Introduce about hobby cnc mill guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Hobby CNC mills are compact, computer-controlled milling machines designed for personal use and small-scale projects. This guide will provide you with essential information about hobby CNC mills, including their quality, cost, suppliers, certifications, market trends, tips, FAQs, and more.

Quality: Hobby CNC mills come in various qualities, ranging from entry-level machines to more advanced models. While high-quality mills offer better precision, durability, and performance, they often come at higher costs. It is essential to determine your specific requirements and budget to find the right balance between quality and affordability.

Cost: The cost of a hobby CNC mill can vary significantly depending on several factors such as brand, specifications, and additional features. Entry-level machines can range from a few hundred dollars to a few thousand dollars, while more advanced models can go up to several tens of thousands of dollars. It’s crucial to consider your budget and intended use to make an informed purchasing decision.

Supplier: Numerous suppliers offer hobby CNC mills, both online and offline. Reputable suppliers often have a wide range of options, reliable customer support, and warranty services. Reading reviews, comparing prices, and evaluating after-sales support can help you choose a trustworthy supplier for your mill.

Certification: When purchasing a hobby CNC mill, consider opting for machines with recognized certifications, such as CE (Conformité Européene) or UL (Underwriters Laboratories). These certifications indicate that the product meets mandatory safety and quality standards.

Market: The market for hobby CNC mills has seen significant growth in recent years. More individuals are embracing DIY projects, prototyping, and small-scale manufacturing, contributing to the growing demand for these machines. As a result, the market offers a wide selection of hobby CNC mills with varying features and prices to cater to different user requirements.

Tips: Before using a hobby CNC mill, it’s essential to thoroughly read and understand the machine’s user manual and safety instructions. Ensure that you have the necessary computer software, such as CAD/CAM programs, to design and generate toolpaths for milling operations. Regular maintenance, including lubrication and cleaning, is crucial for the longevity and optimal performance of your mill.

FAQ: Frequently asked questions about hobby CNC mills may include queries about the setup process, ideal materials for milling, appropriate cutting speeds, troubleshooting issues, and recommended accessories. Checking manufacturers’ websites or online forums dedicated to CNC milling can provide answers to common questions.

In conclusion, hobby CNC mills offer users the ability to create precise and intricate designs within their personal spaces. Consider factors such as quality, cost, suppliers, certifications, market trends, and tips to ensure a successful and enjoyable CNC milling experience.

Types of hobby cnc mill

Hobby CNC mills are The workhorse of any modern machine shop. They are capable of producing a wide range of intricate parts and are perfect for small-scale manufacturing or personal use. There are several types of hobby CNC mills available, each catering to different needs and preferences.

1. Benchtop Mills: These compact machines are designed to fit on a workbench or table. They are suitable for small projects and are often preferred by hobbyists with limited space. Benchtop mills are typically lighter and more affordable than larger models, making them ideal for beginners or those on a budget.

2. Mini Mills: This type of CNC mill is even smaller than benchtop mills and is often portable. Mini mills are commonly used for jewelry making, small crafts, or delicate precision work. They are particularly popular among hobbyists who focus on intricate designs and require high levels of accuracy.

3. Vertical Mills: Vertical mills are the most common type of CNC mill used for hobbyist purposes. They feature a vertical spindle that moves the cutting tool up and down. These machines are highly versatile and can perform various milling operations such as face milling, slotting, and drilling. Vertical mills are capable of handling larger workpieces and can accommodate multiple tooling options.

4. Router Mills: Router mills are mainly used for woodworking projects. They are equipped with a high-speed router that spins at very high RPMs. Router mills are ideal for cutting and shaping wood, plastics, and other soft materials. They are often used by woodworkers, craftspeople, and artists who require precise and detailed cuts.

5. 5-Axis Mills: 5-axis mills are the most advanced and complex CNC mills available for hobbyist use. These machines can perform milling operations in five different axes, allowing for more intricate and multi-dimensional cuts. 5-axis mills are often used by experienced hobbyists or professionals looking to create complex parts or molds.

It’s worth noting that each type of hobby CNC mill comes with its own set of advantages and limitations. The choice of which one to use depends on the specific needs and requirements of the user. Factors such as budget, space availability, desired materials to work with, and desired precision level all play a role in selecting the most suitable hobby CNC mill.

Pros and Cons of Using hobby cnc mill

Using a hobby CNC mill can have several pros and cons. Here are some key points to consider:

Pros:

1. Cost-effective: Hobby CNC mills are generally more affordable compared to industrial-grade machines, making them more accessible to hobbyists and small-scale businesses.

2. Versatility: These machines can be used for various applications, including woodworking, metalworking, engraving, and prototyping, providing users with flexibility.

3. Customizability: Users have the ability to modify and upgrade their hobby CNC mill to suit their specific needs, allowing for personalization and experimentation.

4. Learning experience: Working with a hobby CNC mill can be a valuable learning opportunity, giving users hands-on experience with CNC machining, programming, and problem-solving.

5. Compact size: Hobby CNC mills are typically compact and portable, occupying less space and offering more flexibility in terms of installation and relocation.

Cons:

1. Limited precision and power: Hobby CNC mills often lack the precision and power of industrial-grade machines, which can limit the machining capabilities and quality of the final product.

2. Limited size and capacity: These machines generally have smaller work areas and can only handle smaller workpieces, restricting the size and complexity of the projects that can be undertaken.

3. Limited durability: Hobby CNC mills may not be built to withstand heavy and continuous use, resulting in shorter lifespans and potentially requiring more frequent maintenance and repairs.

4. Limited software and compatibility: The software options available for hobby CNC mills may be limited compared to industrial systems, which can limit the range of functionalities and compatibility with other software applications.

