Knowledge about Pipe Rolling Machine

Pipe rolling machines are a vital tool in the metalworking industry. These machines are used to bend pipes and tubes into various shapes and sizes, depending on the requirements of the project. If you’re a metalworker or fabricator, it’s essential to have a good understanding of how these machines work and how to use them effectively.

The first thing to consider when working with pipe rolling machines is the material you will be working with. These machines are designed to work with a variety of materials, including stainless steel, brass, copper, and aluminum. You must choose the right machine based on the material you will be using.

Next, you need to understand the different types of pipe rolling machines available. There are two main types of machines – manual and hydraulic. Manual machines require a physical effort to operate, while hydraulic machines use hydraulic pressure to bend the pipe. If you’re working with larger or thicker pipes, a hydraulic machine is the better option.

When using a pipe rolling machine, safety is crucial. Always wear safety gear, such as goggles and gloves, and follow the manufacturer’s instructions carefully. Never attempt to bend a pipe that is too thick or too hard, as this can damage the machine and create safety hazards.

Another crucial factor when using pipe rolling machines is accuracy. It’s essential to measure the pipe accurately before beginning the bending process, as any miscalculations can result in the wrong angle or shape. It’s also important to use the correct rollers to achieve the desired shape and size.

In conclusion, pipe rolling machines are an essential tool for metalworkers and fabricators. Understanding the different types of machines, the materials they can work with, and the safety precautions to follow is crucial for successful and safe operation. With the right knowledge and careful attention to detail, you can create accurately bent pipes that meet your project’s needs.

Various Types of Pipe Rolling Machine

Pipe rolling machines are widely used in various industries to bend and shape metal pipes. These machines come in different types depending on the specific needs of the user.

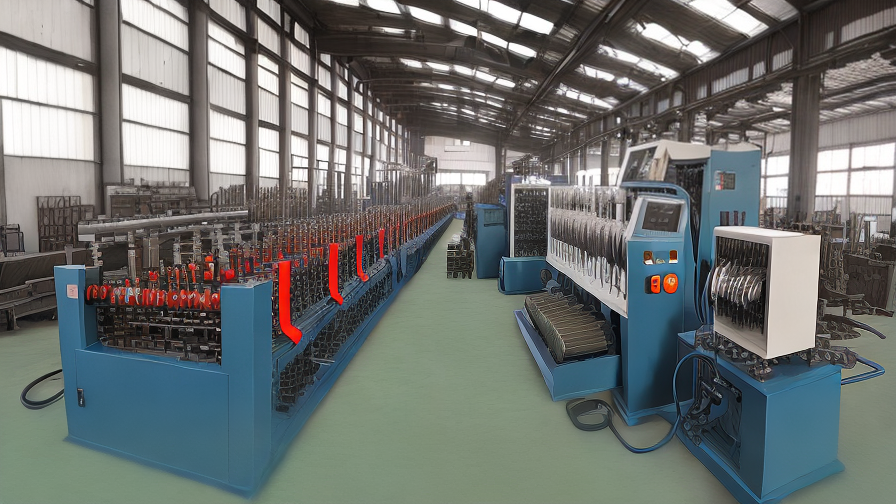

The first type is the Manual Pipe Rolling Machine, which is suitable for small-scale operations. It is operated manually and requires little technical expertise. The machine comes with a set of rollers that can shape pipes in various angles.

The second type is the Hydraulic Pipe Rolling Machine, which is more advanced than manual machines. It is controlled by hydraulics and has a more accurate bending mechanism. This type of machine is ideal for heavy-duty operations and can bend large diameter pipes with ease.

The third type is the CNC Pipe Rolling Machine, which is computer-controlled and automated. It is the most advanced type of pipe rolling machine and can produce complex bends with high precision. This machine is ideal for large-scale operations and is commonly used in the automotive, aviation, and shipbuilding industries.

Another type of pipe rolling machine is the Section Bending Machine, which specializes in shaping metal sections such as angles, bars, and beams. This machine can produce precisely curved sections for use in various construction projects.

