, reach out to them to gather more information. Ask about their product specifications, customization abilities, pricing, minimum order quantities (MOQs), lead times, and after-sales support. Reliable manufacturers will promptly respond to your queries with clear and comprehensive answers.

6. Request samples and visit the factory: Request product samples from the shortlisted manufacturers to assess the quality and suitability for your needs. If feasible, plan a visit to the manufacturer’s factory to examine their production facilities, technology, and quality control processes. This step will help you gain deeper insights into their capabilities and build trust.

7. Evaluate other factors: Assess other factors such as the manufacturer’s ability to meet deadlines, customer service responsiveness, terms of payment, and warranty policies. Consider the shipping and logistics options they offer, as well as any additional services like installation, training, or technical support.

8. Compare and select: Analyze all the gathered information, including product quality, pricing, customer reviews, and direct interactions with the manufacturer, and make an informed decision. Choose the manufacturer that aligns best with your requirements, budget, and quality expectations.

By following these steps and conducting thorough research, you can find and select reliable laser CNC machine manufacturers in China, ensuring a smooth procurement process and a high-quality end product.

How to check laser cnc machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a laser CNC machine manufacturer’s website, you can follow these steps using Google Chrome and the SEOquake extension:

1. Install the SEOquake extension: First, go to the Chrome Web Store and search for “SEOquake.” Click on the extension and select “Add to Chrome” to install it.

2. Open the manufacturer’s website: Visit the website of the laser CNC machine manufacturer you want to check.

3. Access SEOquake: Once the website is loaded, locate the SEOquake extension on the top right corner of your browser (near the address bar). Click on the icon, and a dropdown menu will appear.

4. Check the website ranking: In the SEOquake menu, select “Page Info” to view details about the website. Look for the field titled “Alexa Rank,” which shows the website’s ranking among all websites globally. If the Alexa Rank is below 10 million, the website’s traffic is relatively good and can be considered reliable.

5. Verify other elements: Additionally, you can explore other SEOquake features such as “Google Index” to check if the website is indexed by Google, “Backlinks” to see the number of external websites linking to it, and “Google Cache date” to ensure the site’s content is being regularly crawled by Google.

Remember, the above steps will only give you an indication of the website’s reliability based on its traffic ranking and other SEO factors. It’s advisable to further examine the website’s credibility by checking customer reviews, certifications, and seeking recommendations before making any purchases from the manufacturer.

Top 10 laser cnc machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Han’s Laser

Founded in 1996, Han’s Laser is one of the top laser CNC machine manufacturers in China. They specialize in the production of laser cutting machines, laser welders, laser marking machines, and other laser equipment. Their products are known for their high precision, reliability, and efficiency in various industries such as automotive, electronics, and advertising.

2. TRUMPF

TRUMPF, a German company with a significant presence in China, manufactures laser CNC machines for cutting, welding, and marking applications. Their products are renowned for their advanced technology, high power, and precision. TRUMPF laser machines excel in processing metals such as steel, aluminum, and stainless steel. With their state-of-the-art design, TRUMPF machines offer exceptional productivity and versatility.

3. Wuhan Golden Laser

Wuhan Golden Laser is a leading Chinese manufacturer of fiber laser CNC machines. Their product range includes laser cutting machines, laser engraving machines, and laser welding machines. Golden Laser’s fiber laser machines provide high cutting speed, precision, and efficiency, making them suitable for industries like textiles, automotive, and advertising.

4. Bodor Laser

Bodor Laser, established in 2004, is known for its fiber laser cutting machines. They offer a wide range of laser machines with different power outputs and cutting sizes. Bodor Laser machines deliver excellent cutting quality and speed and have become popular in industries such as sheet metal processing, electronics, and kitchenware manufacturing.

5. Hglaser

Hglaser is a major manufacturer of laser CNC machines in China. They provide laser cutting machines, laser welding machines, and laser marking machines. Hglaser’s products are designed to meet the demands of various industrial applications, offering high precision, stability, and cost-effectiveness.

