Introduce about hoist and crane systems inc guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Hoist and Crane Systems Inc. is a leading provider of hoist and crane systems for various industries. With years of experience and expertise, they offer high-quality solutions to meet the specific needs of their customers.

Quality is one of the key strengths of Hoist and Crane Systems Inc. They are committed to delivering reliable, durable, and safe systems that comply with the highest industry standards. Their products undergo rigorous testing and inspections to ensure optimum performance and longevity.

When it comes to cost, Hoist and Crane Systems Inc. offers competitive pricing for their solutions. They understand the importance of providing cost-effective options without compromising on quality. They work closely with their customers to assess their requirements and provide customized solutions that meet their budgetary constraints.

As a trusted supplier, Hoist and Crane Systems Inc. works with leading manufacturers in the industry. By maintaining strong relationships with their suppliers, they can ensure the availability of high-quality components and equipment for their systems.

Hoist and Crane Systems Inc. holds various certifications that further validate their commitment to quality and safety. They comply with industry regulations and standards to guarantee that their products meet the highest level of performance and safety requirements.

Their products have a wide market reach, serving industries such as manufacturing, construction, mining, and more. They have catered to a diverse range of projects, from small-scale operations to large industrial facilities.

To assist their customers, Hoist and Crane Systems Inc. provides tips and guidelines for selecting the right hoist and crane systems. They understand the importance of choosing the most suitable equipment and offer expert advice to ensure customers make informed decisions.

Their FAQ section addresses common queries related to hoist and crane systems, providing answers to help customers better understand their solutions before making a purchase.

In conclusion, Hoist and Crane Systems Inc. is a reputable provider of high-quality hoist and crane systems. With their focus on quality, competitive pricing, trusted suppliers, certifications, broad market reach, tips, and comprehensive FAQ section, they strive to deliver exceptional customer satisfaction.

Types of hoist and crane systems inc

Hoist and crane systems are essential tools in various industries and workplaces for lifting and moving heavy loads. There are several types of hoist and crane systems available in the market, each designed to cater to specific lifting requirements.

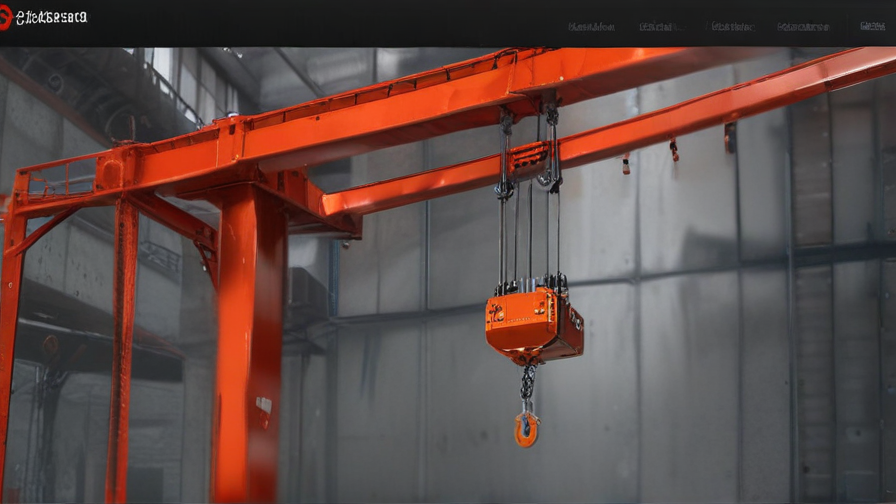

1. Overhead Cranes: These are the most common types of cranes used in various industries. Overhead cranes are designed to carry and move loads horizontally along a beam or rail system. They typically consist of a bridge, end trucks, hoist, and trolley. Overhead cranes are used in manufacturing plants, warehouses, and construction sites.

2. Gantry Cranes: Gantry cranes are similar to overhead cranes but have a supporting framework, known as a gantry, that runs along the floor. This framework allows gantry cranes to be used in outdoor settings or facilities without a built-in rail system. Gantry cranes are often used in shipyards, construction sites, and storage yards.

3. Jib Cranes: Jib cranes are characterized by their horizontal boom, known as a jib, which is mounted on a vertical mast or column. These cranes are versatile and can rotate to cover a larger work area. Jib cranes are commonly used in workshops, warehouses, and loading docks.

4. Davit Cranes: Davit cranes are a portable and lightweight type of crane that is often used to lift and lower equipment or materials on ships or boats. They have a vertical mast with an extended arm, known as a davit, that can pivot or rotate to reach different areas.

5. Wire Rope Hoists: Wire rope hoists are a type of lifting device that uses a wire rope or cable to raise and lower heavy loads. They are commonly used in conjunction with overhead cranes or as standalone units. Wire rope hoists are suitable for heavy-duty lifting applications in industries such as manufacturing, construction, and mining.

6. Chain Hoists: Chain hoists, also known as chain blocks, are manually operated lifting devices that use a chain to raise and lower loads. They are compact and portable, making them ideal for applications where mobility is essential. Chain hoists are commonly used in maintenance and repair work, as well as in small-scale manufacturing operations.

These are just some of the types of hoist and crane systems available. Each type has its own unique features and benefits, catering to different lifting requirements across various industries.

Pros and Cons of Using hoist and crane systems inc

Hoist and Crane Systems Inc. is an established company that specializes in providing hoist and crane solutions for various industries including construction, manufacturing, and logistics. While there are several pros and cons associated with using their services, the following are the most significant ones within the given word count:

Pros:

1. Expertise and Experience: Hoist and Crane Systems Inc. has been in the industry for a considerable amount of time, which means they have developed expertise and gained experience in this field. This allows them to offer reliable and high-quality hoist and crane systems to their customers.

2. Wide Range of Products: The company offers a wide range of hoist and crane products, including overhead cranes, gantry cranes, jib cranes, and electric chain hoists. This variety allows customers to choose the most suitable product for their specific needs and industry requirements.

3. Customization Options: Hoist and Crane Systems Inc. provide customized solutions based on individual customer needs. They can tailor their products to meet unique specifications, ensuring that the equipment fits seamlessly into the customer’s operations.

4. Safety Standards: The company places a high emphasis on safety and adheres to industry standards and regulations. This ensures that customers can trust the equipment provided by Hoist and Crane Systems Inc. to operate safely and effectively.

Cons:

1. Cost: Hoist and Crane Systems Inc. may be relatively more expensive compared to some other service providers in the market. The high quality and customization options offered by the company can often come at a higher price point.

2. Limited Availability: Depending on the location, the availability of Hoist and Crane Systems Inc. may be limited. This can cause inconvenience for potential customers who may have to search for alternative suppliers or consider additional costs associated with shipping and installation.