5. Time-consuming setup and operation: Operating a hobby CNC mill may require more time and effort in terms of machine setup, tooling changes, and program preparation, especially for beginners.

It is important to assess your specific needs, budget, and the potential limitations of a hobby CNC mill before making a purchase decision.

hobby cnc mill Reference Specifications (varies for different product)

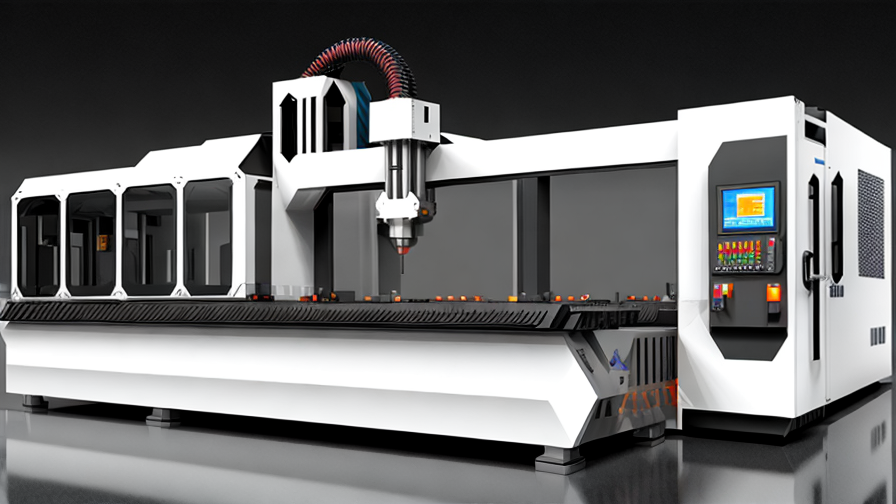

A hobby CNC mill is a versatile and precise tool used for cutting and shaping various materials such as wood, plastic, and aluminum. It is typically smaller and less powerful than industrial CNC mills, making it suitable for smaller projects and hobbyist use.

Some common specifications for a hobby CNC mill include a working area of around 12×12 inches, a spindle speed range of 5000-24000 RPM, and a maximum cutting depth of 0.25 inches. It may also feature a precision ball screw drive system, stepper motor control, and compatibility with a variety of software programs for design and toolpath generation.

The machine may be constructed from aluminum or steel for durability and stability, with an acrylic or glass enclosure for safety and visibility. It may include a control panel with a display screen and push buttons for easy operation, as well as ports for connecting to a computer or external controller.

Other features to look for in a hobby CNC mill include a high-resolution spindle encoder for accurate positioning, dust collection capabilities, and compatibility with different cutting tools such as end mills, drills, and engraving bits. Some models may also offer additional features like automatic tool changers, coolant systems, and wireless connectivity for remote monitoring and control.

Overall, a hobby CNC mill is a valuable tool for any enthusiast looking to create intricate and detailed projects with precision and efficiency. With the right specifications and features, it can open up a world of possibilities for creativity and craftsmanship.

Applications of hobby cnc mill

A hobby CNC mill is a versatile tool that can be used in various applications. Here are some popular applications for hobby CNC mills:

1. Prototyping: Hobby CNC mills are often used for prototyping new product designs. They can accurately and efficiently produce three-dimensional prototypes from a variety of materials, such as plastics, woods, and metals. This is especially useful for hobbyists and inventors looking to test and refine their ideas before moving on to mass production.

2. Engraving and Artwork: With precise control over the cutting tools, hobby CNC mills can create intricate engravings and artwork on various materials. This opens up opportunities for artists and craftsmen to create detailed designs on wood, metal, plastic, and even glass. CNC milling allows for precise and repeatable engraving, making it ideal for producing detailed logos, signs, and sculptures.

3. Small-Scale Production: Hobbyists and small businesses can use CNC mills to produce small batches of customized products. Whether it’s crafting custom parts for hobby projects or small-scale manufacturing of specialized goods, CNC mills can provide accuracy and consistency in production. This versatility allows hobbyists to turn their passion into a small business or side hustle.

4. Jewelers and Watchmakers: Hobby CNC mills are often used by jewelers and watchmakers for precision machining. They can create intricate settings for gemstones, produce precise watch components, and even carve delicate patterns on jewelry pieces. CNC mills allow for high levels of precision and fine detail, making them a valuable tool for these industries.

5. Educational Purposes: Hobby CNC mills are also popular among educators and students as a hands-on learning tool. They provide a practical way to teach principles of design, engineering, and manufacturing. Students can gain experience in computer-aided design (CAD) and computer-aided manufacturing (CAM) as they create their own projects using CNC mills.

Overall, hobby CNC mills open up a world of possibilities for makers and enthusiasts. From prototyping to artistic creations, small-scale production, and educational purposes, these machines offer accuracy, versatility, and the opportunity to turn ideas into reality.

The Work Process and how to use hobby cnc mill

A hobby CNC mill is a versatile machine that allows you to create precise and intricate designs on various materials such as wood, plastic, and metal. Here is a basic overview of the work process and how to use a hobby CNC mill:

1. Design your project using CAD/CAM software: Start by designing your project on computer-aided design (CAD) software. Once you have finalized your design, transfer it to computer-aided manufacturing (CAM) software to generate toolpaths for the CNC mill.

2. Set up your material and workpiece: Secure your material onto the CNC mill’s bed using clamps or a vise. Make sure the material is flat and securely fastened to prevent any movement during the milling process.

3. Load and secure the cutting tool: Insert the appropriate cutting tool into the spindle and securely tighten it in place. Make sure the tool is properly aligned and does not interfere with the material or machine components.