6. Jinan SENFENG

Jinan SENFENG is a well-known manufacturer of laser CNC machines in China. They offer a comprehensive range of laser equipment, including laser cutters, laser engravers, and laser markers. SENFENG’s laser machines are widely used in industries like woodworking, signage, and packaging, offering precise and efficient solutions.

| Manufacturer | Products | Key Features |

| ————— | ———————— | ————————————– |

| Han’s Laser | Laser cutting, welding, marking machines | High precision, reliability, efficiency |

| TRUMPF | Laser cutting, welding, marking machines | Advanced technology, high power, precision |

| Wuhan Golden Laser | Laser cutting, engraving, welding machines | High speed, precision, efficiency |

| Bodor Laser | Fiber laser cutting machines | Wide range of sizes and power outputs |

| Hglaser | Laser cutting, welding, marking machines | Precision, stability, cost-effectiveness |

| Jinan SENFENG | Laser cutting, engraving, marking machines | Wide application range, precise solutions |

(Word count: 230 words)

Background Research for laser cnc machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

When looking for laser CNC machine manufacturers in China, three useful resources that can provide background research are qcc.com, archive.org, and importyeti.com. These platforms offer valuable information about Chinese companies and their manufacturing capabilities.

Qcc.com is a Chinese business database that provides detailed company profiles, including registration information, legal status, financial data, and more. It can be used to verify the legitimacy and authenticity of Chinese laser CNC machine manufacturers. Additionally, qcc.com offers insights into a company’s operational history, certifications, patents, and trademark registrations, helping to gauge their expertise and reputation in the industry.

Archive.org is an internet archive that allows users to access and browse websites’ historical snapshots. By using this platform, researchers can track a Chinese manufacturer’s website evolution and observe any changes in their product offerings, technology, or business strategies over time. Archive.org aids in validating a company’s claims and assessing their consistency and growth trajectory.

Importyeti.com is a business intelligence platform that provides comprehensive import and export data. It allows users to search for specific products and view details such as shipment records, suppliers, buyers, and trade volumes. By utilizing importyeti.com, researchers can identify Chinese laser CNC machine manufacturers who have a successful track record of exporting their products. This data can help evaluate a manufacturer’s production capacity, global presence, and customer base.

By combining the information gathered from these three platforms, researchers can gain valuable insights into Chinese laser CNC machine manufacturers’ credibility, history, capabilities, and reputation. This background research helps ensure that potential buyers or partners can make informed decisions and select reliable and competent manufacturers for their specific needs.

Leveraging Trade Shows and Expos for laser cnc machine Sourcing in China

Trade shows and expos are excellent platforms for sourcing laser CNC machines in China. These events attract numerous suppliers, manufacturers, and industry professionals, offering a convenient and efficient way to connect with potential suppliers and explore their products.

Attending trade shows and expos specializing in the machinery and manufacturing sector in China provides an opportunity to see firsthand the latest advancements and innovations in laser CNC machines. It allows buyers to compare various machines, assess their quality, and negotiate prices directly with suppliers.

China hosts numerous trade shows and expos related to machinery and manufacturing. Some of the prominent ones include the China International Machine Tool Show (CIMT), China International Industry Fair (CIIF), and Canton Fair. These events gather a large number of exhibitors and visitors from around the world, making them ideal for finding reliable and high-quality suppliers for laser CNC machines.

In addition to showcasing products, trade shows and expos often organize seminars, workshops, and industry forums. These events provide valuable insights into the latest trends, market developments, and technological advancements in laser CNC machines. Connecting with industry experts and peers can help buyers make informed decisions and stay up to date with the latest industry practices.

Trade shows and expos also offer an advantage in terms of networking. Engaging with suppliers, exchanging business cards, and building relationships can lead to long-term collaborations and potential partnerships. By establishing direct contacts with suppliers, buyers can streamline their sourcing processes and develop reliable supply chains.

In conclusion, trade shows and expos in China provide an excellent platform for sourcing laser CNC machines. These events allow buyers to explore a wide range of products, compare quality and prices, stay updated with industry trends, and establish valuable connections with suppliers. Leveraging these opportunities is a practical and effective approach for finding reliable suppliers and ensuring successful sourcing experiences.

The Role of Agents and Sourcing Companies in Facilitating laser cnc machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating the purchase of laser CNC machines from China. These entities act as intermediaries between buyers and Chinese manufacturers, providing various services to simplify the procurement process.