Finally, the Profile Bending Machine is a type of pipe rolling machine that is used to shape pipes with different cross-sections. It is commonly used in the fabrication of cylindrical frames and structures for various industries.

In conclusion, pipe rolling machines come in various types, each designed for specific needs. Choosing the right machine depends on the scale of operations, the type of pipe or metal, and the precision required for shaping.

FAQ sourcing Pipe Rolling Machine manufacturer from China

When it comes to sourcing pipe rolling machines from China, there are a few frequently asked questions that arise. Here are some common questions with answers to help you navigate this process.

Q: What options are available for pipe rolling machines from China?

A: The options are vast, with various sizes, shapes, and functionalities of pipe rolling machines available. Some include electric or hydraulic models, and some can handle thicker materials than others.

Q: What is the typical lead time for a pipe rolling machine from China?

A: The lead time can vary depending on the manufacturer and the model of the machine. It’s essential to ask for a lead time estimate before committing to a purchase.

Q: What should I consider when choosing a manufacturer?

A: Consider the manufacturer’s experience, reputation, and whether they have any certifications, such as ISO or CE. Ask for references and research their customer reviews.

Q: What is the price range of pipe rolling machines from China?

A: Prices can vary depending on the model and manufacturer, but typically range from a few thousand dollars to tens of thousands of dollars.

Q: How do I ensure quality control when purchasing from a Chinese manufacturer?

A: It’s essential to communicate your quality expectations with the manufacturer and ask for quality control measures during the manufacturing process. You can also request third-party inspections to ensure the machine meets your standards before shipping.

Q: What is the warranty period for a Chinese manufactured pipe rolling machine?

A: Manufacturers often offer a warranty period of 12 to 24 months, but this can vary.

In conclusion, sourcing a pipe rolling machine from China has numerous options and factors to consider. Taking the time to research and communicate your needs and expectations can result in a successful purchase.

Applications of Pipe Rolling Machine

Pipe rolling machines are used in many industries, including construction, manufacturing, and engineering. These machines are specially designed to bend and shape large pieces of metal into different shapes, sizes, and curves. With their versatility and precision, they have become an indispensable tool in modern industry.

One of the most common applications of a pipe rolling machine is in the construction industry. These machines are used to bend pipes and tubes to different angles and curves without the need for manual labor. This makes it possible to create complex structures and designs, especially in modern architecture. Pipe rolling machines are also used in the creation of handrails, stairs, and fences, as well as architectural features such as arches or trusses.

Another application of pipe rolling machines is in the manufacturing industry. These machines are used to form metal pipes into a wide variety of shapes, from simple round tubes to more complex shapes such as square, rectangular, or triangular tubes. This allows manufacturers to create customized products that meet the specific needs of their customers. Pipe rolling machines are also used in the production of HVAC systems, machinery, and equipment.

In the engineering industry, pipe rolling machines play an important role in the creation of prototypes and new designs. With their ability to produce pipes and tubes of various shapes and sizes, these machines make it possible to test and refine new designs before they are put into production. This can save time and money, allowing engineers to create better products more efficiently.

In summary, pipe rolling machines are a valuable tool in many industries, offering precision, versatility, and efficiency. They are used to create complex structures and designs in construction, to manufacture a wide range of customized products, and to test and refine new designs in engineering. As industries continue to evolve and expand, the demand for pipe rolling machines is likely to grow, making them an essential tool for modern industry.

Manufactured Products made of Pipe Rolling Machine

A pipe rolling machine has brought a revolution in the manufacturing industry. This machine is used to make numerous products that require the bending of metallic pipes. The machine has made the process of bending pipes not only easier but also faster and more accurate. Manufactured products made of pipe rolling machines perform various functions, including supports, frameworks, and storage systems.

One of the main advantages of using the pipe rolling machine is that it can create different pipe shapes, sizes, and angles to fit project-specific requirements. Some of the manufactured products include ring gaskets, motorcycle frames, handrails, and agricultural equipment. The seamless pipes produced by the machine have improved the quality of the finished products, making them more durable and efficient.

