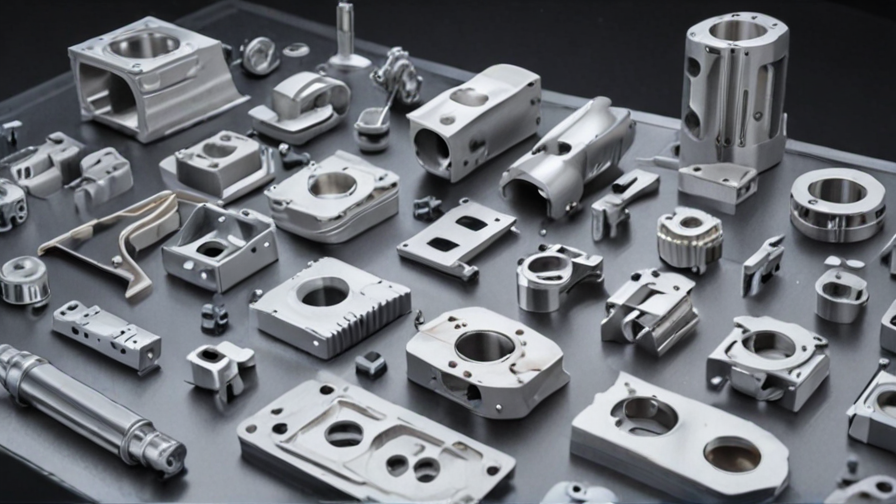

Introduce about cnc milling machine parts guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

A CNC milling machine is a versatile and efficient tool used in various industries such as manufacturing, aerospace, and automotive. Understanding its parts is crucial for effective operation and maintenance. This guide will provide an overview of the important components of a CNC milling machine.

The main parts of a CNC milling machine include the spindle, tool magazine, worktable, control panel, and coolant system. The spindle is responsible for rotating the cutting tool, while the tool magazine stores different types of tools for automatic tool changing. The worktable facilitates the movement of the workpiece, and the control panel manages the machine’s operation. The coolant system ensures that the cutting area stays cool and lubricated during the milling process.

When considering the quality of a CNC milling machine, factors such as precision, speed, and durability must be evaluated. High-quality machines will yield accurate and consistent results, ensuring efficient production processes. The cost of a CNC milling machine can vary depending on its size, specifications, and brand. It is important to research and compare prices from different suppliers to find the best deal.

Finding a reliable supplier is essential for a successful purchase. Look for suppliers with a strong reputation and positive customer reviews. It is also necessary to consider the supplier’s aftersales service and technical support to address any potential issues. Certification, such as ISO 9001, ensures that the supplier adheres to international quality standards.

The market for CNC milling machines is vast and competitive, with several prominent manufacturers offering a wide range of options. Some well-known brands include Haas, DMG Mori, and Makino. Conduct thorough research and compare specifications to find the milling machine that best suits your needs.

Here are some essential tips for using a CNC milling machine effectively:

– Properly secure the workpiece and ensure it is correctly aligned.

– Choose appropriate cutting tools and adjust their parameters for optimal performance.

– Regularly inspect and maintain the machine to prevent breakdowns and ensure longevity.

Frequently Asked Questions (FAQ):

1. What materials can be milled using a CNC milling machine?

2. How can I minimize tool wear during milling operations?

3. What safety precautions should I follow when operating a CNC milling machine?

4. How can I optimize the milling process for faster production?

In conclusion, a CNC milling machine is a valuable asset in various industries. Understanding its parts, quality, costs, suppliers, certifications, and market options is essential before making a purchase. Following tips and guidelines will help maximize efficiency and productivity while operating the machine.

Types of cnc milling machine parts

CNC milling machines are complex machines composed of various parts that work together to perform precise machining operations. Here are the key types of CNC milling machine parts:

1. Base: The base is the foundation of the machine that provides support and stability. It is typically made of cast iron or steel to ensure rigidity.

2. Column: The column is a vertical structure mounted on the base and houses the motor, drive mechanisms, and other components. It provides vertical movement for the machine’s spindle.

3. Spindle: The spindle is a rotating device that holds the cutting tool and performs the milling operation. It is driven by a motor and can offer different speeds and directions for cutting.

4. Table: The table is a flat surface where the workpiece is secured during machining. It can move in multiple directions, including X, Y, and Z axes, allowing for precise positioning and cutting.

5. Workholding devices: These are components used to secure the workpiece to the milling machine’s table. Common workholding devices include vises, clamps, fixtures, and rotary tables.

6. Tooling: Tooling consists of various cutting tools that are mounted on the spindle to shape and remove material from the workpiece. Common tools include end mills, face mills, drills, and reamers.

7. Control panel: The control panel is where the operator interacts with the machine and programs the desired machining operations and parameters. It includes buttons, switches, and displays for inputting and monitoring the CNC program.

8. Drive mechanisms: CNC milling machines use various drive mechanisms, such as ball screws or rack and pinion systems, to provide precise movement along the machine’s axes. These mechanisms are driven by motors and controlled by the CNC software.

9. Coolant system: A coolant system is used to provide lubrication and cooling during the machining process. It helps increase tool life and improves surface finish by reducing heat and removing chips.

10. Safety features: CNC milling machines incorporate various safety features like emergency stop buttons, safety interlocks, and guards to protect the operator and prevent accidents.

These are just some of the key parts found in CNC milling machines. Each component plays a crucial role in ensuring the accuracy, efficiency, and safety of the milling process.

Pros and Cons of Using cnc milling machine parts

Pros:

1. Precision: CNC milling machine parts offer high precision, allowing for accurate and consistent machining. This is particularly beneficial in industries like aerospace and automotive, where tight tolerances are required.

2. Versatility: CNC milling machines can handle a wide range of materials, including metals, plastics, and composites. This versatility makes them suitable for various industries and applications.

3. Efficiency: CNC milling machines are capable of performing multiple machining operations in one setup, eliminating the need for manual repositioning and reducing production time and costs.

4. Automation: CNC milling machines are fully automated, reducing the labor required and allowing for uninterrupted and continuous operation. They can also be programmed to run overnight or during weekends, further maximizing productivity.

5. Complex and intricate designs: CNC milling machines have the ability to produce complex and intricate designs that may be challenging or impossible to achieve with conventional milling machines. This is particularly advantageous for industries like jewelry making or machining specialized parts.

Cons:

1. Cost: CNC milling machines are expensive to purchase and maintain. They require regular maintenance, software upgrades, and skilled operators to ensure optimal performance.

2. Complex programming: Operating a CNC milling machine requires programming skills, which can be time-consuming and challenging to master. Additionally, errors in programming can lead to costly mistakes and rework.

3. Lack of flexibility: CNC milling machines are designed to perform specific tasks and may not be easily adaptable to different applications or designs. This lack of flexibility may limit their use in certain industries or products.