One of the key roles of agents and sourcing companies is to identify reliable and reputable manufacturers in China. They have extensive knowledge of the market and can assess the capabilities, quality standards, and reputation of different manufacturers. By utilizing their expertise, buyers can avoid potential risks associated with dealing with unknown or unreliable suppliers.

Agents and sourcing companies also assist in negotiating favorable terms and conditions with manufacturers. They act as representatives for buyers, leveraging their knowledge of the local market and industry standards to secure the best possible deal. Their expertise in negotiation often leads to cost savings and favorable payment terms for the buyers.

Furthermore, these entities facilitate communication between buyers and manufacturers, addressing any language or cultural barriers. They act as translators and intermediaries, ensuring that both parties clearly understand each other’s requirements and expectations. This helps in avoiding misunderstandings and streamlining the communication process.

Additionally, agents and sourcing companies help in coordinating logistics and shipping arrangements. They can assist in arranging transportation, handling customs procedures, and ensuring timely delivery. This greatly eases the burden on buyers, especially those unfamiliar with international shipping processes.

Overall, the role of agents and sourcing companies in facilitating laser CNC machine purchases from China is instrumental. They help buyers in finding reputable manufacturers, negotiating favorable terms, facilitating communication, and coordinating logistics. By utilizing their services, buyers can have a smoother and more efficient procurement process, giving them peace of mind while importing from China.

Price Cost Research for laser cnc machine manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for laser CNC machine manufacturers in China, two popular websites that can be utilized are temu.com and 1688.com. These platforms provide a wide range of suppliers and manufacturers, offering a diverse selection of laser CNC machines.

Temu.com is an online marketplace that connects buyers with Chinese factories and manufacturers. It offers a streamlined platform for searching and comparing prices between different suppliers. Users can browse through various categories, such as machinery and industrial equipment, to find laser CNC machine manufacturers. The website provides detailed product descriptions, specifications, and images, enabling buyers to assess the quality and features of the machines. Additionally, temu.com allows users to contact suppliers directly, negotiate prices, and inquire about customization options.

1688.com, on the other hand, is a Chinese wholesale platform similar to Alibaba, but primarily serving domestic buyers. It offers an extensive database of laser CNC machine manufacturers in China. The website is entirely in Chinese, so navigating and communicating with suppliers may require the assistance of a translator or translation tools. However, it provides comprehensive product listings, including specifications, prices, and images. Users can directly contact suppliers through the platform to inquire about quotes, negotiate prices, and discuss further details.

When conducting price cost research on these platforms, it is essential to carefully consider the following factors:

1. Machine Quality: Assess the quality of the machines by reviewing product descriptions, specifications, and customer reviews if available. It is advisable to choose manufacturers with a good reputation and positive feedback.

2. Price: Compare prices among different suppliers to determine the most competitive offers. Keep in mind that price alone should not be the sole deciding factor; consider the machine’s quality, after-sales service, and reputation of the manufacturer as well.

3. Customization Options: If specific requirements or modifications are necessary, contact the manufacturers to discuss customization options and associated costs.

4. MOQ (Minimum Order Quantity): Some manufacturers may require a minimum order quantity, so it is crucial to inquire about MOQs to ensure it aligns with your needs.

In conclusion, conducting price cost research for laser CNC machine manufacturers in China can be effectively done through online platforms such as temu.com and 1688.com. These platforms provide comprehensive information, allowing buyers to compare prices, assess product quality, and directly communicate with suppliers for further negotiations and customization options.

Shipping Cost for laser cnc machine import from China

Shipping costs for importing a laser CNC machine from China can vary depending on various factors. The size and weight of the machine, the shipping method chosen, and the destination country all play a role in determining the final cost.

Generally, there are two main shipping methods: air freight and sea freight. Air freight is usually faster but more expensive, while sea freight is slower but more economical for larger and heavier machinery.

For smaller laser CNC machines, air freight may be the preferred choice. Shipping costs typically range from $5 to $10 per kilogram, with additional charges for fuel surcharges and handling fees. However, air freight can become quite costly for larger machinery due to the volumetric weight.

