Introduce about moule injection plastique guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Mould injection plastic guide provides a comprehensive and practical understanding of the process of injecting plastic into moulds to create various products. This guide covers all aspects, from design and prototyping to production and quality control.

Quality plays a crucial role in mould injection plastic manufacturing. It is essential to ensure that the injection moulded products meet the desired specifications and performance requirements. Quality control practices, such as regular inspections and testing, are carried out to identify and rectify any defects or deviations.

Cost is another significant consideration in mould injection plastic manufacturing. Factors such as material selection, mould design, tooling, production volume, and labour costs determine the overall manufacturing cost. Careful planning and strategic decisions can help optimize the costs and achieve cost-effective production.

Choosing a reliable and experienced mould injection plastic supplier is critical for the success of the manufacturing process. Suppliers with a proven track record in producing high-quality injection moulded parts should be preferred. Additionally, evaluating the supplier’s capabilities, capacity, and customer reviews can help in making an informed decision.

Certifications play a vital role in ensuring product quality and compliance with industry standards. Suppliers with ISO certifications or other relevant certifications demonstrate their commitment to quality and continuous improvement.

Mould injection plastic products have a broad market spectrum, including automotive, electronics, consumer goods, healthcare, and packaging industries. The demand for plastic injection moulded products continues to grow due to their versatility, efficiency, and durability.

Here are some tips for successful mould injection plastic manufacturing:

1. Collaborate closely with the design team to ensure the product design is optimized for the injection moulding process.

2. Conduct thorough material selection, keeping in mind the desired properties and requirements of the final product.

3. Regularly schedule preventive maintenance for the moulds to avoid production disruptions and reduce the risk of defects.

Frequently Asked Questions (FAQ):

Q: What are the advantages of mould injection plastic?

A: Mould injection plastic offers high production efficiency, excellent precision, cost-effectiveness, and the ability to produce complex shapes.

Q: What are the common materials used in mould injection plastic?

A: Common materials include polypropylene (PP), polyethylene (PE), polystyrene (PS), acrylonitrile butadiene styrene (ABS), and polyvinyl chloride (PVC), among others.

Q: How long does the mould injection plastic process take?

A: The processing time varies depending on the complexity and size of the part but can range from seconds to minutes.

In summary, the mould injection plastic guide covers all aspects of the manufacturing process, including quality, cost, suppliers, certifications, market applications, and essential tips. This guide serves as a valuable resource for both beginners and professionals in the plastic injection moulding industry.

Types of moule injection plastique

There are several types of mold injection techniques for plastic, each with its own unique advantages and applications. These techniques are used to produce a wide range of plastic products, from small intricate parts to large complex components. Here are four commonly used types of mold injection plastic processes:

1. Conventional Injection Molding: This is the most common and widely used technique in the industry. It involves injecting molten plastic material into a mold under high pressure. The material is then cooled and solidified, allowing the mold to be opened, and the final product to be ejected. Conventional injection molding offers high precision, good surface finish, and is suitable for high-volume production.

2. Insert Molding: Insert molding involves placing metal or plastic inserts into the mold cavity before the injection process begins. Molten plastic material is then injected around the inserts, bonding them to the plastic component. This technique is commonly used for adding threaded inserts, electrical components, or reinforcement to the molded parts, reducing assembly time and increasing component strength.

3. Overmolding: Overmolding is a process where multiple materials are combined to create a single part. It involves injecting a second material over a previously molded part, creating a smooth and tight bond between the two materials. Overmolding is commonly used for adding soft-touch grips, color variations, or additional features to a part, enhancing its aesthetics and functionality.

4. Thin Wall Molding: Thin wall molding is used to produce lightweight and thin-walled plastic parts. It requires specialized molds and high injection speeds to ensure the filling of thin sections without causing defects. This technique is commonly used in food packaging, medical containers, and electronic components manufacturing.

These mold injection techniques can be further enhanced by incorporating advanced technologies such as gas-assisted injection molding, co-injection molding, and micro-injection molding, among others. Each technique offers unique advantages and is selected based on the desired part characteristics, production volume, and cost considerations. It is essential to work closely with mold injection experts and manufacturers to determine the most suitable technique for your specific application.

Pros and Cons of Using moule injection plastique

Injection Molding is a highly versatile manufacturing process used to produce a wide range of plastic parts. Mold injection plastique, or plastic injection molding, offers several advantages and disadvantages, which are outlined below.

Pros:

1. High Precision: Injection molding allows for intricate and complex part designs with precise dimensions and tight tolerances. This method consistently produces high-quality and repeatable parts with minimal variability.

2. Cost-Effective: Injection molding is considered cost-effective for high-volume production runs as it enables the quick and efficient mass production of parts. The cost per part decreases significantly with larger production quantities.

3. Wide Material Selection: There is a vast selection of plastic materials available for injection molding. This enables engineers to choose specific materials that offer various properties such as strength, flexibility, heat resistance, and more.

4. Automation and Efficiency: Injection molding is a highly automated process, requiring minimal human intervention once the mold design is established. This leads to increased production efficiency, reduced labor costs, and quicker cycle times.

5. Waste Reduction: Injection molding generates minimal waste as excess plastic material can be reused. Moreover, this process contributes to a more sustainable production method compared to other manufacturing techniques.

Cons:

1. High Initial Tooling Cost: The primary disadvantage of injection molding is the high upfront cost associated with designing and manufacturing the molds. These molds are typically made from steel or aluminum and require significant time and expertise to develop, which can be expensive for low-volume production or prototyping.

2. Time-Intensive Setup: Setting up the injection molding process involves meticulous attention to detail and can be time-consuming. Factors such as material preparation, mold setup, and machine adjustments must be carefully executed before production commences, potentially delaying time-to-market.

3. Design Limitations: Injection molding has certain design limitations and restrictions, which may impact part complexity and geometry. For example, undercuts or intricate features might require additional mold design considerations and lead to higher tooling costs.