4. Size limitations: CNC milling machines have size limitations, which can restrict the size of the parts or components that can be machined. Larger parts may require specialized equipment or multiple setups, resulting in additional time and costs.

5. Initial setup time: Setting up a CNC milling machine for a new job or project can be time-consuming, requiring precise tooling and fixturing. This setup time may slow down production and affect overall efficiency.

In summary, CNC milling machine parts offer exceptional precision, versatility, and efficiency. However, they come with drawbacks such as high costs, complex programming requirements, and limitations in flexibility and size.

cnc milling machine parts Reference Specifications (varies for different product)

CNC (Computer Numerical Control) milling machines are widely used in the manufacturing industry to produce high precision components and parts. These machines consist of various parts and components, each playing a crucial role in the milling process.

The main components of a CNC milling machine include the base, column, saddle, table, spindle, tool changer, and control panel. The base acts as the foundation and provides stability to the machine. It supports the entire weight of the machine and absorbs vibrations to ensure accurate milling.

The column is mounted on the base and houses the spindle assembly. It provides vertical movement of the spindle, allowing the cutting tool to be positioned at different heights. The saddle is attached to the column and is responsible for providing horizontal movement to the table.

The table is where the workpiece is secured and allows it to be moved in different directions. It is equipped with T-slots to hold the workpiece firmly. The spindle assembly consists of the spindle, which holds the cutting tool, and the motor, which provides the rotational movement required for milling.

The tool changer is an essential component that allows for the automatic changing of tools during the milling process. It improves efficiency by reducing downtime associated with manual tool changes. The control panel is where the operator interacts with the machine. It contains various buttons, switches, and a display screen to input commands and monitor the milling process.

Other important parts of a CNC milling machine include the axis drive system, which controls the movement of the different axes, such as X, Y, and Z. The coolant system is responsible for providing a cooling medium to the cutting tool, reducing heat and prolonging tool life. The chip evacuation system removes chips and debris from the work area to ensure smooth operation.

CNC milling machine parts are typically made of high-quality materials such as cast iron, steel, and aluminum. They undergo stringent quality control procedures to ensure accuracy, durability, and reliability.

In conclusion, CNC milling machines are complex machines that consist of numerous parts and components. Each part plays a critical role in the milling process, ensuring precise and efficient machining. The quality of these parts directly impacts the performance and reliability of the CNC milling machine.

Applications of cnc milling machine parts

CNC (Computer Numerical Control) milling machines are widely used in various industries due to their high precision and versatility. The milling machine parts play a crucial role in a wide range of applications, some of which are highlighted below:

1. Aerospace Industry: CNC milling machines are extensively used in the aerospace industry for manufacturing components such as engine parts, landing gear, wings, and fuselage components. The high precision and accuracy of the milling machine parts ensure the production of complex and intricate designs, vital for aerospace applications.

2. Automotive Industry: In the automotive industry, CNC milling machines are employed for producing critical components like engine blocks, transmission cases, and suspension parts. The ability to precisely cut various materials, including metals and alloys, ensures accurate and reliable quality of these parts.

3. Medical Industry: CNC milling machines find significant applications in the medical field for manufacturing components such as implants, surgical tools, and prosthetics. The computer-controlled milling process guarantees intricate designs that meet the exacting standards required in medical applications.

4. Electronics Industry: PCB (Printed Circuit Board) production heavily relies on CNC milling machines for drilling and precision component placement. The milling machine parts are used to cut and engrave circuit boards with exceptional accuracy, ensuring proper electrical connections and high-quality printed circuits.

5. Mold and Die Making Industry: CNC milling machines are widely used for producing molds and dies required in various manufacturing processes. The milling machine parts allow for precise shaping of the molds and dies, resulting in the creation of consistent and high-quality products.

6. Furniture and Woodworking Industry: CNC milling machines are employed in the production of furniture and woodworking products. The milling machine parts contribute to the precise cutting, carving, and shaping of wood, allowing for the creation of intricate designs and seamless joinery.

7. Prototyping and Rapid Manufacturing: CNC milling machines are extensively used in the prototyping process for quickly transforming digital models into physical parts. The milling machine parts enable the production of prototypes with high accuracy and relatively short lead times, allowing for faster design iterations and product development.

In conclusion, CNC milling machine parts find applications across a wide range of industries, including aerospace, automotive, medical, electronics, mold making, woodworking, and prototyping. Their high precision, accuracy, and versatility make CNC milling machines an indispensable tool in modern manufacturing processes.

The Work Process and how to use cnc milling machine parts

CNC milling machines are highly versatile machines used for cutting and shaping various materials such as metal, plastic, or wood. They utilize computerized numerical control (CNC) to accurately move the milling machine parts and perform precise machining operations. Here is a simplified overview of the work process and how to use CNC milling machine parts.

1. Design and Programming: Use computer-aided design (CAD) software to create a 3D model of the desired part. Then, use computer-aided manufacturing (CAM) software to generate a toolpath program that converts the design into machine-readable code.

2. Setup: Secure the workpiece to the milling machine’s worktable or vise. Ensure it is properly aligned and clamped to avoid any movement during the machining process. Install the appropriate cutting tool, such as an end mill, into the machine’s spindle.

3. Loading the Program: Transfer the program file from the computer to the CNC milling machine using a USB drive, network connection, or other storage methods. Load the program into the machine’s control panel.

4. Homing Sequence: Press the homing button to allow the machine to establish its reference position accurately. This ensures the machine knows its initial location before starting the milling process.

5. Tool Setup: Use the CNC control panel to set the tool length offsets and tool diameter compensation values for precise tool positioning during machining. Proper tool setup ensures accurate and efficient milling operation.

6. Work Origin Setup: Define the work origin, which serves as the reference point for all machining operations. Use the machine’s control panel to set the X, Y, and Z coordinates of the work origin based on the design.

7. Running the Program: Press the start button to begin the milling process. The CNC machine will follow the toolpath program, moving the milling machine parts, including the spindle, in the required patterns to remove material and shape the workpiece.

8. Monitoring and Adjustment: Continuously monitor the milling process to ensure everything is running smoothly. Make any necessary adjustments to feed rates, cutting speeds, or toolpath parameters based on the material, tool, and desired outcome.

9. Finishing and Inspection: Once the milling process is complete, remove the workpiece from the machine. Inspect the finished part for any imperfections or dimensional inaccuracies. Perform any required post-machining operations, such as deburring or finishing, to achieve the desired final product.

By following the above process, individuals can effectively utilize CNC milling machine parts to perform precise and efficient machining operations. It is crucial to have a thorough understanding of the machine’s controls, programming, and tool setup to ensure successful outcomes and safe operation.

Quality Testing Methods for cnc milling machine parts and how to control the quality

Quality testing methods for CNC milling machine parts involve several steps to ensure that the finished products meet the required specifications and performance standards. Here are some commonly used quality testing methods:

1. Visual Inspection: A visual examination is conducted to identify any cosmetic defects, surface imperfections, or dimensional abnormalities. This is usually the first step to identify any visible issues.