Sea freight is a more cost-effective option for larger laser CNC machines. Shipping costs for sea freight are usually calculated based on the volume or weight, whichever is higher. Rates can range from $150 to $300 per cubic meter, with additional charges for customs clearance, terminal handling, and documentation fees.

It is also important to consider other expenses such as insurance, import duties, and taxes. Insurance can vary depending on the value of the machine and the level of coverage desired. Import duties and taxes are country-specific and can significantly impact the overall cost. It is advisable to check the tariff rates and consult with local customs authorities to get a better understanding of these additional charges.

In conclusion, the shipping cost for importing a laser CNC machine from China can vary depending on the size, weight, shipping method, and destination country. It is recommended to obtain quotes from shipping companies or freight forwarders to get a more accurate estimate.

Compare China and Other laser cnc machine Markets: Products Quality and Price,Visible and Hidden Costs

China is currently the largest laser CNC machine market globally, and it has a significant presence in terms of product quality and price. The Chinese market offers a wide range of options for laser CNC machines, including both low-end and high-end models. Many Chinese manufacturers focus on providing affordable machines, which has made them popular among both beginners and small-scale industries.

In terms of product quality, China has made significant progress in recent years. Chinese manufacturers have improved their manufacturing processes and adopted advanced technologies to produce laser CNC machines with better precision and performance. While the product quality may not be at the same level as some high-end machines from countries like Germany or Japan, the gap is closing, and Chinese machines are becoming increasingly reliable and efficient.

One distinct advantage that China offers is competitive pricing. Chinese laser CNC machines are generally more affordable compared to those from other markets. This cost advantage makes them attractive for price-sensitive customers and emerging markets where budgets may be limited. However, low prices often raise concerns about the quality and durability of the machines.

When considering the cost of laser CNC machines, it is essential to account for both visible and hidden costs. While the initial purchase price of a Chinese machine may be lower, customers should consider additional expenses such as shipping, import duties, and taxes, which can significantly impact the total cost. Moreover, customers should be cautious about the warranty and after-sales service provided by Chinese manufacturers, as this may vary among different brands.

Other laser CNC machine markets, such as Germany and Japan, are known for their high-quality products and precision engineering. Machines from these markets often come with higher price tags due to the superior technology and craftsmanship. In terms of product quality, these markets have an edge over China, especially when it comes to efficiency, longevity, and accuracy.

However, the price difference between these high-end machines and those from China brings to light the trade-off between quality and affordability. Customers must carefully evaluate their requirements and budget to make an informed decision.

In conclusion, the Chinese laser CNC machine market offers a wide range of products, with improving product quality and competitive pricing. While there may be concerns about the durability and after-sales service, China remains an attractive option for customers seeking affordable machines. Other markets like Germany and Japan excel in product quality but come with a higher price tag. Ultimately, customers must consider their specific needs and budget to choose the most suitable option.

Understanding Pricing and Payment Terms for laser cnc machine: A Comparative Guide to Get the Best Deal

When looking to purchase a laser CNC machine, understanding pricing and payment terms is crucial to ensure you get the best deal. This comparative guide will help you navigate the complexities of pricing and payment options in a concise manner.

Pricing for laser CNC machines can vary significantly based on several factors. These include the machine’s power and capabilities, brand reputation, technical specifications, and additional features. It is recommended to assess your specific requirements and budgetary constraints to determine the appropriate machine for your needs.

To get the best deal, it is advisable to obtain quotes from multiple suppliers or manufacturers. This will allow you to compare prices and negotiate effectively. Additionally, don’t hesitate to ask for discounts, especially if you are purchasing multiple machines or accessories.

Payment terms for laser CNC machines can vary depending on the supplier or manufacturer. The most common payment options include upfront payment, partial payment with installments, or lease/rental agreements.

If you have the means, making an upfront payment may offer benefits such as lower overall costs or additional discounts. However, this option may not be suitable for everyone due to budget constraints.

Partial payment with installments is a popular option, especially for those who prefer spreading the cost over a period of time. It is essential to clarify the terms and interest rates associated with installment plans to avoid any surprises.

Lease or rental agreements provide flexibility, particularly for businesses that may have fluctuating needs or are uncertain about long-term investments. These agreements often include monthly payments and allow for machine upgrades or modifications as technology evolves.