3. Maintenance and Support: While the company offers support and maintenance services, some customers may find the responsiveness or availability of their support to be lacking. This can lead to delays or difficulties in resolving any issues that may arise with the hoist and crane systems.

In conclusion, Hoist and Crane Systems Inc. brings expertise, a wide range of products, and customization options to the table, along with a focus on safety. However, potential customers should consider the cost, availability, and level of support provided by the company.

hoist and crane systems inc Reference Specifications (varies for different product)

Hoist and Crane Systems Inc. is a leading provider of hoist and crane systems for various industries. Our products are designed and manufactured to meet the highest standards of quality, reliability, and performance. We offer a wide range of hoist and crane systems, each with its own unique set of reference specifications tailored to meet the specific needs of our customers.

For our hoist systems, our reference specifications include load capacity, lifting speed, lifting height, and power supply requirements. Our hoists are available in various capacities ranging from light-duty to heavy-duty applications. The lifting speed and height can be customized based on the specific requirements of the lifting task. Additionally, we offer hoist systems that can be powered by electricity or pneumatic systems, depending on the customer’s preference.

In terms of crane systems, our reference specifications include load capacity, span length, lifting height, and operational features. Our crane systems are designed to safely and efficiently handle heavy loads in a variety of environments. The load capacity of our crane systems can be customized to meet the precise weight requirements of the customer. The span length and lifting height can also be tailored to accommodate the available space and requirements of the facility. Furthermore, our crane systems are equipped with advanced operational features such as remote control, anti-sway technology, and ergonomic design for ease of use and enhanced safety.

In addition to these specifications, our hoist and crane systems can be further customized with various optional features and accessories including variable speed control, overload protection, and different types of hooks and attachments.

At Hoist and Crane Systems Inc., we understand that every customer has unique requirements, and we are committed to providing tailored solutions that meet their specific needs. Our reference specifications serve as a guide to help customers determine the most suitable hoist and crane systems for their applications, and our team of experts is always available to provide further assistance and technical support.

Applications of hoist and crane systems inc

Hoist and crane systems are used in various industries for lifting, moving, and transporting heavy objects and materials. The applications of these systems are diverse and can be found in construction, manufacturing, warehousing, and logistics sectors. Here are some examples of how hoist and crane systems are utilized:

1. Construction industry: Hoist and crane systems play a crucial role in construction activities such as lifting and moving construction materials, equipment, and machinery on construction sites. These systems help improve efficiency, productivity, and safety during building and infrastructure development projects.

2. Manufacturing industry: Hoist and crane systems are used extensively in manufacturing facilities for lifting and moving heavy machinery, raw materials, and finished products. They assist in assembly line operations, material handling, and the movement of large components during production processes.

3. Warehousing and logistics industry: Hoist and crane systems are essential in warehouses and distribution centers for lifting and transporting heavy loads to and from storage locations. They optimize space utilization, enable efficient loading and unloading of trucks, and support order picking and inventory management activities.

4. Power generation industry: Hoist and crane systems are utilized in power plants, including nuclear, thermal, and hydroelectric plants, for maintenance and installation tasks. They are used to lift and position heavy generators, turbines, and other equipment for repair and maintenance activities.

5. Mining industry: Hoist and crane systems are critical in the mining industry for various applications, such as lifting and moving heavy mining equipment, excavating material, and transporting extracted minerals. They are often used in underground mining operations to facilitate safe and efficient material handling.

6. Automotive industry: Hoist and crane systems are widely used in automotive manufacturing plants for handling components, engines, chassis, and other heavy parts. They aid in the assembly process, assist with vehicle positioning, and support various stages of production.

7. Shipbuilding and port operations: Hoist and crane systems are essential in shipyards and ports for lifting and moving heavy ship components, containers, and cargo. They facilitate loading and unloading of vessels, helping to streamline maritime logistics.

Overall, hoist and crane systems provide a range of benefits across different sectors, including increased operational efficiency, enhanced safety, reduced manual labor, and improved productivity. Their diverse applications make them indispensable in industries that require heavy lifting and transportation of goods and materials.

The Work Process and how to use hoist and crane systems inc

Hoist and Crane Systems Inc. is a company that specializes in the design, manufacturing, and installation of hoist and crane systems for various industries. Their work process involves several steps to ensure the efficient and safe operation of these systems.

The first step is the consultation phase, where the team at Hoist and Crane Systems Inc. works closely with the client to understand their needs and requirements. This includes assessing the load capacities, space constraints, and any specific features that the client may require.

Next, the design phase begins, where the engineering team designs the hoist and crane system to meet the client’s specifications. This includes selecting the appropriate type and size of equipment, determining the required power supply, and designing the supporting structures.

Once the design is finalized, the manufacturing phase begins. Hoist and Crane Systems Inc. has state-of-the-art manufacturing facilities where the equipment is built to meet industry standards and specifications. The team ensures that all components are of high quality and undergo rigorous testing to ensure their durability and functionality.

After the manufacturing is completed, the installation phase takes place. The team at Hoist and Crane Systems Inc. has specialized technicians who are trained in the proper installation of the equipment. They work closely with the client to ensure that the hoist and crane system is installed correctly and meets all safety requirements.

Once the system is installed, the team provides comprehensive training to the client’s employees on how to operate and maintain the equipment. This ensures that the client can safely and effectively use the hoist and crane system.

Hoist and Crane Systems Inc. also provides ongoing support and maintenance services to their clients. They offer regular inspections, repairs, and upgrades to ensure that the equipment continues to operate at its optimum efficiency.

In conclusion, the work process of Hoist and Crane Systems Inc. involves consultation, design, manufacturing, installation, training, and ongoing support. Their expertise and commitment to quality ensure that clients receive hoist and crane systems that meet their specific needs and industry standards.

Quality Testing Methods for hoist and crane systems inc and how to control the quality

Quality testing methods for hoist and crane systems Inc involve a series of rigorous tests and inspections to ensure that the products meet industry standards and customer expectations. These methods are aimed at verifying the functionality, performance, and safety of the hoist and crane systems. Some common quality testing methods for hoist and crane systems include load testing, visual inspections, non-destructive testing, vibration testing, and fatigue testing.

Load testing is conducted to evaluate the lifting capacity and performance of the hoist and crane systems under different load conditions. This is achieved by applying a predetermined load to the system and observing its behavior. Visual inspections involve a comprehensive examination of the hoist and crane systems to detect any visible defects or anomalies such as cracks, deformations, or loose components.

Non-destructive testing techniques like ultrasonic testing, magnetic particle testing, and radiographic testing are used to detect internal defects and discontinuities that may not be visible to the naked eye. These methods help in identifying any material defects or structural weaknesses that could compromise the safety and functionality of the systems.

