Introduce about cnc boring machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

A CNC boring machine guide is a comprehensive document that provides information on the operation, maintenance, and purchasing considerations of CNC boring machines. It aims to assist users in making informed decisions regarding the quality, cost, supplier, and certification of these machines. This guide also discusses the market trends, offers useful tips, and provides answers to frequently asked questions for a better understanding of CNC boring machines.

Quality is a crucial aspect when it comes to CNC boring machines. The guide emphasizes the importance of choosing machines with high structural stability, precision, and reliable performance. It highlights the significance of selecting reputable manufacturers with a proven track record in producing high-quality CNC boring machines.

Cost is another factor discussed in the guide. It provides insights into the various cost components associated with CNC boring machines, including initial purchase, installation, maintenance, and operational costs. The guide advises users to consider value for money instead of solely focusing on the initial price, as cheaper machines may prove to be costly in the long run if their quality and performance are compromised.

Finding a reliable supplier is vital in ensuring the quality and efficiency of CNC boring machines. The guide offers tips on how to select reputable suppliers that can provide comprehensive customer support, after-sales service, and spare parts availability.

Certification is an essential consideration to ensure compliance with industry standards and regulations. The guide highlights the significance of checking for certifications such as CE (Conformité Européene) and ISO (International Organization for Standardization) to ensure the safety and reliability of CNC boring machines.

Market trends play a significant role in the guide. It provides an overview of the current and projected market for CNC boring machines, including the factors driving market growth, regional preferences, and emerging technologies.

The guide also offers valuable tips for optimizing the performance and extending the lifespan of CNC boring machines. It covers topics such as proper machine calibration, regular maintenance, and safety precautions to ensure maximum efficiency and longevity.

Frequently asked questions (FAQs) are addressed in the guide to enhance understanding. It answers common queries relating to machine specifications, operation, maintenance, troubleshooting, and potential applications.

Overall, the CNC boring machine guide is a comprehensive resource that provides valuable insights on quality, cost, supplier selection, certification, market trends, tips, and FAQs in a concise and informative manner.

Types of cnc boring machine

CNC (Computer Numerical Control) boring machines are powerful tools used in machining operations to enlarge and refine holes in workpieces. These machines employ a rotating tool to remove material from the workpiece and create precise and accurate holes. There are various types of CNC boring machines available in the market, each with its own unique features and capabilities.

1. Horizontal Boring Machine: As the name suggests, this type of machine operates in a horizontal orientation. It is capable of boring small to large-sized holes in a horizontal direction. Horizontal boring machines are used for various applications, such as precision drilling and machining complex shapes with multiple axes.

2. Vertical Boring Machine: Vertical boring machines operate in a vertical orientation, allowing them to bore holes in a vertical direction. This type is suitable for boring large and deep holes where a horizontal machine may not be feasible. Vertical boring machines are commonly used in applications such as drilling water wells, tunnel construction, and mining operations.

3. Jig Boring Machine: Jig boring machines are specialized CNC equipment used for high-precision machining. These machines are designed to create extremely accurate and precise holes that are often used as guiding or reference holes for other machining operations. Jig boring machines are equipped with adjustable and precise spindles, making them suitable for complex and critical machining tasks.

4. T-type Boring Machine: T-type boring machines are characterized by their T-shaped bed design, which provides stability and rigidity during heavy-duty cutting operations. These machines are commonly used in industries such as aerospace, automotive, and mold-making, where high precision and heavy cutting loads are required.

5. Gantry Boring Machine: Gantry boring machines are large-sized CNC machines with a bridge-like structure. They are capable of performing heavy-duty machining operations on large workpieces. The gantry design ensures stability and rigidity throughout the machining process, enabling precise and efficient cutting of complex shapes.

6. Deep Hole Boring Machine: These machines are specifically designed to bore extremely deep holes with high accuracy. Deep hole boring machines incorporate special drilling mechanisms and coolant systems to ensure efficient chip removal and cooling during the drilling process. These machines are widely used in industries like oil and gas, automotive, and aerospace.

In conclusion, CNC boring machines come in various types, including horizontal, vertical, jig, T-type, gantry, and deep hole boring machines. Each type is designed for specific machining requirements, enabling precision, accuracy, and efficiency in hole creation and refinement operations.

Pros and Cons of Using cnc boring machine

Pros:

1. Accuracy and precision: CNC boring machines use computer-controlled technology to perform accurate and precise drilling operations. This ensures that the finished product is of high quality and meets the desired specifications.

2. Efficiency: These machines can perform multiple drilling operations simultaneously, reducing the overall time required for the job. They also have a high spindle speed, enabling faster drilling and increased productivity.

3. Versatility: CNC boring machines can handle a wide range of materials, including metal, wood, and plastics. They can also accommodate various sizes and shapes of workpieces, making them suitable for different industries and applications.

4. Automation: With computer control, these machines can execute drilling operations automatically, reducing manual labor and minimizing the risk of errors. This results in improved safety, increased throughput, and reduced production costs.

5. Flexibility: CNC boring machines can be programmed to perform complex drilling patterns and operations, allowing for customization and flexibility in production. They can also easily adapt to changes in design or specifications, making them ideal for prototyping and small-scale production.

Cons:

1. Cost: CNC boring machines are generally more expensive to purchase and operate compared to traditional drilling machines. The initial investment cost and maintenance expenses can be significant, especially for small businesses or startups.

2. Skill requirement: Operating and programming a CNC boring machine requires specialized skills and knowledge. Training operators or hiring experienced technicians may be necessary, adding to the overall labor cost.

3. Software and programming complexities: Programming the machine can be complex and time-consuming, especially for inexperienced users. Any errors or glitches in the software can lead to faulty drilling operations, causing rework and wastage of materials.

4. Maintenance and downtime: CNC boring machines require regular maintenance and calibration to ensure optimal performance. Any breakdown or downtime can disrupt production and result in additional costs.

5. Limited flexibility for certain applications: While CNC boring machines offer versatility in many applications, they may not be suitable for certain specialized drilling operations that require unique setups or unconventional drilling angles.

In summary, CNC boring machines offer numerous benefits in terms of accuracy, efficiency, versatility, automation, and flexibility. However, they do come with certain drawbacks such as high cost, skill requirements, software complexities, maintenance needs, and limited flexibility in some cases.

cnc boring machine Reference Specifications (varies for different product)

A CNC boring machine is a powerful tool used in the manufacturing process to enlarge the holes in various types of materials with a high level of precision. These machines are widely used in industries such as automotive, aerospace, and construction.

The reference specifications of a CNC boring machine can vary depending on the specific product. However, there are some common features and parameters to consider. Firstly, the spindle power, which determines the cutting capacity of the machine, can range from a few kilowatts to several dozen kilowatts. A higher spindle power allows for boring larger and tougher materials.