4. Part Size Limitations: Large-scale parts may be challenging to produce using injection molding due to machine and mold size limitations. This might require manufacturers to explore alternative production methods for oversized components.

5. Environmental Impact: While injection molding is generally considered a sustainable manufacturing process due to waste reduction, the disposal of plastic waste remains an ongoing challenge. Manufacturers must adopt responsible waste management practices to minimize the environmental impact.

In conclusion, mold injection plastique offers various benefits such as high precision, cost-effectiveness, material versatility, automation, and waste reduction. However, it also has drawbacks, including the high upfront tooling cost, time-intensive setup, design limitations, part size restrictions, and potential environmental concerns. It is crucial for manufacturers to weigh these pros and cons when considering plastic injection molding for their production requirements.

moule injection plastique Reference Specifications (varies for different product)

The reference specifications for plastic injection molding can vary depending on the specific product being manufactured. However, there are certain common parameters that are typically considered during the design and production of plastic injection molded products.

One important specification is the material used for injection molding. The choice of material depends on the desired properties of the final product, such as strength, rigidity, flexibility, heat resistance, and appearance. Common plastic materials used for injection molding include polyethylene (PE), polypropylene (PP), polystyrene (PS), acrylonitrile butadiene styrene (ABS), and polyvinyl chloride (PVC), among others.

The dimensions and tolerances are crucial reference specifications in injection molding. The part dimensions are determined based on the desired final product’s function and appearance. Tolerances, or allowable variations in dimensions, are specified to ensure the molded parts meet the required dimensional accuracy. This ensures proper fit and function when assembled with other components or in the final product.

Injection molding also requires the determination of the wall thickness. The wall thickness affects the strength, rigidity, and cost of a plastic part. Thicker walls provide greater strength but increase material consumption and production time. Thinner walls, on the other hand, can reduce material consumption but may compromise the structural integrity of the part.

The tooling specifications are another important consideration. These include the number of cavities in the mold, which determines the number of parts produced per cycle. The choice of mold material, such as steel or aluminum, depends on factors like production volume, cost, and durability requirements. The cooling system design is also critical to achieve proper heat dissipation during the molding process and ensure consistent part quality.

Other reference specifications may include surface finish requirements, such as texture or gloss, as well as any additional features like inserts or overmolding.

In summary, reference specifications in plastic injection molding encompass the selection of material, part dimensions and tolerances, wall thickness, tooling specifications, surface finish requirements, and other unique product features. These specifications must be carefully considered to ensure the successful production of high-quality plastic injection molded products.

Applications of moule injection plastique

Injection molding is a versatile manufacturing process that is widely used in various industries for producing plastic components and products. Some common applications of plastic injection molding include:

1. Automotive industry: Injection molded plastic parts are used in vehicles for interior and exterior components such as bumpers, dashboards, door panels, and headlight covers.

2. Consumer goods: Many consumer products, such as toys, kitchenware, appliances, and electronic devices, are made using injection molding due to its efficiency and cost-effectiveness.

3. Medical devices: Injection molding is used to manufacture a wide range of medical devices, including syringes, tubing, surgical instruments, and implantable devices, due to its ability to produce complex and precise components.

4. Packaging industry: Plastic injection molding is commonly used in the production of packaging materials such as bottles, caps, containers, and lids due to its ability to create lightweight, durable, and cost-effective solutions.

5. Aerospace industry: Injection molded plastic components are used in aircraft interiors, seating systems, and structural parts due to their ability to meet stringent industry standards for performance and safety.

Overall, injection molding offers numerous advantages for manufacturers, including high production rates, consistent part quality, design flexibility, and cost-effectiveness. It is a widely utilized manufacturing process that continues to drive innovation and efficiency across a wide range of industries.

The Work Process and how to use moule injection plastique

The work process for using a plastic injection molding machine involves several key steps.

1. Design: The first step in the process is designing the mold that will be used for the injection molding process. The design must be precise and efficient in order to produce high-quality plastic parts.

2. Material Selection: The next step is selecting the appropriate plastic resin for the project. Different types of plastics have different properties, so it is important to choose the right material for the desired end product.

3. Machine Setup: Once the mold design and material selection are completed, the injection molding machine must be set up and calibrated. This involves adjusting the temperature, pressure, and speed settings to ensure optimal production.

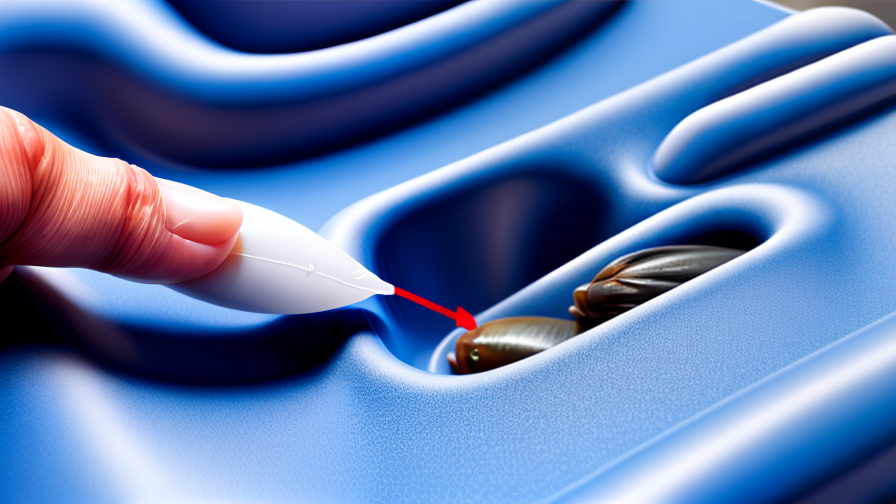

4. Injection: The actual injection molding process involves melting the plastic resin and injecting it into the mold cavity under high pressure. The plastic then cools and hardens, taking on the shape of the mold.