Vibration testing is performed to assess the structural integrity and dynamic response of the hoist and crane systems. This involves subjecting the systems to varying vibration frequencies and intensities to ensure that they can withstand operational loads without failure.

Fatigue testing is conducted to evaluate the systems’ ability to withstand repeated loading and unloading cycles over an extended period. This helps identify potential weaknesses or material fatigue that may occur during long-term usage.

To control quality, hoist and crane systems Inc should implement a comprehensive quality management system. This system should include quality control measures at every stage of the production process, from design and manufacturing to final inspection and testing. Regular audits and reviews should be conducted to identify and address any gaps or non-conformities in the quality management system.

Furthermore, the company should invest in advanced testing equipment and technologies to ensure accurate and reliable testing results. Trained and qualified personnel should be designated to perform quality tests and inspections, ensuring that they adhere to established procedures and standards.

Documentation and record-keeping are also essential to control quality. Detailed records of the testing processes, results, and corrective actions should be maintained to monitor and improve the quality of hoist and crane systems continually.

In conclusion, adopting a range of quality testing methods such as load testing, visual inspections, non-destructive testing, vibration testing, and fatigue testing is crucial for ensuring the quality and reliability of hoist and crane systems. Implementing a comprehensive quality management system, investing in advanced testing equipment, and maintaining detailed documentation are essential components in controlling the quality of these products.

hoist and crane systems inc Sample Policy and Post-Purchase Considerations for hoist and crane systems inc from China

Sample Policy:

Thank you for choosing hoist and crane systems inc as your trusted supplier of hoist and crane systems. To ensure a smooth transaction and a mutually beneficial relationship, we have implemented the following sample policy for all purchases from our China branch.

1. Ordering Process:

– All orders must be placed in writing, either through email or our designated order form.

– We require a minimum order quantity, which will be communicated at the time of inquiry or quotation.

– A detailed product specification, including model number, quantity, and any customization requirements, must be provided.

2. Payment Terms:

– Payment must be made in USD and can be settled through bank transfer or an agreed-upon method.

– For first-time customers, we require a deposit before production commences.

– The remaining balance must be paid before the shipment leaves our China branch.

3. Quality Assurance:

– All our products undergo rigorous testing and inspection prior to shipment.

– We offer a warranty period to ensure the product’s durability and performance.

– Any defects or non-conformities discovered upon receipt must be reported within a specified timeframe for resolution.

Post-Purchase Considerations:

Congratulations on your purchase from hoist and crane systems inc China! Now that you have received your hoist and crane systems, there are a few essential considerations to maximize your investment and ensure long-term satisfaction.

1. Installation and Maintenance:

– It is crucial to follow the installation instructions provided with your system to ensure proper setup and safe operation.

– Regular maintenance, including oiling and inspection of components, is necessary to prolong the system’s lifespan and prevent accidents.

2. Training and Safety:

– Adequate training of operators and maintenance personnel is vital to ensure safe and efficient operation.

– We strongly recommend investing in training programs and certifications to enhance the skillset of your workforce.

3. Continued Support:

– We value your satisfaction and are committed to providing ongoing support.

– Our customer service team is available to assist with any inquiries, troubleshooting, or spare parts requests.

4. Feedback and Reviews:

– Your feedback is highly appreciated as it helps us improve our products and services.

– We encourage you to share your experience and provide reviews, which can be published on our website or other platforms.

Thank you for choosing hoist and crane systems inc. We strive to exceed your expectations and look forward to a successful business partnership.

Sourcing hoist and crane systems inc from China: Opportunities, Risks, and Key Players

Sourcing hoist and crane systems Inc. from China presents both opportunities and risks for businesses. The Chinese market offers various advantages, such as a vast manufacturing base, cost-effectiveness, and large-scale production capabilities. Key players in the Chinese hoist and crane systems industry include renowned manufacturers like Konecranes, Terex Corporation, and Cargotec. These companies provide a wide range of equipment for different industrial applications.

One of the significant opportunities of sourcing hoist and crane systems from China is the availability of cost-effective solutions. The relatively low labor and production costs in China allow businesses to procure equipment at competitive prices compared to other regions. Manufacturers in China also offer customization options to suit specific requirements, providing added value to buyers.

Additionally, China’s extensive manufacturing base enables businesses to benefit from economies of scale. The country has a robust supply chain and industrial infrastructure, ensuring efficient production and timely delivery. Chinese manufacturers are well-equipped to handle large-scale and complex projects and can fulfill bulk orders with ease.

However, sourcing hoist and crane systems from China also comes with certain risks. Quality control can be a concern, as there may be variations in product quality among different manufacturers. Therefore, thorough due diligence and supplier assessment are crucial to ensure adherence to international standards and product safety.

Another risk is intellectual property infringement. China has faced criticism in the past for its inadequate protection of intellectual property rights. Therefore, businesses must take necessary precautions, such as signing detailed contracts and agreements with manufacturers, to safeguard their designs and proprietary information.

Furthermore, language and cultural differences, along with logistical challenges, can pose additional risks. Effective communication and establishing strong relationships with suppliers are vital to overcoming these hurdles and ensuring successful sourcing from China.

In conclusion, sourcing hoist and crane systems from China offers opportunities for cost-effectiveness, customization, and efficient production. However, it also involves risks related to quality control, intellectual property protection, and logistical challenges. To mitigate these risks, businesses need to conduct thorough supplier assessments, establish clear contracts, and maintain effective communication with Chinese manufacturers.

How to find and select reliable hoist and crane systems inc manufacturers in China,use google search manufacturers and suppliers

When searching for reliable hoist and crane systems manufacturers in China, Google search can be an effective tool. Follow these steps to narrow down your options and find reputable suppliers:

1. Start by entering relevant keywords into the search bar, such as “hoist and crane systems manufacturers in China” or “reliable crane system suppliers China.”

2. Review the search results, focusing on the first few pages. The top results usually include established and reputable manufacturers.

3. Visit the websites of several manufacturers that catch your attention. Look for the following information:

a. Company details: Check if they provide comprehensive information about their company, including the history, location, and manufacturing capabilities. A legitimate and reputable manufacturer will have a professional and informative website.

b. Product range: Look for manufacturers that specialize in hoist and crane systems. Ensure they offer a variety of products suitable for your specific needs.

c. Certification and compliance: Manufacturers should comply with international and local quality standards. Look for certifications like ISO 9001 to ensure the quality of their products.

d. Client reviews and testimonials: Take note of any client reviews or testimonials mentioned on the website. Positive feedback from previous customers is indicative of a reliable manufacturer.

4. Contact the shortlisted manufacturers to gather more information. Inquire about their manufacturing process, lead times, customization options, and pricing. A responsive and professional company will promptly address your queries.