2. Geometric Dimensioning and Tolerancing (GD&T): GD&T is a commonly used technique to assess the accuracy and precision of the dimensions, tolerances, and geometric features of the CNC-machined parts. It helps to ensure that the parts conform to the required design specifications.

3. Coordinate Measuring Machine (CMM): CMM is used to measure the precise dimensional characteristics of the parts by mapping multiple points using a probe. This method provides accurate measurements and helps identify any deviations from the design specifications.

4. Material Testing: Material testing methods, such as hardness testing and metallurgical analysis, are performed to ensure that the materials used in the CNC-machined parts meet the required strength, durability, and chemical composition standards.

5. Functional Testing: This involves testing the CNC-machined parts for their proper functioning and performance. It may include running the parts on the intended machines or equipment to check their operational capabilities and overall performance.

To control the quality of CNC milling machine parts, several measures can be implemented:

1. Strict quality control procedures should be established to ensure consistent quality output. This includes ensuring that all machines, tools, and equipment used in the manufacturing process are calibrated and maintained properly.

2. Regular training and skill development programs should be provided to the operators to ensure that they have the necessary knowledge and expertise to operate the CNC machines effectively.

3. Implementing Statistical Process Control (SPC) techniques can help monitor and control the manufacturing process, identify any variations, and take corrective actions promptly.

4. Regular inspections and audits should be conducted to identify any potential issues or non-conformities in the manufacturing process. This helps in addressing any quality concerns at an early stage, thus preventing the production of defective parts.

5. Establishing a robust quality management system, such as ISO 9001, can help standardize the quality control processes and ensure adherence to internationally recognized quality standards.

By implementing these quality testing methods and control measures, manufacturers can ensure that CNC milling machine parts meet the required specifications, improve customer satisfaction, and reduce the risk of malfunction or failure in the field.

cnc milling machine parts Sample Policy and Post-Purchase Considerations for cnc milling machine parts from China

When purchasing CNC milling machine parts from China, it is essential to have a well-defined sample policy in place to ensure that you receive the desired quality and meet your specific requirements. Additionally, there are certain post-purchase considerations that you should keep in mind. Here’s a brief overview in less than 300 words:

Sample Policy:

1. Request for Samples: Before placing a bulk order, request samples of the CNC milling machine parts from the supplier. This will allow you to evaluate the quality, dimensions, and functionality of the parts firsthand.

2. Quantity and Cost: Determine the number of samples required and clarify who will cover the sample and shipping costs. Some suppliers offer free samples, while others may charge a nominal fee.

3. Inspection and Feedback: Thoroughly inspect the samples to check for any defects or deviations from your specifications. Provide detailed feedback to the supplier regarding any improvements required.

4. Revisions or New Samples: If necessary, request revised samples or additional samples to ensure the desired quality is achieved before proceeding with the bulk order.

5. Arranging Production: Once the samples meet your expectations, clearly communicate your requirements to the supplier, including quality standards, quantity, and delivery schedule.

Post-Purchase Considerations:

1. Quality Control: Establish a comprehensive quality control plan with the supplier to consistently monitor the quality of the CNC milling machine parts during production and before shipment. This may include inspections at various stages, such as raw materials, production processes, and final product inspection.

2. Communication and Documentation: Maintain regular communication with the supplier to address any concerns or queries promptly. Ensure that all product specifications and agreements are clearly documented to avoid any misunderstandings.

3. Shipping and Logistics: Discuss the shipping methods, packaging requirements, and delivery timelines with the supplier. Clarify the responsibilities for customs clearance and any associated costs.

4. Warranty and After-Sales Support: Inquire about the warranty period and after-sales support for the CNC milling machine parts. Ensure that the supplier offers reliable technical support and assistance in case of any issues or part replacements.

By implementing a well-defined sample policy and considering the post-purchase aspects, you can mitigate potential risks associated with purchasing CNC milling machine parts from China and ensure a smoother buying experience.

Sourcing cnc milling machine parts from China: Opportunities, Risks, and Key Players

Sourcing CNC milling machine parts from China offers numerous opportunities for businesses. China is known for its manufacturing capabilities and competitive pricing, making it a popular destination for companies looking to reduce costs. The availability of a vast range of suppliers and manufacturers in the country provides businesses with a wide variety of options to choose from.

One of the key opportunities of sourcing from China is the ability to access a diverse range of machine parts. China’s manufacturing industry is highly developed and can provide a comprehensive selection of CNC milling machine parts to meet various requirements. Whether it is specialized components or standardized parts, Chinese suppliers offer a wide range of options, allowing businesses to find the perfect fit for their specific needs.

Another advantage of sourcing from China is cost savings. Chinese suppliers usually offer competitive pricing due to lower manufacturing and labor costs. By sourcing CNC milling machine parts from China, businesses can significantly reduce their production expenses and enhance their profitability.

However, there are also risks associated with sourcing from China. One of the main concerns is quality control. While China has many reputable and reliable manufacturers, there are also lower-quality suppliers in the market. Businesses must carefully evaluate potential suppliers, conduct due diligence, and ensure adherence to quality standards before making any purchasing decisions.

Language and cultural barriers can also pose challenges when sourcing from China. Effective communication is crucial for successful collaboration, and businesses may need to invest in translation services or hire local agents to bridge the language gap.

Despite these risks, China remains a major player in the CNC milling machine parts industry. Key players in China include companies like Tianhui Machine, Yijin Hardware, and Ever Hardware Manufacturing. These companies have established their presence in the market by offering a wide range of high-quality CNC milling machine parts and providing reliable services to their global customers.

In conclusion, sourcing CNC milling machine parts from China presents opportunities for cost-effective solutions and a diverse selection of components. However, businesses must carefully manage risks associated with quality control and communication to ensure successful partnerships with Chinese suppliers. Key players in the industry can provide reliable and high-quality products, making China an attractive destination for sourcing CNC milling machine parts.

How to find and select reliable cnc milling machine parts manufacturers in China,use google search manufacturers and suppliers

Finding and selecting reliable CNC milling machine parts manufacturers in China can be done using Google search for manufacturers and suppliers. Here are some steps to follow:

1. Start by searching for keywords like “CNC milling machine parts manufacturers in China” or “reliable CNC milling machine parts suppliers in China.” This will give you a list of potential manufacturers to work with.

2. Visit the websites of these manufacturers and check for information about their experience, expertise, and product range. Look for certifications and quality control measures they have in place.

3. Verify the manufacturer’s reputation by checking for customer reviews and ratings. Look for testimonials or feedback from other customers who have used their services. This will give you an idea of their reliability and customer satisfaction.

4. Contact the manufacturer directly to inquire about their products, manufacturing capabilities, and pricing. Engage in conversation to assess their responsiveness, professionalism, and willingness to provide information.

