Introduce about principal parts of an overhead traveling crane guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

The principal parts of an overhead traveling crane guide are crucial components that ensure the smooth and efficient operation of the crane. These parts include the bridge, end trucks, hoist, trolley, and control system.

The bridge is the main horizontal beam that spans the width of the working area. It is responsible for supporting the movement of the hoist and trolley. The end trucks are located at either end of the bridge and house the wheels that allow the crane to travel along the runway.

The hoist is the lifting component of the crane and is attached to the trolley. It is used to lift and lower heavy loads. The trolley, on the other hand, moves horizontally along the bridge and allows the hoist to transport the load to different positions. The control system is used to operate and control the movement of the crane.

When selecting an overhead traveling crane guide, several factors should be considered. Quality is of utmost importance to ensure the crane’s reliability, durability, and safety. A high-quality crane guide will minimize the risk of breakdowns and improve overall productivity.

Cost is another crucial factor to consider. It is important to find a crane guide that offers good value for money, taking into account both the initial investment and ongoing maintenance and operating costs.

Choosing a reputable supplier is essential as they will provide guidance, support, and after-sales service. It is important to find a supplier with a strong track record and positive customer reviews.

Certification is a vital consideration as it ensures that the crane guide complies with industry standards and regulations. Look for certifications such as ISO, CE, or OSHA to ensure that the crane guide meets the necessary safety and performance requirements.

The market for overhead traveling crane guides is vast, with numerous suppliers and manufacturers to choose from. It is important to research thoroughly and compare different options to find the most suitable crane guide for specific requirements.

Some tips for selecting an overhead traveling crane guide include conducting a site survey to assess the specific needs and constraints of the working area, considering future expansion and modifications, and seeking expert advice if necessary.

Frequently asked questions about overhead traveling crane guides may include inquiries about load capacity, speed, power requirements, installation process, and maintenance procedures. Consulting with suppliers and manufacturers will provide the most accurate and detailed information to address these inquiries.

In summary, a high-quality, cost-effective, and certified overhead traveling crane guide from a reputable supplier will ensure the safe and efficient operation of the crane, ultimately improving productivity and maximizing return on investment.

Types of principal parts of an overhead traveling crane

There are three main types of principal parts in an overhead traveling crane: the bridge, the hoist, and the end trucks.

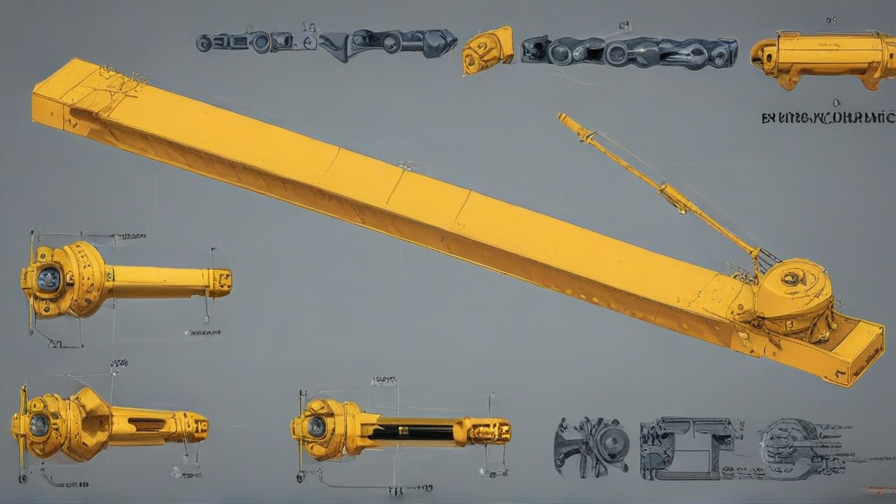

1. The bridge: The bridge is the main horizontal beam of the crane that spans the width of the working area. It is usually supported by two end trucks, which are located at each end of the bridge. The bridge is responsible for carrying the entire weight of the hoist and the load being lifted. It is typically made of steel and is designed to withstand the heavy loads and forces exerted during operation. The bridge moves along a set of rails mounted on the end trucks, allowing the crane to traverse horizontally across the working area.

2. The hoist: The hoist is the component responsible for lifting and lowering the load. It consists of a motor, a gearbox, a drum, and a hook or other lifting device. The motor provides the power to drive the hoist, while the gearbox controls the speed and direction of movement. The drum is a cylindrical drum-shaped device around which the lifting rope or chain is wound. The hoist motor and gearbox work together to rotate the drum, allowing the load to be raised or lowered. The hook or lifting device is attached to the lifting rope or chain and is used to secure the load.

3. The end trucks: The end trucks are the components located at each end of the bridge. They consist of a set of wheels or rollers that are mounted on an axle. These wheels run along the rails installed on the overhead structure, allowing the crane to move horizontally. Each end truck is also equipped with a motor and a gearbox that drives the wheels, enabling smooth and controlled movement. The end trucks play a crucial role in supporting the bridge and maintaining stability during crane operation.

In conclusion, the overhead traveling crane consists of the bridge, hoist, and end trucks as its main principal parts. The bridge carries the weight and spans the working area, the hoist lifts and lowers the load, and the end trucks support the bridge and facilitate horizontal movement. Together, these principal parts work in harmony to provide efficient and reliable lifting and moving capabilities for various industries and applications.

Pros and Cons of Using principal parts of an overhead traveling crane

Using principal parts of an overhead traveling crane has several pros and cons. These principal parts include the bridge, the runway, the hoist, and the trolley.

One of the main advantages of using an overhead traveling crane is its ability to move heavy loads efficiently. The bridge, which runs along the runway, provides a stable and strong platform for lifting and moving heavy objects. The hoist, attached to the bridge, enables vertical lifting and lowering of loads, while the trolley enables horizontal movement along the length of the bridge. This combination of movements allows for precise and controlled handling of heavy items.

Another advantage of using principal parts of an overhead traveling crane is the flexibility it offers in terms of workspace utilization. Since the crane is installed overhead, it frees up the floor space for other activities. This is particularly beneficial in areas with limited space, as it maximizes the usable area for operations or storage. Moreover, the crane’s ability to travel along the runway allows it to cover a larger working area, enhancing its versatility in handling various tasks.

Furthermore, using an overhead traveling crane improves safety in a workplace. The crane’s principal parts are designed to meet stringent safety standards, ensuring operator and personnel safety during operation. The hoist and trolley mechanisms are equipped with safety devices, such as limit switches and emergency stop buttons, to prevent accidents and injuries. Additionally, the overhead position of the crane provides clear visibility, allowing operators to have a better view of the lifting and movement operations, further enhancing safety.

However, there are also some limitations and cons associated with using principal parts of an overhead traveling crane. Firstly, the initial cost of installing such a system can be high, especially for larger and more complex setups. This may deter smaller businesses or those with budget constraints from investing in this technology.

Secondly, the installation of an overhead traveling crane requires structural modifications to the building, such as adding support beams or reinforcing the existing structure to accommodate the crane’s weight and movements. This can be time-consuming and may disrupt regular operations during the installation process.

Lastly, the maintenance and upkeep of an overhead traveling crane can be complicated and expensive. Regular inspections, lubrication, and repairs are necessary to ensure the crane’s smooth and safe operation. Failure to perform proper maintenance can lead to costly breakdowns and potential safety risks.

