Introduce about acrylic laser cutter machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Acrylic laser cutter machines are popular tools used in various industries for cutting and engraving acrylic materials with high precision. This machine guide will provide you with an overview of the quality, cost, suppliers, certifications, market, tips, and frequently asked questions.

Quality: Acrylic laser cutter machines offer excellent cutting and engraving quality with their advanced laser technology. They can achieve intricate designs and smooth edges on acrylic materials.

Cost: The cost of acrylic laser cutter machines varies depending on the specifications and features. Entry-level models may start from a few hundred dollars, while high-end industrial-grade machines can cost several thousand dollars.

Supplier: There are numerous suppliers specializing in acrylic laser cutter machines. It is essential to choose a reliable supplier who offers quality products, good customer support, and warranty options.

Certification: Look for machines that comply with international quality and safety standards, such as CE, FDA, and ISO certifications. These certifications ensure that the machine meets the required standards for performance and safety.

Market: The market for acrylic laser cutter machines is growing rapidly due to the increasing demand for precision cutting and engraving in various industries like signage, advertising, jewelry, and crafts. Both small businesses and large-scale industries utilize these machines for their cutting needs.

Tips: Proper maintenance and cleaning are crucial for the longevity and performance of acrylic laser cutter machines. Regularly clean the laser lens, adjust the beam alignment, and ensure proper ventilation to prevent dust buildup.

FAQ:

1. Can acrylic laser cutter machines cut other materials? Yes, they can cut various materials like wood, paper, fabric, leather, and more, depending on the machine’s power and capabilities.

2. Is training required to operate an acrylic laser cutter machine? Yes, it is recommended to receive training on proper machine operation, safety protocols, and maintenance to ensure efficient and safe usage.

In summary, acrylic laser cutter machines offer high-quality cutting and engraving on acrylic materials. They come at different price ranges, supplied by reliable vendors with necessary certifications. The market for these machines is expanding, and proper maintenance is crucial for their longevity. Training is also recommended for safe and efficient machine operation.

Types of acrylic laser cutter machine

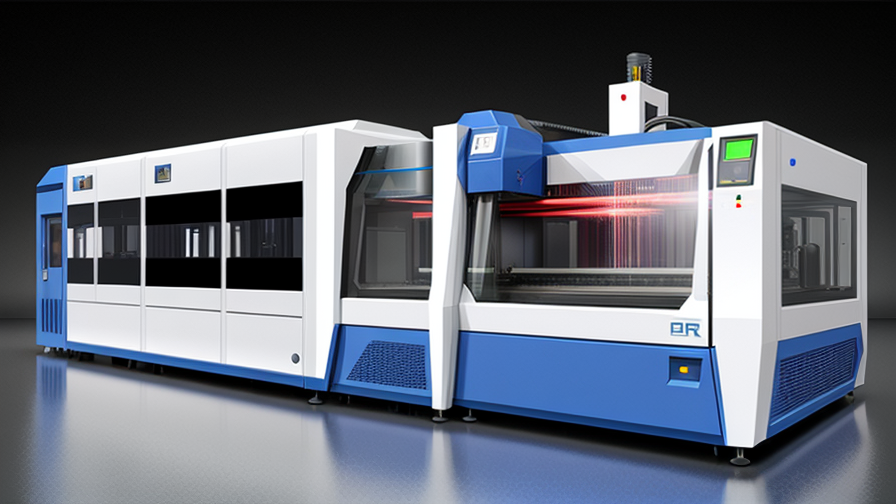

Acrylic laser cutter machines are becoming increasingly popular due to their ability to provide precise and clean cuts on acrylic materials. These machines use a high-powered laser beam to cut through the acrylic, resulting in smooth edges without any chipping or melting. There are several types of acrylic laser cutter machines available in the market, each with its own features and capabilities.

1. CO2 Laser Cutter: This is the most common type of acrylic laser cutter machine. It uses a carbon dioxide laser to cut through the acrylic material. CO2 laser cutter machines are highly versatile and can be used for cutting, engraving, and etching a wide range of materials, including acrylic. They are suitable for both small-scale and industrial applications.

2. Fiber Laser Cutter: Fiber laser cutter machines are known for their high cutting speeds and precision. They use a fiber laser, which is generated by diode pumping, to cut through the acrylic material. Fiber laser cutters are more efficient and consume less energy compared to CO2 laser cutters. They are particularly suitable for cutting thin acrylic sheets and have gained popularity in the signage and advertising industry.