5. Consider requesting samples if necessary. This will allow you to test the quality of the CNC milling machine parts before placing a larger order. Pay attention to the quality of the materials used, precision of the parts, and overall durability.

6. Evaluate the manufacturer’s production capacity. Ensure that they have the capability to meet your required quantity and deliver within your desired timeframe. This can be determined by checking their production facilities and capacity.

7. Inquire about the manufacturer’s after-sales service and technical support. Reliable manufacturers should provide assistance and troubleshooting in case any issues arise with the CNC milling machine parts.

8. Request quotations from multiple manufacturers and compare prices, quality, lead times, and terms and conditions. This will help you make an informed decision and select the most suitable manufacturer for your requirements.

By following these steps and conducting thorough research, you can find and select reliable CNC milling machine parts manufacturers in China through Google search and ensure a successful partnership.

How to check cnc milling machine parts manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a CNC milling machine parts manufacturer’s website, follow the steps below using Google Chrome and the SEOquake plugin:

1. Install SEOquake: Start by installing the SEOquake plugin for Google Chrome browser. Open the Chrome Web Store, search for “SEOquake,” and click “Add to Chrome” to install it.

2. Set SEOquake Parameters: Once installed, click on the SEOquake icon in the Chrome toolbar. In the drop-down menu, select “Parameters” to access the settings.

3. Configure Parameters: In the Parameters window, set the “SE” parameter to “Google” to ensure you search using Google. You can also set your preferred search language, number of search results per page, and other parameters to match your preferences.

4. Perform Google Search: Go to the Google search page and enter the relevant keywords related to the CNC milling machine parts manufacturers you want to evaluate. Click “Enter” or click the “Google Search” button to initiate the search.

5. Analyze Search Results: SEOquake will display a list of search results. To check if the manufacturer’s website is reliable, look for it in the top 10 million results. If it doesn’t appear within this range, it may not be a well-established or recognized manufacturer.

6. Verify Website Information: Click on the relevant search result to visit the manufacturer’s website. Evaluate its design, content, product information, and testimonials to determine reliability. Look for clear and detailed product descriptions, proper contact information, and professional design, which are indicators of a trustworthy manufacturer.

By following these steps, you can efficiently assess the reliability of a CNC milling machine parts manufacturer’s website within a concise write-up of 300 words or fewer.

Top 10 cnc milling machine parts manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Haas Automation Inc. – Haas Automation is a leading manufacturer of CNC milling machines, known for their precision, reliability, and high-performance capabilities. Their product range includes both vertical and horizontal milling machines, equipped with advanced features such as high-speed spindles, tool changers, and multi-axis controls. Haas machines are widely used in industries such as aerospace, automotive, and medical.

2. DMG MORI – DMG MORI is a renowned manufacturer of CNC milling machines in China, offering a diverse range of products for various application requirements. Their milling machines are known for their robust build, exceptional accuracy, and advanced technology. DMG MORI provides a wide selection of models, including 5-axis milling machines, vertical machining centers, and universal milling machines.

3. Mazak Corporation – Mazak Corporation is a globally recognized manufacturer of CNC milling machines, known for their cutting-edge technology and innovative solutions. Their milling machines are designed to deliver high productivity and precision for a range of applications. Mazak offers a comprehensive lineup of vertical and horizontal milling machines, catering to different machining needs.

4. Dalian Machine Tool Group (DMTG) – DMTG is a leading Chinese manufacturer of CNC milling machines, offering a wide range of products including vertical milling machines, gantry-type machining centers, and horizontal machining centers. DMTG’s milling machines are known for their durability, high-performance features, and competitive pricing.

5. Shenyang Machine Tool Co., Ltd. – Shenyang Machine Tool Co., Ltd. is a prominent manufacturer of CNC milling machines in China. Their product portfolio includes vertical milling machines, horizontal milling machines, and gantry-type machining centers. Shenyang’s milling machines are renowned for their reliable performance, precision, and cost-effectiveness.

6. Jinan First Machine Tool Co., Ltd. – Jinan First Machine Tool Co., Ltd. specializes in the production of CNC milling machines, focusing on vertical and horizontal machining centers. Their machines are characterized by high accuracy, stability, and versatility. Jinan First Machine Tool Co., Ltd. offers a wide range of models to meet different machining requirements.

7. Shandong Weiye CNC Machine Tools Co., Ltd. – Shandong Weiye CNC Machine Tools Co., Ltd. is a leading manufacturer of CNC milling machines in China, providing a variety of models such as vertical machining centers, gantry machining centers, and drilling and tapping centers. Their milling machines are known for their rigid structure, high precision, and efficient performance.

8. Beijing No.1 Machine Tool Plant – Beijing No.1 Machine Tool Plant is an established manufacturer of CNC milling machines in China. They offer a range of milling machines including vertical and horizontal machining centers, tailored to meet diverse machining needs. Beijing No.1 Machine Tool Plant is known for their quality craftsmanship, reliability, and competitive pricing.

9. Jiangsu Dongqing CNC Machine Tool Co., Ltd. – Jiangsu Dongqing CNC Machine Tool Co., Ltd. specializes in the production of vertical and horizontal machining centers, offering precision CNC milling machines for various applications. Their machines are designed with advanced features such as automatic tool changers and high-speed spindles, ensuring efficient and accurate machining processes.

10. Yunnan CY Group Co., Ltd. – Yunnan CY Group Co., Ltd. is a well-known manufacturer of CNC milling machines in China, focusing on the production of vertical machining centers and gantry machining centers. Their milling machines are highly regarded for their stability, precision, and versatility. Yunnan CY Group Co., Ltd. offers extensive customization options to cater to specific machining requirements.

Table for Comparison:

| Manufacturer | Product Range | Features | Industries Served |

|———————————-|———————————|—————————————-|——————————|

| Haas Automation Inc. | Vertical and horizontal mills | High-speed spindles, tool changers | Aerospace, automotive, medical |

| DMG MORI | 5-axis, vertical, and universal | Robust build, exceptional accuracy | Various |

| Mazak Corporation | Vertical and horizontal mills | Cutting-edge technology, high productivity | Various |

| Dalian Machine Tool Group (DMTG) | Vertical and horizontal mills | Durability, high-performance features | Various |

| Shenyang Machine Tool Co., Ltd. | Vertical, horizontal, gantry | Reliable performance, precision | Various |

| Jinan First Machine Tool Co., Ltd.| Vertical and horizontal mills | High accuracy, stability | Various |

| Shandong Weiye CNC Machine Tools | Vertical and gantry mills | Rigid structure, high precision | Various |

| Beijing No.1 Machine Tool Plant | Vertical and horizontal mills | Quality craftsmanship, reliability | Various |

| Jiangsu Dongqing CNC Machine Tool| Vertical and horizontal mills | Advanced features such as automatic tool changers, high-speed spindles | Various |

| Yunnan CY Group Co., Ltd. | Vertical and gantry mills | Stability, precision, versatility | Various |

Please note that the above table provides a brief overview and the mentioned manufacturers may offer additional product variations and features beyond those stated.