5. Ejection: Once the plastic has cooled and solidified, the molded part is ejected from the mold cavity.

6. Finishing: Finally, the finished plastic part may require trimming, polishing, or other finishing touches to meet the desired specifications.

Overall, the plastic injection molding process is a highly efficient and cost-effective way to produce large quantities of plastic parts. By following these steps and using proper techniques, manufacturers can produce high-quality plastic products with precision and consistency.

Quality Testing Methods for moule injection plastique and how to control the quality

When it comes to quality testing methods for plastic injection molding, there are several crucial steps to ensure top-notch quality control. First and foremost, it is important to perform initial inspections to check the raw materials before the injection process begins. This involves thorough examination of the plastic pellets for any visual defects or impurities.

Next, during the molding process, regular checking of the injection molding machine parameters is essential. This includes monitoring the temperature, pressure, and cycle time to ensure they are within the specified range for the particular plastic material being used. These parameters can greatly impact the final product’s quality, so any deviations should be promptly addressed.

Post-molding inspections are equally crucial for quality control. This can involve visual inspections to identify any surface defects such as sink marks, flash, or warping. Dimensional checks are also important, utilizing measuring tools to ensure the product conforms to the specified dimensions.

Another commonly used quality testing method is mechanical testing, such as tensile strength, impact resistance, or flexural modulus tests. These tests help determine the product’s mechanical properties and ensure it meets the required standards or specifications.

Particularly in precise and critical applications, the use of non-destructive testing methods like X-ray or ultrasound can be employed to detect any hidden defects within the plastic components.

Additionally, it is vital to establish a robust quality control system. This includes implementing regular quality audits, conducting employee training programs to enhance their understanding of quality standards, and documenting all quality control processes for continuous improvement.

To summarize, quality testing methods for plastic injection molding involve initial material inspections, monitoring machine parameters during the molding process, post-molding inspections for visual and dimensional checks, mechanical testing to assess mechanical properties, and non-destructive testing for critical applications. By implementing a comprehensive quality control system, manufacturers can ensure consistent quality throughout the production process, reducing defects and enhancing customer satisfaction.

moule injection plastique Sample Policy and Post-Purchase Considerations for moule injection plastique from China

Sample Policy and Post-Purchase Considerations for moule injection plastique from China

Sample Policy:

When sourcing moule injection plastique from China, it is essential to establish a clear understanding with the supplier regarding the sample policy. Here are some key points to consider:

1. Sample Availability: Confirm whether the supplier can provide samples of the desired moule injection plastique. This allows you to inspect the product quality, design, and functionality before making a purchase decision.

2. Sample Cost and Shipment: Discuss the cost of samples, including any applicable shipping charges. Determine who will bear the sample expenses and clarify whether the payment will be deducted from future orders.

3. Sample Lead Time: Inquire about the expected lead time for sample production. It is crucial to evaluate whether the supplier can provide samples within an acceptable timeframe.

4. Sample Modifications: If necessary, clarify whether the supplier is open to making modifications to the sample based on your specifications. Establish the terms and conditions for any changes required.

Post-Purchase Considerations:

After the purchase of moule injection plastique from China, certain factors need to be considered for a successful transaction. Here are some key points to evaluate:

1. Quality Assurance: Conduct a thorough inspection of the received products to ensure they meet the agreed-upon specifications and are free from defects. Notify the supplier immediately if any quality issues are identified.

2. Delivery Time: Evaluate whether the supplier has met the agreed delivery timeline. Delays in shipment may impact your production schedule. Communicate with the supplier to address any concerns promptly.

3. Packaging: Assess the packaging of the products to ensure they are adequately protected during transportation. If necessary, provide feedback to the supplier to improve packaging and reduce the risk of damage.

4. Warranty and Support: Discuss any warranty terms and after-sales support provided by the supplier. Understand the conditions under which the supplier will address product defects or offer replacements.

5. Communication: Maintain open communication with the supplier throughout the post-purchase process. Address any concerns or issues promptly to achieve a mutually beneficial resolution.

By considering these sample policy and post-purchase considerations, you can enhance the overall experience of sourcing moule injection plastique from China, ensuring a smooth and successful transaction. Always establish a clear understanding with the supplier regarding expectations, quality, and support to minimize any potential risks associated with the purchase.

Sourcing moule injection plastique from China: Opportunities, Risks, and Key Players

Sourcing plastic injection molding from China offers various opportunities for businesses. China is known for its competitive pricing, making it one of the world’s largest manufacturing hubs. The availability of skilled labor and a developed infrastructure further enhance China’s appeal as a sourcing destination for plastic injection molding.

One of the significant opportunities is cost savings. China’s low production costs enable businesses to obtain high-quality plastic injection molding at a lower price compared to other countries. This cost advantage allows companies to remain competitive and potentially increase their profitability.

Another opportunity is the vast manufacturing capacity in China. Chinese factories are equipped with advanced machinery and technology, which enables them to produce large quantities of plastic injection molding efficiently. This capacity ensures prompt order fulfillment and reduces the risk of delays in production.

Despite the opportunities, there are risks associated with sourcing plastic injection molding from China. Quality control can be a concern, as there is a wide range of manufacturers in China with varying levels of expertise and adherence to international standards. It is essential for businesses to conduct thorough due diligence and select reliable manufacturers to ensure the desired quality.

Intellectual property protection is another risk. China has faced criticism for its lax enforcement of intellectual property rights, which may pose a risk to businesses that rely on proprietary molds or designs. Implementing strict contractual agreements and working with trustworthy partners can help mitigate this risk.

Key players in the plastic injection molding industry in China include Jabil, Hon Hai Precision Industry (Foxconn), Flex Ltd, and Plastic Omnium. These companies have established themselves as leaders in the industry by offering a wide range of plastic injection molding services and maintaining high-quality production standards.