The pipe rolling machine is suitable for mass production, which has helped industries to reduce manufacturing costs significantly. The machine can produce thousands of products within a short period, reducing the need for additional manpower, making it more efficient and reducing the overall expense of the project. Additionally, the machine has also helped to reduce waste by producing products with consistent shapes and sizes.

Another advantage of the pipe rolling machine is that it allows manufacturers to make customized products that meet the client’s specific requirements. The machine’s flexibility allows for the creation of individually tailored products, ensuring that the customer gets precisely what they need. Customization not only adds value to the final product but also adds value to the manufacturing process by increasing efficiency and accuracy.

In conclusion, the pipe rolling machine has transformed the manufacturing industry, enabling businesses to produce high-quality products at a lower cost. The customized products, increased efficiency, and accuracy has made manufacturers more competitive in the global marketplace. Produced products range from simple handrails to industrial equipment, all of which contribute to the development of the economy. In short, the pipe rolling machine has significantly improved how products are manufactured, making them more efficient, cost-effective, and of higher quality.

The Evolution history of Pipe Rolling Machine

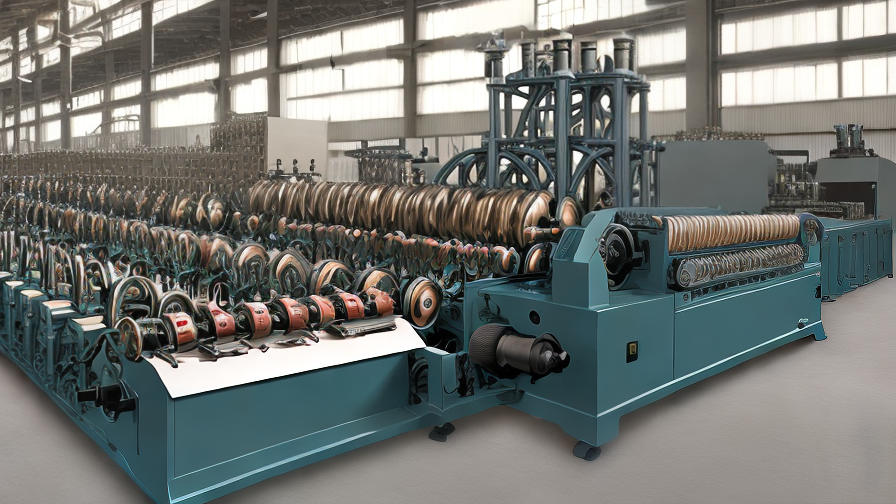

The pipe rolling machine has come a long way since its inception. Originally, manual hand-cranked machines were used in the early 19th century to roll pipes for water and gas transportation. These machines were labor-intensive and took a long time to produce pipes of different sizes.

As industrialization took hold, the demand for pipes grew substantially, and manufacturers began looking for ways to increase their production capacity. In the early 1900s, hydraulic pipe rolling machines were introduced, revolutionizing the industry. These machines were powered by hydraulic cylinders and could roll pipes of various sizes and shapes, greatly reducing the production time.

With the advent of electric motors in the 1920s, pipe rolling machines became even more efficient, faster, and easier to operate. These machines were fully automated, requiring minimal human intervention, and could produce more precise and consistent pipes. They could also handle thicker and heavier materials, expanding the range of applications for rolled pipes.

In the mid-20th century, computer-controlled pipe rolling machines were introduced, allowing for even greater precision and customization. Advanced software was used to control a series of rollers that could bend and shape pipes in complex and unique ways. These machines could produce pipes that were almost perfectly uniform in wall thickness and curvature, making them ideal for a wide range of applications in industries such as construction, automotive, and aerospace.

Today, pipe rolling machines are highly sophisticated, offering incredible precision, speed, and versatility. They can produce pipes in a range of materials, shapes, sizes, and thicknesses, and can be customized to match specific customer requirements. With advanced robotics and computer software, manufacturers can achieve unparalleled accuracy and efficiency, making the pipe rolling machine an indispensable tool in modern-day manufacturing.