3. UV Laser Cutter: UV laser cutter machines use an ultraviolet laser to cut through acrylic materials. They are often used for micro cutting applications where high precision is required. UV laser cutters are capable of achieving intricate designs with minimal heat affected zones, making them suitable for cutting delicate acrylic components.

4. Galvo Laser Cutter: Galvo laser cutter machines utilize galvanometer scanners to direct the laser beam with high speed and accuracy. They are commonly used for laser engraving and marking applications on acrylic surfaces. Galvo laser cutters are ideal for creating detailed designs, logos, and patterns on acrylic materials.

5. Hybrid Laser Cutter: Hybrid laser cutter machines combine multiple laser technologies, such as CO2 and fiber lasers, in a single platform. These machines offer the flexibility to switch between different laser sources and power levels, allowing for a wide range of cutting and engraving options. Hybrid laser cutters are suitable for versatile applications and are often used in industrial settings where different materials and thicknesses need to be processed.

In conclusion, acrylic laser cutter machines come in various types and configurations, each offering unique advantages for specific cutting and engraving applications. Whether it’s a CO2, fiber, UV, galvo, or hybrid laser cutter, these machines enable precise and efficient processing of acrylic materials, making them a preferred choice in industries such as signage, advertising, and manufacturing.

Pros and Cons of Using acrylic laser cutter machine

Acrylic laser cutting machines have gained popularity due to their versatile functionality and precise cutting capabilities. However, like any tool, they have their pros and cons. Here are the key advantages and disadvantages of using acrylic laser cutter machines:

Pros:

1. Precision: One of the major advantages of using acrylic laser cutter machines is their ability to cut with high precision. These machines can achieve intricate designs and deliver clean and sharp edges, ensuring a professional finish.

2. Versatility: Acrylic laser cutter machines are suitable for cutting a wide range of materials, including acrylic, wood, fabric, leather, and more. This versatility makes them a valuable tool for various industries, including crafting, signage, furniture, and automotive.

3. Time and cost-effective: Compared to traditional cutting methods, acrylic laser cutter machines are faster and require fewer manual interventions. They can process a large number of pieces in a shorter time, reducing production time and labor costs.

4. Minimal material wastage: With the focused laser beam, acrylic laser cutter machines remove a thin kerf and produce narrow heat-affected zones, resulting in minimal material wastage. This makes it an economic choice, as less material is wasted and can be utilized effectively.

Cons:

1. Initial investment: Acrylic laser cutter machines can be expensive, especially high-quality models that offer advanced features and enhanced precision. This initial investment may deter small businesses or individuals from purchasing these machines.

2. Safety precautions: Laser cutting involves high heat and emissions that can be hazardous if not handled correctly. Proper safety measures, such as wearing protective gear and ensuring proper ventilation, need to be taken when operating an acrylic laser cutter machine.

3. Limited material thickness: While acrylic laser cutter machines are versatile, they may have limitations when it comes to cutting thicker materials. The power and focus of the laser beam may not be suitable for cutting materials beyond a certain thickness, requiring alternative cutting methods.

4. Maintenance and upkeep: Acrylic laser cutter machines require regular maintenance, including cleaning, aligning, and replacing consumables. This can add to the overall cost of ownership and may require technical expertise to ensure the machine operates optimally.

In conclusion, acrylic laser cutter machines offer precise cutting capabilities, versatility, and time and cost-effectiveness. However, they come with a high initial investment, safety precautions, limited material thickness, and maintenance requirements. Understanding these pros and cons will help individuals and businesses make an informed decision when considering the use of acrylic laser cutter machines.

acrylic laser cutter machine Reference Specifications (varies for different product)

The acrylic laser cutter machine is a versatile tool used for precision cutting and engraving of acrylic materials. It is equipped with a high-powered laser that delivers intense beams of light to cut through or etch the surface of the acrylic.

The machine usually comes in different sizes and power options to cater to various needs. The laser power can range from 40 watts to more than 150 watts, allowing the machine to cut through acrylic sheets of different thicknesses. The cutting size also varies, with smaller machines capable of handling a working area of around 12 x 20 inches, while larger machines can handle up to 48 x 96 inches.

To ensure precise and accurate cuts, the acrylic laser cutter machine uses high-quality lenses and mirrors that direct the laser beam to the desired cutting path. These components are usually made from durable materials, often made with a focus on reducing heat absorption and maintaining beam quality.

The machine also incorporates a control system that allows users to set the cutting or engraving parameters. This typically includes variables such as laser power, cutting speed, and focal length, which can be adjusted to achieve the desired outcome. Some machines even feature automatic focusing systems to simplify the setup process.