4. Zero the machine: Set the origin or zero point for the X, Y, and Z axes of the CNC mill. This will ensure that the machine starts the cutting process from the correct position.

5. Run the program: Load the generated toolpaths onto the CNC mill’s controller and start the cutting process. Monitor the machine’s progress and make any necessary adjustments as needed.

6. Post-processing: Once the milling process is complete, remove the finished workpiece from the machine. If necessary, perform any post-processing tasks such as sanding or painting to complete your project.

Overall, using a hobby CNC mill requires careful planning, proper set up, and close monitoring of the machine during the cutting process. With practice and patience, you can create amazing projects with your hobby CNC mill.

Quality Testing Methods for hobby cnc mill and how to control the quality

Quality testing methods for a hobby CNC mill are essential to ensure accurate and precise results. Here are some efficient methods to control the quality of your hobby CNC mill:

1. Calibration: Regularly calibrate the machine to ensure all axes are perfectly aligned. This involves checking for any backlash, correcting it, and verifying that the machine moves precisely to the desired positions.

2. Dimensional Accuracy: Test the accuracy of your mill by measuring the dimensions of the milled parts using calipers or micrometers. Compare the measured values with the expected dimensions to evaluate the accuracy of your CNC mill.

3. Surface Finish: Examine the surface finish of the milled parts, paying attention to any irregularities or roughness. You can use a handheld microscope or magnifying glass, or even run your fingertips along the surface to identify any imperfections.

4. Repeatability: Test the repeatability of your CNC mill by running the same program multiple times and measuring the results. Verify that the machine consistently produces the same output, demonstrating the reliability and precision of your mill.

5. Test Parts: Mill sample parts with known dimensions to validate the accuracy and precision of your CNC mill. These parts can include simple geometries or complex designs that require intricate milling operations. Measure the dimensions of the parts and compare them to the intended specifications.

6. Tooling Wear: Regularly inspect and measure the tools used in your CNC mill to check for wear. Worn tools can result in inaccurate cuts or poor surface finish. Replace worn tools promptly to maintain the quality of your mill’s output.

7. Software Simulation: Utilize simulation software to verify the toolpaths and detect any potential issues before milling. This allows you to optimize the performance and quality of your CNC mill by identifying potential errors or collisions.

Controlling the quality of your hobby CNC mill involves a combination of these testing methods. By regularly calibrating your machine, measuring the accuracy and surface finish of your parts, evaluating repeatability, testing sample parts, monitoring tool wear, and using software simulation, you can ensure consistent and precise results from your CNC mill.

hobby cnc mill Sample Policy and Post-Purchase Considerations for hobby cnc mill from China

Sample Policy:

1. Warranty: Our hobby cnc mill comes with a 1-year warranty against manufacturing defects.

2. Returns: We accept returns within 30 days of purchase, with a 20% restocking fee.

3. Shipping: We offer free shipping to mainland China and competitive rates for international shipping.

4. Customer service: Our team is available to assist you with any questions or concerns before and after your purchase.

Post-Purchase Considerations:

1. Safety: Make sure to read the user manual carefully and follow all safety guidelines to avoid accidents.

2. Maintenance: Regular maintenance of your hobby cnc mill will prolong its lifespan and ensure optimal performance.

3. Training: If you are new to hobby cnc milling, consider taking a course or workshop to learn how to use the machine effectively.

4. Upgrades: As you gain more experience, you may want to consider upgrading your hobby cnc mill with additional tools or features to enhance its capabilities.

5. Community: Join online forums or local maker groups to connect with other hobby cnc mill users for tips, advice, and inspiration.

By following these post-purchase considerations, you can get the most out of your hobby cnc mill and enjoy creating your own projects with precision and efficiency.

Sourcing hobby cnc mill from China: Opportunities, Risks, and Key Players

Sourcing a hobby CNC mill from China can present both opportunities and risks for buyers. The low cost of manufacturing in China means that buyers have the opportunity to find affordable CNC mills that may not be available from local suppliers. Chinese manufacturers have a wide range of options available, including different sizes, features, and capabilities to suit the needs of hobbyists.

However, there are risks associated with sourcing from China, including issues with quality control, communication barriers, and longer lead times. It is important for buyers to thoroughly vet potential suppliers and ensure they have a good reputation for producing high-quality products. In addition, buyers should also be aware of potential intellectual property issues, as Chinese suppliers have been known to produce knock-off products or violate patents.

Key players in the hobby CNC mill market in China include companies such as SainSmart, ChinaCNCzone, and MYSWEETY. These companies offer a variety of options for hobbyists, from desktop mills to mini CNC machines. Buyers should research these companies and others to find the right supplier for their needs.

Overall, sourcing a hobby CNC mill from China can be a cost-effective option for buyers, but it is essential to carefully consider the risks and take steps to ensure a successful purchase. By working with reputable suppliers and maintaining clear communication, buyers can find a high-quality CNC mill that meets their needs.

How to find and select reliable hobby cnc mill manufacturers in China,use google search manufacturers and suppliers

To find and select reliable hobby CNC mill manufacturers in China, start by conducting a search on Google for “Hobby CNC mill manufacturers in China” or “CNC mill suppliers in China.” This search will provide you with a list of potential manufacturers and suppliers to choose from.

When selecting a manufacturer, it is important to consider a few key factors to ensure reliability and quality. Look for manufacturers with a good reputation in the industry, with positive reviews and testimonials from previous customers. Check for any certifications or quality control measures that the manufacturer may have in place to ensure the products meet industry standards.

Additionally, consider the manufacturer’s experience and expertise in producing CNC mills. Look for manufacturers with a history of producing high-quality products and a track record of delivering on time and within budget.

