Introduce about plate steel fabrication guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

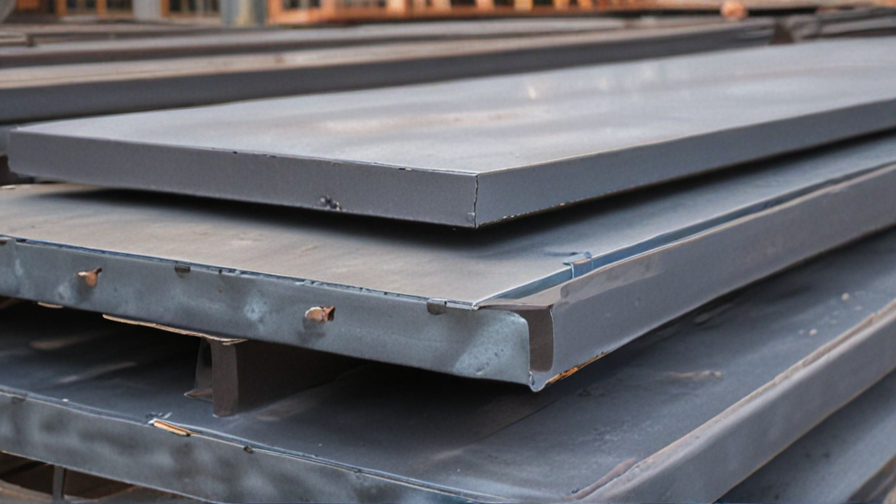

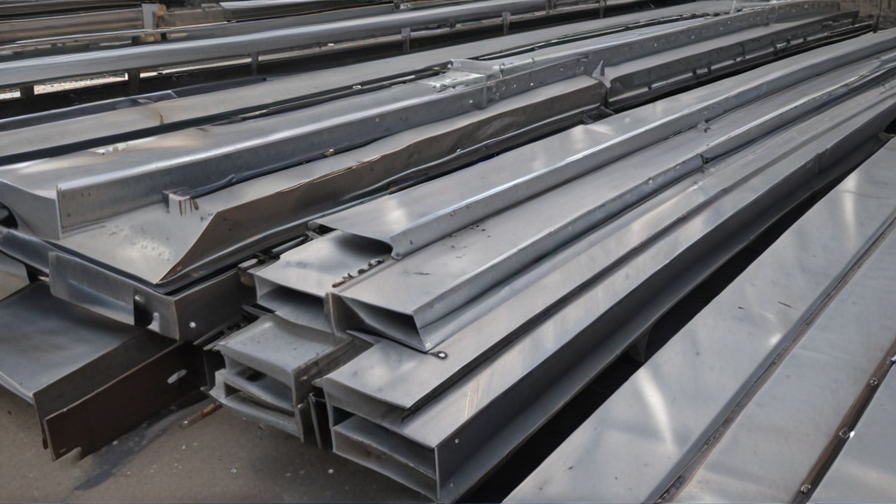

Plate steel fabrication is the process of transforming plain steel plates into desired products using various fabrication techniques such as cutting, bending, welding, and machining. This guide provides essential information about plate steel fabrication, including quality, cost, suppliers, certifications, market trends, useful tips, frequently asked questions (FAQs), all within a concise 300-word limit.

Quality is crucial in plate steel fabrication to ensure the finished products meet required specifications. Top-quality steel should have high strength, excellent weldability, and good formability. It is essential to source steel from reputable suppliers that adhere to stringent quality control measures and industry standards.

Costs of plate steel fabrication can vary depending on factors such as the project’s complexity, size, material thickness, and manufacturing processes involved. Proper planning and material optimization can help minimize costs. Obtaining quotes from multiple suppliers and comparing prices and services can assist in finding the most cost-effective solution.

Reliable steel fabrication suppliers play a vital role in meeting project requirements. It is advisable to select suppliers with a proven track record, experience, and excellent customer reviews. They should offer a wide range of steel plate options to cater to diverse project needs.

Certifications, such as ISO 9001:2015, indicate that a supplier follows strict quality management systems. Choosing certified suppliers ensures a committed approach to quality, consistency, and customer satisfaction.

The plate steel fabrication market is driven by various sectors, including construction, automotive, manufacturing, and infrastructure development. Market trends suggest an increasing demand for lightweight but durable steel structures, sustainability-driven solutions, and technological advancements in fabrication techniques.

Here are some useful tips for plate steel fabrication: optimize material usage through efficient nesting, ensure proper surface preparation before welding, utilize advanced cutting techniques for precise results, and invest in skilled labor and state-of-the-art equipment for better efficiency.

Frequently asked questions related to plate steel fabrication may include queries about material selection, project lead times, customization options, and cost considerations. Addressing these FAQs transparently and promptly helps customers make informed decisions.

In conclusion, plate steel fabrication is a transformative process requiring attention to quality, cost, supplier reliability, and industry certifications. Keeping up with market trends, applying useful tips, and addressing FAQs can enhance the overall plate steel fabrication experience.

Types of plate steel fabrication

Plate steel fabrication involves the manipulation, shaping, and assembly of steel plates to create various structures and components. This process is used in various industries such as construction, automotive, aerospace, and manufacturing. Here are several types of plate steel fabrication techniques:

1. Cutting: Cutting is the first step in plate steel fabrication. It involves the separation of the steel plate into desired shapes and sizes. Common cutting methods include plasma cutting, oxy-fuel cutting, and laser cutting. These methods offer accurate and precise results, ensuring the desired shape is achieved.

2. Forming: Forming is the process of bending and shaping the steel plate to create specific structures. This can be done through methods like rolling, press braking, and stamping. These techniques allow the plate to be shaped into different shapes, such as cylinders, cones, and complex curved surfaces.

3. Welding: Welding is a crucial process that joins multiple steel plates together. It involves heating the edges of the plates to a melting point and fusing them using various welding techniques, such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and arc welding. Welding ensures the structural integrity of fabricated steel components.

4. Machining: Machining involves using specialized tools and equipment to remove material from the steel plate to achieve specific dimensions or shapes. This process is commonly used for precision cutting, drilling, grinding, and milling.

5. Surface treatment: Surface treatment enhances the durability and appearance of fabricated components. Coating techniques like powder coating, galvanizing, and painting are commonly used. These methods protect the steel from corrosion, chemicals, and other environmental factors.

6. Assembly: After individual steel components are fabricated, they are assembled into a final product. This may involve welding, bolting, riveting, or adhesive bonding. Assembly techniques depend on the complexity of the product and the desired strength and integrity.

Overall, plate steel fabrication encompasses a range of techniques to shape, join, and assemble steel plates. The choice of fabrication method depends on factors such as the type of product, required dimensions, strength requirements, and cost considerations.

Pros and Cons of Using plate steel fabrication

Plate steel fabrication is a popular method for producing custom-made metal products by cutting, forming, and welding steel plates. This process offers several advantages and disadvantages, which we will discuss in detail below.