In conclusion, using principal parts of an overhead traveling crane offers numerous benefits, including efficient heavy load handling, enhanced workspace utilization, and improved safety. However, the initial cost, installation requirements, and ongoing maintenance can pose challenges. It is essential for businesses to evaluate their specific needs, budget, and operational requirements before deciding whether an overhead traveling crane is the right choice for them.

principal parts of an overhead traveling crane Reference Specifications (varies for different product)

The principal parts of an overhead traveling crane typically include the bridge, trolley, hoist, and electric control system.

The bridge is the main horizontal beam that supports the hoist and trolley. It is usually made of steel or similar materials and is positioned parallel to the floor. The bridge moves along a rail system that is attached to the building structure, allowing it to traverse the length of the area it covers.

Mounted on the bridge is the trolley, which serves as a carriage for the hoist. It can move horizontally along the bridge using a motorized mechanism. The trolley is responsible for carrying the load to different positions within the working area.

The hoist is the component that lifts and lowers the load. It is typically equipped with a motor, a drum or chain, and a hook or other lifting device. The hoist is controlled by the operator, either from a pendant or a remote control unit. It is used to handle different types of loads, such as containers, machinery, or raw materials.

The electric control system is the brains of the overhead traveling crane. It includes various electrical components, such as motor controllers, limit switches, and safety devices. These components ensure the proper and safe operation of the crane, allowing for precise control of movements and the prevention of accidents.

It is important to note that the specifications of overhead traveling cranes can vary depending on the specific product and its intended use. Factors such as load capacity, span, lifting height, and operating conditions differ between crane models. Therefore, it is crucial to refer to the manufacturer’s reference specifications for precise details on each particular crane model.

In conclusion, the principal parts of an overhead traveling crane are the bridge, trolley, hoist, and electric control system. These components work together to perform lifting and handling operations efficiently and safely. However, it is essential to consult the reference specifications provided by the manufacturer to obtain accurate information about a specific overhead traveling crane model.

Applications of principal parts of an overhead traveling crane

Principal parts of an overhead traveling crane, also known as a bridge crane, include the bridge, hoist, trolley, and controls. These parts play a crucial role in various industries and applications, ensuring efficient and safe material handling and lifting operations. Here are some applications of the principal parts of an overhead traveling crane:

1. Manufacturing: Overhead cranes are extensively used in manufacturing plants, such as automotive, aerospace, and heavy machinery industries. They are capable of lifting and positioning heavy components, machinery, and tools during the production process. The bridge crane’s precise control and adjustable speed facilitate smooth operations and minimize the risk of damage during lifting and assembly procedures.

2. Warehousing and logistics: Overhead cranes have become an essential part of warehousing and logistics operations. These cranes are used for loading and unloading heavy objects, such as pallets, containers, and machinery, from trucks and storage racks. The flexibility of the trolley allows efficient movement of loads across the warehouse floor, while the hoist ensures safe and secure lifting and placement of goods.

3. Construction: Overhead cranes are vital to the construction industry, assisting in the erection of large structures, such as skyscrapers, bridges, and stadiums. They aid in lifting and positioning heavy construction materials, including steel beams, concrete panels, and precast elements. The crane’s ability to travel along the length of the structure allows convenient material delivery and precise placement, enhancing construction efficiency.

4. Power plants: Overhead cranes are widely used in power plants for handling heavy equipment, maintenance activities, and fuel handling. They help in the installation and maintenance of turbines, boilers, and generators, as well as in transporting coal, ash, and other fuel materials. The bridge crane’s robust design, high load capacity, and precise control are crucial in power plant operations.

5. Shipping and ports: In marine terminals and ports, overhead cranes are utilized for loading and unloading cargo from ships, as well as for handling containers in container yards. These cranes play a significant role in ensuring efficient operation, minimizing vessel turnaround time, and optimizing cargo handling productivity.

Overall, the principal parts of an overhead traveling crane find extensive applications across various industries, contributing to improved productivity, increased safety, and enhanced material handling efficiency. Whether in manufacturing plants, warehouses, construction sites, power plants, or shipping and ports, overhead cranes prove to be a valuable asset in lifting and moving heavy loads, ensuring the smooth functioning of industrial operations.

The Work Process and how to use principal parts of an overhead traveling crane

An overhead traveling crane is a type of crane that moves along a track system mounted on the ceiling or elevated structure of a building. It is commonly used in industries for lifting and moving heavy loads or materials. The work process involves several key steps, and understanding the principal parts of the crane is essential for its effective and safe operation.

The work process of an overhead traveling crane begins with the operator receiving instructions for the lifting task. The operator must be trained and licensed to operate the crane to ensure safety. The next step involves inspecting the crane before use, checking for any damages or malfunctions that might affect its performance or safety.

Once the crane is deemed safe, the operator will position the crane along the track system to the desired location. This can be achieved by operating the drives and controls provided in the crane cabin. The cabin is one of the principal parts of the crane, housing the controls and mechanisms necessary for its operation.

The next step involves attaching the load to the crane. This is usually done using a lifting device, such as a hook or magnet, depending on the nature of the load. The hook or lifting device is connected to the hoist, which is another principal part of the crane. The hoist is responsible for raising and lowering the load using a system of pulleys and cables.

Once the load is securely attached, the operator can start the lifting process. This is done gradually to ensure stability and prevent accidents. The operator should have a clear view of the load and the surroundings to avoid any potential hazards.

During the lifting process, the operator must make sure to maintain a safe working load limit, which is the maximum weight that the crane is rated to lift. Exceeding this limit can lead to crane failure, damage to the load, or injury to personnel.

After the load is appropriately positioned, the operator can then lower it to the desired location. Once the load is safely released, the operator should inspect the crane again for any damages, defects, or loose parts that may have occurred during the lifting process.

In conclusion, using the principal parts of an overhead traveling crane involves a systematic work process that includes inspection, positioning, attaching the load, lifting, lowering, and post-task inspection. Understanding and following this work process is crucial for the efficient and safe operation of the crane.

Quality Testing Methods for principal parts of an overhead traveling crane and how to control the quality

When it comes to quality testing methods for the principal parts of an overhead traveling crane, there are several essential approaches to ensure optimal functionality and safety. These methods focus on examining the key components, such as the hoist, trolley, bridge, and electrical systems. Here are some quality testing methods and techniques commonly utilized:

1. Visual Inspection: This involves a complete visual examination of principal parts to identify any visible defects, such as cracks, corrosion, or misalignment.

2. Load Testing: This method involves subjecting the crane to loads close to its maximum capacity to evaluate its structural integrity, stability, and performance under different conditions.

3. Non-Destructive Testing (NDT): NDT techniques like ultrasonic testing, magnetic particle testing, and dye penetrant testing can be employed to identify any hidden defects or material discontinuities.

4. Functional Testing: This evaluates the functioning of various parts and systems, ensuring smooth and proper operation of the crane while checking for any abnormalities or malfunctions.

To control the quality of the crane, a systematic quality control process is necessary. Here are a few measures:

1. Documenting Quality Standards: Establishing comprehensive written guidelines and standards for the manufacturing, assembly, and inspection processes is crucial to ensure consistency and quality control.

2. Regular Inspections: Implementing periodic inspections at different stages of production by trained personnel helps identify any anomalies or deviations from quality standards.

3. Strict Documentation: Maintaining detailed records of inspections, tests, and maintenance procedures enables rigorous quality control and traceability.

4. Certified Component Suppliers: Ensuring the use of high-quality components and materials from certified suppliers improves the reliability and longevity of the crane.

5. Compliance with Industry Standards: Adhering to relevant international and local standards like ISO 9001 or ASME B30.2 helps ensure the crane’s safety and overall quality.