Finally, reach out to the potential manufacturers to request quotes and additional information about their products and services. Ask for samples or demos of their CNC mills to assess the quality and performance before making a final decision.

By taking these steps and conducting thorough research, you can find and select a reliable hobby CNC mill manufacturer in China to meet your needs and specifications.

How to check hobby cnc mill manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

When checking the reliability of a hobby CNC mill manufacturer’s website, there are a few steps you can follow. One of the initial steps involves using Google Chrome and an SEO tool like SEOquake to check the website’s ranking.

First, open the website in Google Chrome. Google Chrome is a widely used and trusted web browser known for its security and reliability. It is advisable to use it for checking the website’s credibility.

Next, install the SEOquake extension on your Google Chrome browser. SEOquake is a powerful SEO tool that provides various metrics and insights about a website, including its ranking.

Once installed, click on the SEOquake icon next to your browser’s address bar. A new window will open, displaying important metrics about the website you are browsing.

Look for the “Rank” metric and check the position of the website in Google’s global search ranking. If the website appears in the top 10 million rankings, it indicates that it has a decent online presence and is relatively reliable. However, keep in mind that higher rankings generally imply better reliability.

Additionally, you can further assess the website’s reliability by considering other factors. Look for reviews and testimonials from customers who have used their CNC mill products. Check if the website provides detailed product information, certifications, and any warranties offered.

It’s also essential to verify the contact information provided on the website. Legitimate manufacturers typically have clear and accessible contact details, including a physical address, phone number, and email address.

Lastly, make sure to read and understand the website’s terms and conditions, return policy, and any additional relevant information regarding the purchase, shipping, and support.

In following these steps, you can conduct a reliable assessment of a hobby CNC mill manufacturer’s website before considering purchasing their products.

Top 10 hobby cnc mill manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Haas Automation: Haas Automation is a renowned manufacturer of hobby CNC mills in China. Their product range includes vertical mills, drill/tap mills, mini mills, and 5-axis mills. With precision engineering and robust build, Haas CNC mills offer high-performance machining capabilities for hobbyists.

2. SIEG: SIEG is well-known for its compact and affordable hobby CNC mills. They have a range of models like X3, X2, and X1 with varying specifications. SIEG mills are suitable for small-scale hobbyists seeking reliable machining solutions.

3. Bolton Tools: Bolton Tools specializes in hobby CNC mills, offering models like XQK9630S, ZX45, and ZX32G. Their mills are designed to provide accurate results and versatility for hobbyists working with various materials.

4. WMT CNC: WMT CNC offers hobby CNC mills like ZX7550W, ZX6350Z, and ZX6350C. These mills feature robust construction and easy-to-use controls, allowing hobbyists to achieve precision machining for their projects.

5. Tormach: Tormach is a leading manufacturer of small hobby CNC mills, known for their PCNC series. These mills are versatile and affordable, suitable for hobbyists looking for precise machining tools at an affordable price point.

6. Grizzly Industrial: Grizzly Industrial produces hobby CNC mills that cater to various skill levels. They have models like G0704, G0796, and G0758, providing hobbyists with options based on their requirements and budget.

7. Taicang Shanhe Machinery Factory: Taicang Shanhe Machinery Factory offers hobby CNC mills with options like XK6325, XK7132, and XQ6232WA. These mills are designed with stability and precision in mind, enabling hobbyists to achieve accurate machining results.

8. Precision Matthews: Precision Matthews manufactures hobby CNC mills like PM-935TS, PM-833T, and PM-727M. Their mills are known for their quality construction and reasonable pricing, making them popular choices among hobbyists.

9. LittleMachineShop: LittleMachineShop specializes in compact and affordable hobby CNC mills. They offer models like HiTorque 3960, HiTorque 3990, and HiTorque 4190, providing hobbyists with reliable machines for precise milling operations.

10. Gowe: Gowe manufactures hobby CNC mills like ZAY7032G, ZAY7040G, and ZAY7045G. These mills are compact yet powerful, suitable for hobbyists who require accurate and efficient milling solutions.

| Manufacturer | Models Available | Key Features |

| ———————— | —————— | —————————————————————– |

| Haas Automation | Vertical mills | Precision engineering, high-performance machining capabilities |

| SIEG | X3, X2, X1 | Compact and affordable, suitable for small-scale hobbyists |

| Bolton Tools | XQK9630S, ZX45 | Reliable and versatile, offering accurate results |

| WMT CNC | ZX7550W, ZX6350Z | Robust construction, easy-to-use controls |

| Tormach | PCNC series | Affordable and versatile, precise machining tools |

| Grizzly Industrial | G0704, G0796, G0758| Options for various skill levels, catering to different budgets |

| Taicang Shanhe Machinery | XK6325, XK7132 | Stability and precision for accurate machining |

| Precision Matthews | PM-935TS, PM-833T | Quality construction, reasonable pricing |

| LittleMachineShop | HiTorque series | Compact and affordable, reliable milling operations |

| Gowe | ZAY7032G, ZAY7040G | Compact and powerful, ideal for efficient milling operations |

These top 10 hobby CNC mill manufacturers in China provide a wide range of options catering to different skill levels and budgets. Whether you are a small-scale hobbyist or seeking high-performance machining capabilities, there is a suitable CNC mill available. Compare the listed features and make an informed decision based on your specific needs.

Background Research for hobby cnc mill manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to hobby CNC mill manufacturers in China, several companies have made a name for themselves. This article will provide background research on some of these manufacturers using the websites qcc.com, archive.org, and importyeti.com.

One prominent company is CHINA CNC MACHINE, which has been in the industry for over 20 years. Despite their focus on industrial CNC machines, they also offer hobby-sized mills suitable for personal use. Their machines are known for their precision and reliability.