Pros:

1. Strength and durability: Plate steel is known for its exceptional strength and durability. It can withstand heavy loads, extreme temperatures, and harsh environmental conditions. This makes it ideal for applications where strength and resilience are crucial, such as in construction, manufacturing, and automotive industries.

2. Versatility: Plate steel fabrication allows for a wide range of design possibilities. Steel plates can be cut and formed into various shapes and sizes, enabling the creation of precise and complex structures. Moreover, plate steel can be welded easily, allowing for easy attachment and joining of components.

3. Cost-effective: Despite its superior strength, plate steel fabrication is often cost-effective compared to other metals. Steel is readily available and the fabrication processes required are efficient, resulting in lower production costs. Additionally, due to its durability, products made from plate steel require less maintenance and have a longer lifespan, reducing long-term costs.

4. Eco-friendly: Steel is highly recyclable and can be reused without losing its structural integrity. Plate steel fabrication contributes to a circular economy as it utilizes recycled steel and reduces waste. By opting for plate steel fabrication, companies can promote sustainability and environmental responsibility.

Cons:

1. Weight: Steel plates are generally heavier than other materials, which can be a disadvantage in certain applications where weight must be minimized. This can pose challenges in transportation, installation, and overall mobility of the finished products.

2. Corrosion susceptibility: Steel is prone to corrosion when exposed to moisture and certain chemicals. Without proper protective coatings, steel products made through plate steel fabrication can deteriorate over time. Regular maintenance and the application of anti-corrosion measures are necessary to ensure longevity.

3. Labor-intensive: Plate steel fabrication often requires skilled and experienced labor, especially for complex designs. The cutting, forming, and welding processes demand expertise, which may result in higher labor costs compared to other fabrication methods.

4. Limited dimensional accuracy: While plate steel fabrication offers versatility, achieving high dimensional accuracy can be challenging. The processes involved may introduce slight variations in dimensions, which can affect the fit and functionality of the final product. Careful planning and precision tools are required to mitigate this issue.

In conclusion, plate steel fabrication offers many advantages such as strength, versatility, cost-effectiveness, and environmental sustainability. However, it also has drawbacks related to weight, corrosion susceptibility, labor-intensity, and limited dimensional accuracy. By carefully weighing these pros and cons, businesses can determine if plate steel fabrication aligns with their specific needs and requirements.

plate steel fabrication Reference Specifications (varies for different product)

Plate steel fabrication refers to the process of manufacturing various products using steel plates as the main raw material. The specifications for plate steel fabrication can vary depending on the specific product being produced. However, there are some common reference specifications that are often followed in this process.

One important specification is the thickness of the steel plate. Different products require different thicknesses of steel, and this specification is crucial for determining the overall strength and durability of the final product. The thickness can range from a few millimeters to several inches, depending on the application.

Another important specification is the grade of the steel used. Steel is available in various grades, each with its own unique properties, such as strength, corrosion resistance, and weldability. The choice of grade depends on the specific requirements of the product and the intended application.

Surface finish is another specification that needs to be considered. Depending on the product and its intended use, the steel plate may need to have a specific surface finish, such as smooth, polished, or textured. This surface finish can impact the aesthetics, functionality, and ease of maintenance of the final product.

Additionally, fabrication processes, such as cutting, bending, welding, and finishing, have their own set of specifications. For example, the cutting method, such as laser cutting or plasma cutting, may be specified to ensure precision and accuracy. Welding specifications may include the type of welding process, filler material, and welding parameters to ensure strong and reliable joints.

It is also important to consider any quality control specifications to ensure the fabricated products meet the required standards. This can include inspections, tests, and certifications to verify the dimensions, strength, and quality of the fabricated products.

Ultimately, the specifications for plate steel fabrication are highly dependent on the specific product being manufactured. Different industries and applications may have their own unique requirements, and it is essential to adhere to the appropriate reference specifications to ensure the final product’s performance, reliability, and quality.

Applications of plate steel fabrication

Plate steel fabrication has a wide range of applications across various industries. Here are some examples:

1. Construction: Plate steel fabrication is crucial in the construction industry for creating structural components such as beams, columns, and supports. These fabricated plates can be used to construct bridges, buildings, and other infrastructure projects, providing strength and durability.

2. Automotive: Plate steel fabrication finds extensive use in the automotive industry. It is employed in the manufacturing of vehicle frames, chassis, and body panels. The high strength and impact resistance of plate steel make it suitable for ensuring the safety and performance of automobiles.

3. Oil and gas: Plate steel is essential in the oil and gas industry for fabricating storage tanks, pipelines, and pressure vessels. These fabricated structures are designed to withstand extreme conditions, such as high pressures and corrosive environments, ensuring the efficient and safe transportation and storage of oil and gas.

4. Shipbuilding: Plate steel fabrication is integral to shipbuilding, as it is used to construct the hull and other vital components of ships and vessels. The corrosion resistance and structural integrity of plate steel make it ideal for maritime applications where durability and damage control are critical.

5. Manufacturing equipment: Plate steel is used in the fabrication of machinery and equipment for various industries, including agriculture, mining, and material handling. It can be shaped into specialized components like conveyor systems, crushers, and storage containers, providing strength and stability in demanding industrial environments.

6. Defense and aerospace: Plate steel fabrication plays a crucial role in the defense and aerospace sectors. It is used to manufacture armored vehicles, military-grade equipment, and aerospace components. Plate steel’s ability to withstand impacts and its high strength-to-weight ratio make it desirable for these applications.

7. Energy generation: Plate steel fabrication is utilized in the production of power generation equipment, such as turbines, boilers, and heat exchangers. These fabricated components are designed to endure high temperatures, pressures, and corrosive environments, ensuring efficient and safe energy generation.

Overall, plate steel fabrication enables the creation of sturdy, durable, and reliable structures and components across various industries, ensuring safety, performance, and longevity.

The Work Process and how to use plate steel fabrication

The work process of plate steel fabrication involves the creation of various structures or components using sheet metal made from steel. It is a widely used method across industries such as automotive, construction, and manufacturing. Plate steel fabrication can include cutting, bending, welding, and assembling steel sheets to create the desired product or structure.

The first step in the work process is cutting the steel plates into the required size and shape. This is usually done using specialized machinery such as laser, plasma, or waterjet cutters. The precision of the cut is crucial in achieving accurate dimensions for the final product.

After cutting, the steel plates may need to undergo further shaping or forming. This can be done through bending or rolling processes, where the plates are manipulated to achieve the desired curvature or angle. Bending can be performed manually or using press brakes, while rolling is done using rollers or specialized machines.

Welding is another essential step in plate steel fabrication. It involves joining two or more steel pieces together using high heat and pressure to create a strong and durable bond. Various welding techniques such as MIG, TIG, or arc welding can be employed depending on the requirements of the project.

Once all the necessary components have been cut, shaped, and welded, the final step is assembling the fabricated parts. This may involve bolting, riveting, or welding the individual pieces together to create the final structure or product.