By integrating these quality testing methods and following robust quality control measures, manufacturers can uphold the highest standards for overhead traveling crane production, minimizing risks and guaranteeing optimal performance and safety for end-users.

principal parts of an overhead traveling crane Sample Policy and Post-Purchase Considerations for principal parts of an overhead traveling crane from China

Sample Policy and Post-Purchase Considerations for Principal Parts of an Overhead Traveling Crane from China:

At [Company Name], we are committed to providing our customers with reliable and high-quality principal parts of an overhead traveling crane sourced from China. To ensure a smooth and satisfactory experience, we have implemented the following policy and post-purchase considerations:

Policy:

1. Quality Assurance: We partner with trusted manufacturers in China who adhere to international quality standards. All principal parts of an overhead traveling crane go through rigorous inspections and tests before they are shipped to our customers, ensuring their reliability and durability.

2. Competitive Pricing: We understand the importance of affordability. Our products are competitively priced without compromising on quality. By sourcing directly from China, we are able to offer cost-effective solutions to meet your budget requirements.

3. Shipping and Delivery: We arrange efficient and secure shipping methods to deliver the principal parts of an overhead traveling crane to your requested destination. We work closely with reliable logistics partners to ensure timely delivery and provide you with tracking information for transparency.

4. Technical Support: Our team of experienced engineers and technicians are available to provide technical assistance and support during installation, operation, and maintenance of the principal parts of an overhead traveling crane. We are committed to ensuring that you have the necessary knowledge and resources to utilize the crane effectively and safely.

Post-Purchase Considerations:

1. Installation and Commissioning: We can provide detailed installation instructions or offer professional installation services upon request. Our team will guide you through the process to ensure smooth installation and efficient commissioning of the principal parts of the overhead traveling crane.

2. Warranty and After-Sales Service: We offer a comprehensive warranty period for the principal parts of the crane. In the unlikely event of any issues or defects, our dedicated after-sales support team will promptly assist you in resolving the problem and provide necessary replacements or repairs.

3. Spare Parts Availability: We maintain a stock of spare parts to ensure quick and hassle-free replacements, minimizing downtime in case of any component failures. Our inventory management system allows us to efficiently supply spare parts according to your needs.

4. Training and Safety Measures: We prioritize safety in crane operation. Upon request, we can provide operator training sessions and safety guidelines to ensure your staff is well-equipped with the necessary knowledge and adhere to safety regulations.

By following our policy and considering these post-purchase elements, we aim to provide a seamless experience and build a long-term partnership with you. We are confident that our principal parts of an overhead traveling crane from China will meet your needs and contribute to your business’s efficiency and productivity.

Sourcing principal parts of an overhead traveling crane from China: Opportunities, Risks, and Key Players

Sourcing principal parts of an overhead traveling crane from China presents both opportunities and risks. China is renowned for its manufacturing capabilities and offers a wide range of cost-effective options. Chinese manufacturers can provide high-quality crane parts and components at competitive prices, which can help reduce production costs and enhance profitability.

One of the key opportunities in sourcing crane parts from China is the vast supplier base. The country has a well-established network of manufacturers specializing in various industrial sectors, including crane production. This allows businesses to have access to a wide range of suppliers and options to meet their specific requirements. Moreover, Chinese manufacturers are often willing to collaborate and customize products according to buyers’ specifications.

Another advantage is the availability of advanced technology and expertise. China has made significant advancements in fields such as steel fabrication, precision machinery, and automation. This means that businesses can source principal parts that are made with advanced manufacturing techniques, ensuring quality and durability.

However, sourcing from China also comes with certain risks that need to be carefully considered. One potential risk is the challenge of maintaining product quality and meeting international standards. It is essential to thoroughly vet potential suppliers, conduct factory visits, and implement rigorous quality control processes to ensure that the crane parts meet the required standards.

Intellectual property protection is another concern when sourcing from China. It is important to work with reputable suppliers and utilize legally binding agreements to protect intellectual property rights. This can help prevent unauthorized replication or counterfeiting of the sourced principal parts.

When considering sourcing from China, it is crucial to identify key players in the market. Some renowned Chinese crane manufacturers include ZPMC, Konecranes, and Henan Mine Crane Co., Ltd. Collaborating with established and reputable manufacturers can provide assurance and minimize the associated risks.

In conclusion, sourcing principal parts of an overhead traveling crane from China offers opportunities in terms of competitive pricing, a vast supplier base, and advanced manufacturing capabilities. However, careful attention must be given to potential risks related to quality control and intellectual property protection. By identifying key players and implementing comprehensive supplier evaluation processes, businesses can leverage the opportunities and mitigate the risks when sourcing crane parts from China.

How to find and select reliable principal parts of an overhead traveling crane manufacturers in China,use google search manufacturers and suppliers

Finding reliable principal parts manufacturers for overhead traveling cranes in China can be a challenging task, but with the help of Google search and following certain guidelines, one can increase the chances of selecting a trustworthy supplier.

Utilize the following steps and tips to streamline the search process within a 300-word limit:

1. Begin by conducting a general Google search using keywords like “overhead traveling crane manufacturers in China” or “principal parts suppliers for overhead traveling cranes.”

2. Browse through the search results to identify potential manufacturers or suppliers. Pay attention to the credibility of the websites, their design and layout, and the information provided.

3. Look for companies that have been in the industry for a considerable period as this indicates experience and reliability. Check the “About Us” or “Company Profile” sections to gather more details about their background.

4. Evaluate the manufacturing capabilities of the shortlisted companies by exploring their product catalogs, especially focusing on the principal parts required for overhead traveling cranes. Ensure that the manufacturer can provide the specific parts that meet your requirements.

5. Look for certifications and quality management systems such as ISO 9001, ISO 14001, or OHSAS 18001. These certifications indicate adherence to international standards and commitment to quality and safety.

6. Check if the manufacturer has any customer testimonials or case studies on their website. Reading reviews and feedback from previous customers can provide insight into their reputation and the quality of their products.

7. Avoid choosing manufacturers solely based on low prices. While cost is important, it should not be the only deciding factor. Quality, reliability, and after-sales service are equally crucial in ensuring a successful partnership.

8. Reach out to the selected manufacturers with specific inquiries regarding the principal parts you require. Assess their responsiveness, technical knowledge, and willingness to provide information and support.

9. Consider attending industry exhibitions or trade shows in China where you can meet potential suppliers in person. Interacting face-to-face can give you a better understanding of their capabilities and build trust.

10. Request samples or visit the manufacturing facilities if feasible. This will allow you to physically inspect the principal parts, ensuring they meet your quality standards.

In summary, finding reliable principal parts manufacturers for overhead traveling cranes in China requires thorough research, careful evaluation of potential suppliers, and a focus on quality and reputation rather than solely on price. Utilizing Google search, examining website credibility, and considering factors like experience, certifications, and customer feedback will help in making an informed decision.

How to check principal parts of an overhead traveling crane manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of an overhead traveling crane manufacturer’s website and its principal parts, you can follow these steps:

1. Use Google Chrome: Open the manufacturer’s website using the Google Chrome web browser. Google Chrome is widely regarded as a reliable browser that offers various useful tools and extensions.

2. Install SEOquake: Add the SEOquake extension to your Google Chrome browser. SEOquake is a popular SEO tool that provides a comprehensive analysis of the website, including its ranking, backlinks, and other useful statistics.

3. Check website ranking: With SEOquake installed, search for the manufacturer’s website on Google. Once you find the website, click on the SEOquake icon in your browser’s toolbar. This will display an overview of the website’s ranking.