Safety measures are essential when operating the acrylic laser cutter machine. Most machines are equipped with interlock switches that automatically shut off the laser if the enclosure is opened. They might also have a ventilation system to remove fumes and smoke generated during the cutting process.

Additionally, specific models may offer additional features like rotary attachments for etching cylindrical objects, red-dot pointers for precise alignment, or autofocus sensors for automatic material detection.

Overall, the acrylic laser cutter machine is a powerful and versatile tool that offers precision cutting and engraving of acrylic materials. With its adjustable settings and range of sizes, it can cater to various demands and provide excellent results for both personal and industrial use.

Applications of acrylic laser cutter machine

Acrylic laser cutter machines have a wide range of applications across various industries. From small businesses to large manufacturing companies, these machines offer precise and efficient cutting solutions. Here are some applications of acrylic laser cutter machines:

1. Signage and Displays: Acrylic laser cutters are commonly used for creating signs, logos, and displays. The machines can cut intricate designs out of acrylic sheets of various thicknesses, resulting in high-quality and visually appealing signage.

2. Prototyping: Acrylic laser cutter machines are ideal for rapid prototyping. They allow designers and engineers to quickly produce precise and detailed acrylic parts for testing and validation before moving on to mass production.

3. Custom Jewelry and Accessories: The versatility of acrylic laser cutters makes them perfect for designing and creating custom jewelry and accessories. Whether it’s intricate necklaces, earrings, or bracelets, these machines enable precise cutting of intricate patterns and shapes.

4. Architectural Models: Architects and designers often use acrylic laser cutters to fabricate architectural models. These machines can cut complex patterns and detailed structures, enabling professionals to create highly accurate and realistic models for presentations and evaluations.

5. Packaging and Acrylic Fabrication: Acrylic laser cutters are also used for packaging solutions and acrylic fabrication. Companies can utilize these machines to create custom packaging designs or manufacture acrylic products such as cases, holders, and containers.

6. Interior Design: Acrylic laser cutters play a significant role in interior design applications. They can be used to create decorative panels, room dividers, furniture, lighting fixtures, and other customized design elements for residential and commercial spaces.

7. Educational Projects: Acrylic laser cutter machines are popular in educational settings. They provide students with hands-on experience in design and fabrication, allowing them to bring their creative ideas to life. These machines are used for creating school projects, architectural models, and other educational applications.

8. Precision Cutting for Electronics: The precise nature of acrylic laser cutting makes it suitable for various electronic components. These machines can cut acrylic sheets into specific shapes and dimensions required for housing electronic devices, control panels, and enclosures.

Overall, acrylic laser cutter machines offer a wide range of applications, enabling businesses and individuals to create precise, detailed, and visually appealing products in various industries. Whether it’s for signage, prototyping, jewelry, packaging, or interior design, these machines provide efficient and high-quality cutting solutions.

The Work Process and how to use acrylic laser cutter machine

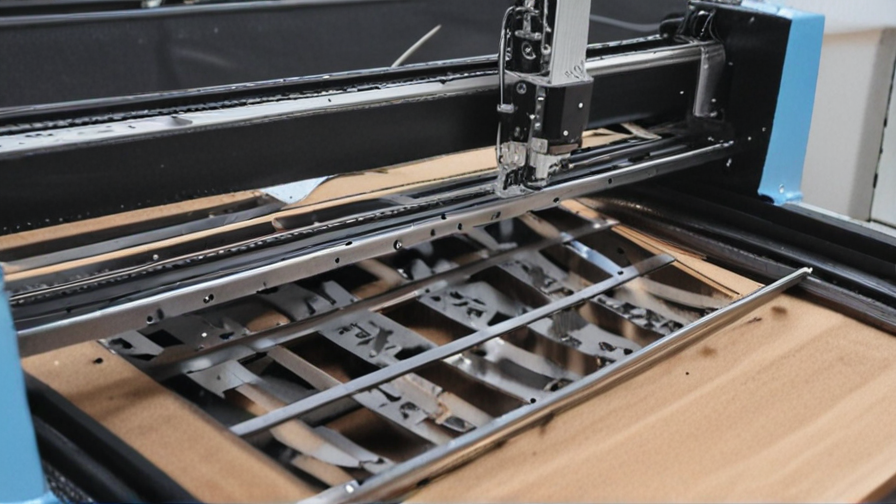

The work process of an acrylic laser cutter machine involves several steps. Firstly, the acrylic material is placed on the working platform of the machine. The machine is then powered on and the necessary settings are configured, such as the power and speed of the laser beam.