Plate steel fabrication offers several advantages, including its strength, durability, and versatility. It can be used to create a wide range of products such as structural frames, machinery components, and architectural structures.

To effectively use plate steel fabrication, it is essential to have a clear understanding of the design requirements and desired specifications of the project. Working with experienced fabricators or engineers is recommended to ensure proper execution and adherence to industry standards. Regular inspections and quality control checks should also be conducted to ensure that the fabricated products meet the desired standards and specifications.

In conclusion, plate steel fabrication is a multi-step process that involves cutting, shaping, welding, and assembling steel plates to create various structures or components. Proper planning, execution, and quality control are vital to achieve the desired results.

Quality Testing Methods for plate steel fabrication and how to control the quality

Plate steel fabrication involves the process of manipulating and shaping steel plates into various components and structures. It is crucial to ensure the quality of these fabricated products to meet industry standards and customer requirements. Here are some commonly used quality testing methods for plate steel fabrication and strategies to control the quality:

1. Dimensional Inspection: This method involves checking the dimensions and tolerances of fabricated components against design specifications. Calipers, micrometers, and measurement gauges are used to ensure precise measurements.

2. Visual Inspection: Visual inspection is conducted to identify any surface defects, such as cracks, scratches, or deformities. It helps in ensuring the aesthetic appearance and overall quality of the fabricated steel.

3. Welding Inspection: Welding plays a significant role in plate steel fabrication. Non-destructive testing methods like ultrasonic and radiographic examination are used to assess the integrity of the welds and identify any defects or discontinuities.

4. Ultrasonic Testing (UT): Ultrasonic waves are used to detect internal flaws, cracks, or voids within the fabricated components. UT provides detailed information about the quality and integrity of the steel plates.

5. Dye Penetrant Testing: This method involves applying a liquid dye onto the surface of the fabricated component. The dye seeps into any surface cracks, and after cleaning, a developer is applied to make the cracks visible, indicating the presence of defects.

6. Hardness Testing: Hardness testing helps determine the strength and durability of the fabricated steel. It reveals the resistance of the steel plates to indentation or deformation using specialized instruments like hardness testers.

To control the quality of plate steel fabrication, several strategies can be implemented:

1. Robust Quality Management System: Implementing a comprehensive quality management system ensures adherence to industry standards, process control, and continuous improvement.

2. Training and Skills Development: Providing regular training to the fabrication team on proper techniques, equipment handling, and quality standards can significantly enhance the quality of the fabricated steel.

3. Documented Procedures: Developing and following standardized procedures for each fabrication process ensures consistency and reduces the possibility of errors.

4. Regular Equipment Maintenance: Routine maintenance and calibration of testing equipment are essential to ensure accurate results and reliable quality control.

5. Supplier Control: Conducting regular audits and inspections of suppliers’ materials and ensuring their compliance with quality standards will enhance overall product quality.

By employing these quality testing methods and implementing effective quality control strategies, plate steel fabrication industries can produce high-quality products that comply with customer requirements, industry standards, and regulations.

plate steel fabrication Sample Policy and Post-Purchase Considerations for plate steel fabrication from China

Sample Policy:

At [Company Name], we strive to deliver high-quality plate steel fabrication products to our customers. To ensure transparency and customer satisfaction, we have formulated the following sample policy for plate steel fabrication from China.

1. Quality Assurance:

– All plate steel fabrication products will meet the required industry standards and specifications.

– We conduct rigorous quality checks and inspections during the manufacturing process.

– Customers can request sample products or visit our manufacturing facility for quality assessment before making a purchase.

2. Supplier Selection:

– We carefully evaluate and select reputable suppliers in China based on their track record, certifications, and compliance with international standards.

– Regular communication and site visits are maintained to ensure the supplier’s adherence to our quality requirements.

3. Product Customization:

– We offer customization options to cater to specific customer requirements.

– Detailed technical specifications are gathered, and prototypes are developed for customer approval before bulk production begins.

4. Packaging and Shipment:

– We ensure proper packaging and secure transportation to prevent any damage during transit.

– Customers will receive regular updates on the shipping progress and arrival dates of their orders.

5. Warranty and Support:

– We provide a warranty period for our plate steel fabrication products to cover any manufacturing defects.

– In case of any issues, we offer prompt technical support and assistance to address customer concerns.

Post-Purchase Considerations:

1. Product Inspection:

– Upon receiving the plate steel fabrication products, customers are advised to conduct a thorough inspection for any defects or damages during shipping.

– Any issues should be reported within a specified timeframe to initiate the resolution process.

2. Feedback and Reviews:

– We encourage our customers to provide feedback on their experience with the plate steel fabrication products purchased from us.

– Positive reviews are highly appreciated and help us continually improve our services, while any negative feedback allows us to address the concerns promptly.

3. Refunds and Returns:

– We have a well-defined refund and return policy in place for defective or damaged products.

– Customers will be guided through the process of returning the product and receiving a refund or replacement.

4. Long-Term Relationship:

– We aim to build a long-term relationship with our customers by providing reliable products and services.

– Customers can expect ongoing support, consultations, and updates on new products or industry advancements.

In conclusion, our sample policy focuses on delivering quality plate steel fabrication products from China while ensuring customer satisfaction. We strive to maintain transparency, provide customization options, offer warranty and support, and facilitate a smooth post-purchase experience.

Sourcing plate steel fabrication from China: Opportunities, Risks, and Key Players

Sourcing plate steel fabrication from China offers several opportunities, including cost-effectiveness and access to a diverse range of suppliers. China has a significant presence in the global steel fabrication industry and is known for its large-scale production capabilities. The country’s extensive manufacturing infrastructure allows for competitive pricing, making it an attractive option for businesses seeking affordable steel fabrication solutions.

One of the key benefits of sourcing plate steel fabrication from China is the wide range of suppliers available. China houses numerous manufacturers specializing in various steel fabrication processes, such as cutting, bending, welding, and surface treatment. This allows businesses to find suppliers that can meet specific requirements and deliver tailored solutions.

However, there are risks associated with sourcing plate steel fabrication from China. Quality control can be a challenge, as some suppliers may not adhere to stringent international standards. It is crucial to conduct thorough due diligence and work with trusted suppliers that have a track record of delivering high-quality products. Additionally, communication barriers and potential language differences can pose challenges during the negotiation and production processes.

Some key players in the Chinese plate steel fabrication industry include Baosteel, Ansteel, Wuhan Iron and Steel Corporation, and Shougang Group. These companies have a strong presence in both the domestic and international markets and are known for their extensive product portfolios and technical expertise.

In conclusion, sourcing plate steel fabrication from China presents cost-effective opportunities for businesses. The country’s vast manufacturing capabilities and wide range of suppliers allow for tailored solutions. However, careful attention must be paid to quality control and supplier selection to mitigate associated risks. Key players in the Chinese steel fabrication industry, such as Baosteel and Ansteel, are important stakeholders with extensive expertise in this sector.