4. Look for ranking in top 10M: In the SEOquake overview, you will find the website’s Alexa Rank. Alexa Rank is a metric that indicates the website’s popularity and traffic compared to other websites worldwide. If the website has a ranking within the top 10 million (e.g., 1,000,000 or lower), it indicates that the website receives a decent amount of traffic and is relatively reliable.

5. Explore principal parts: Navigate through the manufacturer’s website to find sections or pages related to the principal parts of the overhead traveling crane. Look for detailed information, specifications, images, and product descriptions provided by the manufacturer. Make sure the information is comprehensive, accurate, and reliable.

6. Keep it concise: When writing a summary or report, try to limit your content to not more than 300 words. Focus on the critical points, such as the website’s reliability based on the ranking, and highlight any significant features or information about the principal parts of the overhead traveling crane.

By utilizing Google Chrome with the SEOquake extension, you can easily assess the reliability of the manufacturer’s website and gather essential details about the principal parts of the overhead traveling crane.

Top 10 principal parts of an overhead traveling crane manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Henan Mine Cranes Co., Ltd. (160 words):

Henan Mine Cranes Co., Ltd. is a leading overhead traveling crane manufacturer in China. With over 30 years of experience, the company specializes in designing, manufacturing, and servicing various cranes, including single girder, double girder, and gantry cranes. Their products are widely used in industries such as construction, mining, logistics, and manufacturing. Henan Mine Cranes Co., Ltd. is committed to providing high-quality and reliable cranes that meet international standards. Their cranes are known for their robust construction, easy operation, and advanced safety features. Additionally, the company also offers customized solutions based on specific requirements. With advanced manufacturing facilities and a skilled team of professionals, the company ensures prompt delivery and excellent after-sales service.

2. ZPMC (160 words):

ZPMC is a renowned manufacturer of overhead traveling cranes in China. With a rich history spanning over 50 years, the company excels in designing and producing various types of cranes, including single and double girder cranes, bridge cranes, and gantry cranes. ZPMC’s cranes are widely used in industries such as shipping, logistics, construction, and offshore oil exploration. The company is known for its cutting-edge technology, stringent quality control, and unparalleled customer service. ZPMC’s overhead traveling cranes are known for their durability, high load capacity, and precision controls. The company also offers comprehensive after-sales support, including installation, training, and maintenance services. With a global presence, ZPMC is trusted by customers worldwide for their reliable and efficient cranes.

3. Henan Dafang Heavy Machine Co., Ltd. (160 words):

Henan Dafang Heavy Machine Co., Ltd. is a trusted name among overhead traveling crane manufacturers in China. The company specializes in producing high-quality cranes, including single girder, double girder, and gantry cranes. Henan Dafang Heavy Machine Co., Ltd. is known for its strict quality control measures, advanced manufacturing techniques, and innovative designs. Their cranes are widely used in various industries, such as construction, manufacturing, and logistics. The company focuses on continuously improving its products to meet international standards. With a skilled team of engineers and technicians, Henan Dafang Heavy Machine Co., Ltd. offers customized solutions tailored to specific customer requirements. Their cranes are known for their efficiency, reliability, and safety features. Additionally, the company provides excellent after-sales service, including installation, training, and maintenance support.

4. Nucleon (160 words):

Nucleon is a renowned manufacturer of overhead traveling cranes in China, known for its high-quality products and outstanding customer service. With decades of experience in the industry, the company offers a wide range of cranes, including single and double girder cranes, bridge cranes, and gantry cranes. Nucleon’s cranes are suitable for diverse applications, including construction, manufacturing, and logistics. The company is committed to delivering cranes that are robust, reliable, and energy-efficient. Nucleon’s overhead traveling cranes are designed to meet international standards, ensuring superior performance and long lifespan. The company also provides comprehensive after-sales support, including installation, training, and maintenance services. Customers can rely on Nucleon for personalized solutions tailored to their specific needs.

5. Wuhan Vohoboo Import & Export Trade Co., Ltd. (160 words):

Wuhan Vohoboo Import & Export Trade Co., Ltd. is a leading manufacturer of overhead traveling cranes in China. With an extensive range of products, the company caters to diverse industries, including construction, mining, logistics, and manufacturing. Wuhan Vohoboo specializes in single girder, double girder, and gantry cranes. Their cranes are well-known for their advanced features, such as precise control systems, high load capacity, and enhanced safety measures. The company focuses on providing quality cranes that are efficient, reliable, and cost-effective. Wuhan Vohoboo’s commitment to customer satisfaction is reflected in its excellent after-sales service, including installation, training, and maintenance support. With competitive pricing and timely delivery, Wuhan Vohoboo remains a trusted choice for customers seeking reliable overhead traveling cranes.

6. ZOKE CRANE (160 words):

ZOKE CRANE prides itself as one of the foremost manufacturers of overhead traveling cranes in China. With more than 30 years of experience, the company offers a comprehensive range of cranes, including single and double girder cranes, bridge cranes, and gantry cranes. ZOKE CRANE’s cranes are widely used in industries such as construction, manufacturing, and logistics. The company’s commitment to quality is evident in its advanced manufacturing techniques, stringent quality control, and adherence to international standards. ZOKE CRANE’s cranes stand out for their high load capacity, precision controls, and exceptional durability. The company also provides customized solutions to meet specific customer requirements. With a dedicated customer service team, ZOKE CRANE offers prompt delivery and excellent after-sales support, including installation, training, and maintenance services.

7. Hangzhou Nante Machinery Co., Ltd. (160 words):

Hangzhou Nante Machinery Co., Ltd. is a leading manufacturer of overhead traveling cranes based in China. With over 15 years of experience, the company specializes in producing high-quality cranes, including single girder, double girder, and gantry cranes. Hangzhou Nante Machinery Co., Ltd. caters to diverse industries such as construction, manufacturing, and logistics. The company’s cranes are known for their robust construction, efficient performance, and advanced safety features. Hangzhou Nante Machinery Co., Ltd. places a strong emphasis on ensuring customer satisfaction through on-time delivery, excellent after-sales service, and competitive pricing. Their team of experienced engineers and technicians ensures that each crane meets international standards. Hangzhou Nante Machinery Co., Ltd. also offers customized solutions based on specific customer requirements.

8. Weihua Group (160 words):

Weihua Group is a renowned overhead traveling crane manufacturer in China. With over 30 years of industry experience, the company specializes in designing and manufacturing various types of cranes, including single and double girder cranes, bridge cranes, and gantry cranes. Weihua Group’s cranes find applications in industries such as construction, manufacturing, and logistics. The company has a strong focus on technological innovation, ensuring that their cranes incorporate the latest advancements. Weihua Group’s cranes are known for their high load capacity, precise control, and exceptional safety measures. The company also offers comprehensive after-sales support, including installation, training, and maintenance services. Weihua Group’s commitment to quality and customer satisfaction has made them a trusted choice for overhead traveling cranes.

9. Sinoko Cranes Ltd. (160 words):

Sinoko Cranes Ltd. is a leading manufacturer of overhead traveling cranes in China. With years of experience and expertise, the company specializes in designing and producing various cranes, including single and double girder cranes, bridge cranes, and gantry cranes. Sinoko Cranes Ltd. caters to industries such as construction, manufacturing, and logistics. Known for their high-quality products, Sinoko Cranes Ltd. ensures that each crane is built to withstand heavy loads and harsh conditions. The company’s cranes are known for their robust construction, advanced safety features, and precision controls. Sinoko Cranes Ltd. also offers comprehensive after-sales services, including installation, training, and maintenance support. With a commitment to customer satisfaction, Sinoko Cranes Ltd. has established a strong presence in the overhead traveling crane market in China.