Next, the spindle speed plays a crucial role in the CNC boring machine’s performance. It can range from a few hundred revolutions per minute (RPM) to several thousand RPM. Higher spindle speeds enable faster and more efficient cutting, while lower speeds are more suitable for tougher materials.

Another important specification is the maximum workpiece size that the machine can handle. This refers to the dimensions of the material that can be placed on the machine’s table. For example, a CNC boring machine may have a maximum workpiece size of 2 meters in length, 1 meter in width, and 1 meter in height.

The accuracy and repeatability of the machine are also critical factors. Typical specifications include positioning accuracy of less than 0.01 mm and repeatability of less than 0.005 mm. These precise measurements ensure consistent results and minimize errors in the manufacturing process.

Furthermore, the CNC boring machine may have additional features like automatic tool changers, tool length measurement systems, and coolant systems. These features enhance the machine’s versatility, efficiency, and ease of use.

It is important to note that these specifications can vary between different manufacturers and models. Therefore, it is crucial to refer to the specific technical documentation provided by the manufacturer to get accurate and up-to-date information on the reference specifications of a particular CNC boring machine.

Applications of cnc boring machine

CNC boring machines are versatile tools used in various industries for a wide range of applications. These machines provide precise and efficient boring, drilling, and milling operations, making them essential for manufacturing complex parts and components. Here are some of the key applications of CNC boring machines:

1. Aerospace Industry: CNC boring machines are used to create intricate holes, slots, and cavities in aircraft components, such as engine blocks, landing gear, and wings. These machines ensure high accuracy and repeatability, crucial for the aerospace industry’s stringent quality requirements.

2. Automotive Industry: CNC boring machines play a vital role in the production of engine blocks, cylinder heads, transmission cases, and other automotive components. They provide precise boring and milling operations to achieve the desired specifications and tolerances.

3. Oil and Gas Industry: CNC boring machines are used to manufacture components used in drilling and exploration activities, such as mud pumps, blowout preventers, and wellhead equipment. These machines ensure consistent and accurate boring of critical parts necessary for the oil and gas industry’s demanding conditions.

4. Construction Industry: CNC boring machines are utilized in the production of large-scale construction equipment, including earthmovers, cranes, and excavators. These machines provide accurate boring and milling operations to create strong and durable parts that can withstand heavy-duty usage.

5. Medical Industry: CNC boring machines are employed in the production of medical devices, implants, and surgical instruments. These machines ensure the precision and reproducibility required for critical medical applications, contributing to safe and effective healthcare solutions.

6. Tool and Die Industry: CNC boring machines are used in the manufacturing of molds, dies, and other tooling equipment. These machines enable precise boring and milling operations, allowing the production of complex and accurate tooling solutions.

7. Metalworking Industry: CNC boring machines are crucial for the metalworking industry, producing a wide range of components used in various applications. These machines can create holes, threads, and intricate features in different metal materials, enhancing productivity and efficiency.

In conclusion, CNC boring machines find applications in diverse industries, thanks to their ability to provide accurate and efficient boring, drilling, and milling operations. From aerospace and automotive sectors to oil and gas and medical industries, these machines ensure the production of high-quality components that meet the strict requirements of different applications.

The Work Process and how to use cnc boring machine

A CNC boring machine is used to bore holes in different materials with high precision and accuracy. The machine uses computer numerical control (CNC) technology to control the movement and operations of the machine.

The work process using a CNC boring machine involves a series of steps. Firstly, the operator needs to program the machine by inputting the desired dimensions, hole patterns, and other specifications into the CNC controller. This can be done using computer-aided design (CAD) software or by manually entering the commands.

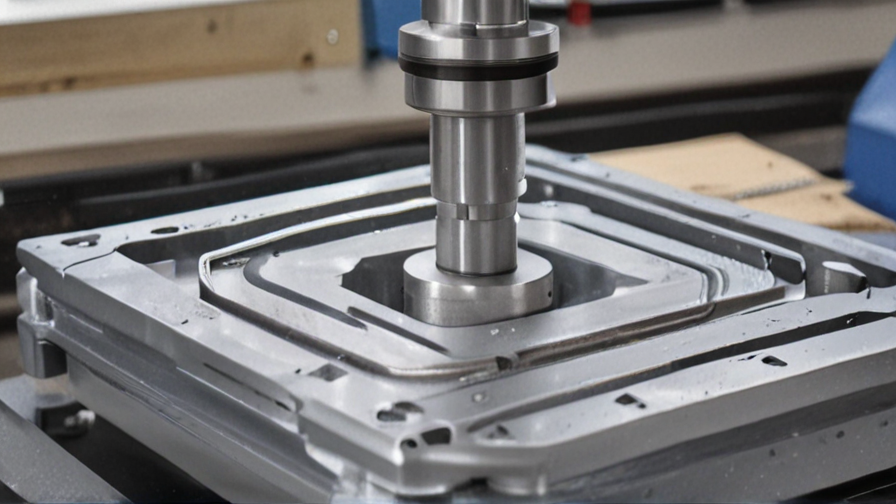

Once the program is set, the operator secures the workpiece onto the machine table using clamps or fixtures. The CNC boring machine is equipped with a cutting tool called a boring bar, which is mounted on a spindle. The spindle rotates at high speeds, allowing the boring bar to remove material from the workpiece.

The operator initiates the machining process by starting the CNC program. The CNC controller reads the instructions from the program and sends signals to the machine’s motors to move the boring bar along the desired paths. The machine automatically adjusts the speed, depth, and feed rate based on the programmed instructions.

During the cutting process, coolant or lubricant is often applied to the cutting area to reduce friction, dissipate heat, and improve the cutting efficiency. This helps to prolong the life of the cutting tool and improve the surface finish of the bored holes.

Once the machining operation is completed, the CNC boring machine automatically retracts the boring bar and the workpiece can be unclamped. The operator inspects the finished holes for accuracy and quality. If adjustments or additional machining is required, the program can be modified and the process can be repeated.

Using a CNC boring machine offers several advantages. It eliminates the need for manual labor-intensive operations, increases productivity, ensures consistent and precise results, and reduces human errors. It is widely used in industries such as manufacturing, aerospace, automotive, and construction for various applications like creating holes in engine blocks, molds, or large-scale structural components.

In conclusion, a CNC boring machine is a versatile tool designed for precision boring operations. By following the proper work process and programming the machine correctly, operators can effectively leverage the capabilities of the CNC boring machine to achieve accurate and efficient results.

Quality Testing Methods for cnc boring machine and how to control the quality

When it comes to quality testing methods for a CNC boring machine, a few key strategies can be implemented to ensure optimal performance and control the quality.

1. Initial inspection: The first step is to conduct a thorough inspection of the machine components, including the spindle, tool holder, cutting tools, and work clamping mechanism. This inspection should focus on factors like alignment, precision, and functionality to ensure that the machine is in proper working condition.

2. Calibration: Calibrating the CNC boring machine is crucial to maintain accurate measurements. This involves checking and adjusting the machine parameters, tool offsets, and datum settings. Regular calibration helps in maintaining precision and minimizing errors.