Background Research for cnc milling machine parts manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to finding CNC milling machine parts manufacturers in China, there are several online platforms that can be utilized for background research. Some popular platforms include qcc.com, archive.org, and importyeti.com.

qcc.com is a comprehensive business database in China that provides information on various companies, including CNC milling machine parts manufacturers. It allows users to search for specific companies, view their profiles, and access their contact information. This platform can be helpful in gathering initial details about potential manufacturers and assessing their credibility.

archive.org is an online platform that archives web pages, providing access to historical versions of websites. This tool can be utilized to search for past versions of manufacturers’ websites, allowing users to track their history, product range, certifications, and any changes in their business operations over time. Analyzing this information can provide valuable insights into the manufacturer’s experience, reputation, and product offerings.

importyeti.com is a specialized platform that focuses on import and export data. It provides detailed records of shipments, helping users understand a manufacturer’s export activities, the countries they have exported to, and the frequency and volume of their shipments. This information can indicate the manufacturer’s level of experience and expertise in the export market, as well as their relationships with international clients.

In summary, conducting background research on CNC milling machine parts manufacturers in China can be facilitated by utilizing platforms such as qcc.com, archive.org, and importyeti.com. These platforms provide valuable information on the companies’ profiles, historical web data, and import/export records, enabling users to assess their credibility, experience, and international business activities.

Leveraging Trade Shows and Expos for cnc milling machine parts Sourcing in China

Trade shows and expos present excellent opportunities for sourcing CNC milling machine parts in China. These events provide a platform for manufacturers, suppliers, and buyers to connect, exchange information, and establish business relationships. By attending these trade shows, businesses can leverage various benefits to efficiently source the required CNC milling machine parts.

Firstly, trade shows and expos offer a concentrated gathering of numerous suppliers and manufacturers specializing in CNC milling machine parts. This concentration enables buyers to easily compare different options, evaluate product quality, and negotiate quotations directly with suppliers. By having multiple options in one place, businesses can save valuable time and effort in sourcing activities.

Secondly, trade shows provide an opportunity to physically examine the products and interact face-to-face with suppliers. This direct engagement allows buyers to scrutinize the quality, material, and precision of CNC milling machine parts, ensuring they meet their specific requirements. Moreover, engaging with suppliers in person facilitates building trust and establishing reliable business partnerships, which is crucial for a successful sourcing process.

Furthermore, trade shows often feature seminars, demonstrations, and product launches, providing valuable insights into the latest trends, technologies, and innovations in the CNC milling industry. This exposure to industry developments can guide businesses in making informed decisions regarding part specifications, features, and any possible customization required.

To optimize the benefits of attending trade shows and expos, buyers should plan their visit in advance, conducting thorough research on the exhibitors and their offerings. This preparation allows businesses to efficiently navigate through the event, focusing on their specific sourcing needs. Additionally, leveraging online platforms and directories dedicated to trade shows can provide further information about exhibitors, their product ranges, and booth locations.

In conclusion, trade shows and expos provide a powerful platform for sourcing CNC milling machine parts in China. Through attending these events, businesses can access a wide range of suppliers, physically evaluate the products, and stay updated on industry trends. By harnessing the opportunities offered by trade shows, businesses can streamline their sourcing process and establish reliable partnerships for their CNC milling machine parts procurement.

The Role of Agents and Sourcing Companies in Facilitating cnc milling machine parts Purchases from China

Agents and sourcing companies play a crucial role in facilitating CNC milling machine parts purchases from China. These intermediaries act as a bridge between buyers and suppliers, ensuring smooth and efficient transactions.

One of the key tasks of agents and sourcing companies is to help buyers find reliable and reputable suppliers in China. They have an extensive network of contacts and access to vast databases of verified suppliers. This saves buyers the time and effort required to conduct comprehensive supplier research and due diligence. Agents and sourcing companies also have in-depth knowledge of the local market, helping them identify the most suitable suppliers based on the specific requirements of the buyers.

Agents and sourcing companies negotiate with suppliers on behalf of the buyers to ensure competitive pricing and favorable terms. Given their expertise in the industry and familiarity with the Chinese market, they can leverage their relationships with suppliers to obtain better prices and discounts. They also help buyers negotiate and finalize contracts, ensuring that all terms and conditions are agreed upon and documented correctly.

Once the purchase order is placed, agents and sourcing companies oversee the production and quality control process. They coordinate with suppliers to ensure timely production, monitor the manufacturing progress, and conduct quality inspections to ensure that the CNC milling machine parts meet the required standards and specifications. This ensures that buyers receive high-quality products as per their expectations.

Furthermore, agents and sourcing companies handle logistics and shipping arrangements. They arrange for the transportation of the goods from the suppliers’ facilities in China to the buyers’ desired location. They take care of all the necessary paperwork, customs clearance, and compliance requirements, ensuring a hassle-free and efficient shipping process.

In summary, agents and sourcing companies play a vital role in facilitating CNC milling machine parts purchases from China. Their expertise, network, and knowledge of the local market enable buyers to find reliable suppliers, negotiate favorable prices, ensure quality control, and manage the logistics and shipping process effectively. Their services streamline the purchasing process and mitigate the risks associated with sourcing products from a foreign market like China.

Price Cost Research for cnc milling machine parts manufacturers Companies in China, use temu.com and 1688.com

In order to conduct price cost research for CNC milling machine parts manufacturers in China, two websites can be used: temu.com and 1688.com. These platforms provide a wide range of options for sourcing high-quality CNC milling machine parts at competitive prices.

Temu.com is a comprehensive online platform that allows users to search and connect with numerous manufacturers and suppliers in China. It provides detailed information about the products, including specifications, prices, manufacturing capabilities, and certifications. Users can directly contact the manufacturers or suppliers for further inquiries and negotiation of pricing.

1688.com, on the other hand, is a popular business-to-business (B2B) platform known for its extensive range of products and competitive prices. It primarily serves the domestic Chinese market, offering a vast selection of CNC milling machine parts from various manufacturers. This platform allows users to compare prices, read customer reviews, and directly communicate with suppliers through its messaging system.

When conducting price cost research on these platforms, it is advisable to follow these steps:

1. Identify the specific CNC milling machine parts required and their specifications, such as dimensions, material, and tolerances.

2. Search for the parts on both platforms using relevant keywords and filters to narrow down the options.

3. Compare the prices, including the cost per unit and any additional charges such as packaging and shipping fees. Consider the minimum order quantities as well.

4. Review the product descriptions, certifications, and ratings to assess the quality and reliability of the manufacturers.

5. Contact the shortlisted manufacturers/suppliers for further inquiries or negotiations. Obtain detailed quotations, delivery terms, and payment options.

