Knowledge about Cartoning Packaging

Cartoning packaging is a type of packaging that uses a carton made of paperboard or corrugated fiberboard to contain and protect products. It is commonly used in the food, beverage, pharmaceutical, and consumer goods industries.

A carton packaging can come in various shapes and sizes, and may be customized to fit the specific needs of a product. It can be designed with different closure mechanisms, such as tuck-end flaps, glue, or adhesive tape. Cartoning packaging may also feature additional elements, such as windows or inserts for product display or promotion.

When it comes to choosing the right cartoning packaging for a product, several factors need to be considered, such as the type of product, its size and weight, and the distribution and storage requirements. For example, fragile or perishable items may need extra protection, while heavy items may require a stronger, more durable carton.

Another important aspect to consider when using cartoning packaging is sustainability. Many consumers are now more conscious about the environmental impact of packaging and are looking for greener alternatives. Using recyclable or biodegradable materials, reducing the amount of packaging, or optimizing the design for transportation and storage can all help reduce the environmental impact of cartoning packaging.

In conclusion, knowing about cartoning packaging is essential for any business that produces and distributes products. Understanding the different types of cartons available, their features and benefits, and how to optimize them for sustainability can make a significant difference in product quality, cost-effectiveness, and environmental impact.

Various Types of Cartoning Packaging

Cartoning packaging is a type of packaging used for various products to ensure safety and ease of handling. Several types of cartoning packaging are available, each providing unique features and benefits. Here are some of the most popular types of cartoning packaging:

1. Tuck Top Carton: It is a classic carton style that is easy to assemble and can be sealed with glue, staples or tape. The tuck top carton is commonly used for packaged foods, pharmaceuticals, and small retail items.

2. Reverse Tuck Cartons: Similar to the tuck top carton, reverse tuck cartons have the sides tucked inwards and the front flap tucks in rearward. They are employed for products that are smaller in size such as lipsticks, creams, medical devices among others.

3. Tray & Sleeve Carton: This type of package is made up of a sleeve and a tray. The sleeve is movable and can slip off to form a rectangular tray. Tray & Sleeve cartons can be manufactured from a variety of materials and are commonly used for food products and other retail items.

4. Seal End Cartons: These cartoning packages have a unique design and are perfect for products that need to be sealed with high strength. They provide a lot of protection from dust and moisture, and can be made from various materials including paper, plastic or foil.

5. Gable top Cartons: Gable top carton is a convenient package with a unique top and is ideal for juices, milk and other beverages.

6. Pillow Pouch Cartons: Pillow pouch cartons are flexible packages that are created in a pillow shape. They are great for products that require flexibility, like cosmetics and personal care products.

In conclusion, cartoning packaging is an ideal way to protect, manage and present various products. Manufacturers can choose from a wide range of cartoning packages depending on their product, budget, and marketing demands to provide adequate marketing and protection to their products.

FAQ sourcing Cartoning Packaging manufacturer from China

If you’re looking to source cartoning packaging from a manufacturer in China, you likely have a lot of questions. We’ve compiled a list of Frequently Asked Questions to help you navigate the process.

Q: Why should I source cartoning packaging from a manufacturer in China?

A: China is the world’s largest manufacturer and exporter of packaging materials, offering a wide range of products at competitive prices.

Q: What types of cartoning packaging can I source from China?

A: Chinese manufacturers offer a variety of cartoning packaging, including folding cartons, corrugated boxes, and rigid boxes.

Q: How do I find a reliable manufacturer in China?

A: Do your research and look for manufacturers with a proven track record of producing high-quality packaging. Check references and ask for samples before placing an order.

Q: Can I customize my cartoning packaging?

A: Yes, most manufacturers in China offer custom packaging solutions to suit your specific needs and requirements.

Q: What is the production time for cartoning packaging in China?

A: Production times vary depending on the complexity of the packaging and the quantity ordered. However, most manufacturers can produce packaging in as little as two weeks.