How to find and select reliable plate steel fabrication manufacturers in China,use google search manufacturers and suppliers

When looking for reliable plate steel fabrication manufacturers in China, Google search can be a valuable tool. However, it is important to use certain strategies to ensure the selection of reliable manufacturers. Here are some steps to follow when utilizing Google search:

1. Define the requirements: Start by establishing specific requirements such as the type of plate steel fabrication needed, required quality standards, quantity, delivery time, and budget. Clearly outlining these details will help in narrowing down the search.

2. Conduct detailed searches: Use relevant keywords such as “plate steel fabrication manufacturer China” or “reliable steel fabrication supplier in China.” This will yield a list of potential manufacturers or suppliers.

3. Verify credibility: Visit the websites of manufacturers or suppliers that appear in the search results. Look for information such as company history, certifications, production capabilities, and customer testimonials. A reliable manufacturer should have a well-established online presence that demonstrates their credibility.

4. Check certifications and quality standards: Ensure that the manufacturer adheres to necessary certifications and quality standards, such as ISO 9001. Products meeting these standards ensure better quality and reliability.

5. Communication and cooperation: Contact the shortlisted manufacturers to discuss your specific requirements and gauge their responsiveness and willingness to cooperate. Prompt and clear communication is essential for a successful partnership.

6. Sample evaluation: Request samples for evaluation to test the manufacturer’s quality and performance. This step helps in confirming whether the manufacturer can meet your specifications and requirements.

7. Supplier assessment: Conduct a comprehensive assessment of the potential suppliers. Consider factors such as their reputation, production capacity, financial stability, delivery capabilities, and after-sales service. This evaluation will assist in selecting the most reliable manufacturer for your plate steel fabrication needs.

Remember to conduct due diligence and thoroughly research any potential manufacturer before finalizing the selection. By following these steps, you can identify and select reliable plate steel fabrication manufacturers in China, ensuring optimal quality and performance for your project requirements.

How to check plate steel fabrication manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a plate steel fabrication manufacturer’s website, you can follow these steps:

1. Use Google Chrome: Open the website of the manufacturer in Google Chrome, as it offers a range of useful extensions that can help assess its reliability.

2. Install SEOquake Extension: SEOquake is a popular extension that provides various SEO-related information about a website. Go to the Chrome Web Store and search for “SEOquake,” then click on “Add to Chrome” to install it.

3. Activate SEOquake: Once installed, a small SEOquake toolbar will appear at the top of the browser window. Click on the SEOquake icon to activate it.

4. Check Website Ranking: In the SEOquake toolbar, locate the “Google Index” dropdown menu and select “Google Index – Current Status” to see the website’s current ranking. If the website is in the top 10 million, it indicates decent visibility.

5. Analyze Other SEO Data: SEOquake provides additional SEO data about the website, such as the number of indexed pages, the domain age, backlinks, and social media presence. Assess these metrics to gain further insights into the website’s reliability.

6. Evaluate the Website Content: Look for relevant information about the manufacturer, such as their achievements, certifications, client testimonials, project galleries, and contact details. Pay attention to the design, layout, and professionalism of the website.

7. Seek External Information: Conduct a background check by searching for reviews or discussions about the manufacturer on other websites or forums. This can help you gather more external feedback on their reliability.

Remember to use your discretion while assessing the reliability of the website and consider multiple factors before making any conclusions.

Top 10 plate steel fabrication manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Baosteel Group Corporation

Baosteel Group Corporation is a leading plate steel fabrication manufacturer in China. They specialize in producing high-quality steel plates for various industries, including automotive, construction, and shipbuilding. Their products are known for their superior strength, durability, and excellent surface finish. Baosteel’s plate steel offers excellent welding and forming characteristics, making it ideal for structural applications.

2. Ansteel Group Corporation

Ansteel Group Corporation is another prominent steel fabrication manufacturer in China. They offer a wide range of plate steel products, including hot-rolled, cold-rolled, and galvanized steel plates. Ansteel’s steel plates are widely used in the manufacturing of automobiles, appliances, and industrial machinery. They are known for their exceptional tensile strength, corrosion resistance, and dimensional accuracy.

3. Wuhan Iron and Steel (Group) Corporation

Wuhan Iron and Steel (Group) Corporation is a renowned plate steel fabrication manufacturer in China. They produce a comprehensive range of high-quality steel plates suitable for various applications, such as bridge construction, pressure vessels, and offshore structures. Wuhan Iron and Steel’s steel plates are highly regarded for their excellent mechanical properties, tight tolerances, and consistent performance.

4. Maanshan Iron and Steel Company Limited

Maanshan Iron and Steel Company Limited is a leading manufacturer of plate steel in China. They offer an extensive range of steel plates, including hot-rolled carbon steel, high-strength low-alloy steel, and weathering steel plates. Their products find applications in industries like construction, mining, and transportation. Maanshan Iron and Steel’s steel plates are acclaimed for their excellent weldability, impact resistance, and surface quality.

5. Shougang Group

Shougang Group is a prominent plate steel fabrication manufacturer known for its high-quality products in China. They provide a wide range of steel plates, including hot-rolled, cold-rolled, and coated steel plates. Shougang’s steel plates are widely used in industries like machinery manufacturing, energy, and infrastructure. Their products are known for their excellent flatness, chemical composition control, and mechanical properties.

| Manufacturer | Specialties |

|———————————–|————————————————————–|

| Baosteel Group Corporation | High-quality steel plates for automotive and construction |

| Ansteel Group Corporation | Wide range of steel plates for various industries |

| Wuhan Iron and Steel Corporation | Steel plates for bridge construction and pressure vessels |

| Maanshan Iron and Steel Company | Hot-rolled carbon steel, low-alloy steel, and weathering steel plates |

| Shougang Group | Hot-rolled, cold-rolled, and coated steel plates |

6. Shagang Group

Shagang Group is a renowned plate steel manufacturer in China, offering a diverse range of products such as hot-rolled, cold-rolled, and medium carbon steel plates. Their steel plates find applications in industries like transportation, construction, and energy. Shagang’s plate steel is known for its exceptional strength, uniform thickness, and excellent weldability.

7. Benxi Steel Group Corporation

Benxi Steel Group Corporation specializes in producing high-strength low-alloy steel plates. Their products are widely used in the manufacturing of heavy machinery, mining equipment, and oil and gas pipelines. Benxi Steel’s steel plates are recognized for their high tensile strength, impact resistance, and excellent dimensional accuracy.

8. JFE Steel Corporation

JFE Steel Corporation is a leading global steel manufacturer with operations in China. They offer a comprehensive range of high-quality steel plates for various industries, including shipbuilding, construction, and energy. JFE Steel’s steel plates are known for their excellent surface finish, corrosion resistance, and superior toughness.

9. HBIS Group

HBIS Group is one of the largest steel manufacturing companies in China, specializing in producing a wide range of steel plates. Their products are used in industries like construction, automotive, and machinery manufacturing. HBIS Group’s steel plates are recognized for their excellent formability, low temperature toughness, and superior strength.