6. Consider factors beyond price, such as the manufacturer’s reputation, production capacity, and customer service.

By utilizing temu.com and 1688.com, thorough price cost research can be conducted on CNC milling machine parts manufacturers in China. These platforms offer a wide range of options, allowing users to find high-quality parts at competitive prices while ensuring a smooth procurement process.

Shipping Cost for cnc milling machine parts import from China

The shipping cost for importing CNC milling machine parts from China can vary depending on several factors. Commonly, there are two main options for shipping: air freight and sea freight.

Air freight is generally faster but more expensive than sea freight. The cost is usually calculated based on the weight and dimensions of the shipment. Additionally, there may be charges for customs clearance, handling, and other fees. To get an accurate estimate, it is essential to provide the exact weight and dimensions of the shipment to the shipping company.

Sea freight is typically cheaper but takes longer. The cost is usually calculated based on the volume of the shipment in cubic meters (CBM) or the weight, whichever is greater. Similar to air freight, there may be additional charges for customs clearance, handling, and other fees.

When importing from China, it is crucial to consider additional costs such as customs duties, taxes, and insurance. Customs duties and taxes vary depending on the country of import and the specific product. These additional costs can significantly impact the overall cost of importing the CNC milling machine parts.

To get the most cost-effective shipping option, it is advisable to compare quotes from different shipping companies and freight forwarders. It is also crucial to ensure that the shipping company has experience in handling machinery and is knowledgeable about customs regulations and paperwork.

In summary, the shipping cost for importing CNC milling machine parts from China can vary based on the chosen shipping method, weight or volume of the shipment, and additional costs such as customs duties and taxes. By considering these factors and obtaining multiple quotes, importers can find the most suitable and cost-effective shipping solution.

Compare China and Other cnc milling machine parts Markets: Products Quality and Price,Visible and Hidden Costs

China is often regarded as a dominant player in the manufacturing industry, including the market for CNC milling machine parts. When comparing China to other markets, several factors need to be considered, such as product quality, price, and both visible and hidden costs.

In terms of product quality, China has gained a reputation for producing both high-quality and lower-quality products. While Chinese manufacturers have improved their quality control measures in recent years, there is still a perception that some products may not meet the same standards as those from other markets. On the other hand, countries such as Germany, Japan, and the United States are known for their precision engineering and high-quality manufacturing, which reflects in their CNC milling machine parts.

Pricing is a significant aspect when comparing these markets. China is often favored for its competitive prices, as the country benefits from a vast manufacturing infrastructure and relatively cheaper labor costs. Consequently, the cost of CNC milling machine parts tends to be lower when compared to parts from other markets. However, countries known for their high-quality manufacturing often have higher price points due to their advanced technology, expertise, and overall reputation.

Visible costs, such as the cost of the product itself, are apparent when comparing pricing in different markets. However, hidden costs associated with sourcing from China should also be considered. These hidden costs can include shipping fees, import duties, and potential delays or difficulties in communication and language barriers. On the other hand, sourcing from countries closer to the destination market may offer faster shipping times, reduced import duties, and potentially better communication, which would minimize hidden costs.

In conclusion, when comparing China to other markets for CNC milling machine parts, there are several notable differences. China offers competitive pricing and has made strides in improving product quality. However, it is essential to consider both visible and hidden costs associated with sourcing from China. Other markets, such as Germany, Japan, and the United States, are known for their high-quality manufacturing, but their products may come at a higher price point. Ultimately, the choice between markets depends on the specific needs and priorities of the buyer.

Understanding Pricing and Payment Terms for cnc milling machine parts: A Comparative Guide to Get the Best Deal

When it comes to purchasing CNC milling machine parts, understanding pricing and payment terms is crucial to ensure you get the best deal. This comparative guide will provide you with essential information to make an informed decision.

Pricing for CNC milling machine parts can vary significantly depending on various factors such as the complexity of the part, material used, quantity ordered, and the supplier. It is essential to obtain multiple quotes from different suppliers to compare prices accurately. This will give you a better understanding of the market range and help you negotiate for the best price.

Payment terms typically differ among suppliers, and it’s important to review them thoroughly. Some common payment terms include:

1. 50% upfront, 50% upon completion: This payment method requires you to pay 50% of the total cost upfront and the remaining 50% once the parts are completed and delivered. It provides a balance between security for the supplier and trust for the buyer.

2. Net 30: This term means that payment is due within 30 days of receiving the parts. It offers flexibility for the buyer but may involve a credit check for the supplier to ensure the buyer’s reliability.

3. Cash on delivery (COD): With this method, payment is made at the time of delivery. It might be suitable for smaller orders or when dealing with a new supplier, as it ensures that you receive the correct parts before making payment.

4. Escrow: This payment method involves using a third-party service to hold the funds until the buyer receives and approves the parts. It provides security for both parties and promotes trust in the transaction.

When comparing quotes, it’s important to consider not only the price but also the quality of the parts, lead time, and the supplier’s reputation. Cheaper prices might sometimes lead to compromised quality or longer lead times. Therefore, striking a balance between price and quality is crucial to ensure you get the best deal.

In conclusion, understanding pricing and payment terms is vital when purchasing CNC milling machine parts. By obtaining multiple quotes, carefully reviewing payment terms, and considering other factors, you will be able to make an informed decision and secure the best deal for your needs.

Chinese Regulations and Industry Standards Certifications for cnc milling machine parts,Import Regulations and Customs for cnc milling machine parts from China

Chinese Regulations and Industry Standards Certifications for CNC Milling Machine Parts:

In China, CNC milling machine parts are subject to various regulations and industry standards certifications to ensure their quality and safety.

One of the key certifications is the ISO 9001:2015 standard for quality management systems. This certification ensures that the manufacturer has implemented a quality control system in the production of CNC milling machine parts. By complying with this standard, manufacturers can demonstrate their commitment to delivering products that meet customer requirements.

Additionally, CNC milling machine parts may need to adhere to specific industry standards certifications. For example, the GB/T 2828.1-2012 standard outlines the sampling procedures and acceptance criteria for part inspection. Manufacturers must comply with these requirements to ensure that their products meet the specified quality level.

Another important certification is the CE Marking. This certification indicates that the CNC milling machine parts meet safety, health, and environmental protection standards within the European Economic Area. It demonstrates compliance with relevant EU directives and allows the products to be marketed and sold in the European market.

Import Regulations and Customs for CNC Milling Machine Parts from China:

Importing CNC milling machine parts from China requires compliance with specific import regulations and customs procedures.

Firstly, importers need to ensure that the CNC milling machine parts comply with the standards and certifications required in their country. This may involve verifying the manufacturers’ certifications and ensuring that the imported parts meet the necessary quality and safety requirements.

Customs documentation, such as commercial invoices and packing lists, must accurately represent the CNC milling machine parts being imported. It is essential to provide detailed information about the parts, such as their specifications, quantities, and values, to facilitate smooth customs clearance.

Customs duties and taxes are applicable when importing CNC milling machine parts from China, and importers should be aware of their country’s specific tariff rates. Additionally, customs authorities may require additional documentation, such as import licenses or permits, depending on the imported quantity or specific regulatory requirements.