The Process of Pipe Rolling Machine

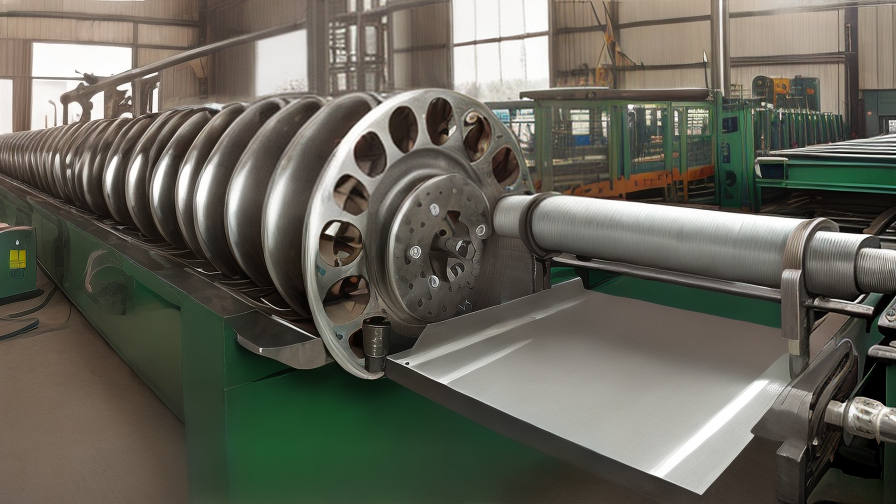

Pipe rolling machines are used to produce round and cylindrical parts from flat strips or sheets of metal. They are a popular tool in the metalworking industry due to their high efficiency and precision.

The process of pipe rolling machine involves several steps. First, the operator loads the material into the machine. The material is typically a flat sheet or strip of metal, such as steel, aluminum or copper, that is fed into the rollers.

Next, the rollers are adjusted to the desired radius of the pipe. The rollers are typically set to create a curve or bend in the material. This is done by adjusting the distance between the rollers or by using different roller shapes.

The material is then fed through the rollers, and the machine applies pressure to bend the material into the desired shape. As the material passes through the rollers, it begins to form a cylindrical shape.

The machine continues to roll the material until it reaches the desired length and diameter. The operator may need to make adjustments to the roller settings to ensure that the desired shape is achieved.

Once the pipe is finished, it is removed from the machine and can be further processed as needed. The pipe may need to be cut to length or have additional shaping done, depending on the application.

Overall, pipe rolling machines are an efficient and precise tool for creating cylindrical parts from flat sheets or strips of metal. By following the proper process and making necessary adjustments along the way, operators can create high-quality pipes for a variety of applications.

Benefits Advantages of Utilizing Pipe Rolling Machine

Pipe rolling machines are used to bend pipes and tubes into any desired shape. They are designed to make the bending process smooth and efficient. This machine has become popular in many industries due to its numerous benefits and advantages.

The first benefit of utilizing a pipe rolling machine is the cost-effectiveness of its operations. The machine is designed in such a way that it can bend pipes and tubes without consuming a lot of energy or requiring a lot of labor. This translates to reduced operational costs, which can have a significant impact on the profitability of a business.

Another advantage is the high level of accuracy and precision that the machine provides. This ensures that the finished product meets the required specifications, which is crucial in many industries. Furthermore, the machine is programmed to carry out multiple bends, ensuring consistency in the product’s quality.

The speed of operation is another significant advantage of using a pipe rolling machine. The machine can process several pipes at once, saving a lot of time and increasing productivity. This is particularly important in industries with high demand for pipes and tubes, where timely delivery and production efficiency are paramount.

The machine’s versatility is also worth mentioning. It can be configured to bend pipes and tubes of varying sizes, shapes, and materials, making it ideal for use in different industries such as construction, automotive, and aerospace. This means that businesses can invest in a pipe rolling machine and enjoy its benefits across different applications.

Perhaps one of the most significant advantages of utilizing a pipe rolling machine is the enhanced safety it provides. The machine is designed with various safety features such as emergency stop buttons, protection guards, and sensors, ensuring the operators’ safety. This reduces the number of mishaps in the workplace, which is crucial for any businesses’ reputation and legal compliance.