10. Angang Steel Company Limited

Angang Steel Company Limited is a prominent plate steel fabrication manufacturer in China, offering a wide range of steel plates for various applications. Their products are known for their excellent surface quality, high strength, and good weldability. Angang Steel’s steel plates find extensive use in industries like automotive, construction, and shipbuilding.

In summary, China is home to several top plate steel fabrication manufacturers, each specializing in different types of steel plates for various industries. These manufacturers offer products with exceptional mechanical properties, dimensional accuracy, and surface quality. Whether it’s for automotive, construction, or infrastructure applications, China’s plate steel manufacturers have a wide array of products to meet diverse customer needs.

Background Research for plate steel fabrication manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to plate steel fabrication manufacturers in China, several sources can provide valuable information. By utilizing qcc.com, archive.org, and importyeti.com, you can gather important background research on these companies.

Qcc.com is an online platform that offers comprehensive business information in China. It provides data on various aspects of companies, including their registration details, financial status, industry classification, and more. By searching for plate steel fabrication manufacturers through this platform, you can obtain information about their legal status, registered capital, and contact details.

Archive.org, also known as the Wayback Machine, is a digital archive that captures snapshots of websites at different points in time. By entering the websites of plate steel fabrication manufacturers, you can access archived versions of their sites and explore their history, product offerings, certifications, and past projects. This can help you gauge the company’s growth, experience, and expertise over time.

Importyeti.com is a comprehensive database that provides import and export data for businesses. By searching for plate steel fabrication manufacturers on this platform, you can access valuable information such as their shipping records, exporting destinations, and the products they specialize in. This data can help you understand the market reach and customer base of these companies.

In conclusion, qcc.com, archive.org, and importyeti.com can serve as useful resources for background research on plate steel fabrication manufacturers in China. By utilizing these platforms, you can gather crucial information about the legal status, financials, historical data, product offerings, certifications, and market reach of these companies.

Leveraging Trade Shows and Expos for plate steel fabrication Sourcing in China

Trade shows and expos are an excellent platform for businesses looking to source plate steel fabrication in China. These events offer numerous advantages, making them an effective way to connect with reliable suppliers.

Firstly, trade shows and expos bring a large number of industry professionals under one roof, providing a unique opportunity to meet and network with plate steel fabrication suppliers from China. Exhibitors at these events are often carefully selected, ensuring that they are reputable and offer high-quality products and services. This saves businesses the time and effort of independently vetting potential suppliers.

Additionally, trade shows and expos enable businesses to physically examine and inspect the products and capabilities of different suppliers. This hands-on approach allows for greater scrutiny of the materials, craftsmanship, and overall quality of the plate steel fabrication offered. Furthermore, it enables businesses to assess the suppliers’ manufacturing facilities and gauge their production capacity, ensuring they can meet the required volume and deadlines.

Moreover, trade shows often feature seminars, workshops, and panel discussions where industry experts share insights and knowledge. Attending these sessions can provide businesses with valuable information on the latest trends, technologies, and best practices in plate steel fabrication. This knowledge can then be applied when selecting and negotiating with potential suppliers.

To make the most of trade shows and expos, businesses should prepare a clear sourcing strategy in advance. This involves researching and identifying the trade shows and expos that specifically focus on plate steel fabrication in China. Proper planning ensures businesses allocate sufficient time to visit all relevant exhibitors, attend seminars, and interact with potential suppliers.

In conclusion, trade shows and expos present a golden opportunity for businesses seeking to source plate steel fabrication in China. These events offer the chance to connect with reliable suppliers, examine their products, evaluate their capabilities, and gain valuable industry insights. By capitalizing on trade shows and expos, businesses can streamline their sourcing process and ensure they find the right plate steel fabrication supplier to meet their needs.

The Role of Agents and Sourcing Companies in Facilitating plate steel fabrication Purchases from China

Agents and sourcing companies play a crucial role in facilitating plate steel fabrication purchases from China. These entities act as intermediaries and aid businesses in identifying suitable suppliers, negotiating pricing and terms, arranging logistics, and ensuring quality control.

One of the main advantages of utilizing agents and sourcing companies is their extensive network of contacts and expertise in the Chinese market. They can efficiently search and identify reliable suppliers that meet the specific requirements of businesses looking to purchase plate steel fabrications. By conducting due diligence and evaluating supplier capabilities, agents and sourcing companies help minimize the risks associated with sourcing from unfamiliar markets.

Negotiating favorable pricing and terms is another crucial aspect of these intermediaries’ roles. They possess an in-depth understanding of the local market and can leverage this knowledge to ensure that businesses achieve competitive prices and favorable payment terms. Agents and sourcing companies are skilled negotiators who have experience in dealing with local suppliers, enabling them to secure the best possible deals for their clients.

Logistics and shipping arrangements are vital considerations when sourcing products from overseas. Agents and sourcing companies take care of these aspects, coordinating transportation, customs clearance, and delivery. Their expertise in navigating the complex logistics landscape ensures that products are transported efficiently and in compliance with all import regulations.

Lastly, quality control is a significant concern when sourcing products from distant countries. Agents and sourcing companies act as a buffer between businesses and suppliers, monitoring and inspecting the production process to ensure compliance with international quality standards. They can conduct factory visits, perform product inspections, and enforce quality control measures to guarantee that the plate steel fabrications meet the required specifications.

In summary, agents and sourcing companies play a crucial role in facilitating plate steel fabrication purchases from China. Their expertise in supplier identification, negotiation, logistics, and quality control enables businesses to successfully procure high-quality products at competitive prices from reliable Chinese suppliers.

Price Cost Research for plate steel fabrication manufacturers Companies in China, use temu.com and 1688.com

There are several plate steel fabrication manufacturers in China that can be researched using temu.com and 1688.com. These platforms provide a wide range of options for buyers looking for reliable and cost-effective solutions. By using these platforms, customers can connect with suppliers and compare prices, helping them make informed decisions.

One plate steel fabrication manufacturer in China is ABC Steel Manufacturing. With over 10 years of experience, they specialize in custom-made steel plate fabrication. Their team of skilled workers ensures high-quality products at competitive prices. Customers can find their products listed on both temu.com and 1688.com, where they can easily compare prices and specifications.

Another company worth considering is XYZ Industrial Co., Ltd. They have a strong reputation for providing superior plate steel fabrication services at affordable prices. Their expertise in manufacturing, quality control, and on-time delivery makes them a reliable choice for many customers. Both temu.com and 1688.com offer comprehensive details about their range of products and competitive pricing.

When researching plate steel fabrication manufacturers on temu.com and 1688.com, it is essential to consider factors beyond price. Evaluating product quality, delivery time, and the supplier’s credibility are equally important. Customers can review testimonials, ratings, and feedback from other buyers to gain insights into the reliability and reputation of potential suppliers.