Another reputable manufacturer is Jinan Blue Elephant CNC Machinery Co., Ltd. With over ten years of experience, they specialize in CNC routers, laser machines, and plasma cutters. While they primarily cater to industrial customers, they also offer hobby machines with smaller working areas and lower prices.

Yocan CNC Technology Co., Ltd., on the other hand, is a relatively newer player in the market. Established in 2014, they have quickly gained recognition for their range of CNC machines, including hobby mills. Their machines are praised for their user-friendly interfaces and reliable performance.

A company worth considering is Jinan Firmcnc Equipment Co., Ltd., established in 2003. They focus on the R&D and manufacturing of CNC routers, lasers, and plasma cutting machines, with options available for hobbyists as well. They offer a comprehensive range of products and have built a solid reputation for their after-sales service.

It is important to research and understand the different specifications and features offered by each manufacturer. Checking customer reviews and ratings can provide valuable insights into the overall quality and satisfaction of their products.

In conclusion, China has numerous hobby CNC mill manufacturers that offer a variety of machines suitable for personal use. Companies like CHINA CNC MACHINE, Jinan Blue Elephant CNC Machinery, Yocan CNC Technology, and Jinan Firmcnc Equipment have all established themselves in the market and could be considered when looking for hobby CNC mills.

Leveraging Trade Shows and Expos for hobby cnc mill Sourcing in China

Trade shows and expos are excellent platforms for sourcing hobby CNC mills in China. These events allow you to meet suppliers face-to-face, inspect their products, and negotiate deals in person. Some of the popular trade shows and expos in China include the China International Machine Tool Show (CIMT), CME China Machine Tool Exhibition, and the Shanghai International Machine Tool Fair.

To make the most of your experience at these events, it is important to do some preparation beforehand. Research the exhibitor list and identify potential suppliers of hobby CNC mills that you want to visit. Prepare a list of questions to ask vendors, such as their manufacturing capabilities, quality control processes, and pricing.

During the trade show or expo, take the time to walk around and explore different booths. Look for suppliers that offer hobby CNC mills that meet your requirements in terms of size, accuracy, and functionality. Talk to vendors and ask for product demonstrations to get a better understanding of their offerings.

When negotiating with suppliers, be prepared to discuss pricing, lead times, minimum order quantities, and shipping options. Don’t be afraid to negotiate for better terms or prices, as many vendors are willing to work with buyers to close a deal.

Overall, trade shows and expos in China are valuable resources for sourcing hobby CNC mills. By doing your research, attending these events, and engaging with suppliers, you can find the right partner to meet your CNC machining needs.

The Role of Agents and Sourcing Companies in Facilitating hobby cnc mill Purchases from China

Agents and sourcing companies play a crucial role in facilitating hobby CNC mill purchases from China. These intermediaries act as a bridge between the buyer and the seller, streamlining the procurement process and ensuring a smooth transaction.

Firstly, agents and sourcing companies have extensive knowledge of the Chinese market and its manufacturing capabilities. They have established relationships with various CNC mill manufacturers, enabling them to source high-quality products at competitive prices. Their expertise in understanding the market dynamics, such as trends, pricing, and quality standards, helps buyers make well-informed decisions.

Secondly, these intermediaries can provide valuable assistance in communication and negotiation. Language and cultural barriers can often pose challenges for international buyers. Agents and sourcing companies act as translators and intermediaries, ensuring effective communication between the buyer and the seller. Their understanding of local business practices and customs helps in negotiating price, terms, and conditions, resulting in favorable outcomes for both parties.

Additionally, agents and sourcing companies can conduct thorough quality inspections. They can inspect the CNC mills for any defects, ensuring that the buyer receives a product that meets their specifications and quality standards. This reduces the risk of receiving subpar machinery and provides reassurance to the buyer.

Furthermore, these intermediaries can handle logistics and shipping arrangements. They have experience in international shipping and can manage the complex logistics involved in transporting the hobby CNC mill from China to the buyer’s location. This includes arranging customs clearance, preparing necessary documentation, and coordinating delivery.

In summary, agents and sourcing companies play a vital role in facilitating hobby CNC mill purchases from China. Their knowledge of the market, assistance in communication and negotiation, quality inspections, and logistical support make the buying process more efficient, reliable, and convenient for international buyers.

Price Cost Research for hobby cnc mill manufacturers Companies in China, use temu.com and 1688.com

When conducting a price cost research for hobby CNC mill manufacturers in China, two reliable sources to consider are temu.com and 1688.com. These platforms provide access to numerous suppliers and manufacturers, offering a range of CNC mills suitable for various hobbyist needs.

First, temu.com is an online platform that connects buyers with manufacturers mainly in the Chinese market. It provides a comprehensive listing of hobby CNC mill manufacturers, offering a wide range of products at different price points. The platform allows users to search for specific products, filter results based on price range, and compare prices across different suppliers. Additionally, temu.com provides detailed product descriptions, images, specifications, and customer reviews, which can aid in making informed purchasing decisions.

Second, 1688.com is a B2B marketplace owned by Alibaba Group, which is specifically designed for the Chinese domestic market. It offers a vast selection of CNC mill manufacturers and suppliers catering to various customer needs. Similar to temu.com, 1688.com allows users to search for specific products, compare prices, and read product descriptions and customer reviews. However, it’s important to note that the language barrier might be a challenge for those who are not proficient in Chinese.

When conducting a price cost research on these platforms, it is advisable to consider factors beyond the initial purchase price. It is essential to review the product specifications, quality, reputation of the manufacturer, as well as shipping and customs costs. Additionally, reaching out to manufacturers directly through the platforms or other means of communication can provide clearer insights into pricing, customization options, and potential discounts for bulk orders.