10. Dersheng Crane Co., Ltd. (160 words):

Dersheng Crane Co., Ltd. is a reputable manufacturer of overhead traveling cranes in China. With a focus on delivering high-quality and reliable cranes, the company offers a diverse range of products, including single girder, double girder, and gantry cranes. Dersheng Crane Co., Ltd. caters to industries such as construction, manufacturing, and logistics. The company’s cranes are known for their durability, high load capacity, and ease of operation. Dersheng Crane Co., Ltd. ensures that each crane meets stringent quality standards and incorporates advanced safety features. The company also provides excellent after-sales service, including installation, training, and maintenance support. With a track record of delivering superior cranes, Dersheng Crane Co., Ltd. has gained a strong reputation among overhead traveling crane manufacturers in China.

|Manufacturer|Product Range|Special Features|

|—|—|—|

|Henan Mine Cranes Co., Ltd.|Single Girder, Double Girder, Gantry Cranes|Robust construction, easy operation, advanced safety features|

|ZPMC|Single Girder, Double Girder, Bridge, Gantry Cranes|Cutting-edge technology, stringent quality control, global presence|

|Henan Dafang Heavy Machine Co., Ltd.|Single Girder, Double Girder, Gantry Cranes|Strict quality control, advanced manufacturing techniques|

|Nucleon|Single Girder, Double Girder, Bridge, Gantry Cranes|Reliable, efficient, and energy-efficient cranes|

|Wuhan Vohoboo Import & Export Trade Co., Ltd.|Single Girder, Double Girder, Gantry Cranes|Advanced features, customized solutions, competitive pricing|

|ZOKE CRANE|Single Girder, Double Girder, Bridge, Gantry Cranes|High load capacity, precision controls, exceptional durability|

|Hangzhou Nante Machinery Co., Ltd.|Single Girder, Double Girder, Gantry Cranes|Robust construction, efficient performance, advanced safety features|

|Weihua Group|Single Girder, Double Girder, Bridge, Gantry Cranes|High load capacity, precise control, exceptional safety measures|

|Sinoko Cranes Ltd.|Single Girder, Double Girder, Bridge, Gantry Cranes|Robust construction, advanced safety features, precision controls|

|Dersheng Crane Co., Ltd.|Single Girder, Double Girder, Gantry Cranes|Durability, high load capacity, ease of operation|

Background Research for principal parts of an overhead traveling crane manufacturers Companies in China, use qcc.com archive.org importyeti.com

In China, there are several manufacturers of overhead traveling cranes that provide a wide range of products and services. The principal parts of these cranes are crucial for their efficient functioning and durability. Three websites that can be used for background research on these manufacturers are qcc.com, archive.org, and importyeti.com.

Qcc.com is a comprehensive business information platform that provides company profiles and registration details of Chinese companies. By searching for crane manufacturers on this website, one can access important information such as their business scope, registration capital, address, and contact details. Additionally, it may also provide information regarding their production facilities, certifications, and quality control measures.

Archive.org is a digital library that enables users to access archived versions of websites. This can be useful for obtaining historical data on crane manufacturers such as their previous product offerings, company updates, and industry trends. By delving into the archived versions of manufacturers’ websites, one can gain insights into the evolution of their products and services over time.

Importyeti.com is an import-export data platform that offers information on shipments between countries. This website can be used to obtain details on the export and import activities of crane manufacturers in China. Import data can provide insights into the types and quantities of principal parts being imported by these manufacturers, which can help identify reliable suppliers and their product specifications.

When conducting this background research, it is important to keep the word limit in mind. Therefore, it is recommended to focus on key information such as company profiles, business scope, production facilities, certifications, historical data, and import-export activities. By utilizing these websites efficiently, one can gather a comprehensive understanding of the principal parts of overhead traveling crane manufacturers in China within the specified word limit.

Leveraging Trade Shows and Expos for principal parts of an overhead traveling crane Sourcing in China

Trade shows and expos in China are excellent platforms for sourcing principal parts of an overhead traveling crane. These events provide a unique opportunity for businesses to connect and engage with a wide range of suppliers, manufacturers, and industry experts all under one roof.

One of the key advantages of attending trade shows and expos is the ability to have face-to-face interactions with potential suppliers. This allows for better communication and understanding of the specific requirements and technical specifications of principal crane parts. Additionally, these events often feature live demonstrations and product showcases, enabling buyers to evaluate the quality and performance of various products firsthand.

Furthermore, trade shows and expos bring together a large number of exhibitors, presenting a greater variety of options to choose from. This is particularly advantageous for overhead traveling crane sourcing as it allows buyers to compare different suppliers, their offerings, pricing, and capabilities. This wide selection also fosters healthy competition among suppliers, leading to better pricing and value-added services.

In addition to sourcing products, industry trade shows and expos are also valuable for networking and gathering market intelligence. Attendees have the opportunity to network with industry professionals, build relationships with potential partners, and gain insights into the latest industry trends and innovations. This knowledge can be crucial in identifying reliable suppliers and making informed sourcing decisions.

To make the most out of these events and efficiently source principal parts of an overhead traveling crane, it is important to plan ahead. Researching and identifying the key trade shows and expos relevant to the industry is essential. Preparing a list of targeted exhibitors and scheduling meetings in advance can save time and streamline the sourcing process.

Overall, leveraging trade shows and expos in China for sourcing principal parts of an overhead traveling crane offers numerous advantages. It enhances communication, increases supplier options, promotes healthy competition, and provides valuable market insights. Utilizing these events effectively can significantly contribute to successful sourcing endeavors in China.

The Role of Agents and Sourcing Companies in Facilitating principal parts of an overhead traveling crane Purchases from China

Agents and sourcing companies play a crucial role in facilitating purchases of principal parts of an overhead traveling crane from China. These intermediaries help streamline the entire procurement process, ensuring efficient communication, quality control, and cost-effective sourcing.

One of the primary functions of agents and sourcing companies is to bridge the language and cultural gaps between buyers and manufacturers. They have the necessary expertise in dealing with Chinese manufacturers and are fluent in both Mandarin and English. This enables them to effectively communicate buyers’ requirements, negotiate prices, and ensure that all technical specifications are met. By acting as a liaison, agents and sourcing companies reduce the chances of miscommunication or misunderstandings, which can lead to costly mistakes.

Quality control is another vital aspect that agents and sourcing companies handle. They have extensive knowledge of the manufacturing industry and understand the quality standards expected by international buyers. They can conduct factory audits, inspect production processes, and perform quality inspections to ensure that the principal parts of the overhead traveling crane meet the required standards. This quality control process minimizes the risk of receiving substandard or defective products, saving both time and money for the buyer.

In addition, agents and sourcing companies are proficient in navigating complicated logistics and shipping procedures. They are well-versed in export and import regulations, documentation requirements, and transportation options. This expertise allows them to efficiently manage the logistical aspects of the procurement process, ensuring timely delivery and minimizing any potential delays or complications.

Moreover, agents and sourcing companies help buyers source the most cost-effective options. They have a network of trusted manufacturers and suppliers in China, which increases the buyer’s access to a wider range of options. By leveraging their industry knowledge and negotiating skills, agents and sourcing companies can secure competitive prices for the principal parts of the overhead traveling crane. This helps buyers save on costs and maximize their value for money.