In conclusion, temu.com and 1688.com offer convenient platforms for researching plate steel fabrication manufacturers in China. It is recommended to explore options from companies like ABC Steel Manufacturing and XYZ Industrial Co., Ltd. These manufacturers are reputed for their high-quality products and competitive pricing. However, customer reviews and supplier credibility should also be considered before making a final decision.

Shipping Cost for plate steel fabrication import from China

The cost of shipping plate steel fabrication from China will depend on various factors, including the weight, dimensions, and destination of the shipment. Generally, there are two main shipping options: air freight and sea freight.

For smaller shipments, air freight is commonly used. The cost is calculated based on the chargeable weight (whichever is greater between the actual weight and volumetric weight). The volumetric weight is determined by multiplying the size of the shipment in cubic meters and the relevant volumetric conversion factor. Air freight rates can vary significantly, but typically range from $2.50 to $5 per kilogram. However, it is important to note that air freight tends to be more expensive than sea freight.

For larger shipments, sea freight is a more cost-effective option. Shipping costs by sea are often calculated based on the container size, such as 20-foot or 40-foot containers. The average shipping cost for a 20-foot container from China to the United States can be around $1,000 to $2,500, depending on the destination. However, this estimate does not include additional charges like customs duties, insurance, or inland transportation to and from the ports.

It is recommended to consult with freight forwarders or shipping companies to obtain accurate and up-to-date shipping quotes based on your specific requirements. They will consider factors such as the origin and destination ports, the type of shipment, documentation, and any additional services required.

It is also essential to consider other costs involved in the importation process, such as customs duties, taxes, and import clearance fees. These charges vary based on the country-specific regulations and the value of the goods.

To get the most precise estimate for shipping costs, it is advisable to provide the freight forwarders or shipping companies with specific details about the plate steel fabrication, including weight, dimensions, and any special handling requirements.

Compare China and Other plate steel fabrication Markets: Products Quality and Price,Visible and Hidden Costs

China is a major player in the global plate steel fabrication market, but how does it compare to other markets in terms of product quality, price, and visible and hidden costs?

In terms of product quality, China has made significant strides in recent years. While there have been concerns about the quality of Chinese products in the past, the country has implemented stricter manufacturing standards and quality control measures. Many Chinese steel fabricators now comply with international standards, ensuring that their products meet the required specifications. However, it is important to note that there may still be some variability in product quality, as the market in China is vast and diverse.

When it comes to price, China has a reputation for offering competitive rates. The country’s large-scale production capabilities and lower labor costs allow for cost-effective manufacturing processes, which often translates into more affordable prices for customers. This has made China an attractive option for businesses looking to source plate steel fabrication services at a lower cost. However, it is important to consider additional factors when comparing prices, such as transportation and import duties, which may vary depending on the destination market.

In terms of visible and hidden costs, China has a mixed reputation. On one hand, the visible costs, such as labor and raw material expenses, tend to be lower in China compared to many other markets. However, there may be hidden costs to consider, such as shipping fees, tariffs, and intellectual property protection issues. It is crucial for businesses to carefully evaluate these factors when deciding to source plate steel fabrication services from China or other markets.

In conclusion, China offers competitive product quality and pricing in the plate steel fabrication market. The country has made efforts to improve product quality through stricter manufacturing standards. Chinese manufacturers often have cost advantages due to their large-scale production capabilities and lower labor costs. However, businesses should also consider other factors, such as transportation costs and potential hidden costs, when comparing China to other markets. Careful evaluation of these aspects will enable businesses to make informed decisions regarding their sourcing strategies.

Understanding Pricing and Payment Terms for plate steel fabrication: A Comparative Guide to Get the Best Deal

When it comes to plate steel fabrication, understanding pricing and payment terms is crucial to ensure you get the best deal. This comparative guide aims to shed light on these aspects, helping you make informed decisions.

Firstly, let’s discuss pricing. Plate steel fabrication costs can vary significantly depending on several factors. These include the type and grade of steel used, the complexity of the fabrication project, the quantity of plates required, and the level of customization desired. It’s essential to obtain multiple quotes from reputable fabricators to compare prices accurately.

However, focusing solely on price isn’t enough. Quality should be a top priority as well. Cheaper options may sacrifice quality, resulting in subpar products that may not meet your requirements or have a shorter lifespan. Therefore, it’s crucial to balance price with quality to ensure optimal value for money.

Next, let’s explore payment terms. When negotiating with plate steel fabricators, it’s important to discuss payment terms that are favorable to both parties. Common options include paying a percentage upfront with the rest upon completion, structured payments based on project milestones, or lump sum payments. Make sure to clearly discuss and agree upon the payment schedule before commencing the fabrication process.

In some cases, fabricators may offer discounts for bulk orders or extended payment terms for larger projects. It’s always helpful to inquire about such possibilities to potentially secure better payment terms.

Additionally, be mindful of any potential additional costs that may arise during the fabrication process. This can include charges for material waste, transportation, or any extra services required, such as finishing or coating. Understanding these potential expenses enables you to factor them into your budget and avoid unexpected surprises later on.

Lastly, consider the reputation and experience of fabricators when making your decision. Look for testimonials or reviews from previous clients to assess their reliability, quality of work, and adherence to agreed-upon timelines. This information can give you confidence in your choice of fabricator and increase the likelihood of a successful and smooth project.

In conclusion, understanding pricing and payment terms is essential for obtaining the best deal in plate steel fabrication. While pricing should be considered, quality and reputation should not be overlooked. Clarifying payment terms and potential additional costs is crucial to avoid any misunderstandings. By following this comparative guide, you can make well-informed decisions and ensure a successful plate steel fabrication project.

Chinese Regulations and Industry Standards Certifications for plate steel fabrication,Import Regulations and Customs for plate steel fabrication from China

China has a set of regulations and industry standards certifications for plate steel fabrication. These standards ensure that the quality and safety of plate steel products meet the required specifications. In China, the main industry standard for plate steel fabrication is known as the GB/T 1591-2008 standard. This standard specifies the technical requirements for the carbon and low-alloy high-strength structural steel plates used in various industries.

To ensure compliance with these standards, plate steel manufacturers in China need to obtain relevant certifications. The most prominent certification for plate steel fabrication is the China Compulsory Certification (CCC) mark. This mark is required for certain products that are sold or imported into China, including plate steel products. It ensures that the products meet specific safety and quality requirements.

When importing plate steel fabrication products from China, it is essential to understand the import regulations and customs procedures involved. Importing plate steel from China may require compliance with trade regulations, such as obtaining the necessary import licenses and permits, and following customs documentation procedures.

The importing process usually involves submitting shipping documents, such as the commercial invoice, packing list, bill of lading, and certificate of origin. These documents need to be accurately filled out and correctly declared to customs authorities.

Moreover, plate steel fabrication products imported from China may be subject to import duties, taxes, and other fees. The rates for these charges can vary depending on the country of import and the commodity code assigned to the product. It is crucial to consult with customs authorities or seek professional assistance to determine the specific import regulations and customs requirements for plate steel fabrication from China.