In conclusion, the pipe rolling machine offers numerous benefits to businesses, including cost-effectiveness, accuracy, speed of operation, versatility, and enhanced safety. It is a valuable investment that can have a significant impact on businesses’ overall efficiency and profitability.

Disadvantages Pipe Rolling Machine

Pipe rolling machines are used to curve and bend pipes for various purposes, including construction and manufacturing. While they offer many advantages, such as increased efficiency and accuracy, there are also several disadvantages that should be considered before investing in one.

One of the biggest disadvantages of using a pipe rolling machine is the cost. They can be quite expensive to purchase and set up, making them cost-prohibitive for smaller businesses or individuals. In addition, the maintenance and repair costs can also be quite high, especially if the machine is not used frequently.

Another disadvantage is that they require specialized training to operate safely and effectively. This can be time-consuming and expensive, especially if the operator is not familiar with the machine or the materials being worked with. Additionally, safety concerns must be taken into consideration when using these machines, as they can be dangerous if used improperly.

Pipe rolling machines can also be limited in their capabilities, depending on the model and the materials being used. For example, some machines may not be suitable for certain types of pipes or materials, which could limit their usefulness in certain industries or applications.

Finally, pipe rolling machines can be quite noisy and disruptive, which can be a problem in certain environments. This can cause discomfort and distraction for workers, as well as being a nuisance for nearby residents or businesses.

Overall, while pipe rolling machines offer many advantages, including increased efficiency and accuracy, they also have several disadvantages that should be considered before investing in one. Ultimately, the decision to use a pipe rolling machine will depend on the specific needs and capabilities of the business or individual using it.

Selecting the Ideal Manufacturer Pipe Rolling Machine

When it comes to selecting the ideal pipe rolling machine, there are several factors to consider. The right machine can greatly enhance the productivity and efficiency of your manufacturing process while providing consistent quality results. Here are some tips to keep in mind when selecting the ideal manufacturer pipe rolling machine.

Consider Your Needs

One of the first things to consider when selecting a rolling machine is the specific needs of your manufacturing process. For instance, what types of materials will you be working with, and what thicknesses will you need to roll? What is the required output capacity of your manufacturing facility, and what is your budget?

Machine Design

The design of the machine is an important factor to consider when selecting a manufacturer pipe rolling machine. It should be easy to use, maintain, and repair when necessary. It should also be sturdy enough to withstand the pressures of continuous use, without breaking down easily.

Quality and Consistency of Output

The consistency and quality of the output are crucial in any manufacturing process. When selecting a rolling machine, opt for a model that provides consistent, high-quality output. This ensures that your customers receive products that meet their standards and expectations.

Safety Features

A good pipe rolling machine should have a range of safety features to protect employees and other personnel from injury. Look for a device that incorporates important safety features such as non-slip surfaces for better grip, sturdy handles and structural reinforcements, as well as protective shields.

Conclusion

When selecting the ideal manufacturer pipe rolling machine, consider your specific needs, the design of the machine, the consistency and quality of the output, and its safety features. By taking these factors into account, you can ensure that your manufacturing process runs smoothly, efficiently and safely.

Things to Consider When Purchasing Pipe Rolling Machine

A pipe rolling machine is an essential tool for any metalworking or fabrication workshop. However, with the myriad of options available, it can be challenging to know which one to choose. Here are some things to consider when purchasing a pipe rolling machine:

1. Capacity: Determine the maximum size of pipe and thickness of material the machine can handle. This is essential to ensure that it can handle the tasks you need to perform.

2. Power: The machine’s motor should have enough power to handle the workload. Choose a machine with a motor that is strong enough to power through the toughest jobs.

3. Durability: Look for a pipe rolling machine that is made of robust, high-quality materials. A more durable machine will be less likely to break down or require frequent repairs, saving time and money in the long run.

4. Precision: Choose a machine with precise and accurate measurements. This is important for ensuring that your project is accurate and meets your specifications.

5. Capacity and Flexibility: Consider the type of work you do and ensure that the pipe rolling machine you choose can handle the work. There are different types of pipe rolling machines in terms of capacity and flexibility. Consider the type of machine that would be best for your intended projects.