In conclusion, agents and sourcing companies play a pivotal role in facilitating purchases of principal parts of an overhead traveling crane from China. Their expertise in communication, quality control, logistics, and sourcing enables a smoother and more efficient procurement process. With their support, buyers can confidently navigate the complexities of sourcing from China and acquire high-quality parts at competitive prices.

Price Cost Research for principal parts of an overhead traveling crane manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for principal parts of overhead traveling crane manufacturers in China, two commonly used websites are temu.com and 1688.com. These platforms provide a comprehensive range of products and are widely utilized by businesses and individuals involved in sourcing and purchasing machinery and equipment.

Temu.com is an online platform that specializes in connecting buyers with suppliers in the machinery industry. It offers a vast selection of overhead traveling crane manufacturers, allowing users to browse through different product categories and compare prices. This platform provides detailed product information and specifications, enabling buyers to make informed decisions based on their specific requirements. With its user-friendly interface and extensive supplier database, temu.com offers a convenient solution for price cost research in China’s overhead traveling crane industry.

1688.com, on the other hand, is a business-to-business (B2B) platform owned by Alibaba Group. It is primarily used by Chinese suppliers and manufacturers, making it an ideal website for conducting price cost research for principal parts of overhead traveling crane manufacturers based in China. As an online marketplace, 1688.com enables users to search for specific products, view pricing details, and negotiate directly with suppliers. This platform provides a wide range of options and allows buyers to communicate with suppliers to inquire about customization, production time, and other relevant factors impacting cost.

To conduct efficient price cost research using these platforms, it is recommended to follow a few key steps. Firstly, specify the principal parts of an overhead traveling crane you are researching, such as the motor, hoist, trolley, or control system. Next, visit temu.com and use their search function to find relevant products. Take note of the prices and specifications of each part and compare them to assess the average cost range. Similarly, repeat this process on 1688.com to gather more options and gain a better understanding of the market.

By utilizing temu.com and 1688.com, buyers can access a vast range of overhead traveling crane manufacturers in China and find the most competitive prices for principal parts. These platforms offer an efficient and convenient way to conduct price cost research, ensuring buyers can make informed decisions and secure the best value for their investment.

Shipping Cost for principal parts of an overhead traveling crane import from China

The shipping cost for importing principal parts of an overhead traveling crane from China can vary depending on several factors. These factors include the weight, dimensions, destination, shipping method, and any additional services required.

Typically, the weight and dimensions of the cargo are crucial in determining the shipping cost. Overhead traveling crane parts can be bulky and heavy, which may require special handling and transportation arrangements. The shipping company will calculate the cost based on the weight or volume of the cargo, whichever is higher.

The destination also plays a significant role in determining the cost. Different shipping companies may have different rates for specific destinations. Additionally, any customs duties, taxes, or import fees imposed by the destination country will add to the overall shipping cost.

The shipping method chosen can also impact the shipping cost. Air freight is generally more expensive than sea freight, but it offers quicker delivery times. Sea freight is typically the more cost-effective option for shipping heavy and bulky cargo like crane parts. However, it can take longer for the cargo to reach its destination.

Furthermore, additional services like insurance, customs clearance, and inland transportation to the final destination should be considered. These services can provide peace of mind and ensure a smooth import process, but they will add to the overall shipping cost.

It is recommended to contact various shipping companies and request quotes based on the specific details of the crane parts’ principal parts, including weight, dimensions, destination, and any additional requirements. By comparing these quotes, one can determine the most cost-effective and suitable shipping option. However, it is important to note that the final shipping cost can only be accurately determined after providing the specific details and engaging with the shipping company directly.

Compare China and Other principal parts of an overhead traveling crane Markets: Products Quality and Price,Visible and Hidden Costs

China is one of the principal parts of the overhead traveling crane market, competing with other major players such as the United States, Germany, and Japan. When comparing China and other markets, several factors need to be considered, including product quality and price, visible and hidden costs.

In terms of product quality, China has made significant strides over the years. Chinese manufacturers are known for their ability to produce cranes that meet international standards and specifications. Chinese crane manufacturers have invested in research and development, improved manufacturing processes, and implemented stringent quality control measures. While China may have had a reputation for producing lower quality products in the past, this perception has largely changed as companies have invested in improving their manufacturing capabilities.

In terms of price, China is often considered to be more competitive than its counterparts. Chinese manufacturing has the advantage of a large labor force and lower production costs, allowing them to offer competitive pricing to their customers. However, it is important to note that pricing alone should not be the deciding factor, as quality is equally important when it comes to overhead traveling cranes.

Visible costs, such as purchase price and shipping costs, are generally comparable across different markets. However, hidden costs can vary significantly. These hidden costs include maintenance and repair, spare parts availability, and after-sales service. Chinese manufacturers have made efforts to improve their after-sales service and spare parts availability, ensuring that customers have access to the necessary support when required. However, it is essential for buyers to thoroughly evaluate the after-sales service provided by the crane manufacturer before making a purchase.

In conclusion, China’s overhead traveling crane market has made significant progress in terms of product quality and competitiveness in pricing. Chinese manufacturers are now able to offer products that meet international standards and provide competitive pricing. However, buyers should also consider hidden costs such as maintenance and after-sales services when comparing different markets. A comprehensive evaluation of these factors is necessary to make an informed decision when choosing an overhead traveling crane.

Understanding Pricing and Payment Terms for principal parts of an overhead traveling crane: A Comparative Guide to Get the Best Deal

When it comes to purchasing the principal parts of an overhead traveling crane, understanding pricing and payment terms is essential to ensure you receive the best deal. In this comparative guide, we will discuss the key factors to consider when evaluating pricing and payment options for these crucial crane components.

1. Research and compare prices: Start by conducting thorough research to determine the general pricing range for the principal parts you require. Explore multiple suppliers and manufacturers to get an idea of the market average. Keep in mind that prices may vary based on specifications, materials, and additional features.

2. Evaluate quality: While comparing prices, ensure that you are also evaluating the quality of the principal parts you are considering. It is important to strike the right balance between affordability and durability. Remember, investing in high-quality components can reduce maintenance costs and extend the lifespan of your overhead traveling crane.

3. Request detailed quotes: Contact different suppliers and request detailed quotes that clearly outline the cost breakdown for each principal part. This will help you understand the pricing structure and identify any hidden fees or additional charges. Don’t hesitate to ask for clarification and negotiate if necessary.

4. Consider payment terms: Payment terms can significantly impact your overall expenses, so carefully review the options provided by the suppliers. Look for favorable terms such as flexible payment schedules or installment options. Some suppliers may also offer discounts for larger orders or upfront payments. Compare these terms to choose the most suitable option for your budget and financial capabilities.

5. Assess warranty and after-sales support: The warranty offered by the supplier is another crucial factor to consider. A longer warranty period indicates the supplier’s confidence in their product’s quality. Additionally, inquire about after-sales support, including technical assistance, spare parts availability, and maintenance services. A reliable supplier should have provisions in place to assist you throughout the lifespan of your overhead traveling crane.

6. Seek customer feedback: Lastly, don’t forget to check customer reviews and testimonials about the supplier and the principal parts you are considering. Feedback from other buyers can provide valuable insights into the supplier’s reliability, product performance, and customer service.

By thoroughly understanding the pricing and payment terms for the principal parts of an overhead traveling crane, you can make well-informed decisions and secure the best deal possible. Remember to balance cost with quality, and prioritize suppliers that offer favorable payment terms and comprehensive after-sales support. With careful consideration and research, you can procure the right crane components to meet your operational requirements efficiently.