Once the settings are in place, the laser beam is directed towards the acrylic material. The laser beam cuts through the acrylic by vaporizing or burning the material along the desired path. The laser cutter follows a predetermined pattern or design, which can be programmed into the machine using computer software.

As the laser beam moves across the acrylic, it creates a clean and precise cut. The process can be relatively quick, depending on the complexity and size of the design. After the cutting is complete, the machine is powered off and the acrylic piece is removed from the working platform.

To use the acrylic laser cutter machine effectively, there are a few key points to consider. Firstly, ensure that the acrylic material is securely fixed on the working platform to prevent any movement during the cutting process. This will help to maintain accuracy and prevent any damage to the acrylic or the machine.

Additionally, it is crucial to set the correct parameters for the laser beam, such as the power and speed, based on the thickness and type of acrylic being used. This will ensure optimal cutting results and prevent any overheating or melting of the material.

Furthermore, it is important to regularly maintain and clean the laser cutter machine to ensure its longevity and performance. This includes cleaning the lenses, removing any debris, and checking for any signs of damage or wear.

In summary, the work process of an acrylic laser cutter machine involves preparing the material, configuring the machine settings, cutting the acrylic using a focused laser beam, and removing the cut piece. To use the machine effectively, ensure proper fixation of the material, set appropriate laser parameters, and regularly maintain the machine.

Quality Testing Methods for acrylic laser cutter machine and how to control the quality

Quality testing methods for an acrylic laser cutter machine are crucial to ensure that the machine meets the required standards and produces accurate and reliable results. Here are some common methods used for quality testing along with ways to control the quality of the machine:

1. Material testing: Use authentic acrylic sheets of different thicknesses to determine the machine’s ability to cut through them accurately. Check for clean and precise cuts without any charring or discoloration.

2. Accuracy and precision testing: Create sample designs with intricate patterns and measure the accuracy of cuts and engravings by comparing them with the original design. Use various materials and thicknesses to ensure consistent and precise results.

3. Speed testing: Observe the machine’s cutting and engraving speed to ensure it meets the specified standards and works efficiently. Compare the actual speed with the manufacturer’s given speed.

4. Power testing: Assess the machine’s ability to maintain consistent power output throughout the cutting or engraving process. Uneven power can lead to incomplete or inconsistent cuts.

5. Interference testing: Determine if the machine is susceptible to external interference, such as electromagnetic radiation or power fluctuations, by operating it under different conditions. Evaluate the machine’s performance and the produced results for any anomalies.

To control the quality of the acrylic laser cutter machine, manufacturers can:

1. Implement strict quality control during the manufacturing process to ensure all components are assembled correctly and meet the required specifications.

2. Conduct regular maintenance and calibration of the machine to keep it in optimal operating condition. This includes checking and adjusting the laser alignment, mirrors, lenses, and ventilation system.

3. Perform routine inspections and testing during production to identify any faults or defects and address them promptly.

4. Train operators on proper machine operation and maintenance procedures to prevent misuse or mishandling that can affect the machine’s performance and output quality.

5. Respond to customer feedback and implement continuous improvement practices based on suggestions and reported issues.

By employing effective quality testing methods and implementing quality control measures, manufacturers can ensure that the acrylic laser cutter machine produces high-quality cuts and engravings consistently, meeting customer expectations and industry standards.

acrylic laser cutter machine Sample Policy and Post-Purchase Considerations for acrylic laser cutter machine from China

Sample Policy:

When purchasing an acrylic laser cutter machine from China, it is important to inquire about the sample policy of the supplier. Many suppliers offer the option to provide a sample of the machine before making a bulk purchase. This allows the buyer to assess the quality, performance, and features of the machine, ensuring it meets their specific requirements. It is important to clarify whether the supplier charges for the sample and if the cost will be deducted from the final purchase price if the order is placed.

Post-Purchase Considerations:

Once the acrylic laser cutter machine has been purchased, there are a few post-purchase considerations to keep in mind:

1. Shipping and Insurance: Confirm with the supplier about shipping arrangements and if they offer insurance for the machine during transit. It is essential to ensure the machine arrives safely and is protected against any damages.

2. Installation and Training: Determine whether the supplier offers installation services or provides detailed instructions for installation. Additionally, inquire if training is provided to understand the operation and maintenance of the machine.