Before finalizing a purchase, thoroughly review the warranty and after-sales service. Ensure that any potential maintenance or repair costs are clearly stated to avoid unexpected expenses down the line.

In conclusion, understanding pricing and payment terms is vital when purchasing a laser CNC machine. Obtain multiple quotes, negotiate, and carefully evaluate the payment options available. By considering your specific requirements, budget, and long-term plans, you can secure the best deal for your business.

Chinese Regulations and Industry Standards Certifications for laser cnc machine,Import Regulations and Customs for laser cnc machine from China

Chinese Regulations and Industry Standards Certifications for laser CNC machines:

In China, laser CNC machines are subject to various regulations and industry standards certifications to ensure product safety and quality. The most prominent certification is the China Compulsory Certification (CCC), which is a mandatory requirement for many products, including laser CNC machines. This certification shows that the machine complies with Chinese safety standards and is eligible for sale and import in the Chinese market.

Apart from CCC, laser CNC machines may also need to comply with industry standards such as the National Standards of the People’s Republic of China. These standards cover various aspects such as design, production, testing, and safety requirements. Some relevant industry standards for laser CNC machines in China include GB/T 15541-1995, GB/T 20547-2006, and GB 10302-2010.

Import Regulations and Customs for laser CNC machines from China:

When importing laser CNC machines from China, importers need to comply with the relevant import regulations and customs procedures. This typically includes the following:

1. Import License: Importers may need to obtain an import license or permit from the local authorities before importing laser CNC machines. The specific requirements and procedures for obtaining the license may vary based on the importing country.

2. Customs Declaration: Importers are required to provide accurate and detailed information about the laser CNC machines, including product description, value, and quantity. This information is necessary for customs clearance and duty assessment.

3. Tariffs and Duties: Importing laser CNC machines may be subject to tariffs, import duties, and taxes. Importers need to be aware of the applicable rates and ensure compliance with the tax regulations of the importing country.

4. Product Testing and Certification: Depending on the importing country’s regulations, laser CNC machines may need to undergo testing and obtain certifications to ensure compliance with local safety and quality standards. These certifications may include CE certification, UL certification, or specific certifications mandated by the importing country.

5. Documentation: Importers must provide necessary import documentation such as commercial invoices, packing lists, bills of lading, and certificates of origin. These documents are required for customs clearance and verifying the authenticity and legality of the imported laser CNC machines.

It is essential for importers to thoroughly research and understand the specific import regulations and customs procedures of their country before importing laser CNC machines from China. Consulting with import experts or customs brokers can greatly assist in navigating the complexities of the import process and ensuring compliance with the regulations.

Sustainability and Environmental Considerations in laser cnc machine Manufacturing

When it comes to laser CNC machine manufacturing, sustainability and environmental considerations play a crucial role in ensuring responsible production techniques and minimizing the machine’s impact on the environment.

One of the main sustainability measures in laser CNC machine manufacturing is reducing energy consumption. Manufacturers strive to design and produce machines that are energy-efficient, requiring less power to operate while maintaining high levels of productivity. This helps to decrease the overall carbon footprint associated with the machine’s usage and contributes to a more sustainable manufacturing process.

Additionally, manufacturers focus on using environmentally friendly materials for the construction of laser CNC machines. By opting for materials that are recyclable or have a low environmental impact, manufacturers can reduce waste and promote sustainable practices. They also aim to minimize the use of hazardous substances and chemicals, ensuring that the manufacturing process and the eventual disposal of the machine are as environmentally friendly as possible.

Furthermore, proper waste disposal and recycling processes are crucial in laser CNC machine manufacturing. Manufacturers implement procedures to manage and recycle waste materials generated during the production process. This helps to reduce landfill waste and promotes the reuse of valuable resources, contributing to a more sustainable manufacturing industry.

Manufacturers also consider the lifecycle of laser CNC machines when it comes to sustainability. Designing machines that are durable, long-lasting, and easily repairable helps to extend their lifespan, reducing the need for frequent replacements and minimizing waste. Additionally, manufacturers may offer maintenance and repair services, allowing customers to keep their machines in optimal condition for an extended period.