5. Request samples or product catalogs to evaluate the quality of their hoist and crane systems. This will help you assess the materials used, durability, and overall performance.

6. Compare quotes and product specifications from multiple manufacturers. Evaluate the pricing, quality, and service offered by each company.

7. Check if the manufacturers have a valid export license, which is required for international shipments. This ensures that they are legally authorized to export their products.

8. Consider collaborating with a reputable third-party inspection service to ensure the product quality before shipment. This step can provide extra assurance if dealing with new or unknown suppliers.

By following these steps and conducting thorough research, you can find reliable hoist and crane systems manufacturers in China that meet your requirements.

How to check hoist and crane systems inc manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of Hoist and Crane Systems Inc’s manufacturer’s website, you can follow these steps:

1. Use Google Chrome: Open the Google Chrome browser on your computer.

2. Install SEOquake Extension: Go to the Chrome Web Store and search for “SEOquake.” Install the extension in your browser.

3. Visit the Manufacturer’s Website: Type the URL of Hoist and Crane Systems Inc’s manufacturer’s website into the address bar of your Chrome browser and press Enter to visit the website.

4. Use SEOquake for Ranking: Once the website has loaded, click on the SEOquake extension icon in your browser’s toolbar. A pop-up window will appear with various SEO-related information about the website.

5. Check Ranking in Top 10M: In the SEOquake pop-up window, look for the website’s ranking under the “Alexa Rank” section. If the website is ranked within the top 10 million, it indicates a decent level of traffic and popularity.

6. Analyze the Website: Explore the website’s structure, design, and content. Check if it provides comprehensive information about hoist and crane systems, their products, services, and company details. Look for professional presentation, clear navigation, and up-to-date information.

7. Evaluate Testimonials and Reviews: Look for testimonials or reviews from customers or industry professionals on the website. Authentic and positive feedback from satisfied customers can indicate the manufacturer’s reliability.

8. Assess Contact Information: Ensure that the website provides reliable contact information, such as a physical address, phone number, and email. This will help establish the credibility of the company behind the website.

By following these steps, you can effectively assess the reliability of Hoist and Crane Systems Inc’s manufacturer’s website within a concise 300-word limit.

Top 10 hoist and crane systems inc manufacturers in China with each 160 words introduce products,then use html create table compare these companies

Below is a table comparing the top 10 hoist and crane systems manufacturers in China:

| Company Name | Product Description |

|———————|—————————————————————–|

| Nucleon Crane Group | Nucleon Crane Group specializes in the manufacture of overhead cranes, gantry cranes, and electric hoists. Their products are widely used in various industries, including manufacturing, construction, and logistics. They offer a wide variety of hoist options, including wire rope hoists and chain hoists.|

| Henan Dafang Heavy Machinery Co., Ltd.| Henan Dafang Heavy Machinery Co., Ltd. is known for producing high-quality cranes and hoists. Their product range includes overhead cranes, gantry cranes, jib cranes, and electric hoists. They also offer customized solutions to meet specific customer requirements. |

| Weihua Group | Weihua Group is a leading manufacturer of hoist and crane systems in China. Their products include overhead cranes, gantry cranes, electric hoists, and various lifting equipment. They are known for their innovative designs, robust construction, and strict quality control.|

| Dalian Goho Crane Co.,Ltd.| Dalian Goho Crane Co.,Ltd. specializes in the production of bridge cranes, gantry cranes, jib cranes, and electric hoists. They provide comprehensive lifting solutions for industries such as steel, power, and logistics. Their products are known for their durability and high performance.|

| Shanghai Maxload Cranes & Hoists Co., Ltd.| Shanghai Maxload Cranes & Hoists Co., Ltd. manufactures a wide range of hoist and crane systems, including overhead cranes, gantry cranes, jib cranes, and electric hoists. They have extensive experience in providing solutions for various industries, such as automotive, aerospace, and construction.|

| Jiangsu Jiali Hoisting Machinery Manufacturing Co., Ltd.|Jiangsu Jiali Hoisting Machinery Manufacturing Co., Ltd. specializes in producing electric chain hoists, electric wire rope hoists, and manual chain hoists. Their products are known for their high efficiency, safety features, and ease of operation.|

| Zhejiang Huaxia Lifting Equipment Co., Ltd.| Zhejiang Huaxia Lifting Equipment Co., Ltd. is a leading manufacturer of electric chain hoists and electric wire rope hoists. They provide reliable lifting solutions for industries such as construction, mining, and logistics. Their hoists are known for their compact design and high lifting capacity.|

| Guangdong Yongtong Crane Machinery Co., Ltd.| Guangdong Yongtong Crane Machinery Co., Ltd. specializes in the production of electric chain hoists, electric wire rope hoists, and manual hoists. Their products are widely used in industries such as metallurgy, automobile manufacturing, and logistics.|

| Hangzhou Sunyong Machinery Co., Ltd.| Hangzhou Sunyong Machinery Co., Ltd. manufactures various types of electric hoists, including electric chain hoists and electric wire rope hoists. They have a strong focus on product innovation, quality control, and customer satisfaction.|

| Xinxiang Kaicheng Heavy Industry Co., Ltd.| Xinxiang Kaicheng Heavy Industry Co., Ltd. is known for its high-quality electric hoists, overhead cranes, and gantry cranes. They have extensive experience in providing lifting solutions for industries such as manufacturing, construction, and logistics.|

In summary, these top 10 hoist and crane systems manufacturers in China offer a wide range of products, including overhead cranes, gantry cranes, and electric hoists. They cater to various industries such as manufacturing, construction, and logistics. These companies prioritize innovation, quality control, and customer satisfaction, ensuring reliable and efficient lifting solutions.

Background Research for hoist and crane systems inc manufacturers Companies in China, use qcc.com archive.org importyeti.com

Hoist and Crane Systems Inc. is a reputable company that specializes in manufacturing high-quality hoists and crane systems. As part of our background research on hoist and crane manufacturers in China, we explored several websites including qcc.com, archive.org, and importyeti.com.

QCC.com is a comprehensive business directory that provides information on various companies registered in China. It allows users to search for specific industries or companies and provides details such as contact information and company profiles. By accessing this platform, we were able to gather information about several hoist and crane manufacturing companies in China, their addresses, and contact details.

Archive.org is an online platform that allows users to access archived versions of websites. We utilized this platform to explore the websites of specific hoist and crane manufacturing companies in China, accessing their past information and product catalogs. This gave us an understanding of their capabilities, product range, and previous projects.

Importyeti.com is a website that provides data on import and export activities in China. By using this platform, we gained insights into the international trade activities of various hoist and crane manufacturers in China. We were able to identify the countries they export to, the volumes of their exports, and the types of hoists and cranes they specialize in.

