Knowledge about Biscuit Making Machine

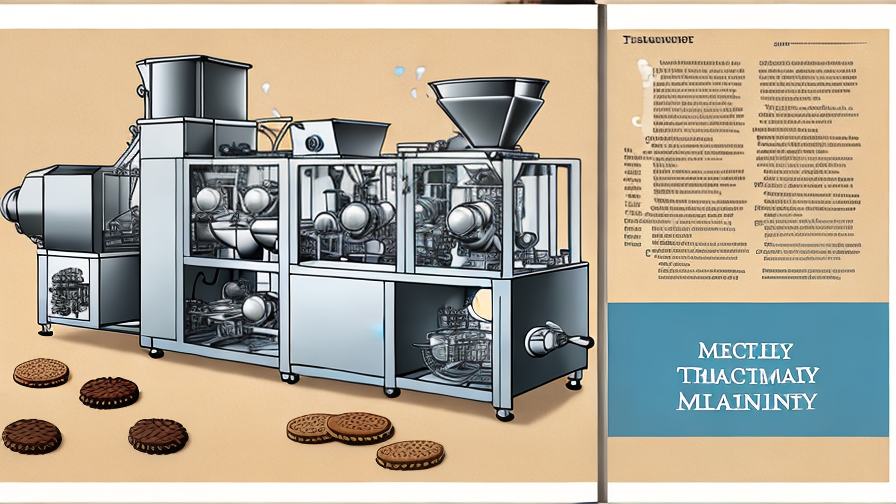

Biscuit making machines have become essential equipment in the food industry for their efficiency and speed. But to use them effectively, you need some basic knowledge about how they work.

These machines are made up of several components, including the dough mixer, feeding unit, laminating unit, and forming die. The dough mixer is used to combine the ingredients, while the feeding unit is designed to move the dough through the machine. The laminating unit is responsible for sheeting the dough consistently and evenly, while the forming die is responsible for shaping the dough into the desired biscuit.

One of the most critical factors in biscuit making is the dough’s consistency or the ingredients’ ratio, and this can be achieved by precise measurement of the ingredients. Once all ingredients have been mixed, the dough should be allowed to rest for a while to relax the gluten, making it easy to work with.

Feeding the dough into the machine requires some level of skill too, as too much dough can clog the machine while too little may not allow for consistent production. Before feeding the machine, ensure that the blades are clean and in good condition.

The laminating unit is crucial as it determines the texture of the biscuit. To achieve the desired thickness, you should adjust the roller gap using the machine’s gauge or control panel.

Finally, the forming die shapes the dough into the final product. Depending on the type of biscuit desired, various dies can be used, such as those for round biscuits, rectangular biscuits, or fancy biscuits. It’s essential to change the forming die regularly to avoid cross-contamination and ensure consistent production.

In conclusion, biscuit making machines have changed the food industry significantly, increasing production efficiency while reducing labor costs. However, to achieve optimal production and guarantee quality products, you need some basic knowledge about the different components and processes involved in making biscuits with these machines.

Various Types of Biscuit Making Machine

Biscuit making machines are an essential component of a biscuit production line. These machines help to automate the processes involved in producing biscuits and cookies, thereby increasing efficiency and reducing labor costs. There are different types of biscuit making machines available, based on the specific needs of the manufacturer.

The first type of biscuit making machine is the dough mixer. This machine is used to mix the dough ingredients, including flour, sugar, butter, and water, to create a consistent and uniform dough. The dough mixer can be either a vertical or horizontal machine, depending on the manufacturer’s preference.

The sheeter is another type of biscuit making machine. This machine is used to spread out the dough to a uniform thickness. It is equipped with a set of rollers that flatten the dough to the required thickness. The sheeter can be manual or automatic, depending on the size of the biscuit production line.

Next is the rotary molder. This machine assists in shaping the dough into the desired shape, such as round, square, or rectangular shapes. The rotary molder consists of cylindrical rollers that shape the dough as it passes through them.

The gauge roll is another type of biscuit making machine. It is used to create a uniform thickness for the dough sheet produced by the sheeter. The gauge roll has a series of rollers arranged in decreasing diameters, which press the dough sheet to the desired thickness.