Due to the potential complexity of importing CNC milling machine parts, it is advisable to engage professional import agents or freight forwarders who have experience in handling customs procedures. These experts can assist with customs documentation, compliance, and provide guidance on import regulations to ensure a seamless importation process.

Sustainability and Environmental Considerations in cnc milling machine parts Manufacturing

In recent years, sustainability and environmental considerations have become increasingly important in the manufacturing industry, including in CNC milling machine parts manufacturing. CNC milling machines are used to produce a wide range of components for various industries, and optimizing their production processes to be more sustainable can have significant positive impacts.

One key area of focus for sustainability in CNC milling machine parts manufacturing is energy consumption. By utilizing energy-efficient machinery and optimizing production processes, manufacturers can reduce the amount of energy required to produce each component. This can be achieved by minimizing idle time and optimizing tool paths to reduce machining time, as well as implementing energy-saving technologies, such as regenerative drives and motor controls.

Another important aspect of sustainability in this industry is waste management. CNC milling machine parts manufacturing generates various types of waste, including metal shavings, coolant waste, and packaging materials. Implementing effective waste management systems, such as recycling and proper disposal methods, can reduce environmental impacts. Additionally, manufacturers can explore ways to use recycled materials in the production of CNC milling machine parts, reducing the demand for new raw materials.

Furthermore, an area of growing concern in manufacturing is the use of hazardous substances. Manufacturers should prioritize the use of environmentally friendly materials and avoid the use of harmful substances like lead, mercury, and solvents. This not only benefits the environment but also protects the health and safety of workers and end-users.

To ensure sustainability in CNC milling machine parts manufacturing, collaboration with suppliers is crucial. Manufacturers should work with suppliers who share their sustainability goals and provide environmentally friendly materials and processes. By building long-term partnerships with such suppliers, manufacturers can collectively work towards reducing environmental impacts associated with the production of CNC milling machine parts.

Overall, incorporating sustainability and environmental considerations into CNC milling machine parts manufacturing is essential for reducing energy consumption, managing waste, and minimizing the use of hazardous materials. By adopting sustainable practices, manufacturers can contribute to a greener future while ensuring the efficient production of high-quality milling machine components.

List The Evolution history of “cnc milling machine parts”

The evolution history of CNC milling machine parts began in the mid-20th century and has since witnessed significant advancements in technology and capabilities. It all started with traditional milling machines, which were manually operated and utilized various cutting tools for machining tasks.

The first notable development was the introduction of numerical control (NC) systems in the 1940s. These early computerized systems utilized punched cards or tapes to control machine movements and operations. By the 1950s, the concept of Computer Numerical Control (CNC) was introduced, enabling the use of computers to control machine functions.

During the 1960s and 1970s, CNC milling machines began to incorporate more sophisticated electronics and electromechanical systems. These advancements allowed for greater precision, higher speed, and increased automation in the machining process.

In the 1980s, the use of microprocessors and integrated circuits revolutionized CNC milling machines. Machines became more versatile, capable of handling complex machining tasks, and incorporating multiple axes for simultaneous movement. This period marked a significant shift towards computer-controlled machining.

By the 1990s, CNC milling machines became even more advanced with the integration of advanced software programs. CAD/CAM systems (Computer-Aided Design/Computer-Aided Manufacturing) transformed the way designs were created and executed. This integration greatly enhanced efficiency, accuracy, and customization possibilities.

Over the past few decades, the continuous improvement of CNC milling machine parts has been driven by advancements in robotics, sensors, and artificial intelligence. These technologies have made it possible to automate machine setup, tool changing, and real-time monitoring of machining processes. Additionally, the use of high-speed spindles, advanced cutting tools, and improved materials has further improved machining speed, precision, and surface quality.

Looking to the future, CNC milling machine parts are expected to continue evolving with the integration of internet connectivity and data analytics. The concept of Industry 4.0 brings forth the idea of smart manufacturing, where CNC machines can communicate with each other in real-time and make autonomous decisions to optimize production processes.

In conclusion, the evolution history of CNC milling machine parts has witnessed significant advancements in technology, from manual machines to computer-controlled systems. It has transformed manufacturing processes, allowing for greater precision, speed, automation, and customization possibilities. The future is set to bring even more innovative developments to further enhance the capabilities of CNC milling machines.

The Evolution and Market Trends in cnc milling machine parts Industry

The CNC milling machine parts industry has witnessed significant evolution and market trends over the years. CNC (Computer Numerical Control) milling machines are essential in the manufacturing process, allowing for precise and efficient machining of various materials.

One of the notable evolutions in the industry is the advancement in machine technology. CNC milling machines have become more sophisticated, with improved accuracy, higher processing speeds, and increased automation capabilities. This evolution has led to enhanced efficiency in production processes and improved quality of machined parts.

The introduction of multi-axis CNC milling machines has also been a significant development in the industry. These machines can perform complex operations, such as simultaneous milling on multiple surfaces, which were previously difficult to achieve. This has expanded the range of applications for CNC milling machines and opened up opportunities in industries such as aerospace, automotive, and medical.

Moreover, there has been a growing demand for customized parts, leading to the emergence of the market for personalized CNC milling machine parts. Manufacturers are now offering tailored solutions to meet specific customer requirements. This trend has been driven by the need for unique designs, prototypes, and small-batch production in industries like jewelry making, mold making, and art and design.

Another prominent market trend in the CNC milling machine parts industry is the integration of smart technologies. IoT (Internet of Things) and AI (Artificial Intelligence) are being employed to improve machine performance, monitor processes remotely, and optimize production scheduling. This integration enhances productivity, reduces downtime, and enables predictive maintenance.

Furthermore, there is a growing focus on sustainability in the industry. Manufacturers are adopting eco-friendly practices, such as using energy-efficient machines, recycling materials, and reducing waste generation. This trend aligns with the increasing global emphasis on environmental responsibility and contributes to the overall market growth of CNC milling machine parts.

In conclusion, the CNC milling machine parts industry has evolved significantly, incorporating advanced technologies, personalized solutions, smart integration, and sustainable practices. These trends have shaped the market, making it more competitive, efficient, and responsive to customer needs.

Custom Private Labeling and Branding Opportunities with Chinese cnc milling machine parts Manufacturers

Chinese cnc milling machine parts manufacturers provide excellent opportunities for custom private labeling and branding. With their expertise in manufacturing precision parts, they can help businesses create unique products and establish a strong brand presence in the market.

Private labeling allows businesses to market products under their own brand name and logo, thereby building brand recognition and customer loyalty. Chinese cnc milling machine parts manufacturers offer custom labeling services, enabling companies to add their branding elements to the products they source.

These manufacturers also provide branding opportunities through customized packaging. By designing packaging that aligns with the brand’s identity, businesses can create a memorable and professional impression on their customers.