Q: What is the minimum order quantity (MOQ) for cartoning packaging in China?

A: MOQs vary depending on the manufacturer and the type of packaging being produced. However, most manufacturers will require a minimum order of 1,000 to 5,000 units.

Q: What are the payment terms when sourcing cartoning packaging from China?

A: Payment terms vary among manufacturers, but most will require a deposit before production begins and the remaining balance when the order is ready to ship.

In conclusion, sourcing cartoning packaging from a manufacturer in China can be a great way to access a wide range of products at competitive prices. However, it’s important to do your research and work with a reliable manufacturer that can produce high-quality packaging to meet your unique needs.

Applications of Cartoning Packaging

Cartoning packaging is a type of packaging that is used to store and transport goods safely. This type of packaging is designed to provide protection and security to the goods inside while making it easy for them to be moved from one place to another.

One of the most common applications of cartoning packaging is in the food industry. This type of packaging is used to pack a wide variety of food items, including cereals, snacks, frozen foods, and bakery products. It ensures that the food items are kept fresh and protected from contamination during transport and storage.

Another application of cartoning packaging is in the pharmaceutical industry. This type of packaging is used to store and transport medicines, medical devices, and other healthcare-related products. It ensures that the drugs and medical devices remain sterile and safe during transport and storage.

Cartoning packaging is also used in the cosmetics industry. This type of packaging is used to pack a wide variety of cosmetic products, including creams, lotions, and serums. It ensures that the products remain fresh and protected from contamination during transport and storage.

In addition, cartoning packaging is also used in the electronics industry. This type of packaging is used to store and transport electronic goods such as phones, tablets, and cameras. It ensures that the electronic goods are protected from damage during transport and storage.

Cartoning packaging is also used in the e-commerce industry. This type of packaging is used to store and transport products that are sold online. It ensures that the products are protected from damage during transport and also helps to reduce the risk of theft.

In conclusion, cartoning packaging is a versatile type of packaging that is widely used in various industries. Its use has helped to ensure that goods are protected from damage, contamination, and theft during transport and storage.

Manufactured Products made of Cartoning Packaging

Cartoning packaging is widely used for the manufacturing of products such as food, electronics, cosmetics, and pharmaceuticals. The materials used in cartoning packaging are lightweight and cost-effective, making it an ideal option for mass production.

One of the most significant benefits of cartoning packaging is that it can be easily customized to fit the product’s shape and size. The packaging can be designed in various styles, such as different shapes, colors, and opening mechanisms. This flexibility makes cartoning packaging desirable for manufacturers as they can create unique and personalized packaging for their products.

The packaging can be made of various materials such as paperboard, corrugated material, or a combination of both. This material is environmentally friendly and can be recycled, leading to minimal waste production.

Cartoning packaging is also secure, reducing the risk of contaminated or damaged products. The packaging protects the product from exposure to light, air, and moisture, which ensures that the product remains intact and is safe for consumption or use.

One major disadvantage of cartoning packaging is that it lacks the durability and strength of other materials like plastic. However, this can be addressed through combining cartoning packaging with other packaging materials to decrease the risk of damage and ensure the product’s safety.

In conclusion, cartoning packaging is a reliable and eco-friendly solution for packaging manufactured products. Its flexibility and customization features make it an excellent packaging choice for manufacturers looking to differentiate their products from others. It is an affordable, recyclable, and secure packaging option that ensures the product is safe for consumption or use.

The Evolution history of Cartoning Packaging

Cartoning packaging has been used for centuries to conveniently transport and store various items. The evolution of this packaging can be traced back to the early 19th century when cardboard boxes began to replace wooden crates.

In the early 1900s, cartoning packaging became more widespread as the demand for pre-packaged goods increased. Advances in printing technology also allowed for colorful and visually appealing packaging designs that helped differentiate products from their competitors.