Another machine is the biscuit cutting machine. This machine is used to cut the dough into specific shapes and sizes. The biscuit cutting machine can be either rotary or reciprocating. The rotary machine cuts the dough in a circular motion, while the reciprocating machine cuts in a back-and-forth motion.

Finally, the baking oven is the most important machine in the biscuit production line. The oven bakes the biscuits to the desired color and texture. There are different types of baking ovens, including the direct gas-fired oven, indirect gas-fired oven, and electric oven

FAQ sourcing Biscuit Making Machine manufacturer from China

Biscuit making machines have become a popular investment option for many entrepreneurs or companies that aim to produce large quantities of biscuits for commercial purposes. Many manufacturers in China offer these machines at various prices and specifications, making it a bit tricky to choose the best one. Here are some frequently asked questions (FAQs) when sourcing a biscuit making machine manufacturer from China.

Q: What are the factors to consider when choosing a biscuit making machine manufacturer in China?

A: Consider the manufacturer’s reputation, experience, product quality, delivery time, and after-sales service. Also, look for manufacturers who offer customizable solutions to meet your specific needs.

Q: What are the types of biscuit making machines Chinese manufacturers offer?

A: Most Chinese biscuit making machine manufacturers offer wire cutters, rotary machines, and laminators, to mention a few.

Q: What are wire cutters, and are they suitable for me?

A: Wire cutters are used to cut doughs into smaller sizes with the desired shape. They are ideal for small to medium-sized biscuit production.

Q: What are rotary biscuit making machines?

A: These machines are used to roll and cut biscuits in large quantities. They are ideal for large scale commercial biscuit making.

Q: What should I consider when choosing a laminator?

A: Consider the number of sheets it can laminate per minute, the width of the sheets, the thickness range of sheets, and the type of sheets that the laminator can handle.

Q: What are the common features of a Chinese biscuit making machine?

A: Common features include stainless steel construction, PLC control system, automatic material feeding, adjustable speed, and adjustable thickness.

In conclusion, when sourcing a biscuit making machine from a Chinese manufacturer, it is essential to conduct extensive research and consider various factors such as reputation, experience, and product quality. Also, make sure the machine meets your specific needs and requirements.

Applications of Biscuit Making Machine

Biscuit making machines have revolutionized the way biscuits are made in commercial kitchens. Not only do they increase the speed of the biscuit-making process, but their use also ensures consistent quality and uniformity of the final product.

The applications of biscuit making machines are numerous. Firstly, they are used in bakeries and other commercial kitchens where there is a high demand for biscuits. A good quality machine can produce thousands of biscuits per hour, which saves time and labor costs.

Secondly, biscuit making machines are also used for making different types of biscuits. Manufacturers can customize the machines to create varieties of biscuits like sweet biscuits, crackers, and savory biscuits. Therefore, biscuit-making machines are an essential tool for meeting the diverse demands of the market.

Another application of the biscuit-making machine is that it can be used to make different shapes and sizes of biscuits. This includes traditional biscuit shapes like rounds or rectangles, to more elaborate cookie shapes like stars, hearts, and animals. This level of customization can be useful in creating unique products, attracting customers, and increasing sales.

Lastly, biscuit-making machines can also be used for making specialized biscuits like gluten-free, vegan, and organic biscuits. With the increasing demand for specialized dietary needs, biscuit-making machines are a valuable asset to manufacturers, allowing them to produce high-quality biscuits that cater to customers’ specific needs.

To sum up, biscuit-making machines are versatile and useful tools that are essential in the biscuit manufacturing process. They improve the efficiency of the production process, and their use ensures the consistent quality of the final product. Therefore, this machine is an excellent investment for anyone who wants to expand their biscuit production capacity or start a business in biscuit manufacturing.

Manufactured Products made of Biscuit Making Machine

The biscuit making machine is a versatile device that has revolutionized the way we produce biscuits. These machines have been used for decades to produce biscuits in large quantities that meet the ever-increasing demand. The biscuit making machine can also be used to make other manufactured products that are popular in the market.