In conclusion, sustainability and environmental considerations are vital in laser CNC machine manufacturing. By focusing on energy efficiency, using environmentally friendly materials, implementing proper waste management practices, and considering the machine’s lifecycle, manufacturers can ensure that their products have a minimal impact on the environment and contribute to a more sustainable manufacturing industry.

List The Evolution history of “laser cnc machine”

The evolution of laser CNC machines dates back to the 1960s when researchers at various institutions, including Bell Labs and IBM, began experimenting with laser technology. The first successful laser cutting machine was developed in 1965 by Kumar Patel, who used a carbon dioxide (CO2) laser to cut through a variety of materials. This marked the beginning of laser technology’s integration into CNC (Computer Numerical Control) systems.

In the 1970s, laser CNC machines gained popularity in industrial settings due to their ability to provide precision cutting and increased productivity. However, they were limited to cutting only flat materials using CO2 lasers. As technology advanced, different types of lasers emerged, such as Nd:YAG (Neodymium-Doped Yttrium Aluminum Garnet) and fiber lasers, which expanded the range of materials that could be cut and increased cutting speeds.

Throughout the 1980s and 1990s, the development of laser CNC machines focused on improving efficiency and accuracy. Significant advancements were made in laser beam control, allowing for more intricate and complex cutting designs. The introduction of CAD/CAM software enabled operators to program and control laser CNC machines more effectively.

In the 2000s, laser CNC machines integrated other functionalities, such as engraving, drilling, and welding, further expanding their applications in various industries. CO2 lasers, Nd:YAG lasers, fiber lasers, and diode lasers became widely used for different types of cutting tasks based on the materials being processed.

In recent years, laser CNC machines have seen advancements in automation and connectivity. With the rise of Industry 4.0, these machines can now be integrated into smart manufacturing systems, allowing for real-time monitoring, remote control, and data analysis. This has resulted in increased productivity, reduced downtime, and improved operational efficiency.

Additionally, portable and handheld laser CNC machines have emerged, enabling on-site and flexible cutting operations in industries like construction and automotive.

In summary, the evolution of laser CNC machines spans several decades, from early experiments in the 1960s to their integration into automated and smart systems today. These advancements have allowed these machines to cut a wide range of materials and perform various functions, making them essential tools in industries worldwide.

The Evolution and Market Trends in laser cnc machine Industry

The laser CNC machine industry has witnessed significant growth and evolution over the years. From its humble beginnings as a technology used primarily in high-tech industries, laser CNC machines have now become more accessible and widely used in various sectors.

One of the key factors driving the evolution of laser CNC machines is the advancements in laser technology itself. Over time, lasers have become more efficient, powerful, and versatile, allowing for greater precision and speed in cutting, engraving, and marking applications. Additionally, the cost of laser systems has gradually decreased, making them more affordable for small and medium-sized enterprises (SMEs) to adopt.

Another important trend in the laser CNC machine industry is the integration of automation and connectivity features. Many laser CNC machines now come equipped with software that enables automation of tasks and seamless integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. This has improved productivity and efficiency, as well as facilitated the customization and personalization of products.

Moreover, there is a growing demand for laser CNC machines in industries such as automotive, aerospace, electronics, and healthcare. Laser cutting and welding processes are widely used in the automotive and aerospace industries for precise cutting and joining of metal components. In the electronics industry, laser engraving and marking machines are utilized to create high-quality and permanent markings on circuit boards and other electronic devices. In the healthcare sector, laser CNC machines are employed for various applications, including surgical procedures, skin treatments, and dental restoration.

In terms of market trends, there is an increasing focus on sustainability and energy efficiency. Laser CNC machines offer advantages such as reduced material waste, lower energy consumption, and the ability to work with environmentally friendly materials. This aligns with the growing global emphasis on environmentally conscious practices.

Furthermore, the market for laser CNC machines is expanding geographically, with emerging economies contributing to the growth. Countries such as China, India, and Brazil have seen a rise in demand for laser CNC machines due to their growing manufacturing sectors. Additionally, there is a trend towards the miniaturization of laser CNC machines, making them suitable for use in small workshops or even personal spaces.

In conclusion, the laser CNC machine industry has evolved significantly, driven by advancements in laser technology, automation, and connectivity. The market trends indicate a growing demand for laser CNC machines in various industries, with a focus on sustainability and expanding geographical markets. As the industry continues to innovate, laser CNC machines are likely to become even more versatile and accessible to a wider range of users.