In conclusion, sourcing plastic injection molding from China presents opportunities for businesses to reduce costs and access large manufacturing capacity. However, businesses should carefully assess the risks, such as quality control and intellectual property protection, before engaging with Chinese manufacturers. Working with reputable key players in the industry can help mitigate these risks and ensure successful sourcing from China.

How to find and select reliable moule injection plastique manufacturers in China,use google search manufacturers and suppliers

When it comes to finding and selecting reliable plastic injection molding manufacturers in China, Google search is a useful tool that can help you discover various manufacturers and suppliers. Here are a few guidelines to follow when using Google search to narrow down your options:

1. Start by typing relevant keywords such as “plastic injection molding manufacturers in China” or “reliable plastic injection molding suppliers” in the search bar. This will provide you with a list of potential manufacturers.

2. Visit the websites of the manufacturers in the search results. Pay attention to the design and quality of the website, as a professional and well-maintained website often indicates a reliable manufacturer. Look for information about the company’s experience, certifications, production capacity, and range of services.

3. Check for customer reviews and testimonials. Search for feedback or reviews from previous clients, either on the manufacturer’s website or on reputable review platforms. This will give you an idea of the manufacturer’s reputation and the quality of their products.

4. Contact the manufacturers directly. Request quotes, ask questions about their processes, materials, and quality control measures. A reliable manufacturer will be responsive, provide detailed information, and address any concerns or queries.

5. Consider visiting trade shows or exhibitions related to plastic injection molding in China. This allows you to meet potential manufacturers in person, view samples of their products, and establish personal connections.

6. Verify the manufacturer’s credibility. Look for certifications such as ISO 9001, which ensures adherence to quality management systems. Additionally, consider conducting a factory audit or asking for samples to assess the manufacturer’s production capabilities and quality standards.

7. Compare and evaluate multiple manufacturers. Don’t rush into making a decision. Compare quotes, lead times, quality standards, and overall customer service to determine the most suitable manufacturer for your requirements.

Remember to do thorough research, ask relevant questions, and consider multiple factors beyond price alone when selecting a reliable plastic injection molding manufacturer in China.

How to check moule injection plastique manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a plastic injection molding manufacturer’s website, use Google Chrome with the SEOquake extension to check if they rank in the top 10 for relevant keywords. This will help you gauge their popularity and credibility in the industry. Additionally, look for customer reviews, testimonials, and case studies on their website to see if they have a history of providing quality products and services. Check if they have certifications or partnerships with reputable organizations in the industry. Look for a physical address, contact information, and a clear about us page to ensure they are a legitimate company. Finally, compare the information provided on their website with other sources to verify their claims and ensure they are a trustworthy manufacturer.

Top 10 moule injection plastique manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. ACO Mold

ACO Mold is a professional plastic injection molding manufacturer in China. They specialize in providing high-quality custom injection molding services for various industries. Their products include plastic molds, injection molded parts, and custom plastic injection molding solutions.

2. Focare Mould

Focare Mould is a leading plastic injection molding company in China, offering a wide range of plastic injection molding products such as auto parts, electrical components, and medical devices. They are known for their precision and attention to detail in every project.

3. Sositar Mould

Sositar Mould is a reputable plastic injection molding manufacturer in China, known for their innovative designs and high-quality products. They offer a wide range of plastic injection molding services, including rapid prototyping, mold design, and production.

4. HQMOULD

HQMOULD is a trusted plastic injection molding company in China, providing custom injection molding solutions for a variety of industries. Their products include plastic molds, injection molded parts, and tooling solutions.

5. Xiamen Karo Co., Ltd

Xiamen Karo Co., Ltd is a well-established plastic injection molding manufacturer in China, offering a wide range of plastic injection molded products such as household items, electronic components, and automotive parts. They are known for their excellent quality and reliability.

6. Hongsinn Precision Mould

Hongsinn Precision Mould is a professional plastic injection molding company in China, specializing in providing high-quality plastic injection molding solutions for various industries. They offer custom mold design, mold making, and production services.

7. Dongguan Yixun Industrial Co., Ltd

Dongguan Yixun Industrial Co., Ltd is a leading plastic injection molding manufacturer in China, offering custom injection molded products for industries such as electronics, automotive, and medical. They are known for their advanced technologies and competitive pricing.

8. Taizhou Huangyan JMT Mould Co., Ltd

JMT Mould Co., Ltd is a reputable plastic injection molding company in China, providing high-quality injection molded products for industries such as automotive, electrical, and medical. They offer custom mold design, mold making, and production services.

9. Shanghai PDM Mould & Plastic Co., Ltd

Shanghai PDM Mould & Plastic Co., Ltd is a professional plastic injection molding manufacturer in China, specializing in providing custom injection molding solutions for industries such as electronics, automotive, and household appliances. They are known for their high-quality products and excellent customer service.

10. Kunshan Feiya Precision Moulding Co., Ltd

Feiya Precision Moulding Co., Ltd is a well-established plastic injection molding company in China, offering a wide range of injection molded products for industries such as automotive, electronics, and medical. They provide custom mold design, mold making, and production services to meet their customers’ specific requirements.

| Manufacturer | Specialization | Products | Innovative Designs |

| — | — | — | — |

| ACO Mold | Various industries | Plastic molds, injection molded parts | No |

| Focare Mould | Auto parts, electrical components, medical devices | Plastic injection molding products | Yes |

| Sositar Mould | Custom injection molding services | Rapid prototyping, mold design | Yes |

| HQMOULD | Various industries | Plastic molds, injection molded parts | No |

| Xiamen Karo Co., Ltd | Household items, electronic components, automotive parts | Plastic injection molded products | No |

| Hongsinn Precision Mould | Various industries | High-quality plastic injection molding solutions | No |

| Dongguan Yixun Industrial Co., Ltd | Electronics, automotive, medical | Custom injection molded products | Yes |

| Taizhou Huangyan JMT Mould Co., Ltd | Automotive, electrical, medical | High-quality injection molded products | No |

| Shanghai PDM Mould & Plastic Co., Ltd | Electronics, automotive, household appliances | Custom injection molding solutions | No |

| Kunshan Feiya Precision Moulding Co., Ltd | Automotive, electronics, medical | Injection molded products | No |

Background Research for moule injection plastique manufacturers Companies in China, use qcc.com archive.org importyeti.com

When looking for mold injection plastic manufacturers in China, there are several platforms and websites that can provide valuable background research. Three key resources for this purpose are qcc.com, archive.org, and importyeti.com.