One of the main products that are made using the biscuit making machine is cookies. Cookies are a popular snack item that is enjoyed by people of all ages. They come in various flavors and sizes, and the biscuit making machine can produce them in large numbers, making it possible to meet the market demand.

Another product that can be made using the biscuit making machine is crackers. Crackers are versatile products that can be enjoyed as a snack or used as an ingredient in various recipes. The biscuit making machine can produce crackers in different shapes and sizes to match the market demand.

Biscuits are also a popular product that is made using the biscuit making machine. Biscuits can be enjoyed as a snack or used as an ingredient in various recipes. The biscuit making machine can produce biscuits that are soft or crispy, depending on the market demand.

Apart from cookies, crackers, and biscuits, other products that can be made using the biscuit making machine include wafers, biscuits with filling, and sandwich biscuits. These products are becoming increasingly popular in the market, and the biscuit making machine has made it possible to produce them in large quantities to meet the demand.

In conclusion, the biscuit making machine is a versatile device that can be used to produce various manufactured products. The machine has revolutionized the way we produce biscuits, cookies, crackers, wafers, biscuits with filling, and sandwich biscuits. With the increasing demand for these products, the biscuit making machine is becoming an essential tool in the food manufacturing industry.

The Evolution history of Biscuit Making Machine

The history of biscuit making machines dates back to the early 1800s, when these devices were developed to automate the process of biscuit production. Early biscuit making machines were used to produce a wide variety of biscuit products, including cookies, crackers, and other baked goods.

Over the years, these machines have evolved and improved to meet the growing demands of the food industry. The first biscuits were made by hand and required a lot of skill to produce high-quality products. However, as the demand for these products increased, manufacturers began to seek out more efficient and cost-effective ways to produce biscuits.

Early biscuit making machines were manual, with the operator turning a crank to move the dough through the machine. As technology advanced, automated machines were developed that could produce a larger output with less labor. The introduction of electricity during the industrial revolution also facilitated faster and more efficient production processes.

In the mid-20th century, the development of high-speed rotary molders revolutionized the biscuit making industry. These machines were capable of producing up to 2,000 biscuits per minute, greatly increasing production and reducing labor costs.

Today, biscuit making machines have continued to evolve with new innovations such as computer-controlled systems that ensure consistent product quality, energy-efficient designs, and the ability to produce a wide range of biscuit products. These machines are also now becoming more versatile, as they can produce gluten-free, low-fat, and sugar-free biscuits.

In conclusion, the evolution of the biscuit making machine has revolutionized the food industry. From hand-cranked devices to high-speed automated machines, today’s biscuit making machines are more reliable, efficient, and versatile than ever before. With continuous advancements in technology, the future of biscuit making machines looks bright, ensuring that this beloved snack will continue to delight us for years to come.

The Process of Biscuit Making Machine

Biscuits are a popular snack that is enjoyed by millions of people around the world. The process of biscuit making involves several steps, and with the help of high-tech machines, this process has become more efficient and faster than ever before.

The first step in biscuit making is the mixing of ingredients. The ingredients are mixed together in a ratio that is specific to the type of biscuit being made. After the ingredients are mixed, the dough is formed and passed through a series of rollers to flatten it out.

Next, the dough passes through a cutting machine that cuts it into the desired shape and size before being placed onto a baking tray. The trays are then loaded onto a conveyor belt that moves them into an oven for baking.

The baking temperature and time are specific to each type of biscuit being made. This is where the art of biscuit making comes in as bakers master the perfect temperature and time for each biscuit to achieve the desired texture and flavor.

After baking, the biscuits are passed through a cooling machine that cools them down to room temperature. Once they are cool, the biscuits are sorted and packaged for distribution.

Biscuit making machines have revolutionized the biscuit making industry. These machines have made the process faster, more efficient, and more consistent. With the help of these machines, biscuit makers can produce a large quantity of biscuits with minimal effort and without compromising on quality.

In conclusion, the process of biscuit making machine involves mixing, rolling, cutting, baking, cooling, and packaging of the biscuits. These machines have made the process faster, efficient, and consistent. As technology advances, we can only expect to see more innovations that will make biscuit making even easier and faster.