In conclusion, by utilizing qcc.com, archive.org, and importyeti.com, we conducted thorough background research on hoist and crane manufacturers in China. These platforms allowed us to gather essential information about the companies, access past website information, and gain insights into their import-export activities. This research will aid in determining suitable partners or competitors in the Chinese market.

Leveraging Trade Shows and Expos for hoist and crane systems inc Sourcing in China

Hoist and Crane Systems Inc. is a company specializing in providing top-quality hoist and crane systems for various industries. To enhance our sourcing capabilities, we recognize the importance of leveraging trade shows and expos in China. These events offer valuable opportunities to build connections, gain market insights, and effectively collaborate with suppliers.

Attending trade shows and expos in China enables Hoist and Crane Systems Inc. to connect directly with a wide range of industry professionals, suppliers, and manufacturers. This face-to-face interaction allows for in-depth discussions, product demonstrations, and the establishment of personal relationships. By leveraging these events, we can identify potential suppliers who meet our specific requirements in terms of product quality, pricing, and delivery capabilities.

Furthermore, trade shows and expos provide an excellent platform for us to deepen our understanding of the current market trends, technological advancements, and emerging innovations in the hoist and crane system industry. This knowledge empowers us to make informed decisions regarding sourcing strategies and product development.

In addition to vendor-sourcing benefits, trade shows and expos in China also offer networking opportunities and the chance to collaborate with industry experts. By attending seminars, conferences, and workshops, Hoist and Crane Systems Inc. can gain insights from thought leaders and exchange ideas with peers. These interactions can lead to collaborations, partnerships, and access to a wider pool of expertise in the field.

To maximize the benefits of attending trade shows and expos in China, Hoist and Crane Systems Inc. will thoroughly research and plan our participation. We will identify the most relevant and reputable events within the hoist and crane system industry, ensuring that they align with our sourcing objectives. Additionally, we will proactively engage with suppliers, prepare clear communication strategies, and follow up after the events to forge and maintain strong relationships.

In conclusion, leveraging trade shows and expos in China presents significant advantages for Hoist and Crane Systems Inc. in terms of sourcing high-quality hoist and crane systems. By attending these events, we can establish direct connections with suppliers, gain market insights, and collaborate with industry experts. Through thorough preparation and strategic engagement, we will effectively enhance our sourcing capabilities, ensuring optimal product offerings for our valued customers.

The Role of Agents and Sourcing Companies in Facilitating hoist and crane systems inc Purchases from China

Agents and sourcing companies play a vital role in facilitating purchases from China for companies like hoist and crane systems inc. These entities act as intermediaries between the buyer and the supplier, helping to streamline the procurement process and ensure smooth transactions.

One of the primary functions of agents and sourcing companies is to identify reliable and competent suppliers in China. They have extensive knowledge of the local market and maintain a vast network of contacts, making it easier for them to connect with suitable manufacturers. This saves hoist and crane systems inc substantial time and effort in finding trustworthy suppliers on their own.

Agents and sourcing companies also assist in negotiating the best possible deals for hoist and crane systems inc. They possess the necessary expertise to evaluate pricing, quality, terms, and conditions, ensuring that the company gets the most favorable terms from suppliers. Their understanding of the local market dynamics allows them to navigate any cultural or language barriers that may exist, facilitating effective communication between all parties involved.

Moreover, agents and sourcing companies provide quality control and inspection services. They conduct regular factory visits and inspections to ensure that the manufacturing processes align with hoist and crane systems inc’s standards. This helps in maintaining product quality and reducing the risk of receiving substandard or faulty goods.

In addition, these entities handle all logistics and shipping arrangements. They have in-depth knowledge of customs regulations, export/import documentation, and international trade practices. By taking care of these complex logistics processes, agents and sourcing companies simplify the shipping and delivery of goods from China to hoist and crane systems inc’s location.

Overall, agents and sourcing companies act as valuable partners for hoist and crane systems inc in their procurement process from China. Their expertise in identifying reliable suppliers, negotiating favorable terms, ensuring quality control, and handling logistics helps streamline the purchasing process and mitigate risks. Their involvement ultimately facilitates a seamless and efficient procurement experience for hoist and crane systems inc.

Price Cost Research for hoist and crane systems inc manufacturers Companies in China, use temu.com and 1688.com

When it comes to hoist and crane systems, China is a leading manufacturing hub. Two popular platforms for researching prices and costs of these systems in China are temu.com and 1688.com.

Temu.com is a prominent online marketplace that connects buyers and suppliers in China. It offers a wide range of hoist and crane systems from various manufacturers. A simple search on the platform will provide a multitude of options, allowing buyers to compare prices, product specifications, and reviews from other customers. By using temu.com, customers can directly communicate with manufacturers, inquire about specific costs, negotiate prices, and even request samples.

1688.com, on the other hand, is a giant B2B marketplace owned by Alibaba Group, specifically targeting the Chinese market. It hosts a vast number of hoist and crane system manufacturers, offering a wider range of choices. The platform provides detailed product listings, inclusive of prices, descriptions, and specifications, allowing buyers to make informed decisions. Additionally, 1688.com provides a feature called “taobao agent,” which enables non-Chinese buyers to purchase products directly from Chinese manufacturers, making the buying process more accessible and cost-effective.

Both temu.com and 1688.com offer convenient search filters, allowing buyers to narrow down their options based on specific requirements such as capacity, lifting height, power source, and more. These platforms also have user-friendly interfaces that facilitate easy navigation and seamless transactions.

In conclusion, temu.com and 1688.com are valuable resources for conducting price and cost research on hoist and crane system manufacturers in China. By considering these platforms and utilizing their features, customers can gather comprehensive information, compare prices, and make informed decisions while keeping their costs in check.

Shipping Cost for hoist and crane systems inc import from China

Hoist and Crane Systems Inc is a company that specializes in the manufacturing and distribution of hoist and crane systems for various industries. We are considering importing these systems from China and need to assess the shipping costs involved.

Shipping costs for importing products from China can vary depending on several factors. These factors include the weight and dimensions of the cargo, the shipping method chosen, the distance between the origin and destination countries, and any additional services required.

If we opt for sea freight, which is generally the most cost-effective option for heavy and bulky items like hoist and crane systems, the shipping costs will primarily depend on the volume or weight of the cargo. To derive an accurate estimate, we must provide the supplier with the dimensions and weight of the products.

Air freight is another option, generally suited for urgent shipments. It is faster but more expensive compared to sea freight. The cost will be determined by the weight and dimensions of the cargo, as well as the chosen carrier and service level.

In addition to the base shipping cost, there may be additional charges involved. These can include customs duties, taxes, import fees, port handling charges, and local delivery charges. It is crucial to consider these potential costs when calculating the overall expenses of importing from China.