During the latter half of the 20th century, cartoning packaging evolved to meet the needs of various industries. For example, pharmaceutical companies began to use child-resistant packaging to help prevent accidental ingestion of medication by young children.

The rise of e-commerce in the 21st century has led to further developments in cartoning packaging. Companies have looked for ways to streamline their packaging processes while also reducing waste. This has led to the development of smaller, more efficient boxes that use less material, as well as the integration of automation and technology into the packaging process.

Today, cartoning packaging continues to evolve as companies seek to meet changing consumer demands and environmental concerns. From eco-friendly packaging materials to innovative designs that enhance the customer experience, the future of cartoning packaging looks bright.

The Process of Cartoning Packaging

Cartoning is a process that involves packing products into cartons for transportation or storage. The cartoning packaging process is essential for the protection of products during transportation, as well as ensuring that they are presentable when displayed for sale. Here is an overview of the process of cartoning packaging.

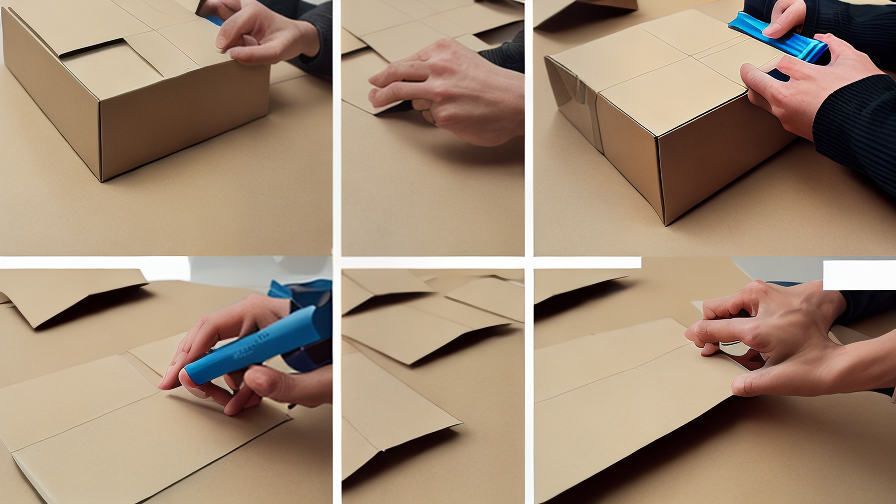

Firstly, products are prepared for packaging by arranging them in the right order and grouping them according to their size, shape, and quantity. Once the products are arranged in the correct sequence, they are fed into a machine that will wrap and seal them in cartons.

The machine used for the cartoning process will depend on the type of product being packaged. The machine will fill the cartons with the products and seal the cartons using heat, glue, or pressure. The machine may also add labels or printed information to the cartons during the packaging process.

Once the cartons are sealed, they are inspected for any defects or damages. This ensures that the product is well-protected and that the packaging is of the highest quality. The packaging is also checked for correct labeling information to ensure that the correct product is being shipped.

The final step of the cartoning packaging process is stacking the sealed cartons onto pallets for transportation. The pallets are then wrapped in plastic or shrink wrap to protect them during transportation.

In conclusion, the cartoning packaging process is essential for the transportation and storage of products. It involves arranging products in the correct sequence and using machines to wrap and seal them in cartons. The packaging is checked for any defects or damages, and the cartons are stacked onto pallets for transportation. The process ensures that products are well-protected during transportation and reach their destination in good condition.

Benefits Advantages of Utilizing Cartoning Packaging

Cartoning packaging refers to the process of packing or wrapping products in a carton or box. The packaging is widely used by various industries, including food, cosmetics, pharmaceuticals, and electronic devices, among others, due to its numerous benefits and advantages.

The first significant advantage of cartoning packaging is its sustainability. The packaging is made of recyclable materials, including paper and cardboard, which can be recycled and reused, reducing environmental waste. Additionally, the packaging helps to reduce the overall carbon footprint of the industry and promote eco-friendly practices.