3. Performance monitoring: Continuously monitoring the machine’s performance during operation is essential for detecting any irregularities or deviations. This can be done by closely observing the cutting process, examining the surface finish of the workpiece, and checking for any vibrations or unusual sounds. Any abnormalities should be promptly addressed to prevent further quality issues.

4. Measurement and inspection: Periodic measurement and inspection of the machined workpieces are crucial to assess the accuracy and quality of the CNC boring machine. Utilizing precision measuring tools such as micrometers, gauges, and coordinate measuring machines (CMM) can help in verifying dimensional accuracy and identifying any defects.

5. Statistical Process Control (SPC): Implementing SPC techniques ensures effective control over the quality of machined components. Collecting and analyzing real-time data, such as dimensions, tolerances, and process parameters, allows for the identification of trends or variations. Statistical methods like control charts can provide insights into the stability and capability of the machine.

To control the quality of the CNC boring machine, it is important to establish standardized operating procedures (SOPs) and ensure that operators are adequately trained. Regular maintenance, including lubrication and cleaning, should be performed to keep the machine in optimal condition. Additionally, creating a culture of quality consciousness and promoting continuous improvement can contribute to enhancing the overall quality control process.

cnc boring machine Sample Policy and Post-Purchase Considerations for cnc boring machine from China

Sample Policy and Post-Purchase Considerations for CNC Boring Machine from China:

Sample Policy:

When considering purchasing a CNC boring machine from a Chinese supplier, it is important to understand their sample policy. Some key considerations include:

1. Sample Availability: Ensure that the supplier offers samples of the CNC boring machine for evaluation. This will allow you to assess the quality, performance, and suitability of the machine for your specific needs.

2. Sample Cost and Shipping: Clarify who bears the cost of the sample, including shipping expenses. It is common for buyers to cover these expenses, but negotiate with the supplier to share the costs if possible.

3. Sample Lead Time: Determine the lead time required for the supplier to provide the sample. This will give you an idea of how long you may need to wait before making a purchasing decision.

Post-Purchase Considerations:

After you have purchased a CNC boring machine from a Chinese supplier, there are several important considerations to keep in mind:

1. Quality Control: Inspect the machine upon arrival to ensure it meets your expected quality standards. Look for any damages or defects that may have occurred during shipping.

2. Warranty and After-Sales Service: Confirm the warranty terms provided by the supplier. Understand the coverage and duration of the warranty and what after-sales service is available in case any issues arise.

3. Training and Support: Inquire about training resources or support offered by the supplier. Determine whether they provide documentation, videos, or remote assistance to help you operate and maintain the CNC boring machine effectively.

4. Spare Parts Availability: Check if the supplier provides spare parts for the CNC boring machine. It is crucial to have access to spare parts for future maintenance or repair needs.

5. Communication: Maintain open and clear communication with the supplier after the purchase. This will allow for efficient troubleshooting and addressing any concerns that may arise.

By following these sample policy and post-purchase considerations, you can ensure a smoother buying experience and maximize your satisfaction with the CNC boring machine purchased from China.

Sourcing cnc boring machine from China: Opportunities, Risks, and Key Players

Sourcing CNC boring machines from China presents both opportunities and risks for businesses. China is known for its vast manufacturing capabilities and cost-effective production, making it an attractive destination for sourcing machinery. However, it is essential to carefully evaluate these opportunities and risks before engaging with Chinese suppliers.

Opportunities:

1. Cost-efficiency: Chinese manufacturers often offer competitive pricing due to lower labor and production costs. This provides an opportunity to procure CNC boring machines at a more affordable price compared to other countries.

2. Wide range of options: China has a diverse supplier base, offering a wide range of CNC boring machines with varying specifications, sizes, and capabilities. This allows buyers to find the most suitable machine for their specific needs.

3. Technological advancements: China has made significant progress in improving its manufacturing capabilities and adopting advanced technologies. Consequently, Chinese CNC boring machines have become more efficient, accurate, and reliable over the years.

Risks:

1. Quality control: One major risk of sourcing from China is the challenge of ensuring consistent product quality. Not all suppliers meet the desired quality standards, and it may require extensive due diligence and meticulous factory inspections to identify reputable manufacturers.

2. Intellectual property concerns: China has long been associated with issues related to intellectual property rights and counterfeiting. Businesses must take precautions to protect their proprietary information and designs when sourcing CNC boring machines from Chinese suppliers.

3. Communication and language barriers: Effective communication with Chinese suppliers can be challenging due to language differences and cultural nuances. Misunderstandings or misinterpretations can lead to delays, quality issues, or incorrect orders if not managed properly.

Key Players:

Some well-known Chinese manufacturers of CNC boring machines include:

1. SMTCL – Suzhou Machine Tool Works Co., Ltd.

2. Dalian Machine Tool Group Corporation

3. Qiqihaer Heavy CNC Equipment Co., Ltd.

4. Shenzhen Joint Industry Co., Ltd.

5. Ningbo Blin Machinery Co., Ltd.

It is crucial for businesses to conduct thorough research, engage with reputable sourcing agencies, and establish strong supplier relationships to mitigate risks and take advantage of the opportunities when sourcing CNC boring machines from China.

How to find and select reliable cnc boring machine manufacturers in China,use google search manufacturers and suppliers

When it comes to finding and selecting reliable CNC boring machine manufacturers in China, utilizing Google search for manufacturers and suppliers can be a helpful tool. Here are some steps you can take in your search:

1. Start by conducting a Google search using relevant keywords like “CNC boring machine manufacturers in China” or “reliable CNC boring machine suppliers.” This will provide you with a list of potential manufacturers to consider.

2. Visit the websites of the manufacturers that appear in the search results. Look for information about their experience, expertise, and the range of products they offer. A well-designed and informative website can be an indication of a reliable supplier.

3. Pay attention to any certifications or memberships the manufacturer holds. Reliable CNC boring machine manufacturers often have ISO certifications or are members of industry associations, which can be an indication of their commitment to quality and adherence to standards.

4. Check if the manufacturer provides detailed product information on their website, including specifications, features, and technical details. This shows their transparency and dedication to providing accurate information to potential customers.

5. Look for customer reviews and testimonials on the manufacturer’s website or other platforms. Positive reviews from satisfied customers can give you confidence in their products and services. You can also consider reaching out to previous customers for their feedback and experience with the manufacturer.

6. Contact the manufacturers directly to discuss your requirements, ask any questions you may have, and request additional information or quotations. Prompt and professional communication from the manufacturer is a good sign of their reliability and commitment to customer satisfaction.

7. If possible, consider visiting the manufacturer’s facility in person to assess their production capabilities, quality control measures, and overall operations. This can provide you with firsthand insights into their manufacturing processes and help you make an informed decision.