Qcc.com is a popular Chinese business information platform that offers comprehensive company profiles and relevant business records. It provides a detailed overview of a company’s registration information, such as its legal status, registration date, business scope, and operating conditions. Additionally, qcc.com also offers financial data, shareholder information, and company contacts, which can be useful for assessing the credibility and reputation of mold injection plastic manufacturers in China.

Archive.org is a renowned digital library that archives and preserves content from the internet. It can be utilized to access historical records, including previous versions of websites and company information. This resource can help in evaluating the long-term performance and stability of manufacturers, enabling the identification of any potential issues or changes in their operations over time.

Importyeti.com is a widely used trade data platform that provides valuable import and export information. By searching for specific company names or products, importyeti.com allows the retrieval of shipment records, including details about the consignee, consignor, quantity, and destination. This information can be helpful in verifying a manufacturer’s exporting experience, market reach, and the type of clients they typically work with.

Combining these resources can offer a comprehensive understanding of mold injection plastic manufacturers in China. The information retrieved from qcc.com, archive.org, and importyeti.com provides valuable insights into a company’s background, credibility, stability, and market reach. By utilizing these platforms, individuals and businesses can make informed decisions when selecting a reliable manufacturer for their mold injection plastic needs.

Leveraging Trade Shows and Expos for moule injection plastique Sourcing in China

Trade shows and expos can be a valuable resource for sourcing moule injection plastique in China. These events provide companies with the opportunity to connect with a wide range of suppliers, compare products and services, and build relationships with potential partners.

By attending trade shows and expos focused on plastic injection molding, companies can gain insights into the latest trends and developments in the industry. They can also explore different suppliers and manufacturers, all in one convenient location. This can help companies streamline their sourcing process and find the right partner for their specific needs.

Additionally, trade shows and expos provide companies with the chance to meet face-to-face with suppliers, ask questions, and see product samples firsthand. This can help companies assess the quality of the products, the capabilities of the suppliers, and their overall compatibility with the company’s requirements.

To make the most of trade shows and expos for moule injection plastique sourcing in China, companies should come prepared with a clear understanding of their sourcing needs, a list of potential suppliers to visit, and a budget for sourcing activities. They should also take the time to network with other industry professionals, attend relevant seminars and presentations, and follow up with potential partners after the event.

Overall, leveraging trade shows and expos for moule injection plastique sourcing in China can be a cost-effective and efficient way to find the right supplier for your business. It allows companies to access a wide range of options, make informed decisions, and build strong relationships with suppliers that can lead to long-term success.

The Role of Agents and Sourcing Companies in Facilitating moule injection plastique Purchases from China

Agents and sourcing companies play a crucial role in facilitating purchases of moule injection plastique (plastic injection molds) from China. These intermediaries serve as the bridge between the buyers and manufacturers, ensuring a smooth and efficient sourcing process. Their involvement brings numerous benefits to international buyers looking to purchase injection molds from China.

Firstly, agents and sourcing companies possess extensive knowledge and expertise of the local market in China. They have a deep understanding of the country’s manufacturing landscape, particularly in the field of injection molding. This expertise allows them to identify reputable and reliable manufacturers capable of meeting the buyer’s specific requirements. By pre-vetting and screening potential suppliers, agents and sourcing companies save buyers from the arduous and time-consuming process of researching and evaluating manufacturers themselves.

Secondly, these intermediaries provide effective communication facilitation between the buyer and the Chinese manufacturers. They act as a proxy between the parties, ensuring that the buyer’s requirements and specifications are accurately communicated to the manufacturer. This helps in avoiding miscommunication and potential misunderstandings that may arise due to language barriers or cultural differences.

Furthermore, agents and sourcing companies assist in negotiating favorable pricing and contractual terms with the manufacturers. They possess an in-depth understanding of the Chinese market dynamics, including pricing trends, production costs, and local business practices. Leveraging this knowledge, they can help buyers secure competitive prices, favorable payment terms, and quality assurances from the manufacturers.

Additionally, agents and sourcing companies provide quality control services throughout the production process. They conduct regular factory inspections and ensure that the manufacturing process adheres to the highest industry standards. This helps in mitigating the risk of substandard products and ensuring compliance with the buyer’s specifications.

Lastly, agents and sourcing companies also handle logistical aspects such as shipping, customs clearance, and documentation. They streamline the entire supply chain process, ensuring that the products are shipped promptly and arrive at the buyer’s destination without any complications.

In conclusion, the role of agents and sourcing companies in facilitating moule injection plastique purchases from China is critical. Their expertise in the local market, communication facilitation, negotiation skills, quality control services, and logistical support ensure a seamless and successful sourcing experience for international buyers.

Price Cost Research for moule injection plastique manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for plastic injection mold manufacturers in China, two popular online platforms to consider are temu.com and 1688.com. These platforms provide a wide range of options with competitive pricing for buyers looking to source from Chinese manufacturers.

temu.com is an online marketplace that connects buyers and suppliers in various industries. It offers a convenient search feature that allows users to filter their search criteria and find suitable plastic injection mold manufacturers. The platform provides detailed product information, company profiles, customer reviews, and pricing information, which enables buyers to compare prices and make informed decisions. With a user-friendly interface, temu.com simplifies the process of price cost research and streamlines communication with potential suppliers.