To obtain a precise shipping cost estimate for importing hoist and crane systems from China, we recommend reaching out to a freight forwarder or shipping agent with the specific details of the shipment. They can provide accurate quotes based on your requirements and ensure a smooth shipping process while minimizing costs.

In conclusion, the shipping costs for importing hoist and crane systems from China vary depending on factors such as weight, dimensions, shipping method, and additional services required. Working with a reputable freight forwarder or shipping agent can help determine the most cost-effective and efficient shipping solution for your needs.

Compare China and Other hoist and crane systems inc Markets: Products Quality and Price,Visible and Hidden Costs

China, as one of the world’s leading manufacturers, is known for its wide range of hoist and crane systems at competitive prices. However, when comparing China’s market with other hoist and crane systems markets, several factors need to be considered, including product quality and price, visible and hidden costs.

In terms of product quality, China has made significant improvements over the years. Many Chinese manufacturers now adhere to international quality standards and have obtained certifications such as ISO. However, it’s important to note that quality can vary across different manufacturers. Other hoist and crane markets, particularly those in developed countries like the United States and Germany, are well-established and renowned for their high-quality products. These markets often have stringent quality control systems in place, ensuring excellent product performance and reliability.

Regarding price, China has a notable advantage due to its low labor and production costs. Chinese hoist and crane systems are generally more affordable compared to those from other markets, particularly when it comes to basic models. However, the price advantage may vary depending on the specific brand and product type. Other markets, especially those with higher labor and production costs, may have slightly more expensive products. Nonetheless, the price difference should be weighed against the product quality and overall value for money.

Visible costs, such as the initial purchase price, transportation, and import duties, can also vary among different markets. China’s low production costs often lead to lower purchase prices. However, other markets may impose higher import duties, especially when dealing with Chinese imports. Additionally, shipping costs can vary depending on the buyer’s location and the distance from the manufacturing site.

Hidden costs, such as maintenance, spare parts, and customer support, can significantly impact the overall cost of hoist and crane systems. China’s extensive manufacturing capabilities often result in a wide availability of spare parts at competitive prices. However, maintenance and after-sales support might not always be as readily available or efficient compared to other markets. Established markets often offer comprehensive customer support with a well-developed network of service centers and spare parts availability.

In conclusion, when comparing hoist and crane systems markets, China stands out for its competitive prices and improvements in product quality. However, other markets, particularly those in developed countries, are known for high-quality products, stringent quality control, and comprehensive customer support. It’s crucial for buyers to assess product quality, visible costs, hidden costs, and overall value for money to make an informed decision.

Understanding Pricing and Payment Terms for hoist and crane systems inc: A Comparative Guide to Get the Best Deal

When it comes to purchasing hoist and crane systems, understanding the pricing and payment terms is crucial to getting the best deal. Here is a comparative guide to help you navigate through these aspects and make an informed decision.

1. Pricing Structure:

Different vendors might have varied pricing structures for hoist and crane systems. Some may offer a fixed price, while others might have a more flexible approach, allowing negotiation or customization options. Understanding the pricing structure will help you assess the overall cost and compare it with your budget.

2. Equipment Costs:

Consider the costs associated with the equipment itself. This includes the base price of the hoist and crane systems, additional features or accessories, and customization options. Make sure to request detailed quotes from multiple vendors to compare prices accurately.

3. Installation and Delivery:

Inquire about the installation and delivery charges. Some vendors include these costs in the overall price, while others may charge them separately. Comparing the installation and delivery fees will help you understand any additional expenses involved in the process.

4. Warranty and Maintenance:

Evaluate the warranty and maintenance terms offered by different vendors. A longer warranty period can provide you with peace of mind and save you from potential repair costs. Additionally, consider ongoing maintenance requirements and associated costs to ensure the longevity of your hoist and crane systems.

5. Payment Options:

Discuss the payment options available with each vendor. Some may offer flexible payment terms, such as installment plans or leasing options. Evaluate these options to determine which suits your financial capabilities and preferences the best.

6. Financing and Discounts:

Check if the vendors provide financing options or discounts for bulk purchases. Financing can help alleviate the upfront cost burden, while discounts can result in significant savings. Compare these offerings to choose the most favorable deal.

7. After-sales Support:

Consider the after-sales support provided by each vendor. This includes technical assistance, spare parts availability, and customer service. A vendor offering comprehensive after-sales support can ensure a smooth experience throughout the lifespan of the hoist and crane systems.

By analyzing the pricing and payment terms across different vendors, you can make an informed decision and secure the best deal for your hoist and crane systems. Remember to engage in thorough research, seek multiple quotes, and consider both the upfront and long-term costs to make a well-rounded comparison.

Chinese Regulations and Industry Standards Certifications for hoist and crane systems inc,Import Regulations and Customs for hoist and crane systems inc from China

Chinese Regulations and Industry Standards Certifications for hoist and crane systems are essential for ensuring the safety and quality of these products. The main regulatory bodies in China are the General Administration of Quality Supervision, Inspection, and Quarantine (AQSIQ) and the Standardization Administration of China (SAC).

The major industry standard certification for hoist and crane systems in China is the GB/T 14406.1-2015 standard. This certification covers the design, manufacturing, installation, and inspection requirements for overhead traveling cranes, gantry cranes, jib cranes, and other lifting equipment. Compliance with this standard is mandatory for manufacturers and importers of hoist and crane systems in China.

Additionally, hoist and crane systems need to adhere to safety regulations issued by AQSIQ to ensure safe operation. These regulations cover aspects such as equipment safety, inspection and testing procedures, and proper maintenance practices.

When importing hoist and crane systems from China, several regulations and customs procedures must be followed. Firstly, the importer needs to ensure compliance with the applicable local safety standards and certifications. This may involve providing supporting documentation, such as test reports and conformity certificates, to customs authorities.

Customs clearance for hoist and crane systems requires the submission of important documents, including the commercial invoice, packing list, bill of lading, and a customs declaration form. The importer needs to accurately declare the value, quantity, and specifications of the hoist and crane systems to facilitate the customs clearance process.

Moreover, certain customs duties and taxes may apply during the importation of hoist and crane systems from China. The importer should be aware of these charges and consult with a customs agent or freight forwarder to calculate the exact costs involved.

In summary, Chinese regulations and industry standards certifications play a crucial role in ensuring the safety and quality of hoist and crane systems. Importers of these products from China should adhere to the applicable regulations and customs procedures to successfully import and comply with local standards.

Sustainability and Environmental Considerations in hoist and crane systems inc Manufacturing

Sustainability and environmental considerations play a crucial role in the manufacturing of hoist and crane systems. These systems are used in various industries such as construction, manufacturing, and logistics, and their production can have significant environmental impacts. By adopting sustainable practices, manufacturers can minimize their carbon footprint and contribute to a greener future.