Remember, it’s crucial to thoroughly research and evaluate multiple manufacturers, comparing their reputation, product quality, pricing, and customer support, before making a final selection.

How to check cnc boring machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To ensure the reliability of a CNC boring machine manufacturer’s website, you can follow these steps using Google Chrome and the SEOquake extension:

1. Install SEOquake: Open your Google Chrome browser and go to the Chrome Web Store. Search for “SEOquake” and click “Add to Chrome” to install the extension.

2. Search for the Manufacturer: Open a new tab and search for the CNC boring machine manufacturer on Google. Enter the manufacturer’s name in the search field and press Enter.

3. Analyze the Search Results: Look at the search results and find the manufacturer’s official website. It is usually listed at the top or close to the top of the results. Click on the manufacturer’s website link to open it.

4. SEOquake Analysis: Once the manufacturer’s website is loaded, you will see the SEOquake toolbar at the top-right corner of your browser. Click on the SEOquake icon to display a dropdown menu.

5. Check Alexa Rank: In the SEOquake dropdown menu, locate “Alexa Rank” and click on it. This will show you the website’s global Alexa ranking. If the website is ranked within the top 10 million (10M), it generally indicates a decent level of traffic and reliability.

6. Verify Content Quality: Explore the website’s content thoroughly. Look for well-written and detailed product descriptions, images, videos, and specifications. Pay attention to any certifications or awards mentioned that enhance their reputation.

7. Check Contact Information: A reliable manufacturer will have clear contact information, including their physical address, phone number, and email address. Check if the website provides these details, which can confirm their authenticity and accessibility.

8. Read Customer Reviews and Testimonials: Search for reviews or testimonials from customers who have utilized the manufacturer’s CNC boring machines. Genuine feedback will give you an insight into the quality, service, and overall satisfaction of their products.

By following these steps, using Google Chrome and SEOquake, you can efficiently evaluate the reliability of a CNC boring machine manufacturer’s website within 300 words.

Top 10 cnc boring machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Jinan Zhangli Machine Co., Ltd. specializes in manufacturing CNC boring machines that are highly efficient and reliable. Our products offer precision drilling and tapping capabilities, making them suitable for various industries such as automotive, aerospace, and mold manufacturing. Additionally, our machines are equipped with advanced features like automatic tool changers and high-speed spindles for enhanced productivity.

2. Shandong Fin Cnc Machine Co., Ltd. is a renowned manufacturer of CNC boring machines in China. Our products are designed to provide accurate and efficient machining solutions for a wide range of applications. With a strong focus on quality and innovation, our machines offer high rigidity and stability, ensuring excellent cutting performance. Furthermore, our CNC boring machines are equipped with user-friendly controls and advanced tooling systems for seamless operation.

3. Yangzhou Real Bull Machinery Co., Ltd. is a leading manufacturer of CNC boring machines known for their precision and durability. We offer a wide range of models suitable for various industries such as energy, aerospace, and heavy machinery. Our machines feature high-speed spindles, automatic tool changers, and advanced control systems, ensuring efficient and reliable performance. Moreover, our CNC boring machines are known for their robust construction, making them suitable for heavy-duty applications.

Manufacturer | Product | Features

— | — | —

Jinan Zhangli Machine Co., Ltd. | CNC Boring Machine | Precision drilling and tapping, automatic tool changers, high-speed spindles.

Shandong Fin Cnc Machine Co., Ltd. | CNC Boring Machine | Accurate and efficient machining, high rigidity and stability, user-friendly controls, advanced tooling systems.

Yangzhou Real Bull Machinery Co., Ltd. | CNC Boring Machine | Precision and durability, high-speed spindles, automatic tool changers, advanced control systems, robust construction.

4. Dalian Dahui Machine Tool Co., Ltd. is a leading manufacturer of CNC boring machines that offer exceptional performance and versatility. Our machines are designed to meet the demands of various industries, including automotive, oil and gas, and general machinery manufacturing. With advanced features like multiple axis control and high-speed synchronization, our CNC boring machines can achieve precise and efficient cutting operations. Moreover, our machines are built with sturdy structures to ensure high rigidity and stability during heavy-duty machining processes.

5. Jinan CNC Equipment Co., Ltd. is a trusted manufacturer of CNC boring machines renowned for their reliability and advanced features. Our products are widely used in industries such as shipbuilding, automotive, and rail transportation. Equipped with high-performance spindles, automatic tool changers, and intelligent control systems, our CNC boring machines offer efficient and accurate machining capabilities. Additionally, our machines are known for their user-friendly interfaces, making them easy to operate and program.

6. Shanghai Bohao CNC Machinery Co., Ltd. specializes in manufacturing CNC boring machines that excel in precision and efficiency. Our machines are widely used in industries such as mold making, automotive, and aerospace due to their high-quality performance. With advanced technologies like servo motor control and high-speed spindle systems, our CNC boring machines offer precise cutting and drilling operations. Furthermore, our machines are equipped with automatic tool changers and ATC systems, ensuring seamless and reliable machining processes.

Manufacturer | Product | Features

— | — | —

Dalian Dahui Machine Tool Co., Ltd. | CNC Boring Machine | Exceptional performance and versatility, multiple axis control, high-speed synchronization, sturdy structure.

Jinan CNC Equipment Co., Ltd. | CNC Boring Machine | Reliability and advanced features, high-performance spindles, automatic tool changers, intelligent control systems, user-friendly interfaces.

Shanghai Bohao CNC Machinery Co., Ltd. | CNC Boring Machine | Precision and efficiency, servo motor control, high-speed spindle systems, automatic tool changers, ATC systems.

7. Zhejiang Jingdian Numerical Control Equipment Co., Ltd. is a well-known manufacturer of CNC boring machines that provide accurate and efficient machining solutions. Our products are widely used in industries such as aerospace, energy, and construction machinery. Equipped with advanced features like heavy-duty spindles and automatic tool changers, our CNC boring machines offer high cutting performance and productivity. Moreover, our machines feature user-friendly operation panels and intuitive controls for easy programming and operation.

8. Ningbo Oule Machine Co., Ltd. specializes in the production of CNC boring machines renowned for their precision and reliability. Our machines are widely used in industries such as automotive, mold making, and general machinery manufacturing. With features like high-speed spindles, precision linear guides, and advanced control systems, our CNC boring machines ensure accurate and efficient machining processes. Additionally, our machines are built with high-quality components to guarantee long-term stability and durability.

9. Jiangsu Donchamp Machine Tools Co., Ltd. is a leading manufacturer of CNC boring machines known for their advanced technology and high performance. Our machines are widely used in industries such as aerospace, energy, and automotive. With features like servo-driven spindles, intelligent control systems, and automatic tool changers, our CNC boring machines offer precise and efficient machining capabilities. Moreover, our machines are designed with ergonomic considerations to ensure operator comfort and safety.