In conclusion, temu.com and 1688.com are valuable resources for conducting price cost research on hobby CNC mill manufacturers in China. Utilizing these platforms, buyers can explore a broad range of options, compare prices, and make informed purchasing decisions based on their specific requirements and budgetary constraints.

Shipping Cost for hobby cnc mill import from China

The shipping cost for importing a hobby CNC mill from China can vary depending on various factors such as the weight and dimensions of the package, shipping method chosen, and the destination country.

Typically, there are two main shipping methods for importing products from China: air freight and sea freight.

Air freight is the faster option but tends to be more expensive. The cost is usually calculated based on the weight and dimensions of the package. Some additional charges may include fuel surcharge, customs clearance fee, and handling fee. On average, air freight from China to other countries can range from $3 to $8 per kilogram. For a hobby CNC mill that weighs around 100 kg, the air freight cost can be estimated at around $300 to $800.

Sea freight is the more cost-effective option for larger and heavier packages. It is charged based on the volume or weight of the package, whichever is greater. The cost can also vary depending on the shipping company, route, and other factors. Generally, sea freight from China to other countries can range from $500 to $3000 for a cubic meter. For a hobby CNC mill that occupies around 1 cubic meter, the sea freight cost can be estimated at around $500 to $3000.

It’s important to note that these estimates are just an approximation and the actual shipping cost could be higher or lower depending on the specific circumstances and negotiation with the shipping company. Furthermore, additional costs such as customs duties, taxes, and local delivery charges may also apply, which should be considered when calculating the overall cost of importing a hobby CNC mill from China.

Compare China and Other hobby cnc mill Markets: Products Quality and Price,Visible and Hidden Costs

When comparing China to other hobby CNC mill markets, several factors must be considered, including product quality and price, visible and hidden costs.

In terms of product quality, China’s market has traditionally been associated with lower quality products. However, this perception has been changing in recent years as Chinese manufacturers have invested in improving product quality. There are now reputable Chinese manufacturers offering hobby CNC mills with excellent precision and durability, comparable to those from other markets. Other hobby CNC mill markets, such as the United States, Europe, and Japan, have a long-standing reputation for producing high-quality machines. While the quality of products from these markets may still be perceived as superior, Chinese manufacturers have made significant progress in closing the gap.

In terms of price, China has a distinct advantage. Chinese hobby CNC mills tend to be more affordable compared to those from other markets. This lower price can be attributed to various factors, including lower labor and manufacturing costs in China. Other markets may offer higher-priced machines due to higher production costs or branding. However, it should be noted that the price alone should not be the sole determinant of product quality and performance.

When considering visible and hidden costs, China may have some advantages and disadvantages. Visible costs such as shipping and import duties may be higher when importing from China compared to purchasing locally in other markets. Additionally, communication and language barriers may exist when dealing with Chinese manufacturers, which can increase coordination costs. On the other hand, hidden costs can vary depending on the specific manufacturer and market. It is essential to thoroughly research and understand the reputation and track record of both Chinese and other market manufacturers to assess the hidden costs associated with after-sales services, warranty, and spare parts availability.

In conclusion, while China was previously associated with lower quality hobby CNC mill products, Chinese manufacturers have made significant improvements in recent years. The price advantage of Chinese machines remains significant, making them an attractive option for hobbyists. However, it is crucial to consider the visible and hidden costs involved, such as shipping, import duties, and after-sales support, before making a purchasing decision. Ultimately, the choice between China and other markets depends on the specific needs, budget, and preferences of the buyer.

Understanding Pricing and Payment Terms for hobby cnc mill: A Comparative Guide to Get the Best Deal

When looking to purchase a hobby CNC mill, it’s important to understand the pricing and payment terms to ensure you get the best deal possible.

Prices for hobby CNC mills can vary depending on the brand, size, and features included. It’s essential to research different brands and models to find one that meets your needs and budget. Consider the size of the machine, the materials it can work with, and the level of precision it offers. Additionally, compare prices from different retailers to find the best deal.

When it comes to payment terms, some retailers may offer financing options or payment plans to make the purchase more manageable. Consider these options if you’re on a tight budget or prefer to spread out the cost over time. However, keep in mind that financing may come with interest charges, so be sure to understand the terms and conditions before signing up.

Another important factor to consider is the warranty and after-sales support offered by the manufacturer or retailer. Make sure to inquire about the warranty period, what it covers, and how to access support in case of any issues with the machine.

By understanding pricing and payment terms, you can make an informed decision when purchasing a hobby CNC mill. Compare prices, explore financing options, and consider the warranty and support offered to get the best deal possible.

Chinese Regulations and Industry Standards Certifications for hobby cnc mill,Import Regulations and Customs for hobby cnc mill from China

In China, hobby CNC mills are subject to various regulations and industry standards certifications to ensure product safety and quality. Some key certifications that manufacturers should obtain include CE certification, RoHS compliance, and ISO 9001 certification. These certifications demonstrate that the product meets specific standards for performance, safety, and environmental impact.

When importing hobby CNC mills from China, it is important to be aware of the country’s import regulations and customs procedures. Importers should ensure that the product complies with all relevant regulations and standards in their destination country, and may be required to provide documentation such as a certificate of conformity or test reports.

Customs procedures for importing hobby CNC mills from China typically involve paying customs duties and taxes based on the value of the goods. Importers should also be prepared to provide information such as the product’s country of origin, its classification under the Harmonized System (HS) code, and any relevant certifications or documentation.

To facilitate a smooth importing process, it is advisable to work with a reputable customs broker or freight forwarder who can help navigate the complexities of import regulations and customs procedures. By ensuring compliance with regulations and having the necessary documentation in place, importers can minimize the risk of delays or issues with customs when importing hobby CNC mills from China.