Another benefit of cartoning packaging is its cost-effectiveness. The materials required to make the packaging are readily available and affordable, making it a cost-effective option for businesses looking to package their products. Additionally, the packaging is lightweight, reducing shipping and handling costs.

Cartoning packaging is also versatile, and businesses can customize the packaging to meet their specific needs. The packaging can be designed in various sizes, shapes, and colors to match the product and brand image. The customization helps to create a unique identity for the brand while keeping the product well-protected.

In addition to customization, cartoning packaging provides excellent protection for the product. The packaging is sturdy and strong, providing a safe and secure environment for the product during transportation and storage. The packaging also protects the product from external factors such as dust, moisture, and sunlight that may affect the quality and freshness of the product.

Lastly, cartoning packaging is easy to handle and store. The packaging is designed to be convenient and easy to use, requiring minimal effort to assemble and pack. The packaging is also stackable, maximizing storage space, and making it easy to organize and transport.

In conclusion, cartoning packaging offers numerous benefits and advantages, making it a popular choice for businesses across various industries. Its sustainability, cost-effectiveness, versatility, excellent protection, and ease of handling make it a reliable packaging solution that helps to enhance product value and brand image.

Disadvantages Cartoning Packaging

Cartoning packaging is the process of creating boxes to contain and protect a wide range of products, including food, cosmetics, toys, and electronics. While cartoning packaging has numerous advantages, including widespread usage, cost-effectiveness, and enhanced brand identification, it also has several disadvantages that should be considered before using it.

One significant disadvantage of cartoning packaging is its environmental impact. While corrugated cartons can be recycled, many of them end up in landfills, where they take up valuable space and contribute to the pollution of our environment. Additionally, the production of cartons requires the use of a significant amount of resources, including water, energy, and wood, which can result in deforestation and other negative environmental impacts.

Another disadvantage of cartoning packaging is its lack of flexibility. Cartons come in fixed sizes, which may not suit all products. This issue can create potential storage and transportation problems as well. It requires more space to store more products when different cartons sizes needed. For example, products that are unusually shaped or large may need custom cartons, which can be costly and time-consuming to produce. Moreover, it can be a problem in retail stores due to the limited storage.

Lastly, cartoning packaging can be challenging to open and dispose of properly. Consumers may have difficulty opening the cartons, which can lead to product damage or frustration. Additionally, some consumers may not know how to recycle the cartons properly, leading to wasted resources and increased pollution potential.

In conclusion, while cartoning packaging has many advantages, it also has several disadvantages that must be taken into consideration. These include its negative environmental impact, limited flexibility, and difficulty in opening and disposing of properly for consumers. Despite these disadvantages, cartoning packaging continues to be one of the most commonly used types of packaging worldwide, thanks to its affordability and versatility.

Selecting the Ideal Manufacturer Cartoning Packaging

When it comes to cartoning packaging, selecting the right manufacturer is critical. The ideal manufacturer will not only provide you with high-quality packaging but can also advise on the most suitable type of packaging for your products. There are several factors to consider when selecting the ideal manufacturer for your cartoning packaging.

Experience – You want to work with a company that has proven experience in producing successful packaging solutions. A company with years of experience in the industry will understand your needs, and they will be able to provide relevant advice based on their expertise.

Quality – The manufacturer’s quality level is another essential factor to consider. You want to be sure that they use top-quality materials in their packaging manufacturing process. It is important to note that quality cartoning packaging will protect your products from damage during shipping and handling.

Customization – The manufacturer should be able to customize your cartoning packaging to fit your specific needs. This includes everything from size, shape, and design, to the materials used in the packaging.

Pricing – Price is another significant factor to consider when selecting a cartoning packaging manufacturer. You want to work with a company that offers competitive pricing without sacrificing quality. Be sure to compare prices and quality levels among different manufacturers before making a decision.