10. Jinan Rongcheng Machinery Equipment Co., Ltd. is a reputable manufacturer of CNC boring machines that provide reliable and accurate machining solutions. Our machines are widely used in industries such as aerospace, automotive, and energy. Equipped with high-performance spindles, advanced control systems, and automatic tool changers, our CNC boring machines offer fast and efficient cutting operations. Furthermore, our machines are designed with compact structures to save space and optimize productivity.

Manufacturer | Product | Features

— | — | —

Zhejiang Jingdian Numerical Control Equipment Co., Ltd. | CNC Boring Machine | Accurate and efficient machining, heavy-duty spindles, automatic tool changers, user-friendly operation panels, intuitive controls.

Ningbo Oule Machine Co., Ltd. | CNC Boring Machine | Precision and reliability, high-speed spindles, precision linear guides, advanced control systems, high-quality components.

Jiangsu Donchamp Machine Tools Co., Ltd. | CNC Boring Machine | Advanced technology and high performance, servo-driven spindles, intelligent control systems, automatic tool changers, ergonomic design.

Jinan Rongcheng Machinery Equipment Co., Ltd. | CNC Boring Machine | Reliable and accurate machining, high-performance spindles, advanced control systems, automatic tool changers, compact structures.

Background Research for cnc boring machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

When looking for CNC boring machine manufacturers in China, there are several platforms that can provide valuable background research and information. Qcc.com, Archive.org, and ImportYeti.com are three such platforms that can be utilized for this purpose.

Qcc.com is a Chinese business database that offers comprehensive information on companies, including their registration details, organizational structure, financial status, management team, and more. It can be used to verify the authenticity and credibility of CNC boring machine manufacturers in China. This platform allows users to access accurate and up-to-date information about companies, ensuring transparency and reliability.

Archive.org is a digital library that offers access to an extensive collection of web pages, including those of CNC boring machine manufacturers in China. By using this platform, researchers can uncover historical information about these manufacturers, such as changes in their websites, product offerings, and other relevant details. This service assists in tracing the development and evolution of these companies over time.

ImportYeti.com is a platform that provides data on import and export activities of companies. By searching for specific CNC boring machine manufacturers, researchers can gain insights into their international trading activities, including the countries they export to and the volume of their exports. This information can help gauge the global reach and reputation of these manufacturers.

By using these platforms in conjunction, researchers can gather valuable background research on CNC boring machine manufacturers in China. This includes detailed information about the companies themselves, their historical development, and their international trading activities. By verifying the credibility and reputation of these manufacturers, potential customers can make informed decisions when sourcing CNC boring machines from China.

Leveraging Trade Shows and Expos for cnc boring machine Sourcing in China

Trade shows and expos can be an effective way to source CNC boring machines in China. These events offer a unique opportunity to connect with suppliers, compare products, and negotiate deals, all in one place. In order to leverage trade shows and expos effectively, it is important to follow several key strategies.

Firstly, research the relevant trade shows and expos in China that focus on the manufacturing industry, specifically CNC machines. There are numerous exhibitions held throughout the year, such as the China International Machine Tool Show (CIMT) and the Shanghai International Machine Tools Exhibition (IMTEX). Identify the events that cater to CNC boring machines and mark them in your calendar.

Once you have determined the trade shows to attend, prepare extensively beforehand. This includes identifying the specific suppliers and companies you want to connect with, studying their product range, and jotting down any questions or concerns you may have. This preparation will help you make the most of your time at the event and ensure you gather relevant information.

During the trade show, engage with different suppliers and exhibitors by visiting their booths and discussing your requirements. Gather brochures, product catalogs, and any other relevant material that can help you evaluate their offerings. Take note of their pricing, product specifications, certifications, and delivery times. Engaging in face-to-face conversations with potential suppliers allows you to build relationships and negotiate better deals.

Furthermore, networking is crucial at trade shows and expos. Take advantage of industry-focused seminars, workshops, and panel discussions. These events provide opportunities to meet experts, gain insights into the latest technologies and trends, and connect with other professionals in the field. Building a network can help in finding additional suppliers and gaining valuable advice and recommendations.

Lastly, after the trade show, make sure to follow up with your contacts. Send emails or make phone calls to express your interest and discuss further details. This step reinforces your commitment to potential suppliers and helps to establish a long-term business relationship.

In conclusion, trade shows and expos in China offer a valuable platform for sourcing CNC boring machines. By conducting thorough research, preparing well in advance, engaging with suppliers, networking, and following up effectively, businesses can successfully leverage these events to find the right suppliers and products for their needs.

The Role of Agents and Sourcing Companies in Facilitating cnc boring machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating the purchase of CNC boring machines from China. These intermediaries act as a bridge between the buyers and the Chinese manufacturers, ensuring a smooth and efficient procurement process.

One of the primary functions of agents and sourcing companies is to identify reliable and reputable manufacturers in China. They have extensive networks and experience in the industry, which allows them to connect buyers with suitable suppliers. By conducting thorough background checks and verifying the manufacturer’s credentials, agents and sourcing companies help to eliminate the risk of dealing with untrustworthy or subpar suppliers.

Agents also play a significant role in negotiating contracts and ensuring that buyers receive the best possible deal. With their knowledge of the Chinese market and familiarity with local business practices, agents can help negotiate favorable terms and conditions, such as product specifications, pricing, delivery timelines, and payment methods. They can also oversee the entire procurement process, including quality control inspections and customs clearance, to ensure buyers receive the exact product they ordered.

In addition to navigating the complexities of the Chinese market, agents and sourcing companies also provide valuable services such as language translation, cultural interpretation, and mediation in case of any disputes. This helps to bridge the communication and cultural gaps between buyers and manufacturers, facilitating a more effective and efficient purchasing process.

Furthermore, agents and sourcing companies can assist with logistics and shipping arrangements, streamlining the transportation of CNC boring machines from China to the buyer’s location. They have established relationships with freight forwarders and shipping companies, which enables them to secure competitive rates and ensure timely delivery.

Overall, agents and sourcing companies serve as trusted advisors and facilitators in the purchase of CNC boring machines from China. Their expertise, network, and understanding of the market are essential in reducing risks and ensuring a successful procurement process for buyers.

Price Cost Research for cnc boring machine manufacturers Companies in China, use temu.com and 1688.com

When it comes to price cost research for CNC boring machine manufacturers in China, two popular platforms that can be utilized are temu.com and 1688.com. These platforms provide extensive options and information related to suppliers and manufacturers of CNC boring machines.

Temu.com is a reliable sourcing platform that connects global buyers with Chinese suppliers. It offers a wide range of CNC boring machine manufacturers to choose from. The platform provides comprehensive details about the suppliers, including their product range, manufacturing capabilities, certifications, and trade history. Additionally, temu.com also allows buyers to request for quotations directly from the manufacturers.