Chinese Regulations and Industry Standards Certifications for principal parts of an overhead traveling crane,Import Regulations and Customs for principal parts of an overhead traveling crane from China

Chinese Regulations and Industry Standards Certifications for principal parts of an overhead traveling crane:

In China, the principal parts of an overhead traveling crane are subject to regulations and industry standards certifications to ensure their safety, quality, and performance. These regulations and certifications are overseen by various government agencies and industry bodies, including the State Administration for Market Regulation (SAMR) and the Standardization Administration of China (SAC).

The main regulation governing overhead traveling cranes is the GB/T 14406-2017 standard, which specifies the general technical requirements for the design, manufacturing, and testing of cranes. This standard covers aspects such as structural design, electrical systems, safety devices, and lifting capacity limits. Compliance with this standard is mandatory for manufacturers, importers, and users of overhead traveling cranes in China.

Additionally, specific certifications are required for certain principal parts of the crane. For example, the crane’s hoisting mechanism must comply with the GB/T 3811-2016 standard, which covers the design and manufacturing requirements for wire rope hoists. The electric control system of the crane needs to comply with the GB/T 13757-2012 standard, ensuring its safe and reliable operation.

Import Regulations and Customs for principal parts of an overhead traveling crane from China:

Importing principal parts of an overhead traveling crane from China involves complying with import regulations and meeting customs requirements. The import process is overseen by the General Administration of Customs (GAC) in China and may vary depending on the destination country.

To import these crane parts, the importer needs to provide necessary documentation such as a commercial invoice, packing list, and bill of lading or airway bill. These documents should accurately describe the principal parts, their quantity, value, and origin.

Customs clearance process entails submitting these documents to the customs authorities of the destination country. The customs officials will assess the import duties, taxes, and any other applicable fees. Compliance with safety standards and certifications may also be assessed by customs to ensure the imported principal parts meet the required technical specifications.

It is crucial for the importer to appoint a licensed customs broker or agent who is familiar with the import regulations and customs procedures of the destination country. This ensures smooth clearance of the principal parts through customs and minimizes the risk of delays or additional costs.

In conclusion, Chinese regulations and industry standards certifications, along with import regulations and customs procedures, apply to the principal parts of an overhead traveling crane. Complying with these regulations and certifications is essential for meeting safety, quality, and customs requirements when importing these crane parts from China.

Sustainability and Environmental Considerations in principal parts of an overhead traveling crane Manufacturing

Sustainability and environmental considerations are essential in the manufacturing process of overhead traveling cranes, as they promote the responsible use of resources, minimize waste generation, and reduce environmental impact. Several key aspects can be addressed to achieve sustainability in the production of these cranes.

Firstly, selecting environmentally friendly materials is crucial. The use of sustainable and recyclable materials, such as low-carbon steel or aluminum, can help reduce the carbon footprint associated with the manufacturing process. Additionally, utilizing materials with a longer lifespan and higher durability can reduce resource consumption over time.

Secondly, energy efficiency plays a significant role in overhead traveling crane production. Implementing energy-efficient technologies, such as LED lighting systems and regenerative drives, can save energy and decrease greenhouse gas emissions. Manufacturers can also invest in renewable energy sources, such as solar panels, to power production facilities and reduce reliance on fossil fuels.

Furthermore, waste management and recycling practices should be incorporated into the manufacturing process. Implementing a comprehensive waste reduction strategy, including recycling and disposing of waste properly, can minimize the environmental impact. This can involve recycling metal scrap, reusing packaging materials, and partnering with waste management companies to ensure responsible disposal of hazardous waste.

Moreover, water conservation measures should be employed to minimize water consumption. Implementing water-saving technologies, such as high-efficiency spray nozzles or closed-loop cooling systems, can significantly reduce water usage during the manufacturing process. Additionally, manufacturers can implement water management strategies to track and optimize water consumption.

Finally, a strong emphasis should be placed on employee education and training to ensure sustainability practices are implemented effectively. Training programs can raise awareness among employees about the importance of sustainability, encouraging them to adopt eco-friendly manufacturing practices.

In conclusion, considering sustainability and environmental factors in the manufacturing process of overhead traveling cranes is crucial. By selecting environmentally friendly materials, promoting energy efficiency, implementing waste management practices, conserving water, and educating employees, manufacturers can contribute to a more sustainable and environmentally responsible production process.

List The Evolution history of “principal parts of an overhead traveling crane”

The evolution history of the principal parts of an overhead traveling crane can be traced back to ancient times, where humans used basic mechanisms to lift and move heavy objects. Over the centuries, technological advancements and innovations have led to the development of more sophisticated and efficient crane systems.

The earliest known form of cranes dates back to ancient Greece, where simple machines like levers and pulleys were used to lift heavy loads. These early cranes consisted of a basic structure with a beam and a lifting mechanism.

In the 19th century, significant strides were made in crane technology. The invention of steam power revolutionized the industry, allowing for the construction of much larger and more powerful cranes. The introduction of steam engines enabled cranes to lift heavier loads and cover larger areas.

With the advent of electricity in the late 19th century, the first electric overhead traveling crane was developed. This marked a significant milestone in crane technology, as it allowed for more precise control and smoother movements. Electric cranes also eliminated the need for steam boilers and reduced the risk of accidents associated with the use of steam power.

Further advancements in the 20th century saw the introduction of various technological features, such as wireless remote control systems, hydraulic systems, and automated functions. These innovations improved productivity, efficiency, and safety in crane operations.

In recent years, the integration of computer systems and automation has revolutionized the crane industry. Modern overhead traveling cranes are equipped with advanced sensors, data analysis capabilities, and programmable logic controllers (PLCs). These features allow for accurate load monitoring, real-time diagnostics, and precise control, ultimately leading to improved safety and productivity.

Moreover, advancements in materials used for crane construction, such as high-strength steel and aluminum alloys, have enabled the development of lighter yet stronger crane structures. This has resulted in increased lifting capacities and improved maneuverability.

In conclusion, the evolution history of the principal parts of an overhead traveling crane spans centuries of technological advancements. From simple levers and pulleys to steam, electricity, and modern computer-controlled systems, cranes have become indispensable tools for heavy lifting and material handling in various industries.

The Evolution and Market Trends in principal parts of an overhead traveling crane Industry

The overhead traveling crane industry has undergone significant evolution over the years, driven by advancements in technology and the ever-changing market demands. As a crucial part of the material handling industry, overhead traveling cranes have continuously evolved to improve efficiency, safety, and productivity in various sectors such as construction, manufacturing, and logistics.

One of the major trends in the industry is the adoption of automation and digitalization. Overhead traveling cranes are now equipped with advanced technologies such as sensors, cameras, and programmable logic controllers (PLCs) that enable them to operate autonomously and integrate with other systems. This trend allows for more precise and efficient operations while reducing the need for manual labor, ultimately increasing overall productivity.

Another significant trend is the focus on safety. Manufacturers are continually developing innovative safety features to minimize accidents and improve worker protection. These features include overload protection systems, collision avoidance systems, and emergency stop capabilities. Additionally, the integration of machine learning and artificial intelligence technologies allows for real-time monitoring and predictive maintenance, ensuring optimal performance and minimizing downtime.

In terms of market trends, there is a growing demand for customized overhead traveling cranes. As various industries have specific material handling needs, manufacturers are increasingly offering tailor-made solutions to meet these requirements. Customizable features can include crane capacity, lifting height, span length, and specialized attachments, enabling the crane to handle diverse loads and environments.