Customer Service – The ideal cartoning packaging manufacturer should provide excellent customer service. They should be able to communicate with you effectively, listen to your needs, and provide timely feedback.

In conclusion, choosing the right cartoning packaging manufacturer is essential for any business. With the factors mentioned above in mind, you should be able to narrow down the options and find the ideal manufacturer for your packaging needs. Remember to prioritize quality and customization, as these will ensure that your products are protected during transit and presented in the best way possible.

Things to Consider When Purchasing Cartoning Packaging

When it comes to packaging products, there are a lot of options out there. One of the most popular options is cartoning packaging. Cartoning packaging refers to the process of packaging a product in a carton or box. It is an affordable and customizable way to package products that come in various shapes and sizes. Before making a purchase, there are several things to consider when deciding on the right cartoning packaging for your product.

1. Product Size and Weight: The size and weight of your product is crucial when selecting cartoning packaging. Choosing the wrong size could result in damage to your product during shipping or storage. Ensure that your product fits snugly into the packaging without adding extra weight.

2. Packaging Strength: Ensure that the cartoning packaging you select is of high quality and will withstand normal shipping and handling conditions. The thickness of the cartoning packaging should correspond with the weight of your product.

3. Customization Options: Customization is key to building brand awareness and identity. Most cartoning packaging companies offer an array of customization options such as printing, coloring, and designing. Ensure that the company you choose offers reliable customization options that meet your product’s branding strategy.

4. Sustainability: With the global concern for the environment, underscore the importance of sustainable packaging. While selecting cartoning packaging, consider environmentally friendly options that use recycled materials or cut down on the total amount of packaging used.

5. Equipment Compatibility: Before purchasing cartoning packaging, confirm that your equipment can handle the packaging process. Different cartoning packaging machines have different requirements on the size and weight of the carton or box.

In conclusion, when purchasing cartoning packaging, consider your product size and weight, packaging strength and customization options, sustainable packaging, and equipment compatibility. By doing so, you can help protect your product during shipping, reduce costs, and effectively promote your brand.

Properties of Cartoning Packaging

The properties of cartoning packaging make it a popular choice for packaging various products. Cartoning packaging is made of cardboard, which is known for its strength, durability, and versatility. The packaging can be customized to fit the product, and it can also display product information and branding.

Cartoning packaging has several properties that make it ideal for packaging. Firstly, it is lightweight, which makes transportation and handling easy. The packaging can be easily stacked and transported in large quantities, which reduces transportation costs.

Secondly, cartoning packaging is durable and reliable. The packaging can protect the product from external factors such as moisture, dust, and temperature changes. This helps to prolong the shelf life of the product and maintain its quality.

Thirdly, cartoning packaging is customizable. The packaging can be designed to match the product’s shape, size, and weight. This ensures that the product fits perfectly in the packaging, which reduces the risk of damage during transportation.

Fourthly, cartoning packaging is eco-friendly. Cardboard is made from renewable resources and can be recycled. This makes cartoning packaging a sustainable option that helps reduce waste and promotes environmental protection.

Finally, cartoning packaging is cost-effective. The materials used in cartoning packaging are affordable and readily available. The packaging is also easy to assemble, which reduces labor costs.

In conclusion, cartoning packaging is a versatile option that is ideal for packaging various products. Its properties, including lightweight, durability, reliability, customizability, eco-friendliness, and cost-effectiveness make it an ideal packaging solution.

How to use Cartoning Packaging

Cartoning packaging is a popular choice of packaging for many different products, including food, beverages, pharmaceuticals, and cosmetics. It is a cost-effective and efficient way to protect and transport your products, while also creating a desirable image for the consumer.

The first step in using cartoning packaging is to choose the right type of carton for your product. There are many different types of cartons available, including corrugated boxes, folding cartons, and rigid boxes. Each type of carton has its own advantages and disadvantages, and the choice of carton will depend on the product being packaged, the volume of products, and the budget.