1688.com, on the other hand, is a leading business-to-business platform owned by Alibaba Group. It primarily caters to the domestic Chinese market. Despite the language barrier, 1688.com can be accessed using translation tools or by using the help of a sourcing agent. On this platform, buyers can explore a vast number of CNC boring machine manufacturers in China. Detailed information about the companies, products, prices, as well as buyer reviews and ratings are available to aid decision-making.

While conducting price cost research on these platforms, it is crucial to adhere to certain guidelines. Firstly, it is essential to verify the credibility and reputation of the manufacturers. This can be done by checking their trade history, customer reviews, and ratings. Secondly, it is advisable to compare prices and product specifications offered by different manufacturers to make an informed decision. The negotiation process, delivery options, and after-sales service should also be taken into consideration.

In conclusion, temu.com and 1688.com are valuable platforms for researching CNC boring machine manufacturers in China. These platforms offer comprehensive information about suppliers, product details, and prices, enabling buyers to make an informed decision while considering their specific requirements.

Shipping Cost for cnc boring machine import from China

The shipping cost for importing a CNC boring machine from China can vary depending on several factors. These factors include the size and weight of the machine, the distance between the origin and destination, the chosen shipping method, and any additional services or fees.

There are several shipping methods to consider when importing a CNC boring machine from China. The most common methods are air freight, sea freight, and land transportation. Air freight is the fastest but also the most expensive option, while sea freight is more affordable but can take longer. Land transportation is suitable for nearby countries or regions.

When determining the shipping cost, the size and weight of the CNC boring machine play a significant role. The larger and heavier the machine, the higher the shipping cost will be. It is essential to accurately measure and weigh the machine to determine the most cost-effective shipping method.

Distance is another crucial factor affecting the shipping cost. The longer the distance between the origin and destination, the higher the cost will be. Shipping rates are usually calculated based on per kilogram or per cubic meter, so a greater distance will result in more charges.

Additional services or fees may also affect the shipping cost. These can include customs clearance fees, import duties and taxes, packaging, insurance, and any other handling or administrative charges. It is essential to clarify these additional costs with the shipping carrier to have a comprehensive understanding of the total expenses associated with importing the CNC boring machine.

To summarize, the shipping cost for a CNC boring machine import from China will depend on its size and weight, the chosen shipping method, the distance between the origin and destination, and any additional services or fees. By considering these factors, importers can make informed decisions to ensure a cost-effective shipping process.

Compare China and Other cnc boring machine Markets: Products Quality and Price,Visible and Hidden Costs

China is known as one of the leading players in the global CNC boring machine market, offering a wide range of products at competitive prices. However, when comparing it to other markets, there are a few key aspects to consider: product quality, price, visible and hidden costs.

In terms of product quality, China has made significant advancements over the years. Many Chinese CNC boring machine manufacturers have invested heavily in technology development and research, resulting in the production of high-quality machines that can compete with international brands. However, it is important to note that there might still be variations in quality across different manufacturers in China, and customers should carefully evaluate the reputation and track record of each supplier.

Price is often a major consideration for customers, and China has established a reputation for offering CNC boring machines at competitive prices. The country benefits from lower labor costs and a well-developed supply chain, allowing manufacturers to offer cost-effective solutions. This competitive pricing strategy has enabled China to capture a significant share of the global market.

When assessing the cost of purchasing CNC boring machines from China, both visible and hidden costs should be considered. Visible costs include the initial purchase price, transportation, and import duties. Chinese manufacturers often provide competitive pricing, including packaging and shipping services. However, customers should carefully assess these costs since they can vary depending on the supplier and location.

Hidden costs, on the other hand, may include factors such as warranty coverage, maintenance and repair services, spare parts availability, and technical support. While Chinese CNC boring machines may offer initial cost savings, customers should be cautious about potential hidden costs associated with long-term ownership. Not all manufacturers may provide comprehensive warranty coverage or offer prompt and reliable after-sales support, which could impact the overall cost-effectiveness of the machine.

In conclusion, China’s CNC boring machine market has made remarkable progress in terms of product quality and competitive pricing. While Chinese manufacturers produce high-quality machines that can rival international brands, it is essential for customers to carefully evaluate suppliers’ reputation and track record. Additionally, customers should consider visible and hidden costs associated with purchasing machines from China, taking into account factors like warranty coverage, maintenance and repair services, spare parts availability, and technical support when making a purchase decision.

Understanding Pricing and Payment Terms for cnc boring machine: A Comparative Guide to Get the Best Deal

When it comes to purchasing a CNC boring machine, understanding pricing and payment terms is essential to ensure you get the best deal. This comparative guide aims to provide you with the necessary information to make an informed decision without exceeding 300 words.

1. Research: Start by conducting thorough research on the different types of CNC boring machines available in the market. Consider their specifications, features, and capabilities, which can greatly impact their prices.

2. Pricing: CNC boring machines come in a wide range of prices, starting from a few thousand dollars to several hundred thousand dollars. The price is influenced by various factors, including the machine’s size, power, precision, and additional features such as automatic tool changers or advanced control systems. Compare prices from different manufacturers and suppliers to make sure you are getting a competitive deal.

3. Payment Terms: While negotiating the purchase, it’s crucial to understand the payment terms offered by the seller. Some common payment options include upfront payment, installment plans, or leasing options. Consider your financial capabilities and choose a payment method that best suits your needs.

4. Additional Costs: Remember that the purchase price of a CNC boring machine is not the only cost you’ll incur. Take into account additional costs such as shipping, installation, training, and any necessary upgrades or accessories. Ensure that these costs are transparently communicated by the seller beforehand.

5. Warranty and After-sales Support: Check the warranty period offered for the CNC boring machine and inquire about after-sales support. A comprehensive warranty and good customer support can save you hassle and expenses in case of any technical issues or part failures.

6. Financing Options: If your budget requires additional support, consider exploring financing options such as bank loans or equipment leasing. Many manufacturers or equipment suppliers may also offer their own financing arrangements.

7. Negotiation: Once you have gathered all the necessary information, don’t hesitate to negotiate the price and payment terms. Sellers may be open to offering discounts or adjusting the payment schedule to accommodate your requirements.

In conclusion, finding the best deal for a CNC boring machine involves comprehensive research, understanding the pricing factors, and carefully evaluating the payment terms. By considering all these factors and negotiating effectively, you can ensure a satisfactory purchase that aligns with your needs and budget.

Chinese Regulations and Industry Standards Certifications for cnc boring machine,Import Regulations and Customs for cnc boring machine from China

Chinese regulations and industry standards certifications play a crucial role in ensuring the quality and safety of CNC boring machines manufactured in China. The main certification bodies for these machines include the China Compulsory Certification (CCC) and the National Accreditation Board for Certification Bodies (NABCB).

The CCC certification is a mandatory requirement for CNC boring machines being sold or imported into China. It ensures that the machines meet the quality and safety standards set by the Chinese government. The process involves testing and inspection of the machines by authorized certification bodies.