1688.com, owned by Alibaba Group, is a leading B2B platform specifically designed for the Chinese market. It offers a vast selection of suppliers, including plastic injection mold manufacturers, often at lower prices than other platforms. While the website is in Chinese, buyers can use translation tools or work with agents familiar with the language to navigate and search for manufacturers. They can contact suppliers directly, negotiate prices, and request quotations to gather cost-related information effectively.

When conducting price cost research, it is essential to consider factors such as the quality of the products, the manufacturer’s capabilities and certifications, the production capacity, and the supplier’s reputation. Reading customer reviews and ratings can provide valuable insights into the reliability and trustworthiness of the manufacturers. It is also recommended to contact multiple suppliers to compare their prices, terms, and conditions before making any purchasing decisions.

By utilizing temu.com and 1688.com, buyers can access a wide range of plastic injection mold manufacturers in China. These platforms provide an opportunity to gather price cost information and ensure a transparent and competitive sourcing process.

Shipping Cost for moule injection plastique import from China

When importing plastic injection molds from China, the shipping cost will depend on various factors including the size and weight of the molds, the shipping method chosen, and the distance between China and the destination country.

For small molds, air freight may be the most cost-effective option. The average air freight cost from China to most countries is around $3-$6 per kg for small parcels. However, for larger molds, sea freight may be a more economical choice. The average sea freight cost from China to most countries is around $400-$800 per cubic meter.

Additionally, there may be additional costs such as customs duties, import taxes, and handling fees that need to be taken into consideration. These costs can vary depending on the country of import and the value of the molds.

To ensure that the shipping cost does not exceed $300, it is important to carefully calculate the dimensions and weight of the molds, compare different shipping options, and consider consolidating multiple orders to save on shipping expenses. Working with a reputable freight forwarder or shipping agent can also help ensure that the shipping process is smooth and cost-effective.

Overall, by carefully considering all factors and choosing the most suitable shipping method, it is possible to import plastic injection molds from China without exceeding a shipping cost of $300.

Compare China and Other moule injection plastique Markets: Products Quality and Price,Visible and Hidden Costs

China is known for its large-scale production of plastic injection molding products, offering a wide range of products at competitive prices. The quality of products produced in China is generally good, with many manufacturers meeting international standards for production. However, there can be variability in quality depending on the supplier and production processes used.

Other mold injection plastic markets, such as those in Europe or the United States, are often seen as offering higher quality products compared to China. Manufacturers in these markets tend to have more stringent quality control measures in place, resulting in products that are more consistent and reliable. As a result, products from these markets may be higher priced compared to those from China.

Visible costs, such as the initial purchase price of products, may be lower when sourcing from China compared to other markets. However, there are hidden costs that may need to be considered when sourcing from China, such as shipping and import duties. These additional costs can impact the overall price competitiveness of products sourced from China.

In contrast, products sourced from other mold injection plastic markets may have higher upfront costs but may have lower hidden costs due to closer proximity to the end market. This can result in a more predictable total cost of ownership for products sourced from these markets.

In conclusion, while China offers a wide range of plastic injection molding products at competitive prices, other markets may offer higher quality products with potentially lower hidden costs. Businesses should carefully evaluate their sourcing options to determine the most suitable market for their specific needs.

Understanding Pricing and Payment Terms for moule injection plastique: A Comparative Guide to Get the Best Deal

When negotiating pricing and payment terms for moule injection plastique, it is important to consider the quality of the product, the complexity of the mold, and the quantity being produced.

One important factor to consider is the cost of materials and labor required to manufacture the mold. It is also important to consider the overhead costs and profit margin of the manufacturer.

When comparing different suppliers, it is important to ask for detailed quotes that break down all costs including materials, labor, overhead, and profit margin. This will help you understand the true cost of the mold and compare pricing more accurately.

Payment terms can vary between suppliers, with some requiring full payment upfront, others requiring a deposit with the remainder upon completion, and others offering a payment plan. It is important to consider your cash flow and budget when negotiating payment terms.

When negotiating pricing and payment terms, it is important to also consider the reputation and track record of the supplier. A lower price may not always be the best deal if it means sacrificing quality or reliability.

In conclusion, to get the best deal on moule injection plastique, it is important to compare quotes from multiple suppliers, consider the total cost of the mold, negotiate payment terms that work for your budget, and consider the reputation of the supplier. By taking these factors into consideration, you can ensure you are getting the best value for your money.

Chinese Regulations and Industry Standards Certifications for moule injection plastique,Import Regulations and Customs for moule injection plastique from China

In China, mold injection plastic products must adhere to certain regulations and industry standards in order to ensure quality and safety. Some of the key certifications that manufacturers must obtain include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and ISO 13485 for medical devices.

Importing mold injection plastic products from China may involve certain regulations and customs procedures. It is important to consider factors such as tariffs, import duties, and product labeling requirements. Additionally, customs authorities may require documentation such as a bill of lading, commercial invoice, and packing list.

When importing mold injection plastic products from China, it is recommended to work with a reputable manufacturer who can provide the necessary certifications and comply with industry standards. It is also advisable to partner with a reliable freight forwarder or customs broker who can assist with the import process and ensure compliance with regulations.

By adhering to these regulations and certifications, as well as understanding import regulations and customs procedures, businesses can ensure that their mold injection plastic products meet quality standards and can be successfully imported from China.

Sustainability and Environmental Considerations in moule injection plastique Manufacturing

Sustainability and environmental considerations play a crucial role in the manufacturing process of plastic injection molding. Plastic injection molding is a widely used and highly efficient manufacturing method for producing a wide range of plastic products. However, it is necessary to address the sustainability challenges associated with this process to minimize its environmental impact.

To achieve sustainability in plastic injection molding, several key aspects need to be considered. Firstly, the selection of raw materials is vital. Choosing sustainable and eco-friendly materials, such as biodegradable plastics or recycled materials, can greatly reduce the environmental footprint of the manufacturing process. Additionally, optimizing the material used for each product to minimize waste is essential.