Sustainability and Environmental Considerations in hobby cnc mill Manufacturing

Sustainability and environmental considerations in hobby CNC mill manufacturing play a crucial role in reducing the negative impact on the environment and promoting sustainable practices. Here are a few key aspects to consider within this manufacturing process:

1. Material sourcing: Opting for sustainable and responsibly sourced materials is essential. Using recycled or reclaimed metals and other materials can help minimize resource extraction and reduce energy consumption associated with raw material production.

2. Energy-efficient manufacturing: Implementing energy-efficient practices during the manufacturing process can significantly reduce the carbon footprint. This could involve using energy-efficient machinery, optimizing the production cycle, and minimizing energy waste through proper insulation and equipment maintenance.

3. Waste management: Proper waste management is critical to minimize the environmental impact. Recycling and reusing materials whenever feasible can significantly reduce waste generation. Additionally, implementing effective waste disposal methods, such as proper segregation and treatment, helps mitigate negative environmental consequences.

4. Chemical usage: Minimizing the use of harmful chemicals, such as certain solvents and adhesives, can prevent pollution and reduce environmental damage. Substituting hazardous substances with eco-friendly alternatives can promote a safer and sustainable manufacturing process.

5. Packaging and transportation: Implementing sustainable packaging solutions, such as using recycled and biodegradable materials, can minimize the environmental impact associated with the transportation and storage of the hobby CNC mills. Additionally, optimizing transportation routes and reducing packaging waste can further contribute to sustainability.

6. End-of-life considerations: Designing hobby CNC mills with end-of-life considerations in mind can promote a circular economy. By incorporating recyclable components and facilitating ease of repair and upgradeability, manufacturers can prolong the product’s lifespan and minimize waste generation.

In conclusion, sustainability and environmental considerations in hobby CNC mill manufacturing are crucial for reducing the impact on the environment. By implementing responsible practices like sourcing sustainable materials, minimizing waste, using energy-efficient manufacturing methods, and considering the end-of-life stage, manufacturers can contribute to a more sustainable and eco-friendly manufacturing process.

List The Evolution history of “hobby cnc mill”

The history of hobby CNC mills can be traced back to the early 1990s when the concept of computer numerical control (CNC) technology became more accessible and affordable for hobbyists. The increasing popularity of personal computers played a significant role in the evolution of these mills.

In the early years, hobbyists primarily relied on converting manual milling machines to CNC using homemade or commercially available kits. These kits consisted of stepper motors, motor controllers, and computer software that allowed users to control the movement of the mills through the computer.

During the late 1990s and early 2000s, companies began to manufacture compact and affordable CNC mills exclusively designed for hobbyists. These mills were often desktop-sized and offered improved precision and ease of use compared to the converted manual machines.

Advancements in technology continue to shape the evolution of hobby CNC mills. The introduction of more powerful computers and sophisticated software enabled hobbyists to create more intricate designs and achieve higher levels of accuracy. Additionally, the affordability and availability of 3D printing technology have allowed hobbyists to integrate additive manufacturing capabilities into their CNC mills, further expanding their potential applications.

Another significant development in recent years is the rise of open-source CNC milling projects. These initiatives allow hobbyists to access plans, designs, and software for building their CNC mills at a fraction of the cost of purchasing a commercial one. This approach promotes innovation and collaboration within the hobbyist community.

Furthermore, the advent of online marketplaces has made it easier for hobbyists to access various components and accessories for their CNC mills. These marketplaces offer a wide range of options, from affordable basic components to high-end precision parts, catering to the diverse needs and budgets of hobbyists.

Looking ahead, it is expected that hobby CNC mills will continue to evolve, driven by advancements in automation, artificial intelligence, and robotics. These advancements are likely to enhance the capabilities, efficiency, and versatility of hobby CNC mills, making them more accessible and appealing to a broader range of hobbyists.

The Evolution and Market Trends in hobby cnc mill Industry

Over the years, hobby CNC mills have seen a significant evolution in both technology and market trends. One of the key advancements is the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) software, allowing hobbyists to design and create intricate and precise parts. This has made hobby CNC mills more accessible to a wider range of users, as the learning curve has been greatly reduced.

Another trend in the hobby CNC mill industry is the increasing availability of affordable and compact machines. Many manufacturers now offer desktop-sized CNC mills that are suitable for hobbyists and small-scale production. These machines are easy to set up and operate, making them ideal for beginners who are just getting started with CNC machining.

Market trends also show a growing demand for customization and personalization in hobby CNC mills. Users are looking for machines that offer a high degree of flexibility and the ability to work with a variety of materials. This has led to the development of CNC mills that can handle not only traditional materials like wood and plastics but also metals and composites.

Overall, the hobby CNC mill industry is experiencing rapid growth, driven by advancements in technology, increased affordability, and a growing demand for customization. As more hobbyists and makers embrace CNC machining, we can expect to see further innovations and improvements in the coming years.

Custom Private Labeling and Branding Opportunities with Chinese hobby cnc mill Manufacturers

Chinese hobby CNC mill manufacturers offer custom private labeling and branding opportunities for individuals and businesses looking to establish their own brand in the market. These manufacturers understand the importance of branding and are willing to work with customers to create a unique and personalized product that reflects their brand image.

With custom private labeling, customers can have their own logo, name, and design printed or engraved on the CNC mills. This helps in creating brand recognition and loyalty among customers. It also allows businesses to differentiate themselves from competitors and showcase their professionalism and commitment to quality.