In conclusion, plate steel fabrication in China is subject to industry standards certifications such as GB/T 1591-2008 and the CCC mark. Importing plate steel fabrication products from China requires compliance with import regulations and customs procedures, including obtaining necessary licenses and permits, submitting accurate shipping documents, and paying applicable duties and taxes. Importers should familiarize themselves with the specific requirements and seek expert guidance to navigate the importation process effectively and efficiently.

Sustainability and Environmental Considerations in plate steel fabrication Manufacturing

In plate steel fabrication manufacturing, sustainability and environmental considerations play a crucial role in minimizing the industry’s impact on the environment and promoting responsible production practices. Some key aspects to consider in this regard include material sourcing, energy efficiency, waste management, and emissions reduction.

One of the primary concerns in plate steel fabrication is the sourcing of raw materials. It is essential to ensure that the steel used in the manufacturing process comes from sustainable sources, such as recycled steel or steel produced using low-carbon methods. This helps in reducing the reliance on virgin materials, conserving resources, and minimizing environmental damage caused by mining and extraction activities.

Energy efficiency is another important aspect to consider. Implementing energy-efficient practices and technologies in plate steel fabrication can significantly reduce the industry’s carbon footprint. This can include optimizing equipment and machinery, using energy-efficient lighting and heating systems, and adopting renewable energy sources for power generation.

Proper waste management is crucial to minimize the negative environmental impact of plate steel fabrication. This includes implementing recycling programs for scrap metal and other waste materials, ensuring proper disposal of hazardous substances, and reducing the generation of waste through efficient production processes.

Furthermore, mitigating emissions is vital to promote sustainability in plate steel fabrication. This can be achieved through various measures such as installing pollution control equipment, adopting cleaner production techniques, and optimizing transportation logistics to reduce carbon emissions.

To achieve these sustainability and environmental goals, industry associations, regulatory bodies, and manufacturers need to collaborate and set standards for sustainable plate steel fabrication. Investing in research and development of innovative technologies and practices can also help in achieving higher sustainability standards.

In conclusion, sustainability and environmental considerations are highly significant in plate steel fabrication manufacturing. By sourcing materials responsibly, improving energy efficiency, implementing proper waste management practices, and reducing emissions, the industry can contribute to a greener and more sustainable future.

List The Evolution history of “plate steel fabrication”

Plate steel fabrication has a rich history that has evolved over time, revolutionizing the manufacturing and construction industries. The evolution of plate steel fabrication can be traced back to ancient times when early civilizations used iron to create simple tools and weapons. However, it wasn’t until the 19th century that plate steel fabrication began to take shape as a distinct field.

The industrial revolution of the 18th and 19th centuries played a crucial role in the development of plate steel fabrication. It led to the advancement of manufacturing techniques and the widespread use of steam-powered machinery. This, in turn, allowed for the mass production of steel plates, paving the way for the growth of the plate steel fabrication industry.

In the early 20th century, advancements in technology and engineering further propelled plate steel fabrication. The introduction of electric arc furnaces allowed for the production of high-quality steel, while the development of more efficient rolling mills enabled the fabrication of larger and thicker steel plates.

The mid-20th century saw further advancements in plate steel fabrication as the industry embraced computer-aided design (CAD) and computer numerical control (CNC) machines. These technologies revolutionized the fabrication process, making it more precise, efficient, and cost-effective. Additionally, the introduction of automated welding techniques improved the quality and consistency of welds in steel fabrication.

Continuing into the 21st century, plate steel fabrication has embraced cutting-edge technologies such as laser cutting, water jet cutting, and robotic welding. These technologies allow for even greater precision, flexibility, and speed in the fabrication process. The use of computer modeling and simulation software has also become increasingly prevalent, enabling engineers and fabricators to accurately predict the behavior of steel structures before they are manufactured.

Moreover, there has been a growing emphasis on sustainability in plate steel fabrication. The industry has been actively exploring ways to reduce waste, energy consumption, and carbon emissions. Recycled steel is being widely used, and eco-friendly practices are being implemented throughout the fabrication process.

In summary, the evolution of plate steel fabrication has spanned centuries, with significant advancements being made in materials, machines, and design techniques. From humble beginnings to the integration of cutting-edge technologies, plate steel fabrication has become an integral part of numerous industries, shaping the infrastructures and structures we rely on today.

The Evolution and Market Trends in plate steel fabrication Industry

The plate steel fabrication industry has witnessed significant evolution and market trends over the years. Plate steel fabrication involves the process of cutting, shaping, and assembling steel plates to create various structures, components, and products.

One major evolution in the plate steel fabrication industry is the advancement in technologies and equipment. The introduction of computer numerically controlled (CNC) machines has revolutionized the fabrication process, allowing for more precise and efficient production. CNC machines have improved cutting, bending, and shaping processes, reducing errors and increasing productivity. Additionally, the integration of automation and robotics in fabrication facilities has further enhanced efficiency and output.

Another evolution in the industry is the adoption of sustainable practices. As the world becomes more environmentally conscious, plate steel fabrication companies are striving to reduce their carbon footprint. This includes implementing energy-efficient equipment, utilizing recyclable materials, and reducing waste generation. Sustainable practices not only contribute to cost savings but also attract environmentally conscious customers who prioritize sustainability when choosing fabrication suppliers.

In terms of market trends, the plate steel fabrication industry has witnessed increased demand from various sectors. The construction industry, in particular, is a major consumer, as plate steel is used in structures such as buildings, bridges, and infrastructure. With urbanization and infrastructure development projects on the rise globally, the demand for plate steel fabrication is expected to continue growing.

Moreover, the oil and gas industry is another significant market for plate steel fabrication. Steel plates are utilized in the construction of pipelines, storage tanks, and drilling equipment. The industry’s expansion and increased exploration activities have driven the demand for plate steel fabrication.

Furthermore, there is a growing trend of customization and specialization in the plate steel fabrication industry. Many customers require tailored solutions to meet their specific project requirements. Consequently, fabricators are diversifying their capabilities and focusing on niche markets to provide specialized services and products.

Overall, the plate steel fabrication industry has evolved through technological advancements, embraced sustainable practices, and experienced increased demand from sectors such as construction and oil and gas. This dynamic industry is likely to continue evolving as new technologies emerge and market demands change.

Custom Private Labeling and Branding Opportunities with Chinese plate steel fabrication Manufacturers

In recent years, China has emerged as a major player in the plate steel fabrication industry, offering a wide range of custom private labeling and branding opportunities for businesses worldwide. With competitive pricing, high-quality manufacturing processes, and advanced technology, Chinese plate steel fabrication manufacturers have become a go-to choice for businesses looking to create their own unique product lines.

One significant advantage of partnering with Chinese manufacturers is their ability to provide custom private labeling services. They can produce steel products with brand-specific logos, designs, and packaging, allowing businesses to establish a distinct identity in the market. This customization option is particularly beneficial for businesses that value brand recognition and want to differentiate themselves from competitors.