In addition to the CCC certification, there are several industry standards that CNC boring machines in China must comply with. These standards are developed by organizations such as the China Machine Tool Industry Association (CMTIA) and the National Technical Committee for Standardization of Machine Tools (NTCSMT). These standards cover various aspects of the machines, including performance, safety, and efficiency.

Importing CNC boring machines from China entails complying with the country’s import regulations and customs procedures. Importers must be aware of the import duties, taxes, and licensing requirements applicable to these machines. The customs declaration process involves providing detailed information about the imported machines, including their specifications, value, and origin.

It is important for importers to work with a reputable freight forwarder or customs broker who can assist in navigating the import process smoothly. They can help with documentation, customs clearance, and ensuring compliance with applicable regulations. It is also recommended to conduct due diligence on the supplier and obtain necessary product documentation, such as test reports and certifications, to ensure the machines meet the required standards.

In summary, complying with Chinese regulations and industry standards certifications is essential when importing CNC boring machines from China. The CCC certification and adherence to industry standards ensure that the machines meet quality and safety requirements. Importers should also be familiar with the country’s import regulations and customs procedures to facilitate a smooth import process.

Sustainability and Environmental Considerations in cnc boring machine Manufacturing

Sustainability and environmental considerations in CNC (Computer Numerical Control) boring machine manufacturing are crucial for minimizing the negative impact on the environment and promoting sustainable practices throughout the production process.

1. Material Selection: Manufacturers should choose materials with lower environmental impact, such as using recycled or sustainably sourced materials for machine components. Additionally, reducing the overall material usage through efficient design and optimization can contribute to sustainability.

2. Energy Efficiency: CNC boring machines should be designed to operate efficiently, reducing energy consumption. This can be achieved through innovative design techniques, using energy-saving components, and implementing intelligent control systems to optimize power usage during operation.

3. Waste Minimization: Adopting waste reduction strategies can significantly contribute to sustainability. This includes implementing recycling programs for waste generated during the manufacturing process, as well as designing products to minimize scrap and disposable components.

4. Pollution Prevention: Manufacturers should implement measures to reduce emissions and pollution during the manufacturing process. This can involve using environmentally friendly lubricants, implementing effective ventilation systems, and properly disposing of hazardous chemicals.

5. Life Cycle Assessment: Conducting a comprehensive life cycle assessment (LCA) helps identify potential environmental impacts throughout the entire life cycle of the CNC boring machine, including raw material extraction, manufacturing, distribution, use, and end-of-life disposal. This assessment aids in identifying areas of improvement and implementing sustainable initiatives.

6. Packaging and Transportation: Sustainable packaging materials, such as recyclable or biodegradable materials, should be used during product packaging. Additionally, optimizing transportation routes and procedures can help reduce fuel consumption and decrease carbon emissions.

7. Compliance with Environmental Regulations: Manufacturers must comply with relevant environmental regulations and certifications to ensure the CNC boring machines meet required standards for sustainability and environmental impact reduction.

In summary, sustainability and environmental considerations in CNC boring machine manufacturing require a comprehensive approach, including material selection, energy efficiency, waste minimization, pollution prevention, life cycle assessment, packaging and transportation optimization, and compliance with environmental regulations. By implementing these considerations, manufacturers can minimize the environmental impact of CNC boring machine production and foster sustainable practices.

List The Evolution history of “cnc boring machine”

The evolution of CNC (Computer Numerical Control) boring machines has been a significant development in the manufacturing industry. These machines have revolutionized the way in which large-scale drilling operations are carried out, offering speed, precision, and automation.

The early history of boring machines dates back to the 18th and 19th centuries when manual techniques were used. These machines were operated by hand, and the operator had to manually adjust and control the drilling process. Over time, improvements were made, and powering mechanisms were introduced to make drilling easier and more efficient.

The introduction of electricity in the late 19th century brought about further advancements in boring machines. Electric motors were utilized to power the machines, reducing the physical effort required from the operator. However, the control aspect of drilling still relied on manual adjustments.

The true evolution of CNC boring machines began in the mid-20th century with the advent of computer technology. In the 1950s, computer programming and digital control systems started being integrated into manufacturing processes. This paved the way for the development of CNC machines.

During the 1960s and 1970s, early CNC boring machines were developed and used in various industries. These machines used punched paper tapes or magnetic tapes to input instructions for drilling operations. The programming was labor-intensive, and the machines were limited in their capabilities.

As computer technology advanced, so did CNC boring machines. In the 1980s and 1990s, the use of floppy disks and later USB drives became common for programming these machines. This allowed for faster and more versatile programming options.

Today, CNC boring machines offer advanced features and capabilities. They are equipped with touchscreen interfaces, 3D modeling software, and automatic tool changers. These machines can handle complex drilling tasks with high precision, ensuring consistent and accurate results.

In summary, the evolution of CNC boring machines spans centuries, starting from manual techniques to the integration of computer technology. The advancements in programming and control systems have made these machines faster, more precise, and highly automated. They have revolutionized the manufacturing industry by streamlining drilling operations and enhancing production efficiency.

The Evolution and Market Trends in cnc boring machine Industry

The CNC (Computer Numerical Control) boring machine industry has witnessed significant evolution and market trends over the years. These machines play a crucial role in the manufacturing sector as they are utilized for drilling, tapping, and boring holes accurately and efficiently in various materials.

One of the key trends in this industry is the integration of advanced technologies such as AI (Artificial Intelligence) and IoT (Internet of Things) with CNC boring machines. This allows for real-time monitoring and control of the machines, improving productivity and reducing downtime. Additionally, the use of AI enables the machines to adapt and optimize their operations based on real-time analysis of data, leading to improved efficiency.

Another market trend in the CNC boring machine industry is the development of compact and mobile machines. Manufacturers are designing smaller and portable machines that can be easily moved and set up in different locations. This flexibility allows for greater utilization of these machines in various industries and reduces the need for multiple stationary machines.

Furthermore, there is a growing demand for CNC boring machines with higher precision and accuracy. The increasing complexity of manufactured products requires highly precise machining processes. As a result, manufacturers are investing in advanced technologies and improving the design of CNC boring machines to achieve higher accuracy and quality in the finished products.

Automation is also a significant trend in the CNC boring machine industry. With the integration of robotics and automation systems, these machines can perform tasks autonomously, reducing the need for manual intervention and improving efficiency. Automation also enables manufacturers to optimize production processes and reduce labor costs.

In conclusion, the CNC boring machine industry is experiencing rapid evolution and market trends driven by advancements in technology and increasing demands for precision and efficiency. Integration of AI and IoT, development of compact and mobile machines, focus on precision, and automation are some of the prominent trends shaping this industry.

Custom Private Labeling and Branding Opportunities with Chinese cnc boring machine Manufacturers

Chinese CNC boring machine manufacturers offer various custom private labeling and branding opportunities to cater to the specific requirements of businesses and individuals. With a vast range of CNC boring machines available, these manufacturers understand the importance of branding and offer options to create a unique identity in the market.