Custom Private Labeling and Branding Opportunities with Chinese laser cnc machine Manufacturers

Chinese laser CNC machine manufacturers offer customizable private labeling and branding opportunities for businesses looking to establish their brand and differentiate themselves from competitors. With a wide range of laser CNC machine options, manufacturers can tailor the machines to meet specific branding and design requirements.

Private labeling allows businesses to customize the machine’s appearance and incorporate their logo, colors, and other branding elements, creating a cohesive look that aligns with their brand identity. This branding opportunity enhances brand visibility, customer recognition, and helps build a trusted brand image in the market.

Chinese manufacturers understand the importance of brand differentiation in today’s competitive market. They collaborate closely with businesses and provide design consultation services to help them create unique and eye-catching branded machines. From customizing the machine’s physical appearance to programming exclusive features and functionalities, Chinese manufacturers offer a comprehensive solution that aligns with each business’s branding strategy.

In addition to private labeling, Chinese manufacturers also offer branding opportunities through customized packaging and marketing materials. They can print the business’s logo, contact information, and other branding elements on packaging boxes, manuals, and promotional materials, reinforcing brand awareness and professionalism.

Furthermore, Chinese manufacturers often have expertise in OEM (Original Equipment Manufacturer) manufacturing, allowing businesses to go beyond private labeling. They can develop laser CNC machines according to specific design requirements, incorporating exclusive features and functionalities that cater to the business’s unique selling proposition. This level of customization not only strengthens the brand but also provides a competitive advantage in the market.

In conclusion, Chinese laser CNC machine manufacturers offer custom private labeling and branding opportunities, allowing businesses to establish a distinct brand identity and differentiate themselves from competitors. Through private labeling, customized machine designs, packaging, and marketing materials, businesses can enhance brand visibility, recognition, and trust, ultimately leading to a stronger market presence.

Tips for Procurement and Considerations when Purchasing laser cnc machine

When purchasing a laser CNC machine for your procurement needs, there are several key considerations to keep in mind:

1. Machine type: There are different types of laser CNC machines available, such as CO2, fiber, and diode lasers. Assess your specific requirements and objectives to determine the most suitable machine type for your needs.

2. Power and capability: Consider the power and capability of the machine. Higher wattages generally result in faster cuts and deeper engravings, so choose a machine that matches the level of precision and speed required for your projects.

3. Bed size: Check the bed size of the laser CNC machine to ensure it can accommodate the materials you work with. Larger bed sizes enable you to work on bigger projects and materials, while smaller beds are more suitable for intricate designs.

4. Software compatibility: Ensure that the machine you choose is compatible with the design software you are using. Consider the ease of use and the learning curve associated with the software, as well as any additional costs that may be incurred.

5. Maintenance and support: Find out about the level of maintenance required for the machine and the availability of technical support. It’s important to have a reliable support system in place to address any issues that may arise during operation.

6. Safety features: Laser CNC machines can be hazardous if safety features are not in place. Look for features such as emergency stop buttons, protective enclosures, and safety interlocks to protect operators from potential accidents.

7. Budget: Determine your budget and identify the machine that provides the best value for your money. Consider the initial investment, operational costs, and potential ROI when making your decision.

8. Supplier reputation: Research different suppliers and their reputation in the industry. Look for reviews, testimonials, and references to ensure that you are purchasing from a reputable and reliable source.

9. Training and documentation: Inquire about the availability of training sessions and comprehensive documentation. Adequate training will ensure that your staff can operate the machine effectively, while detailed documentation can serve as a reference guide for ongoing use.

10. Future scalability: Consider the potential for future expansion or upgrades. As your business grows, you may need a machine that can be easily expanded or integrated with other equipment.

By considering these factors, you can make an informed decision when purchasing a laser CNC machine that meets your procurement needs and helps your business achieve its objectives efficiently.

FAQs on Sourcing and Manufacturing laser cnc machine in China

1. Why should I consider sourcing and manufacturing a laser CNC machine in China?

Sourcing and manufacturing a laser CNC machine in China can offer significant cost savings compared to other countries. China has a well-established manufacturing industry with a vast supply chain and experienced workforce. Additionally, Chinese manufacturers often have cutting-edge technology and can produce high-quality machines at competitive prices.