Once you have chosen the right type of carton, the next step is to design the packaging. This is an important process as the carton design is what will draw customers to your product. The packaging should be visually appealing, easy to read, and include important information such as the product name, brand, and ingredients.

After designing the packaging, the next step is to produce the cartons. This can be done in-house or outsourced to a packaging company. The production process involves cutting and folding the carton, printing the design onto the carton, and then assembling the carton.

When the cartons have been produced, it is time to fill them with your products. This can be done manually or using a cartoning machine. Cartoning machines are an efficient way to fill cartons, as they can fill a large volume of cartons quickly and accurately.

Finally, the filled cartons are ready to be stored and shipped. Cartoning packaging is designed to protect products during storage and transport, ensuring they arrive at their destination in perfect condition.

In conclusion, cartoning packaging is a cost-effective and efficient way to package your products. By choosing the right type of carton, designing the packaging, producing the cartons, filling them with your products, and storing and shipping them, you can ensure your product arrives in perfect

Glossary Terminology Terms for Cartoning Packaging

Cartoning Packaging refers to the process of assembling, filling and sealing cartons with products for shipment or storage. The understanding of certain key terminology terms within this packaging process is crucial, and so here is a list of the most commonly-used terms in the industry.

1. Carton: This term refers to a box made out of paperboard. This container is assembled, filled, and sealed during the packaging process.

2. Hopper: This is a container that holds the product that will be filled into the carton during the packaging process.

3. Conveyor: This is a mechanized system for transporting cartons and products to be packaged. It speeds up the packaging process and makes it more efficient.

4. Carton erector: This is a machine that opens the folded carton into the desired shape.

5. Closing and sealing: This refers to the process of closing and sealing the carton with either adhesive tape or glue.

6. Overwrap: This is a material made out of either plastic or paper that is wrapped around the finished carton to protect it during shipping.

7. Tuck flap: This refers to the tab closure on the top of the carton which folds over and tucks inside the outer flaps.

8. Glue flap: This refers to the tab closure on the top of the carton which is sealed with glue.

9. Window: This is a window-like opening on the front of the carton that displays the contents inside.

10. Insert: This refers to an additional piece of packaging that is inserted into the carton for either promotional or protective purposes.

The above list of terminology terms for Cartoning Packaging is a basic and essential guide that helps in understanding the different processes of packaging. The knowledge of these terminology terms allows businesses to discuss and communicate their packaging needs effectively with packaging experts.

Cartoning Packaging Price

Cartoning packaging is used to package different types of products such as food, pharmaceuticals, cosmetics, and others. It is an efficient and easy way of getting products on the market speedily while ensuring that they are secure and presentable. When considering the cost of cartoning packaging, it is important to take into account factors such as the type of material used, the size of the packaging, and the printing process involved.

The price of cartoning packaging varies according to the type of material used. Cardboard is one of the most commonly used materials for carton packaging because it is cost-effective and easy to obtain. Plastic, on the other hand, is more expensive than cardboard but it is more durable and can protect products from moisture and airborne contaminants. The price of glass packaging is much higher than cardboard or plastic, but it adds a touch of elegance to the product, making it more attractive to consumers.

Another factor that influences the cost of cartoning packaging is the size of the packaging. The bigger the carton, the more expensive it is to produce, as it requires more materials and labor. In addition, larger cartons require more storage space, which adds to the cost of production.

The printing process used also plays a significant role in determining the cost of cartoning packaging. High-quality printing requires more time and expertise, and therefore costs more than a simple black and white design. Color, complexity, and graphics used in the design also increase the price of cartoning packaging.

In conclusion, the cost of cartoning packaging varies depending on the material used, size of the packaging, and printing process used. Businesses must consider their budget and the type of product being packaged when selecting the right carton packaging. It is important to balance quality and cost-effectiveness while ensuring the packaging is fit for purpose to attract customers and protect the product.