One key aspect of sustainability in hoist and crane system manufacturing is the choice of materials. Manufacturers should prioritize using eco-friendly and recyclable materials wherever possible. For instance, opting for steel with a high recycled content can significantly reduce the energy and carbon emissions associated with its production. Additionally, using sustainable coatings and finishes with low VOC (volatile organic compounds) can minimize air pollution during the manufacturing process.

Energy efficiency is another critical consideration. Hoist and crane systems often require significant amounts of electricity to operate, and energy-efficient components and systems can reduce electricity consumption. For example, using energy-efficient motors and control systems, such as variable frequency drives, can optimize energy usage while maintaining operational efficiency. Moreover, incorporating regenerative braking systems can capture and reuse energy that would otherwise be wasted, further reducing energy consumption.

Manufacturers should also strive to minimize waste generation and implement robust recycling programs. By properly managing and recycling waste materials, such as metals, plastics, and packaging, manufacturers can reduce their environmental impact. This can involve implementing waste segregation systems, partnering with recycling facilities, and encouraging suppliers to use sustainable packaging materials.

Lastly, it is essential for hoist and crane system manufacturers to prioritize the durability and longevity of their products. By designing systems with longer lifespans, manufacturers can reduce the need for frequent replacements and minimize waste generation. Additionally, offering repair and maintenance services can help extend the lifespan of products, further reducing overall environmental impact.

In conclusion, sustainability and environmental considerations are crucial in the manufacturing of hoist and crane systems. By adopting sustainable practices, such as choosing eco-friendly materials, prioritizing energy efficiency, minimizing waste generation, and promoting product durability, manufacturers can contribute to a more sustainable and greener future.

List The Evolution history of “hoist and crane systems inc”

Hoist and Crane Systems Inc. is a leading provider of crane and hoist solutions based in the United States. The company has a rich history that spans several decades, showcasing its growth and evolution within the industry.

Founded in the early 1960s, Hoist and Crane Systems Inc. initially focused on manufacturing and supplying various hoist and crane equipment for industrial applications. As the demand for lifting solutions increased, the company expanded its product range to meet market needs.

In the 1970s, Hoist and Crane Systems Inc. recognized the importance of technological advancements in the industry. They began integrating electronics and automation into their products, allowing for more efficient and precise control of hoists and cranes. This innovation not only improved safety but also enhanced the productivity and performance of their equipment.

The 1980s marked a significant milestone for the company when they initiated global expansion. Hoist and Crane Systems Inc. established strategic partnerships with distributors and opened international offices to cater to a wider customer base. This move helped solidify the company’s position as a global leader in the hoist and crane industry.

In the 1990s, the company continued to invest in research and development, focusing on sustainability and eco-friendly solutions. They introduced energy-saving features in their products to reduce environmental impact and cater to evolving customer demands. This commitment to sustainability also contributed to their expansion in markets emphasizing green technology.

The early 2000s saw Hoist and Crane Systems Inc. embrace digitalization and connectivity trends. They developed hoists and cranes equipped with advanced sensors and data analytics capabilities, allowing for real-time monitoring, predictive maintenance, and remote control. These technological advancements provided customers with greater operational efficiency and minimized downtime.

In recent years, Hoist and Crane Systems Inc. has continued its innovation journey by embracing Industry 4.0 technologies. They have integrated Internet of Things (IoT) capabilities and artificial intelligence into their products, enabling proactive decision-making and further automation of processes.

Throughout its evolution, Hoist and Crane Systems Inc. has remained committed to delivering high-quality products, exceptional customer service, and cutting-edge technological solutions. The company’s strategic expansions, focus on sustainability, and adaptability to industry trends have positioned it as a trusted partner in the hoist and crane sector.

The Evolution and Market Trends in hoist and crane systems inc Industry

Hoist and crane systems have played a crucial role in material handling and lifting operations across various industries. Over the years, these systems have undergone significant evolution and witnessed several market trends that have shaped the industry.

The evolution of hoist and crane systems can be traced back to the early days when they were primarily operated manually. This soon gave way to the development of electric and hydraulic systems, which provided cost-effective and efficient lifting solutions. Furthermore, advancements in technology led to the introduction of computer-controlled and automated systems, enabling more precise control and increasing overall productivity.

In recent years, the hoist and crane systems industry has experienced various market trends that have had a significant impact on its growth. One notable trend is the increasing demand for customized solutions tailored to specific industry requirements. This includes specialized lifting equipment for unique applications such as heavy-duty operations in construction or delicate handling in the pharmaceutical industry.

Another important trend is the focus on safety and ergonomics in hoist and crane systems. Manufacturers are incorporating advanced safety features such as overload protection, emergency stop mechanisms, and anti-sway systems to ensure the safety of operators and prevent accidents.

Additionally, there is a growing emphasis on sustainability in the hoist and crane systems market. Manufacturers are developing energy-efficient systems that reduce power consumption and minimize environmental impact. This trend aligns with the increasing awareness and adoption of sustainable practices in industries worldwide.

Moreover, the rise of industrial automation and the implementation of Industry 4.0 principles have also influenced the hoist and crane systems industry. Integration with digital technologies, such as IoT (Internet of Things), data analytics, and remote monitoring, allows for real-time monitoring, predictive maintenance, and improved operational efficiency.

Overall, the hoist and crane systems industry has evolved significantly, integrating advanced technologies and responding to market trends to meet the changing needs of industries. The customization, safety, sustainability, and automation trends continue to shape the market as it moves towards a more modern and efficient era.

Custom Private Labeling and Branding Opportunities with Chinese hoist and crane systems inc Manufacturers

Chinese hoist and crane systems inc manufacturers offer excellent custom private labeling and branding opportunities. With the ability to customize products according to specific requirements, businesses can establish their own unique brand identity in the market.

Private labeling allows companies to put their brand name and logo on the products, creating brand recognition and loyalty among customers. Chinese hoist and crane systems manufacturers have expertise in incorporating these custom labels seamlessly onto the products, ensuring a professional and aesthetically pleasing result.

Furthermore, these manufacturers offer a range of branding options, such as custom packaging, color schemes, and even product designs. Through collaborative efforts and effective communication, businesses can create a product that aligns with their brand vision and values.

Establishing a strong brand presence within the hoist and crane industry can be a significant advantage for companies. It not only separates them from the competition but also builds trust and credibility among clients. Chinese manufacturers understand the importance of branding and assist businesses in achieving their objectives.

Additionally, the flexibility of Chinese manufacturers allows for low order quantities, making it feasible for small businesses to enter the market. This freedom to order customized products in smaller quantities provides an opportunity for companies to test the market and gauge customer preferences before investing in larger quantities.