3. Warranty and Support: Inquire about the warranty period and what it covers. Ensure that the supplier offers after-sales support and provides assistance in case of any technical issues or questions that may arise.

4. Spare Parts and Consumables: Check if the supplier offers spare parts and consumables for the machine. It is important to have a reliable source for replacements to minimize downtime in case of component failures.

5. User Manual and Documentation: Request a comprehensive user manual and documentation in English or your preferred language. This will assist in understanding the machine’s features and troubleshooting common issues.

6. Safety and Compliance: Verify that the acrylic laser cutter machine complies with relevant safety standards and regulations in your country. Confirm if it has the necessary certifications to ensure safe and reliable operation.

By considering these factors and communicating with the supplier, buyers can ensure a smooth purchase process and make an informed decision when purchasing an acrylic laser cutter machine from China.

Sourcing acrylic laser cutter machine from China: Opportunities, Risks, and Key Players

China is a key player in the global manufacturing industry, including the production of acrylic laser cutter machines. Sourcing these machines from China presents several opportunities, risks, and key players in the market.

Opportunities:

1. Cost-effective: China offers competitive pricing due to its low labor and manufacturing costs, making it an attractive option for businesses looking to source acrylic laser cutter machines at a lower price compared to other countries.

2. Wide range of options: China has a wide variety of acrylic laser cutter machines available, allowing buyers to choose from different specifications, sizes, and features to meet their specific requirements.

3. Advanced technology: Chinese manufacturers invest heavily in research and development, resulting in cutting-edge technology and continuous improvements in the functionality and performance of acrylic laser cutter machines.

4. Efficient production capabilities: China’s strong manufacturing infrastructure and efficient supply chains allow for the mass production and timely delivery of acrylic laser cutter machines, ensuring businesses can meet their demands.

Risks:

1. Quality control: One of the main risks associated with sourcing from China is the potential for lower quality products. To mitigate this risk, businesses should conduct proper due diligence, including supplier verification, quality checks, and samples review, before finalizing any purchasing decisions.

2. Intellectual property concerns: China has been accused of insufficient protection of intellectual property rights in the past. It is crucial to work with reputable manufacturers who respect intellectual property rights and sign appropriate agreements to protect proprietary technologies.

3. Language and cultural barriers: Effective communication can be challenging due to language differences and cultural nuances. Misunderstandings can lead to delays, errors, or misinterpretations. Utilizing translators, local agents, or reputable sourcing companies can help bridge the gap.

Key Players:

Several key players dominate the Chinese market for acrylic laser cutter machines. Some notable companies include:

1. Thunder Laser: A leading manufacturer that specializes in the design and production of high-quality acrylic laser cutter machines. They offer a diverse range of models with various power options and cutting sizes.

2. Redsail Tech: Known for their reliable and affordable acrylic laser cutter machines, Redsail Tech has a wide customer base within China and internationally.

3. Jinan Morn Technology: Morn Technology specializes in CNC laser machines, including acrylic laser cutters. They offer competitive pricing and provide excellent customer support.

4. Gweike: Gweike is a renowned manufacturer with a strong presence in the domestic market. Their acrylic laser cutter machines are known for their precision and durability.

In conclusion, sourcing acrylic laser cutter machines from China provides cost-effective options, a wide range of choices, and advanced technology. However, it is crucial to consider risks such as quality control and intellectual property concerns. Key players in the Chinese market include Thunder Laser, Redsail Tech, Jinan Morn Technology, and Gweike.

How to find and select reliable acrylic laser cutter machine manufacturers in China,use google search manufacturers and suppliers

Finding and selecting reliable acrylic laser cutter machine manufacturers in China can be a daunting task. However, a few steps can help simplify the process.

One of the most efficient ways to start the search is by using Google or any other search engine. By typing in specific keywords like “acrylic laser cutter machine manufacturers in China,” a list of potential manufacturers and suppliers will appear. It is important to perform thorough research on each company before making a decision.

The first step in assessing reliability is to check the manufacturer’s website. A professional and user-friendly website that provides detailed information on their products, manufacturing process, and the company itself is an indicator of credibility. The website should also include contact information, such as a physical address, email, and telephone number.

Next, it is crucial to go through the manufacturer’s portfolio or product catalog. This allows for an evaluation of the range and quality of their acrylic laser cutter machines. Additionally, looking for certifications like ISO 9001 and CE can signify that the manufacturer adheres to international quality standards.