6. Brand and Warranty: Choose a reputable brand that offers a good warranty. This helps to ensure that you are getting a high-quality machine that will last for years to come.

7. Cost: Consider the cost of the machine and whether it fits within your budget. Remember, a more expensive machine may be more durable and provide better results, but it may not be cost-effective if you do not use it frequently.

In conclusion, purchasing a pipe rolling machine is an essential investment for any metalworking or fabrication workshop. Consider the above factors when purchasing your machine to ensure that it is durable, powerful, precise, and cost-effective. By doing so, you will be able to choose a machine that meets your needs and helps you achieve the results you need

Properties of Pipe Rolling Machine

A pipe rolling machine is a versatile tool that can produce a variety of shapes and sizes of pipes. It can bend, curve and shape pipes in a precise and efficient manner. They are commonly used in manufacturing facilities, construction sites, and metal fabrication shops. With its many benefits, there are specific properties that make the pipe rolling machine unique.

Precision is one of the most significant properties of a pipe rolling machine. These machines are built with high-tech features that allow for precise measurement and manipulation. It is the ideal tool for creating complex shapes and bending angles of various degrees. The precision of the machine ensures that the finished product meets the required specifications.

The durability of a pipe rolling machine is another property that sets it apart. Most machines are built with high-quality steel components, making them long-lasting and durable. They are designed to withstand the rigors of constant use and can operate for long hours without breaking down. The high durability of the machine makes it cost-effective over a prolonged period.

Pipe rolling machines are also known for their efficiency. They can take on multiple tasks quickly and can complete them in a single process. They reduce the need for additional equipment and save time, resources, and money. They are ideal for large production operations, as they can mass-produce pipes of various sizes and shapes.

The flexibility of a pipe rolling machine and its adaptability to various applications set it apart from other machines in the industry. With the different configurations of dies and rolls, these tools can be used to create customized pipes of various shapes and sizes. They can easily switch from one type of pipe to another, making them perfect for small as well as large-scale requirements.

In conclusion, the pipe rolling machine has a unique set of properties that makes it an essential tool in many industries. Its precision, durability, efficiency, and flexibility have contributed to its widespread use. Its ability to produce precise and customized pipes with varied shapes and sizes is a significant benefit, and its cost-effectiveness over a prolonged period makes it

How to use Pipe Rolling Machine

A pipe rolling machine is an essential tool for bending and shaping metal pipes with a high degree of accuracy. They are commonly found in metal fabrication shops and are ideal for working with pipes made of material like steel, aluminum, or copper.

To use a pipe rolling machine, you will first need to select the correct size and shape of the pipe that you want to work with. Then, adjust the machine’s rollers to match the diameter of the pipe.

Position the pipe in the rollers so that it is held securely in place. Turn the hand lever to begin rolling the pipe through the machine.

As you roll the pipe through the machine, apply gentle pressure in the direction you want the pipe to bend. Keep rolling and applying pressure until the pipe has been shaped to the desired angle.

It is important to keep the pipe lubricated throughout the rolling process. This will help to reduce friction and prevent the pipe from getting stuck in the machine.

If you need to make multiple bends in the same pipe, simply repeat the process with the machine set to the desired angle. With a bit of practice, you will soon be able to create intricate bends and shapes with ease.

In conclusion, a pipe rolling machine is an extremely useful tool for anyone working with metal pipes. By following these simple steps, you can create precise and accurate bends that will meet the exact specifications of your project.