Another important consideration is energy consumption. Reducing energy consumption during the manufacturing process can significantly reduce greenhouse gas emissions and contribute to a more sustainable operation. This can be achieved through the use of energy-efficient machinery, implementing energy-saving practices, and utilizing renewable energy sources.

Waste management is a critical aspect of sustainability in plastic injection molding. Implementing recycling programs and proper waste segregation procedures can help minimize the amount of waste generated during the manufacturing process. Additionally, reusing scrap materials and properly disposing of hazardous waste are essential steps in reducing the environmental impact.

The concept of product lifecycle management should also be taken into account in plastic injection molding. Designing products that are durable, recyclable, and have a longer lifespan can contribute to reducing waste and conserving resources. Additionally, incorporating circular economy principles, such as product repair and refurbishment, can further enhance the sustainability of the manufacturing process.

Finally, it is important to consider the social aspect of sustainability in plastic injection molding. Ensuring a safe and healthy working environment for employees, along with fair labor practices, contributes to overall sustainability.

In conclusion, achieving sustainability in plastic injection molding involves considering various environmental aspects such as material selection, energy consumption, waste management, and product lifecycle management. By addressing these factors, manufacturers can minimize the environmental impact of the process and contribute to a more sustainable future.

List The Evolution history of “moule injection plastique”

The evolution history of “moule injection plastique” or plastic injection molding can be traced back to the late 19th century. The process was developed as a solution for manufacturing complex and intricate plastic parts.

In the early stages, plastic injection molding involved the manual injection of molten plastic into a mold cavity. The injection was typically performed using a plunger or a screw-type mechanism. However, this method was slow, labor-intensive, and not suitable for large-scale production.

The first significant development in the evolution of plastic injection molding came in the 1930s with the introduction of the screw injection molding machine. This innovation allowed for faster and more efficient injection of plastic into molds. The screw mechanism enhanced the consistency and accuracy of the injection process.

During the 1940s and 1950s, further advancements were made in the field of plastic injection molding. These included the introduction of automatic injection molding machines and the use of thermoplastics for molding. The use of thermoplastics provided improved flexibility and reusability of molds, making the process more cost-effective.

In the 1960s, computerization and automation started to revolutionize plastic injection molding. Computer-controlled injection molding machines were developed, which allowed for precise control over the injection process, resulting in high-quality plastic parts. The automation of various stages of the process, such as mold closing and ejection, further increased efficiency and productivity.

The 1980s witnessed the adoption of technological advancements such as the use of 3D computer-aided design (CAD) and computer-aided manufacturing (CAM) systems for mold design and production. These systems enabled faster design iterations and improved accuracy.

In recent years, there have been continuous improvements in plastic injection molding technology. The development of electric and hybrid injection molding machines has led to energy savings and reduced environmental impact. The integration of robotics and automation has further streamlined and optimized the manufacturing process, minimizing human error and increasing productivity.

With the ongoing advancements in materials, machinery, and technology, plastic injection molding continues to evolve. It has become a vital manufacturing method in various industries, including automotive, electronics, medical, and consumer goods, due to its versatility, efficiency, and cost-effectiveness.

The Evolution and Market Trends in moule injection plastique Industry

The mould injection plastique industry has undergone significant evolution and witnessed various market trends in recent years. This industry primarily involves the production of plastic parts through the process of injection moulding.

One of the key evolutions in this industry is the adoption of new technologies and materials. With advancements in manufacturing processes, mould injection plastique companies have been able to improve the precision, speed, and quality of plastic parts production. The introduction of computer numerical control (CNC) machines has allowed for more efficient and automated production, reducing labor costs and increasing productivity. Additionally, the development of new plastic materials with enhanced properties, such as high strength and heat resistance, has expanded the applications of mould injection plastique in various industries.

In terms of market trends, one notable trend is the increasing demand for lightweight and eco-friendly products. With growing concerns about sustainability and environmental impact, there is a growing preference for plastic parts that are lightweight, recyclable, and made from bio-based materials. This trend has prompted manufacturers in the mould injection plastique industry to invest in research and development of innovative materials and production processes that align with sustainability goals.

Another trend in the industry is the rising demand for complex and customized plastic parts. With increased competition and changing consumer preferences, manufacturers are focused on offering products that meet specific requirements and provide unique functionalities. This has led to the adoption of advanced mould design and simulation software, enabling manufacturers to produce complex geometries and achieve tight tolerances in their plastic parts.

Furthermore, the global market for mould injection plastique is expanding due to various factors such as industrialization, urbanization, and the growth of automotive and electronics industries. The increasing demand for consumer goods, medical devices, and packaging materials has further contributed to the market growth. As a result, mould injection plastique companies have been investing in capacity expansion, geographical expansion, and mergers and acquisitions to cater to the growing market demand.

In conclusion, the mould injection plastique industry has evolved significantly with the adoption of new technologies and materials. Market trends include the demand for lightweight and eco-friendly products, customization, and the expansion of the global market. With these developments, the industry is poised for continued growth and innovation in the coming years.

Custom Private Labeling and Branding Opportunities with Chinese moule injection plastique Manufacturers

Looking to create a unique product line with custom private labeling and branding? Look no further than Chinese moule injection plastique manufacturers! These manufacturers offer a wide range of customization options to help you bring your vision to life.

From choosing the color and material of your products to adding logos, slogans, and other branding elements, Chinese moule injection plastique manufacturers have the expertise and capabilities to help you create a truly one-of-a-kind product line. Whether you’re looking to launch a new line of consumer goods, promotional items, or industrial products, these manufacturers can help you achieve your goals.

With years of experience in the industry, Chinese moule injection plastique manufacturers have a reputation for producing high-quality, cost-effective products that meet the needs of their clients. They work closely with you throughout the design and production process to ensure that your custom private labeling and branding requirements are met to your satisfaction.

So if you’re ready to take your brand to the next level with custom private labeling and branding opportunities, consider partnering with a Chinese moule injection plastique manufacturer. With their expertise, experience, and commitment to quality, you can trust that your products will be produced to the highest standards and help you stand out in the competitive marketplace.