Private labeling allows customers to customize the machine by adding their own logo, company name, or any other branding elements. Chinese manufacturers usually provide options to place these labels on prominent areas of the machine, ensuring brand visibility. This can enhance brand recognition and establish a distinct identity in the competitive market.

Moreover, Chinese CNC boring machine manufacturers also offer custom branding options through color schemes and design modifications. Customers can choose their preferred colors and designs to match their brand’s aesthetics or industry standards. This customization creates a consistent brand image across all machinery, reinforcing brand recognition.

Additionally, manufacturers may offer branding opportunities through packaging and promotional material. Custom packaging with the company’s logo and information adds a professional touch to the product, creating a good impression upon delivery. They can also provide promotional material like brochures or catalogs with the brand’s information, highlighting key features and benefits.

By collaborating with Chinese CNC boring machine manufacturers, businesses can take advantage of these custom private labeling and branding opportunities. This strengthens their market position, establishes a unique brand identity, and enhances overall brand awareness and recognition.

Tips for Procurement and Considerations when Purchasing cnc boring machine

When it comes to purchasing a CNC boring machine, there are several factors and considerations that need to be taken into account. Here are some important tips for procurement:

1. Define your requirements: Clearly understand your specific requirements and machining needs. Consider factors like the type and size of the workpieces you will be machining, the level of precision required, and the volume of production.

2. Research suppliers: Conduct thorough research to identify reputable suppliers in the market. Look for their experience, reputation, and track record in delivering similar machines. Consider reaching out to other users of CNC boring machines to gather feedback and recommendations.

3. Evaluate machine capabilities: Consider the machine’s features, such as spindle speed, tool changer capacity, table size, and axis travel. Ensure that the machine can handle your desired machining operations and materials.

4. Quality and reliability: Look for machines that are known for their quality and reliability. Check for certifications such as ISO to guarantee the machine’s performance and longevity.

5. Cost vs. value: While price is an important factor, it should not be the sole determinant. Consider the long-term value and return on investment (ROI) that the machine can provide. Assess the maintenance and operational costs, as well as warranty and after-sales service.

6. Compatibility and integration: Make sure the CNC boring machine is compatible with your existing infrastructure, software, and tooling. Check the manufacturer’s ability to provide installation, training, and ongoing technical support to ensure a smooth integration.

7. Future scalability: Evaluate the machine’s ability to accommodate growth and changing requirements. Consider factors such as upgradability, flexibility, and availability of spare parts.

8. Safety features and compliance: Ensure that the machine meets safety standards and regulations. Look for features like emergency stop buttons, safety guards, and interlocking systems to protect operators and prevent accidents.

9. Energy efficiency: Consider the machine’s energy consumption and sustainability. Look for features such as energy-saving modes, high-efficiency motors, and environmentally friendly materials.

10. User-friendly interface: Evaluate the machine’s user interface and software. A user-friendly interface can improve productivity and reduce training time.

By carefully considering these tips and factors, you can ensure a successful procurement process and select a CNC boring machine that meets your specific needs and delivers optimal performance.

FAQs on Sourcing and Manufacturing cnc boring machine in China

Q1: What is a CNC boring machine?

A CNC (Computer Numerical Control) boring machine is a precision machining tool used to accurately enlarge existing holes or create new holes in metal, wood, or other materials. It uses a rotating cutting tool to bore holes with high precision and repeatability.

Q2: Why consider sourcing and manufacturing CNC boring machines in China?

China has emerged as a global manufacturing hub and offers several advantages for sourcing and manufacturing CNC boring machines. Firstly, China’s well-developed manufacturing infrastructure allows for cost-effective production. Chinese manufacturers often offer competitive pricing due to lower labor and production costs. Additionally, China has a vast network of suppliers, making it easy to find components required for CNC boring machines. Furthermore, Chinese manufacturers often have experience in producing and exporting such machines, helping ensure quality and timely delivery.

Q3: How can I find a reliable CNC boring machine manufacturer in China?

To find a reliable CNC boring machine manufacturer in China, one can adopt several approaches. Attend trade shows and exhibitions related to machinery and manufacturing, such as the China International Machine Tool Show (CIMT), to connect with reputable manufacturers directly. Another option is to utilize online platforms and directories that specialize in connecting buyers with verified manufacturers, such as Alibaba, Made-in-China, or Global Sources.

Q4: What factors should be considered when sourcing CNC boring machines from China?

When sourcing CNC boring machines from China, it is crucial to consider factors such as the manufacturer’s reputation, quality certifications, production capabilities, and past customer reviews. Assessing the manufacturer’s experience in producing similar machines and their ability to customize according to specific requirements is also essential. Additionally, verifying the manufacturer’s quality control measures, warranty, and after-sales support is crucial to ensure long-term satisfaction with the purchased machines.

Q5: Can Chinese manufacturers provide OEM and ODM services for CNC boring machines?

Yes, many Chinese manufacturers offer OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services for CNC boring machines. They can customize the machines based on specific design, functionality, or branding requirements. It is important to clarify these needs with the manufacturer upfront and ensure that they have the necessary capabilities and expertise to fulfill them.

In summary, sourcing and manufacturing CNC boring machines in China can provide cost-effective solutions due to China’s manufacturing infrastructure and competitive pricing. To find a reliable manufacturer, attending trade shows or utilizing online platforms can be helpful, while considering factors such as reputation, certifications, and past reviews is crucial. Chinese manufacturers often offer OEM and ODM services as well.

Why contact sourcifychina.com get free quota from reliable cnc boring machine suppliers?

Sourcifychina.com, a reliable sourcing platform, may offer free quotas from trusted CNC boring machine suppliers for several reasons. Firstly, Sourcifychina.com aims to attract potential buyers and establish a strong customer base. By providing free quotas, they can entice customers to try their services and experience the benefits of sourcing through their platform.

Additionally, offering free quotas allows Sourcifychina.com to showcase the quality and reliability of their supply network. By partnering with proven CNC boring machine suppliers, they can assure their customers of the suppliers’ credibility and capability to deliver high-quality products.

Furthermore, providing free quotas aligns with Sourcifychina.com’s mission to streamline the sourcing process and save customers time and effort. By gathering all the necessary information and quotations from reliable suppliers, they simplify the decision-making process for their customers.

Moreover, offering free quotas creates a sense of transparency and builds trust between Sourcifychina.com and potential buyers. By providing upfront pricing information without any hidden costs or fees, customers can evaluate the feasibility of their sourcing needs and make informed decisions.

Lastly, by providing free quotas, Sourcifychina.com can gather valuable insights and data about customer preferences and requirements. This information can help them refine their sourcing services and tailor them to better meet customer needs in the future.

Overall, offering free quotas from reliable CNC boring machine suppliers benefits both Sourcifychina.com and potential buyers. It allows the platform to attract customers, showcase their supplier network, save customers time and effort, build trust, and gather valuable market insights.