Furthermore, the market is witnessing an increase in the adoption of electric overhead traveling cranes. The shift towards sustainable and environmentally friendly solutions has fueled the demand for electric cranes, which offer benefits such as reduced emissions, lower energy consumption, and quieter operations compared to traditional diesel-powered cranes.

In conclusion, the overhead traveling crane industry has evolved to meet the changing demands of modern industries. The adoption of automation, digitalization, and customization has enabled enhanced productivity, safety, and flexibility in material handling operations. As the market continues to evolve, the focus on sustainability and eco-friendly solutions is expected to shape the future of the industry.

Custom Private Labeling and Branding Opportunities with Chinese principal parts of an overhead traveling crane Manufacturers

Chinese manufacturers are increasingly embracing private labeling and branding opportunities for their overhead traveling crane products. With advanced manufacturing capabilities and cost-effective production processes, these manufacturers offer a lucrative option for companies looking to establish their brand presence in the industry.

Private labeling allows companies to market products under their own brand name, creating a distinct identity and enabling better control over the marketing and sales process. Chinese manufacturers are open to partnering with businesses seeking such opportunities, offering customizable solutions to meet specific requirements.

One key advantage of working with Chinese manufacturers is the flexibility in customizing product features. From the overall design to specific components and functionalities, companies can modify the overhead traveling crane to align with their brand’s unique requirements. Chinese manufacturers have well-equipped R&D departments, enabling them to develop and incorporate these customizations efficiently and cost-effectively.

Another advantage is the accessibility to a wide range of materials and production techniques. Chinese manufacturers have access to a variety of high-quality materials at competitive prices. This allows businesses to choose durable and aesthetically appealing materials that align with their brand image. Additionally, Chinese manufacturers excel in various production techniques, ensuring the product’s quality and consistency meet international standards.

Furthermore, branding opportunities extend beyond the product itself. Chinese manufacturers can accommodate private labeling requirements by customizing packaging, labeling, and documentation to reflect the brand image. This helps in creating a cohesive brand experience, reinforcing customer perception and loyalty.

It is important for companies to ensure that the chosen Chinese manufacturer complies with international quality standards and certifications. Conducting thorough due diligence, including factory inspections and product testing, is indispensable to ensure product safety and reliability.

In conclusion, Chinese manufacturers present compelling private labeling and branding opportunities for companies seeking to establish their presence in the overhead traveling crane market. With their manufacturing expertise, customization capabilities, and access to cost-effective materials, these manufacturers offer companies the chance to tailor their products and create a distinctive brand identity in a competitive industry.

Tips for Procurement and Considerations when Purchasing principal parts of an overhead traveling crane

When purchasing principal parts of an overhead traveling crane, there are several important considerations and tips to keep in mind:

1. Define your requirements: Clearly identify the specific requirements of the crane, such as the maximum weight capacity, span length, and lifting height. This will help you in selecting the appropriate principal parts.

2. Research reputable suppliers: Look for reliable and established suppliers with a proven track record in manufacturing crane parts. Read customer reviews and seek recommendations from industry experts to ensure quality products.

3. Opt for quality: While cost is important, prioritize the quality and durability of the parts. Investing in high-quality principal parts will ensure a longer lifespan and minimize maintenance costs.

4. Compatibility: Ensure that the principal parts you purchase are compatible with your existing crane system. This includes considering the specific connection points, electrical requirements, and dimensions.

5. Safety standards: Verify that the principal parts meet all safety standards and regulations. Look for certifications such as CE marking or ISO compliance to ensure the parts adhere to recognized safety protocols.

6. Warranty and after-sales support: Check the warranty offered by the supplier and what after-sales support they provide. This is crucial to address any issues that may arise after the purchase.

7. Consider customization: If your crane system has specific requirements or unique specifications, consider suppliers who offer customization services. This will ensure that the principal parts meet your exact needs.

8. Price negotiation: Once you have shortlisted potential suppliers, negotiate the pricing to achieve a fair deal. Comparing quotes from multiple suppliers can help in determining a competitive price range.

9. Delivery and lead time: Discuss the delivery schedule and lead time with the supplier to ensure that the principal parts will be delivered within the required timeframe.

10. Maintenance and spare parts availability: Inquire about the availability of spare parts and the supplier’s support in maintenance activities. This will help you plan for future maintenance requirements.

By considering these tips and considerations, you can make an informed decision when purchasing the principal parts of an overhead traveling crane. Remember to prioritize quality, compatibility, and safety, while also considering customization options and after-sales support.

FAQs on Sourcing and Manufacturing principal parts of an overhead traveling crane in China

Q: Why should I source and manufacture principal parts of an overhead traveling crane in China?

A: China is one of the leading countries in the manufacturing industry and has a strong reputation for producing high-quality products at competitive prices. The cost of production in China is generally lower compared to other countries, allowing you to save on manufacturing costs. Additionally, China has a vast network of suppliers and manufacturers specializing in overhead traveling crane parts, ensuring a wide range of options and availability.

Q: How can I find reliable suppliers and manufacturers in China for principal parts of an overhead traveling crane?

A: One way to find reliable suppliers and manufacturers in China is by attending trade shows and exhibitions in the industry. These events provide an opportunity to meet with suppliers directly, assess the quality of their products, and negotiate deals. Another option is to use online directories and platforms such as Alibaba or Global Sources, which allow you to search and connect with verified suppliers.

Q: What factors should I consider when selecting a supplier or manufacturer in China?

A: When selecting a supplier or manufacturer in China for principal parts of an overhead traveling crane, several factors should be considered. These include the company’s reputation and track record, product quality, manufacturing capabilities, compliance with international standards, pricing, delivery timeframes, and after-sales support. It is also advisable to request samples or visit the supplier’s facilities to evaluate their operations firsthand.

Q: How can I ensure the quality of products when sourcing from China?

A: To ensure the quality of products when sourcing from China, it is crucial to conduct thorough due diligence on potential suppliers. This includes checking certifications, requesting product samples for testing, and reviewing the supplier’s quality control processes and documentation. Additionally, conducting a factory audit or inspection before placing large orders can help identify any potential quality issues early on.

Q: What are the advantages and challenges of sourcing and manufacturing in China?

A: The advantages of sourcing and manufacturing principal parts of an overhead traveling crane in China include competitive pricing, a wide range of options, efficient supply chains, and experienced workforce. However, challenges may include language barriers, cultural differences, varying manufacturing standards, intellectual property protection, and logistics management. It is important to work with trustworthy partners and establish clear communication channels to mitigate these challenges effectively.

In conclusion, sourcing and manufacturing principal parts of an overhead traveling crane in China offer numerous benefits such as cost savings, quality products, and a wide variety of options. By conducting thorough research, due diligence, and working with reliable partners, you can successfully navigate the process and leverage the advantages that Chinese manufacturing offers.

Why contact sourcifychina.com get free quota from reliable principal parts of an overhead traveling crane suppliers?

Sourcifychina.com, a leading sourcing and procurement company based in China, obtains a free quota from reliable principal parts of an overhead traveling crane suppliers for several reasons.

Firstly, Sourcifychina.com has established long-term partnerships with reputable suppliers of overhead traveling crane parts. Through these partnerships, the company has demonstrated its commitment and reliability in terms of consistently high-quality sourcing and procurement services. As a result, the suppliers are willing to provide a certain quota of principal parts of the cranes to Sourcifychina.com free of charge as a token of appreciation for their continued business relationship.