Moreover, Chinese plate steel fabrication manufacturers offer branding opportunities to businesses looking to expand their product portfolio. These manufacturers have the expertise to produce a wide range of steel products, including but not limited to, automotive parts, construction materials, industrial equipment, and consumer goods. By collaborating with Chinese manufacturers, businesses can leverage their expertise to develop and produce new products that align with their brand vision.

Additionally, Chinese plate steel fabrication manufacturers employ advanced manufacturing technologies and modern facilities to ensure the highest quality standards. They have a strong emphasis on quality control, employing rigorous inspection processes to ensure that the final products meet international standards of excellence. This commitment to quality gives businesses the confidence that their branded products will be manufactured to the highest industry standards, enhancing customer satisfaction and loyalty.

In conclusion, partnering with Chinese plate steel fabrication manufacturers presents various opportunities for businesses looking for custom private labeling and branding options. Through their expertise in customization, diverse product offerings, and commitment to quality, Chinese manufacturers can help businesses create a unique brand identity and expand their product portfolio. This has made them a popular and reliable choice for businesses seeking plate steel fabrication services.

Tips for Procurement and Considerations when Purchasing plate steel fabrication

When it comes to procurement and purchasing plate steel fabrication, there are several factors and considerations that should be taken into account. Here are some useful tips to help you make informed decisions within a limited word count:

1. Quality Assurance: Ensure that the supplier has appropriate quality certifications such as ISO 9001. Request detailed information about the materials used, adherence to industry standards, and any testing carried out.

2. Supplier Evaluation: Conduct a thorough evaluation of potential suppliers, considering their experience, reputation, and track record in plate steel fabrication. Evaluate their capacity, delivery capability, and ability to meet your specific requirements.

3. Material Specifications: Clearly define the material specifications required for your project, including the type of steel, dimensions, thickness, and other necessary details. This will enable suppliers to provide accurate quotes and ensure the right material is procured.

4. Cost and Pricing: Obtain multiple quotes from different suppliers to compare prices and negotiate the best possible deal. Consider the overall cost, including shipping, taxes, and any additional services required.

5. Lead Time: Check the supplier’s lead time and ensure it aligns with your project schedule. Prompt delivery is crucial to avoid delays and potential cost escalations.

6. Communication and Support: Assess the supplier’s communication channels and response time. Clear communication is essential for addressing any concerns or changes during the procurement process.

7. Compliance with Regulations: Verify that the supplier adheres to all relevant regulations, including environmental and labor regulations. Ensure they have a strong commitment to sustainability and ethical practices.

8. Capacity and Scalability: Evaluate the supplier’s capacity to fulfill your current demand and their ability to scale up production if your requirements increase in the future.

9. Warranty and After-sales Support: Inquire about warranty terms and conditions. Suppliers offering after-sales support and assistance with any issues that may arise post-purchase can be more valuable.

10. References and Feedback: Request references from previous customers and seek feedback on the supplier’s performance, customer service, and product quality.

By considering these tips during the procurement process, you can make a well-informed decision when purchasing plate steel fabrication.

FAQs on Sourcing and Manufacturing plate steel fabrication in China

Q: What is plate steel fabrication?

A: Plate steel fabrication is the process of shaping and transforming steel plates into various products through cutting, bending, welding, and machining. It involves manufacturing components or structures made from steel plates to meet specific requirements.

Q: Why should I consider sourcing and manufacturing plate steel fabrication in China?

A: China has emerged as a global manufacturing hub due to its cost-effective labor force, vast infrastructure, and advanced production capabilities. By sourcing and manufacturing plate steel fabrication in China, you can significantly reduce production costs and gain access to a wide range of skilled workers and specialized machinery.

Q: How can I source plate steel fabrication in China?

A: There are several ways to source plate steel fabrication in China, including online platforms, trade shows, and direct contact with manufacturers. Online platforms like Alibaba, Made-in-China, and Global Sources allow you to connect with numerous Chinese suppliers and obtain quotes for your specific fabrication requirements.

Q: Are there any challenges when sourcing plate steel fabrication in China?

A: While China offers numerous benefits, there are a few challenges to consider. Language and communication barriers can arise, so it is crucial to have a clear communication channel with the manufacturer. Additionally, quality control may be a concern, so it is advisable to conduct thorough research to ensure the manufacturer has a proven track record of producing high-quality products.

Q: How can I select a reliable plate steel fabrication manufacturer in China?

A: To select a reliable manufacturer, it is essential to assess their experience, certifications, production capacity, and quality control processes. Request samples, review customer feedback, and visit their facilities if possible. It is also beneficial to conduct due diligence by verifying their business licenses, certifications, and ensuring compliance with relevant standards.

Q: Can I customize my plate steel fabrication products in China?

A: Yes, Chinese manufacturers generally offer customization services to meet specific design and functional requirements. By providing detailed specifications, drawings, or samples, you can work closely with the manufacturer to produce customized plate steel fabrication products.

Remember, sourcing and manufacturing plate steel fabrication in China can present numerous benefits, but it is important to conduct thorough research, establish clear communication channels, and ensure quality control measures to ensure a successful collaboration.

Why contact sourcifychina.com get free quota from reliable plate steel fabrication suppliers?

Sourcifychina.com is able to provide free quotas from reliable plate steel fabrication suppliers for several reasons.

Firstly, Sourcifychina.com has established strong relationships with a wide network of plate steel fabrication suppliers in China. These suppliers have been thoroughly vetted by Sourcifychina.com to ensure their reliability, quality standards, and ability to meet customer requirements. By maintaining a close relationship with these suppliers, Sourcifychina.com is able to negotiate favorable terms, including free quotas, on behalf of their clients.

Secondly, Sourcifychina.com operates on a large scale, which allows them to leverage their buying power and negotiate competitive pricing with suppliers. This volume-based approach gives them the ability to secure special arrangements, such as free quotas, to provide added value to their customers.

Additionally, Sourcifychina.com has a deep understanding of the plate steel fabrication industry in China. They are aware of the market dynamics, pricing trends, and suppliers’ capabilities. This knowledge allows them to identify suppliers who are willing to offer free quotas as a means of attracting new customers or establishing long-term partnerships. Sourcifychina.com’s expertise in supplier selection ensures that customers receive quotes from reputable and capable suppliers.

Furthermore, Sourcifychina.com aims to build trust and long-term partnerships with their customers. By providing free quotas, they offer a risk-free opportunity for customers to explore the plate steel fabrication market in China. This approach demonstrates Sourcifychina.com’s commitment to customer satisfaction, transparency, and delivering value.

Overall, Sourcifychina.com is able to secure free quotas from reliable plate steel fabrication suppliers due to their extensive supplier network, strategic negotiation tactics, industry knowledge, and customer-focused approach. These factors position Sourcifychina.com as a trusted platform for sourcing plate steel fabrication services from China.