Tips for Procurement and Considerations when Purchasing moule injection plastique

When it comes to purchasing moule injection plastique, there are several considerations and tips that can help ensure a successful procurement process. Here are some key factors to keep in mind:

1. Define your requirements: Before initiating the purchasing process, clearly define your specific requirements for the moule injection plastique. Consider factors such as the size, complexity, material, and desired output of the mold.

2. Quality assurance: Ensure that the manufacturer you choose has robust quality assurance procedures in place. Request information on their quality control processes, certifications, and previous experience in manufacturing molds.

3. Supplier selection: Take time to research and select a reputable supplier or manufacturer for your moule injection plastique. Consider factors such as their track record, expertise, and customer reviews.

4. Customization options: Determine whether you require any customization options for your mold. Some suppliers may offer customization options such as surface finishes, textures, or inserts.

5. Cost considerations: While price should not be the sole factor in your decision, it’s essential to evaluate the cost of the moule injection plastique. Request quotes from multiple suppliers and compare them based on factors such as quality, lead time, and additional services.

6. Lead time: Discuss the expected lead time with the supplier and ensure that it aligns with your project timelines. Delay in the delivery of molds can disrupt your production schedule.

7. Support and after-sales service: Inquire about the support and after-sales service provided by the supplier. It’s crucial to have assistance and troubleshooting available in case of any issues or concerns.

8. Intellectual property protection: If you have unique designs or proprietary technology, make sure the supplier has mechanisms in place to protect your intellectual property rights.

9. Communication and collaboration: Establish clear lines of communication and maintain open dialogue with the supplier throughout the procurement process. Regular updates and clear expectations can help mitigate any potential issues.

10. Testing and validation: Prioritize rigorous testing and validation of the moule injection plastique. The supplier should provide testing reports and ensure the mold meets your specifications and requirements.

By considering these tips and factors when purchasing moule injection plastique, you can enhance the chances of obtaining a high-quality mold that fulfills your needs efficiently.

FAQs on Sourcing and Manufacturing moule injection plastique in China

1. What is the process of sourcing and manufacturing moule injection plastique in China?

The process of sourcing and manufacturing moule injection plastique in China involves several steps. Firstly, the buyer identifies a suitable supplier by conducting research, attending trade shows, or using online platforms. Communication with potential suppliers is essential to discuss requirements, obtain quotes, and clarify any doubts.

Once a suitable supplier is identified, the buyer sends the specifications, design drawings, and other relevant information to the supplier. The supplier then prepares a sample or prototype for approval. Amendments or modifications may be requested before finalizing the design.

After the design is approved, the supplier proceeds with the manufacturing process. This includes building the mold, injecting the plastic material, and conducting quality control checks. Once the products are manufactured, they are packaged and prepared for shipment.

2. How can quality control be ensured in the manufacturing process?

To ensure quality control in the manufacturing process of moule injection plastique, regular inspections and tests should be conducted. It is important to establish clear quality standards and communicate them to the supplier.

The buyer can conduct factory visits or hire third-party inspection agencies to assess the manufacturing facility and monitor the production process. Inspections can be carried out at different stages of production, such as during mold construction, injection, and final product assembly.

Implementing a well-defined quality control plan and using proper testing equipment can help identify any defects or deviations from specifications. Open and honest communication with the supplier is crucial to address any quality issues promptly.

3. What are the advantages of sourcing and manufacturing moule injection plastique in China?

Sourcing and manufacturing moule injection plastique in China offer various advantages. China has a vast manufacturing infrastructure and is known for its cost-effectiveness. The availability of skilled labor, advanced machinery, and materials contributes to efficient production.

Moreover, Chinese suppliers often have extensive experience in mold making and injection molding. They can provide valuable technical expertise and support during the design and manufacturing processes.

China’s established supply chain network allows for quick turnaround times and flexible production capacity. This enables buyers to meet varying demand levels and introduce new products to the market more rapidly.

However, it is crucial to conduct thorough due diligence and select trustworthy suppliers to avoid potential quality issues or intellectual property infringement. Strong communication, effective project management, and regular quality control measures are necessary to ensure a successful sourcing and manufacturing experience in China.

Why contact sourcifychina.com get free quota from reliable moule injection plastique suppliers?

Sourcifychina.com offers a free quota to connect with reliable plastic injection mold suppliers for several reasons.

Firstly, sourcing plastic injection molds from China can be a complex task, especially for businesses that are new to the industry or do not have a strong network of suppliers. Sourcifychina.com aims to simplify this process by offering a free quota, allowing businesses to easily connect with reputable and trusted suppliers in China.

Secondly, working with reliable plastic injection mold suppliers is crucial for ensuring the quality and success of a product. Sourcifychina.com has curated a network of pre-vetted suppliers who have a proven track record of delivering high-quality molds. By offering a free quota, businesses can access these trusted suppliers without having to go through a lengthy and costly supplier qualification process themselves.

Additionally, Sourcifychina.com understands the importance of cost-effectiveness and competitive pricing for businesses. By providing a free quota, they enable businesses to compare quotes from different suppliers, ensuring they get the best possible price for their plastic injection molds. This helps businesses to reduce costs and improve their overall profitability.

Moreover, Sourcifychina.com recognizes that time is of the essence for businesses. By offering a free quota, they facilitate a quick and efficient sourcing process. Businesses can easily submit their requirements and receive multiple quotes from trusted suppliers in a timely manner. This saves businesses valuable time and allows them to focus on other critical aspects of their product development and manufacturing process.

In conclusion, Sourcifychina.com offers a free quota to connect with reliable plastic injection mold suppliers to simplify the sourcing process, ensure quality control, promote cost-effectiveness, and save businesses time. This allows businesses to access trusted suppliers in China without the hassle of extensive supplier qualification procedures, ultimately helping them to streamline their supply chain and successfully manufacture their products.