Chinese manufacturers also provide branding opportunities by offering custom packaging options. This includes designing and printing customized packaging boxes or cases that not only protect the CNC mill during transit but also serve as a promotional tool. Custom packaging helps to add value to the product and create a memorable unboxing experience for customers, making the brand stand out in the marketplace.

Moreover, manufacturing in China allows for flexibility in order quantities, making it feasible for individuals or small businesses to launch their own branded CNC mills without huge upfront investments. Chinese manufacturers often have low minimum order quantities, allowing customers to start with small quantities and gradually increase their orders as their business grows.

By partnering with Chinese hobby CNC mill manufacturers for custom private labeling and branding, individuals and businesses can create a unique product that reflects their brand identity, gain a competitive edge in the market, and establish a loyal customer base. These manufacturers offer cost-effective solutions and a range of customization options, making it a favorable choice for many looking to expand their brand presence in the CNC mill industry.

Tips for Procurement and Considerations when Purchasing hobby cnc mill

When purchasing a hobby CNC mill, there are several factors to consider to ensure you get the best machine for your needs. Here are some tips and considerations to keep in mind:

1. Budget: Set a budget for your CNC mill and stick to it. There are a wide range of options available at different price points, so make sure to choose one that fits within your budget.

2. Size and capacity: Consider the size of the CNC mill you need based on the types of projects you will be working on. Make sure it has enough capacity to accommodate the materials you will be using.

3. Accuracy and precision: Look for a CNC mill that offers high levels of accuracy and precision, as this will ensure your projects are completed with quality results.

4. Ease of use: Consider how user-friendly the CNC mill is, especially if you are a beginner. Look for a machine that comes with user-friendly software and clear instructions.

5. Durability and quality: Invest in a CNC mill that is made from high-quality materials and built to last. This will ensure that your machine can handle the demands of your hobby projects.

6. Customer reviews: Before making a purchase, read reviews from other hobbyists who have purchased the same CNC mill. This will give you insights into the machine’s performance and reliability.

7. Support and warranty: Check if the manufacturer offers good customer support and a warranty for the CNC mill. This will give you peace of mind in case you encounter any issues with the machine.

By considering these tips and factors, you can make an informed decision when purchasing a hobby CNC mill that meets your needs and budget.

FAQs on Sourcing and Manufacturing hobby cnc mill in China

Q: Why should I consider sourcing and manufacturing a hobby CNC mill in China?

A: China is known for its low manufacturing costs, which can help you save money on production. Additionally, China has a vast network of suppliers, factories, and expertise in CNC machining. This allows for greater customization options and access to advanced technologies.

Q: How do I find a reliable supplier or manufacturer in China for a hobby CNC mill?

A: There are several methods to find reliable suppliers. One approach is to search through online sourcing platforms such as Alibaba or Global Sources. These platforms provide a wide range of suppliers, allowing you to compare prices, reviews, and certifications. It is also recommended to conduct a factory audit or request samples before finalizing a supplier.

Q: Can I customize the hobby CNC mill according to my specifications?

A: Yes, one of the advantages of sourcing from China is the ability to customize products to your specific requirements. You can work closely with the supplier to modify the design, functionality, or features of the CNC mill. However, keep in mind that customization may increase the lead time and production costs.

Q: How can I ensure the quality of the hobby CNC mill manufactured in China?

A: To ensure quality, it is crucial to conduct thorough due diligence before choosing a supplier. This includes checking their certifications, production capabilities, and reviewing customer feedback. It is also advisable to request quality control inspections during the manufacturing process and before shipping. Hiring a third-party inspection company can help guarantee product quality.

Q: What are the typical lead times and shipping options for hobby CNC mills from China?

A: Lead times can vary depending on factors such as customization and order volume. On average, manufacturing a hobby CNC mill in China can take around 4-8 weeks. When it comes to shipping, you can choose between air freight, sea freight, or express courier services like DHL or FedEx. Each option has different costs, transit times, and considerations.

In conclusion, sourcing and manufacturing a hobby CNC mill in China can offer cost savings, customization options, and a wide range of suppliers. However, it is essential to conduct thorough research, due diligence, and quality control to ensure a successful outcome.

Why contact sourcifychina.com get free quota from reliable hobby cnc mill suppliers?

SourcifyChina.com gets free quotas from reliable hobby CNC mill suppliers as a way to incentivize customers to use their sourcing platform. By partnering with these suppliers, SourcifyChina.com can offer their customers additional benefits and value when they source CNC mills through their platform.

There are several reasons why these suppliers are willing to provide free quotas. Firstly, it allows them to reach a wider customer base and increase their market visibility. By offering free quotas through SourcifyChina.com, suppliers can attract potential customers who may not have otherwise considered purchasing from them.

Secondly, providing free quotas is a marketing strategy for the suppliers. It allows them to showcase their products and services to potential buyers who are looking for CNC mills. By offering a free quota, suppliers can demonstrate the quality and functionality of their machines, thus increasing the chances of converting these potential customers into paying ones.

Furthermore, offering free quotas can also help suppliers build relationships with the customers. It provides an opportunity for them to offer personalized assistance and guidance in finding the right CNC mill for their specific needs. By offering a free quota and engaging with customers early in the sourcing process, suppliers can establish trust and credibility, enhancing the chances of securing a sale.

Lastly, the collaboration with SourcifyChina.com benefits the suppliers by allowing them to tap into the platform’s customer base, which includes individuals and businesses that are actively seeking CNC mills and related products. This exposure to a targeted audience increases the suppliers’ chances of connecting with potential buyers and expanding their customer network.

In conclusion, offering free quotas through SourcifyChina.com benefits suppliers by increasing their market visibility, showcasing their products, building customer relationships, and accessing a larger customer base. This partnership allows both parties to leverage each other’s strengths and ultimately create a win-win situation for all involved.