Furthermore, Chinese cnc milling machine parts manufacturers can offer OEM (Original Equipment Manufacturer) services, where they produce parts according to specific design and technical specifications provided by the brand. This enables businesses to tailor the product to their exact requirements, enhancing product differentiation and exclusivity.

Working with Chinese manufacturers also presents cost advantages, enabling businesses to competitively price their products. Additionally, they can provide guidance on market trends and product enhancements, leveraging their expertise in the industry.

Custom private labeling and branding opportunities with Chinese cnc milling machine parts manufacturers offer businesses the chance to create unique and high-quality products that stand out in the market. By partnering with these manufacturers, companies can build their brand reputation and establish a strong competitive edge.

Tips for Procurement and Considerations when Purchasing cnc milling machine parts

When it comes to the procurement of CNC milling machine parts, there are several important considerations to keep in mind. These considerations will help ensure that you purchase the right parts that meet your specific needs and requirements. Here are some tips to help you with the procurement process:

1. Identifying your requirements: Before you start searching for CNC milling machine parts, it is essential to understand your specific needs. Consider what types of parts you require, the quantity needed, and the budget you have allocated for the purchase.

2. Supplier reliability: Look for a reputable supplier with a proven track record. Read customer reviews and seek recommendations. A reliable supplier will ensure quality products and prompt delivery, reducing the risk of downtime.

3. Quality and compatibility: Quality is crucial when it comes to CNC milling machine parts. Make sure the parts you purchase are high-quality and built to last. Additionally, ensure that the parts are compatible with your machine’s make and model.

4. Customization options: Depending on your requirements, you may need customized parts. Consider suppliers that offer customization services to meet your specific needs. This will ensure that the parts fit perfectly and enhance machine performance.

5. Price and cost-effectiveness: While price is an important factor, it should not be the sole consideration. Ensure that you strike a balance between price and quality to get the best value for your money. Also, consider the long-term cost-effectiveness of the parts, as cheaper options may lead to frequent repairs and replacements in the future.

6. Warranty and after-sales support: Look for suppliers that offer warranties on their products. A warranty provides assurance that the supplier stands behind the quality of the parts. Additionally, check if they provide after-sales support, such as technical assistance or replacement services.

7. Delivery time: Time is critical in the production environment, so consider the supplier’s ability to deliver the parts within your required timeframe. Delayed delivery can disrupt your production schedule and cause costly downtime.

8. Technical specifications: Ensure that you have a clear understanding of the technical specifications of the parts you require. Communicate these specifications effectively to the supplier to avoid any compatibility issues or misinterpretations.

By following these tips and considerations, you can streamline your procurement process for CNC milling machine parts and ensure that you make the right purchasing decisions.

FAQs on Sourcing and Manufacturing cnc milling machine parts in China

FAQs on Sourcing and Manufacturing CNC Milling Machine Parts in China

1. Why should I consider sourcing CNC milling machine parts from China?

China has long been a leading manufacturer and exporter of mechanical and electronic components. The country boasts a vast supply chain network, advanced manufacturing facilities, and competitive pricing. Sourcing from China can often result in significant cost savings without compromising on quality.

2. What steps should I take to find reliable suppliers in China?

To find reliable suppliers in China, thorough research and due diligence are crucial. Start by searching online platforms, such as Alibaba or Global Sources, to identify potential suppliers. Verify their credibility by checking customer reviews, certifications, and business licenses. Conduct background checks and communicate directly with the suppliers to assess their capabilities, manufacturing processes, and quality control systems.

3. How can I overcome the language barrier during communication?

English language proficiency in China varies among manufacturers, so it is advisable to hire a translator or work with a sourcing agent who can bridge the language gap. Alternatively, use clear and concise communication, including simple and visual drawings, to ensure better understanding.

4. Can I visit the manufacturing facilities in China before making a purchase?

Yes, visiting the manufacturing facilities in China can provide valuable insights into the supplier’s capabilities and quality control processes. It allows you to gauge the manufacturer’s infrastructure, machinery, and workforce, as well as build a stronger relationship with the supplier. However, it is advisable to make the necessary arrangements beforehand to ensure a productive visit.

5. How can I ensure the quality of CNC milling machine parts from China?

Ensuring quality requires a comprehensive approach. Begin by requesting samples or prototypes before placing a larger order. Establish clear product specifications and quality standards in written agreements with the supplier. Implement regular quality inspections during production and before shipment. Independent third-party testing and certifications can further validate the quality of the parts.

6. What are the lead times for manufacturing CNC milling machine parts in China?

Lead times vary depending on the complexity of the parts, order quantity, and the supplier’s production capacity. Generally, it is advisable to allow a sufficient buffer for manufacturing, transportation, and any unforeseen delays. Discuss lead times and production schedules with the supplier to ensure realistic expectations and minimize potential disruptions.

7. What is the payment process when sourcing CNC milling machine parts from China?

Payment terms can be negotiated with the supplier, typically involving a deposit at the order placement and the remaining balance upon completion or before shipment. It is advisable to use secure payment methods, such as bank transfers, to ensure financial security and transparency. A clear payment schedule should be agreed upon in writing to avoid any miscommunication or disputes.

In conclusion, sourcing CNC milling machine parts from China offers various advantages in terms of cost, manufacturing capabilities, and supply chain efficiency. However, conducting thorough research, establishing clear communication, and implementing robust quality control measures are essential to ensure a successful sourcing experience.

Why contact sourcifychina.com get free quota from reliable cnc milling machine parts suppliers?

Sourcifychina.com is a platform that connects businesses with reliable CNC milling machine parts suppliers in China. They offer a unique service of providing free quotas from these suppliers to help businesses make informed decisions before making any financial commitments.

There are several reasons why sourcifychina.com is able to provide this service. Firstly, the platform has established long-term relationships with a network of trusted CNC milling machine parts suppliers in China. These suppliers have been thoroughly vetted and proven to meet the high standards set by sourcifychina.com. This ensures that businesses receive quality products and services.

Secondly, sourcifychina.com acts as a bridge between businesses and suppliers, facilitating effective communication and negotiation. By understanding the specific requirements of businesses, they are able to connect them with the most suitable suppliers and negotiate competitive prices. The free quota offered by sourcifychina.com allows businesses to obtain a clear idea of the potential costs associated with sourcing CNC milling machine parts from China.

Furthermore, sourcifychina.com has invested in a dedicated team of sourcing experts who have extensive knowledge and experience in the CNC milling machine parts industry. They are able to guide businesses through the entire sourcing process, providing valuable insights and advice. This expertise helps businesses minimize risks and make informed decisions.

In summary, sourcifychina.com offers free quotas from reliable CNC milling machine parts suppliers due to their established relationships with trusted suppliers, effective communication and negotiation capabilities, and a team of sourcing experts. This service enables businesses to assess potential costs and choose the most suitable supplier for their specific needs, ultimately saving time and resources in the sourcing process.