Benefits Advantages of Utilizing Biscuit Making Machine

A biscuit making machine is an essential piece of equipment for many food manufacturing factories that make biscuits on a large scale. These machines make the entire biscuit-making process more efficient, fast, and cost-effective. Utilizing a biscuit making machine can create numerous benefits and advantages for businesses.

Firstly, using a biscuit making machine will increase productivity, as it allows for a higher volume of biscuit production in less time. With less time spent on manual labour, this means businesses can scale up, and meet larger production demands. A biscuit making machine is also highly automated, which helps reduce the chances of error in the manufacturing process, further increasing productivity.

Secondly, using a biscuit making machine can save on costs involved in the biscuit manufacturing process. The most significant factor contributing to cost-saving is time. By speeding up the manufacturing process, businesses can manufacture more biscuits in a shorter amount of time, thus reducing labour costs. Additionally, biscuit making machines produce consistent and uniform products, minimising off-cuts, waste, and defects, therefore reducing loss and increasing efficiency.

Thirdly, a biscuit making machine allows businesses to easily produce a variety of biscuit types and flavors. The machines are highly flexible, and allow for customization through different moulds, making various biscuit shapes, and sizes.

Finally, a biscuit making machine assists in maintaining food safety standards. With highly automated machinery in place, the process is much more hygienic than manual labour. Biscuit making machines also provide a highly controlled working environment which lessens the risk of contamination, resulting in a safe and high-quality biscuit product.

In conclusion, the benefits and advantages of utilizing a biscuit making machine are numerous. From increased productivity, cost savings, customizable production, to maintaining high food safety standards. As biscuit consumption continues to grow, and with the global trend for snack foods on the rise, making an investment in a biscuit making machine seems like a smart move for any food

Disadvantages Biscuit Making Machine

Biscuit making machines are becoming increasingly popular in the food industry. The machines are designed to automate processes that were previously done by hand. While there are several advantages to using a biscuit making machine, there are also some disadvantages that need to be considered.

One of the main disadvantages of a biscuit making machine is the cost. Machines are expensive to purchase and maintain. This can be a significant investment for small business owners or start-ups, making it difficult to justify the expense.

Another disadvantage is the potential for machine breakdowns. Biscuit making machines require regular maintenance and repairs to ensure they operate efficiently. Machine breakdowns can cause production delays, leading to lost revenue and a damaged reputation.

In addition to the cost and potential for breakdowns, biscuit making machines require skilled operators. These machines are complex pieces of equipment that require specialized training to operate correctly. Hiring skilled labor can be challenging and expensive.

Biscuit making machines have limited flexibility. They are designed to make one specific product and are not capable of changing quickly to produce a different product. This limitation can be an issue for bakeries that want to offer a wide range of biscuit varieties.

Finally, biscuit making machines require a significant amount of space in the kitchen. Some machines are large and require dedicated spaces. This can be challenging for smaller bakeries or restaurants that have limited space.

In summary, biscuit making machines have several disadvantages that must be weighed against their benefits. While the machines can automate processes and increase efficiency, they require significant investment in terms of cost, maintenance, and skilled labor. Additionally, they have limited flexibility and require a significant amount of space. It is essential for bakery owners and restaurant managers to consider all factors when deciding whether to invest in a biscuit making machine.

Selecting the Ideal Manufacturer Biscuit Making Machine

Biscuit making machines have become essential equipment for biscuit manufacturers, as they simplify the production process and ensure uniformity in the final product. However, selecting the ideal machine can be a daunting task, especially with the multitude of options available in the market. Here are some tips to help you choose the perfect biscuit making machine for your business.

Firstly, consider the production capacity of the machine. The size of the machine must match the scale of your production needs. In other words, if you run a small biscuit manufacturing enterprise, selecting a large-capacity machine will not be cost-effective. Similarly, if your business is large, choosing a machine with a low production capacity will negatively affect your production cycle.

Secondly, take a look at the machine’s design, build quality, and durability. Biscuit making machines with high-quality materials are durable, require less maintenance, and produce high-quality biscuits. Also, the design of the machine needs to be user-friendly and easy to clean, reducing the time required for cleaning and maintenance.