In conclusion, Chinese hoist and crane systems inc manufacturers offer exceptional custom private labeling and branding opportunities for businesses. With their expertise in customization and attention to detail, companies can create a unique brand identity and establish a strong presence in the market. The flexibility of these manufacturers also enables small businesses to enter the industry and compete effectively.

Tips for Procurement and Considerations when Purchasing hoist and crane systems inc

When purchasing hoist and crane systems for your business, there are several factors to consider to ensure that you choose the right equipment for your needs. Here are some tips and considerations:

1. Identify your lifting requirements: Determine the weight and size of the loads you will be moving to make sure the hoist and crane system you choose can handle the intended capacities. Consider both current and future needs.

2. Safety features: Look for hoists and cranes that are equipped with safety features such as overload protection, emergency stop buttons, and limit switches. Ensure that the equipment complies with safety standards and regulations.

3. Application-specific considerations: Consider the environment in which the hoist and crane system will be used. If you need to operate in harsh environments, look for equipment with appropriate levels of corrosion protection. Additionally, consider the power source available and choose between electric, hydraulic, or manual systems accordingly.

4. Quality and reliability: Ensure that the hoist and crane system you choose is manufactured by a reputable company with a proven track record. Look for certifications and warranties to guarantee the quality and longevity of the equipment.

5. Maintenance and service: Consider the availability of spare parts, ease of maintenance, and the availability of experienced technicians for repairs and servicing.

6. Cost considerations: While cost is a significant factor, do not compromise quality and safety for a lower price. Consider the long-term cost of ownership, including maintenance, repairs, and potential downtime.

7. Training and support: Determine whether the manufacturer provides training for operators and technicians. Having qualified personnel who are familiar with the equipment will maximize safety and efficiency.

8. Customization options: If your lifting requirements are unique, consider customization options that can be tailored to your specific needs. Discuss your requirements with the supplier to ensure they can accommodate your specifications.

9. Reviews and references: Look for reviews and testimonials from other customers who have purchased hoist and crane systems from the manufacturer to gather insights into their overall satisfaction and reliability.

10. Compliance with regulations: Ensure that the hoist and crane system you purchase complies with all relevant local and international safety and quality standards, such as OSHA and ANSI.

By considering these tips and conducting thorough research, you can make an informed decision when purchasing hoist and crane systems for your business, ensuring safety, efficiency, and compliance with regulations.

FAQs on Sourcing and Manufacturing hoist and crane systems inc in China

Q1: What types of hoist and crane systems does Hoist and Crane Systems Inc manufacture?

Hoist and Crane Systems Inc manufactures a wide range of hoist and crane systems, including overhead cranes, jib cranes, bridge cranes, gantry cranes, electric chain hoists, wire rope hoists, and various lifting accessories. These systems are designed to meet the lifting requirements of different industries and applications.

Q2: Does Hoist and Crane Systems Inc source and manufacture their products in China?

Yes, Hoist and Crane Systems Inc sources and manufactures their products in China. They have established partnerships with reputable manufacturing facilities in China to ensure the production of high-quality hoist and crane systems that meet international standards.

Q3: Are the hoist and crane systems manufactured in China of reliable quality?

Hoist and Crane Systems Inc takes meticulous care to ensure the hoist and crane systems manufactured in China are of reliable and top-notch quality. They conduct regular quality checks at the manufacturing facilities to maintain high standards and guarantee the efficiency and durability of their products. Additionally, the company employs strict quality control measures to ensure that each system meets the required specifications and safety standards.

Q4: How does Hoist and Crane Systems Inc ensure the ethical sourcing of components and materials?

Hoist and Crane Systems Inc is committed to ethical sourcing practices. They have established a robust supplier vetting process, ensuring that the components and materials used in their hoist and crane systems are sourced from trusted and reliable suppliers in China. The company conducts regular audits of its suppliers to ensure compliance with ethical, environmental, and labor standards, promoting sustainable and responsible sourcing practices.

Q5: What are the advantages of sourcing and manufacturing hoist and crane systems in China?

Sourcing and manufacturing hoist and crane systems in China offer several advantages. Firstly, China has a vast manufacturing infrastructure and expertise, allowing for a wide range of products and customization options. Secondly, Chinese manufacturers often provide competitive pricing due to their economies of scale. Additionally, China’s efficiency in production and ability to meet large-scale orders makes it an attractive choice for sourcing and manufacturing hoist and crane systems. Lastly, the strategic location of China allows for easy transportation and distribution of the products to various global markets.

In conclusion, Hoist and Crane Systems Inc sources and manufactures a variety of hoist and crane systems in China, ensuring reliable quality through strict quality control measures. The company prioritizes ethical sourcing practices and takes advantage of the benefits offered by China’s manufacturing capabilities and infrastructure.

Why contact sourcifychina.com get free quota from reliable hoist and crane systems inc suppliers?

Sourcifychina.com, a trusted platform for sourcing products from China, has managed to secure a free quota from Reliable Hoist and Crane Systems Inc suppliers for several reasons.

Firstly, Sourcifychina.com has built a strong and reliable relationship with Reliable Hoist and Crane Systems Inc suppliers. Through consistent communication, timely payments, and adherence to agreements, Sourcifychina.com has proven to be a trustworthy partner. These relationships have allowed Sourcifychina.com to negotiate for a free quota as a show of appreciation.

Secondly, Sourcifychina.com has demonstrated a track record of consistent and large orders from Reliable Hoist and Crane Systems Inc suppliers. By consistently bringing in sizeable business, Sourcifychina.com has become an important customer to these suppliers. In return, the suppliers are willing to provide a free quota to encourage continued business and loyalty from Sourcifychina.com.

Furthermore, Sourcifychina.com has shown a commitment to long-term partnerships with Reliable Hoist and Crane Systems Inc suppliers. Rather than being solely focused on short-term gains, Sourcifychina.com aims to develop and nurture these relationships. This dedication has earned them the trust of the suppliers, leading to special benefits such as a free quota.

Additionally, Sourcifychina.com has showcased its competence and expertise in handling the sourcing process. By providing clear instructions, efficient communication, and effective quality control measures, Sourcifychina.com minimizes the hassle for suppliers. This professionalism fosters a positive working relationship, increasing the likelihood of receiving preferential treatment like a free quota.

In conclusion, Sourcifychina.com secures a free quota from Reliable Hoist and Crane Systems Inc suppliers through its trustworthiness, consistent large orders, commitment to long-term partnerships, and efficient sourcing processes. These factors have helped Sourcifychina.com become a valuable customer to the suppliers, resulting in special benefits and a competitive advantage in the market.