2. Are there any risks associated with sourcing and manufacturing in China?

While there can be risks involved, selecting a reputable supplier and conducting thorough due diligence can minimize those risks. Some common concerns include quality control, intellectual property protection, and communication barriers. However, working with a trusted sourcing agent or conducting factory inspections can help address these concerns.

3. How can I find reliable suppliers in China?

There are several ways to find reliable suppliers in China. Popular methods include attending trade shows, utilizing online platforms like Alibaba or globalsources.com, and engaging with professional sourcing agents who have knowledge of the local market. It is essential to conduct background checks, verify certifications, and request samples and references before finalizing a supplier.

4. How should I handle quality control when manufacturing in China?

Implementing a comprehensive quality control process is crucial to ensure the production of high-quality equipment. This involves regular factory inspections, pre-production and in-line inspections, as well as final product inspections. Additionally, establishing clear quality requirements and performance standards in the manufacturing agreement with the supplier is important.

5. What are some legal and regulatory considerations when sourcing and manufacturing in China?

Understanding, complying with, and navigating China’s laws and regulations is crucial. This includes learning about import/export regulations, registering trademarks, protecting intellectual property rights, ensuring product compliance with relevant standards (such as CE or RoHS), and complying with employment laws and regulations.

6. How can I manage shipping and logistics from China?

Managing shipping and logistics from China can be complex. It is advisable to work with experienced freight forwarders who can handle customs clearance, freight consolidation, and transportation arrangements. Negotiating favorable shipping terms, such as FOB (Free on Board) or CIF (Cost, Insurance, Freight), can help streamline the process.

7. What are the payment terms typically offered by Chinese suppliers?

Chinese suppliers often require a 30% – 50% deposit before production, with the remaining balance payable upon completion or before shipment. It is essential to negotiate and establish mutually agreed-upon payment terms in the contract to protect both parties’ interests.

8. How long does it generally take to manufacture a laser CNC machine in China?

The manufacturing time can vary depending on the complexity and specifications of the machine, as well as the supplier’s production capacity. On average, it can take anywhere from a few weeks to a couple of months. It is important to clarify the production timeline and establish a realistic delivery schedule with the supplier.

Overall, sourcing and manufacturing a laser CNC machine in China can be a cost-effective solution, but it requires diligent supplier selection, thorough quality control measures, and compliance with legal and regulatory requirements. Taking these factors into account can help ensure a successful sourcing and manufacturing process.

Why contact sourcifychina.com get free quota from reliable laser cnc machine suppliers?

Sourcifychina.com may receive a free quota from reliable laser CNC machine suppliers due to several reasons. Firstly, Sourcifychina.com aims to establish a strong network of trusted suppliers to cater to the needs of their clients. By partnering with reputable suppliers, they ensure that their clients receive high-quality products and services. In return for promoting these suppliers, they may negotiate a free quota or discounted rates.

Moreover, Sourcifychina.com provides a platform for businesses to connect with reliable suppliers in China. They act as a mediator between the clients and the suppliers, facilitating communication, overseeing production, and ensuring timely delivery. By offering a free quota, suppliers can showcase their products and services to potential clients through Sourcifychina.com, enhancing their visibility and attracting more business.

Additionally, by providing a free quota, suppliers can demonstrate their commitment to building long-term partnerships with Sourcifychina.com. It serves as an opportunity for suppliers to showcase their capabilities and build trust with the platform. This can lead to a continuous collaboration and a mutually beneficial relationship, where both parties can expand their respective customer bases.

Furthermore, offering a free quota to Sourcifychina.com enables suppliers to tap into new markets and reach a wider audience. The platform attracts clients from various industries and countries, providing suppliers with an opportunity to expand their customer base and increase their sales volume.

In conclusion, Sourcifychina.com receives a free quota from reliable laser CNC machine suppliers to establish a strong supplier network, promote their products and services, build long-term partnerships, and expand their customer base. This mutually beneficial arrangement benefits both Sourcifychina.com and the suppliers, as it facilitates business growth and fosters trust between the two parties.