Thirdly, it is essential to consider the features and capabilities of the biscuit making machine. Various types of machines offer different features, such as customization of the design and shape of the biscuits, adjustable speed controls, and automated processes. Choosing a machine that caters to your specific needs will reduce the chance of making an investment in the wrong equipment for your business.

Finally, consider the manufacturer’s reputation and experience in the biscuit manufacturing industry. Manufacturers with a good reputation in producing biscuit making machines that offer high-quality performance and are reliable will instill trust in the product.

In conclusion, selecting the ideal biscuit making machine for your business is crucial for its success. Keeping your business’s production capacity, quality and features of the machines, and the manufacturer’s reputation in mind will help in the selection process.

Things to Consider When Purchasing Biscuit Making Machine

A biscuit making machine is a versatile piece of equipment that can help you produce delicious and flavorful biscuits in no time. However, like any other machinery, there are some aspects you should consider before purchasing a biscuit making machine.

Firstly, you should think about the size of the biscuit making machine that you require. Biscuit making machines come in different sizes which have varying production capacities. Hence, it is important to determine the output required by your bakery or business to ensure that the machine you select suits your needs.

Secondly, consider the dough type you will use for making biscuits. Some biscuit making machines are designed to handle specific types of dough, such as soft or hard dough. Therefore, consider your dough requirements to ensure that your machine is capable of handling your preferred dough type.

Thirdly, think about the maintenance and cleaning of the machine. Choose a machine that is easy to clean and maintain, as this will save you time and money in the long run. Additionally, consider purchasing a machine with easy access to internal parts, as this makes cleaning and maintenance much easier.

Fourthly, check the machine’s durability and the quality of the materials used in building it. Make sure that the machine is made of high-quality materials that will not deteriorate quickly, causing frequent repairs and replacements.

Finally, consider the overall cost of the machine. While it is essential to find a biscuit making machine that fits your budget, do not compromise on quality. The cheapest machine available may not be the best choice, as it can end up being more expensive in the long run due to frequent repairs.

In conclusion, investing in a biscuit making machine requires careful consideration of various factors, including size, dough type, maintenance, durability, and cost. By keeping these factors in mind, you can choose a machine that best suits your needs and budget, ensuring that your biscuits are of high quality and consistently delicious.

Properties of Biscuit Making Machine

A biscuit making machine is usually used for making different types of biscuits in large quantities. The properties of a good biscuit machine play a key role in ensuring the production of high-quality biscuits.

Firstly, a biscuit making machine must have a sturdy and durable structure to withstand continuous and heavy-duty use. It should be made from high-quality materials like stainless steel or aluminum which are rust-resistant and easy to clean.

Secondly, the machine should have sufficient capacity to produce the required quantity of biscuits. This means that it should be able to handle the dough efficiently and have a proper cutting system to cut the biscuits to the required size and shape.

Thirdly, a good biscuit machine should have a user-friendly design with clear controls and easy-to-follow instructions. This makes it easy for operators to operate and maintain the machine.

Fourthly, the speed and automation of the biscuit making machine also plays a critical role in its overall performance. A good machine should have a high production rate and be equipped with automated systems like programmable logic controllers and touchscreens.

Fifthly, the machine should have a proper cooling system to ensure that the biscuits are cooled quickly and uniformly. This is essential in preventing the biscuits from becoming too brittle or hard.

Lastly, a good biscuit making machine should be easy to clean and maintain. This means that it should have easily removable parts and require minimal disassembly to clean.

In conclusion, a good biscuit making machine should have a sturdy and durable design, sufficient capacity, user-friendly features, high automation, efficient cooling system, and easy-to-clean parts. These properties ensure that the machine produces high-quality biscuits, has a long lifespan, and requires minimal maintenance.

How to use Biscuit Making Machine

Biscuit making machines are an essential tool in any bakery, large or small. These machines can make the biscuit-making process faster and more efficient, ensuring that you can meet your customers’ demands for fresh and delicious biscuits. However, if you’re new to using a biscuit making machine, it can be tricky to use. Below are some tips on how to use a biscuit making machine.