Glossary Terminology Terms for Pipe Rolling Machine

A pipe rolling machine is a versatile equipment widely used in manufacturing companies. However, it comes with specific terminologies which are essential to understand for efficient operations. The following glossary terminology terms are commonly used in pipe rolling machines:

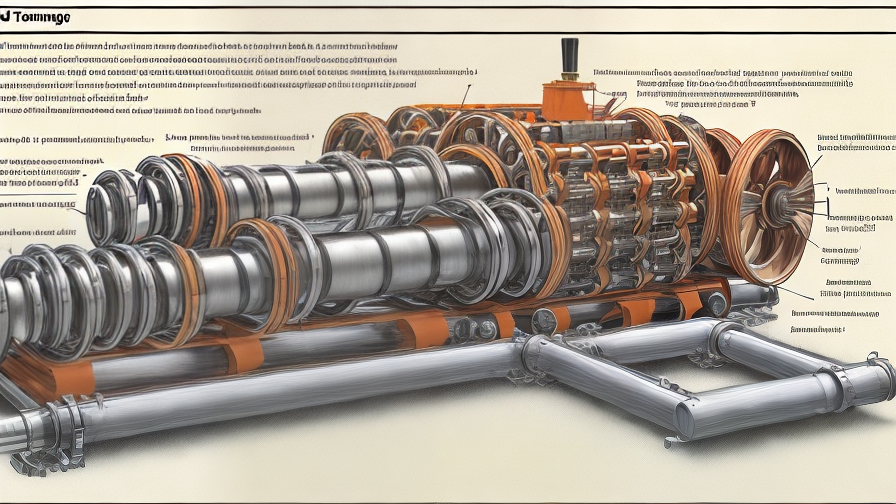

1. Bend Radius: This is the minimum radius of curve that a pipe can be bent without causing damages or breaking.

2. Centerline Radius: This refers to the measurement from the center of the roll to the center of the pipe.

3. Mandrel: A mandrel is a component used to keep the pipe in position and prevent it from deforming or collapsing when it is being bent.

4. Pinch Roll: Pinch rolls are the pressure tools that exert even pressure on a pipe during the rolling process.

5. Roll Set: This refers to the set of rollers used in the machine. It may include mandrels, pinch-rolls, and other specialized tools, depending upon the size and shape of the pipe.

6. Chamfering: Chamfering is a process that removes the sharp edges of a pipe before it is rolled. This is important to ensure that the pipe does not get damaged during the rolling process.

7. Flattening: Flattening is a process by which the pipe is compressed or flattened. This technique is used to achieve a specific shape.

8. Hardness: The hardness of the pipe is one of the critical factors that determine the success of the rolling process. A pipe that is too hard may crack or break during the rolling process.

9. OD (Outside Diameter): The outside diameter of a pipe is the total distance around the rounded surface of the pipe, measured from one side to the other.

10. ID (Inside Diameter): The inside diameter of a pipe is the measurement of distance between the inside of two walls of the pipe.

Understanding these glossary terminology terms will help you in your operations with a pipe rolling machine. With the proper use of these terms, you can increase your productivity, reduce waste

Pipe Rolling Machine Price

Pipe rolling machines are an essential tool for any industry dealing with pipe and tube rolling needs. These machines allow for precise and efficient rolling of pipes and tubes for use in various applications. However, one of the primary concerns that users have when looking for such equipment is the price.

Pipe rolling machine prices vary depending on many factors such as brand, size, features, and capability. Basic models with fewer features may cost $2,000, while more advanced models with many capabilities and features can cost over $50,000. However, the fact that a machine costs more doesn’t always mean it’s a better option.

When looking at pipe rolling machine prices, it’s important to consider the needs and the budget of the user. A small workshop may not require a top-of-the-line machine, while a large industrial facility may need a more advanced model. In any case, it’s crucial to compare prices and features with different manufacturers before making a purchase.

Many manufacturers offer customized machines that meet the specific needs of the buyer. This allows the buyer to get the most out of their investment and use the machine for a variety of applications. The cost of customization will vary from one manufacturer to another, so it’s important to shop around.

In addition to the price of the machine, the operating cost should also be considered. These costs include maintenance, energy consumption, and repair costs. When choosing a machine, it’s essential to look at a comprehensive price that factors in all these costs to ensure the machine is cost-effective.

In conclusion, when looking at pipe rolling machines, it’s essential to compare different manufacturers’ prices and features to get the most out of the investment. Buyers must consider the needs of their workshop or facility, the total cost of ownership, and their budget when making a purchase. With careful consideration of these factors, buyers can find a pipe rolling machine that meets all their needs at the best possible price.