First, prepare your biscuit dough according to your recipe. Be sure to adhere to the instructions, so your dough is the perfect consistency for the machine.

Next, attach the cylinder full of dough to the biscuit making machine. Ensure that the machine is set up correctly and securely before beginning the biscuit-making process.

Now, set the thickness and shape of the biscuits that you desire. Most machines have settings that will allow you to adjust the thickness and shape of each biscuit. You can experiment with these settings until you find the perfect ones that work best for you.

Once the settings are in place, start the machine and begin making your biscuits. The machine will automatically cut out the dough and create the shapes of the biscuits according to your chosen settings.

After the machine has finished making the biscuits, remove them from the machine and place them onto a baking tray. At this point, you can bake them in the oven based on your recipe’s instructions.

In conclusion, using a biscuit making machine is relatively easy, and with a bit of practice, you can create delicious biscuits that your customers love. Follow these simple tips to ensure that you get the most out of your machine and consistently create perfect biscuits.

Glossary Terminology Terms for Biscuit Making Machine

If you’re involved in the biscuit making industry, you know that it requires the use of complex machinery, and there are several terminology terms you must know. Here are the glossary terminology terms for biscuit making machine:

1. Dough feeder: A machine that helps with the process of dough transferal. This is placed on top of the biscuit machine to provide a continuous flow of dough and does not cause any interruptions when making biscuits.

2. Dough sheeting machine: This is used to press the dough into a flat sheet before the biscuit cutting process. It is essential to obtain an even thickness, which ensures consistent baking.

3. Biscuit moulder: After dough sheeting, the biscuit moulder is used to shape the dough sheet to the required height and width before being cut. The machine works by pressing the dough sheet against a moulder roll to achieve the desired shape.

4. Biscuit cutter: This is a crucial part of the biscuit making machine that cuts the dough sheet into the required shape using a cutter wheel shaped in different forms or patterns. The cutter can also adjust the thickness of the dough sheet.

5. Oven: This is the final and most crucial part of the process. After the dough sheet has been cut into the desired shape, it is transferred to the oven to bake for the appropriate time to set, become firm and crisp.

6. Cooling conveyor: After the biscuits are baked, the cooling conveyor then takes the freshly baked biscuits onto a cooling rack conveying them through a cooling chamber.

7. Stacking machine: This is used to stack biscuits automatically. They are arranged in a predetermined combination before being transferred to the packaging area.

Final thoughts

These are the key glossary terminology terms that you should know about biscuit making machines. If you’re going to embark on a career in the biscuit industry, understanding these terms is a vital step towards your success. With the proper knowledge, you can operate the biscuit making machines

Biscuit Making Machine Price

Biscuits are one of the most-loved snacks all around the world. From simple butter biscuits to chocolate chip cookies, there’s a kind of biscuit for every kind of taste bud. With the increasing demand for biscuits, biscuit making machines have become increasingly popular. These machines not only save time and effort of labor but also produce a large quantity of biscuits in a single batch. In this article, we will discuss the biscuit making machine price.

The price of biscuit making machines varies greatly depending on the size, capacity, and brand. Small-sized biscuit making machines, which can produce 50-100 kg of biscuits per day, are available for around $2,000. The price of medium-sized biscuit making machines with a capacity of around 200-300 kg per day begins from $5,000. Large biscuit making machines, which can produce 500 kg or more of biscuits per day, cost over $10,000.

Another factor that affects the price of a biscuit making machine is the type of biscuits it can produce. There are specific machines available in the market for producing particular types of biscuits, such as cookies or wafers. The machines made for producing more complex biscuits or cookies with unique shapes and designs also come with a higher price tag.

Brand name and warranty are two other factors that impact the biscuit making machine price. Renowned brands are known for their quality products and often come with higher price tags. However, buying from a reputed brand assures durability, reliability, and support.

In conclusion, the price of biscuit making machines varies significantly based on factors such as size, capacity, brand name, and the type of biscuits it can produce. As with any machinery purchase, it’s essential to do thorough research, compare prices and features, and buy from a reliable source. A biscuit making machine’s cost may seem steep at first, but it’s a beneficial investment that will offer a high return in the long term.