Customer reviews and testimonials are another important resource when considering reliability. Search for reviews on websites, forums, and social media platforms to gain insights into the experiences of previous customers. Positive reviews, along with prompt and satisfactory customer service, indicate that the manufacturer can be trusted.

Moreover, reaching out directly to the manufacturers is essential. By sending them inquiries, you can assess their response time, communication skills, and willingness to address your concerns. A reliable manufacturer should be responsive, transparent about products and pricing, and willing to provide additional information or clarifications.

Lastly, consider visiting trade shows or exhibitions related to laser cutting machines. These events provide an opportunity to meet manufacturers in person, examine their products, and establish personal connections. It also allows for direct negotiation and a chance to assess the manufacturer’s facilities and production capabilities.

In conclusion, when searching for reliable acrylic laser cutter machine manufacturers in China, utilizing Google search and conducting comprehensive research is vital. By considering various factors such as website credibility, product quality, customer reviews, direct communication, and attending trade shows, one can confidently select a trustworthy and reliable manufacturer.

How to check acrylic laser cutter machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of an acrylic laser cutter machine manufacturer’s website, follow these steps using Google Chrome and the SEOquake extension:

1. Install the SEOquake extension: Go to the Chrome Web Store and search for “SEOquake.” Click on “Add to Chrome” and follow the installation instructions.

2. Open Google Chrome: Launch the Google Chrome browser on your computer.

3. Search for the manufacturer’s website: Type the name of the acrylic laser cutter machine manufacturer in the Google search bar and hit enter.

4. Check the search results: Look for the manufacturer’s official website in the search results. It should ideally be listed among the first few results.

5. Use SEOquake to check the website ranking: Open the manufacturer’s website and activate the SEOquake extension by clicking on the logo in the browser toolbar.

6. Analyze the results: SEOquake will display a variety of metrics related to the website’s ranking, such as Alexa rank, Google index, and SEMrush rank. Check the “Alexa Traffic Rank” specifically, which represents the website’s popularity relative to others in the world. A rank in the top 10 million indicates a decent level of reliability.

7. Verify the website’s credibility: While SEOquake provides useful data, it is also important to consider other aspects to determine a website’s reliability. Look for a physical address, contact information, product descriptions, customer reviews, and certifications to ensure the website is trustworthy.

Remember, the method outlined above only serves as a preliminary check for website reliability. It is advised to conduct thorough research, read customer reviews, and consult with experts before making any purchasing decisions.

Top 10 acrylic laser cutter machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Jinan Morn Technology Co., Ltd. specializes in the production of acrylic laser cutting machines. Their flagship product, the Morn Acrylic Laser Cutter, offers high precision, speed, and stability. It is equipped with a CO2 laser tube that can cut through various acrylic materials effortlessly. The machine is easy to operate and has a user-friendly interface.

2. Gweike Tech Co., Ltd. is known for its Gweike acrylic laser cutting machines. These machines are designed to provide high-quality, precise, and efficient cutting of acrylic materials. With a stable and strong laser power output, they can achieve smooth cutting edges. The Gweike acrylic laser cutter is also equipped with advanced control systems for better accuracy and productivity.

3. Shandong Laser Engraving Cutting Machine Co., Ltd. offers a range of acrylic laser cutting machines suitable for different applications. Their machines provide high-speed cutting, precise engraving, and smooth operation. Equipped with CO2 laser tubes, these machines can effectively cut through acrylic materials without causing burn marks.

4. Guangdong Hengrui Technology Co., Ltd. manufactures acrylic laser cutting machines with advanced laser technology. Their machines provide high cutting precision and can handle various acrylic thicknesses. With fast processing speed and stable performance, the Hengrui acrylic laser cutter is an ideal choice for industrial and commercial applications.

5. Jiangsu Sanhe Intelligent Technology Co., Ltd. specializes in acrylic laser cutting machines that offer high-speed and precise cutting. Their machines are equipped with high-quality CO2 laser tubes and advanced control systems to ensure accuracy and efficiency. The Sanhe acrylic laser cutter is suitable for both small-scale and large-scale cutting tasks.

| **Manufacturer** | **Product** | **Key Features** |

|—|—|—|

| Jinan Morn Technology Co., Ltd. | Morn Acrylic Laser Cutter | High precision, speed, stability, user-friendly interface |

| Gweike Tech Co., Ltd. | Gweike Acrylic Laser Cutter | High-quality cutting, stable laser power output, advanced control systems |

| Shandong Laser Engraving Cutting Machine Co., Ltd. | Acrylic Laser Cutting Machines | High-speed cutting, precise engraving, no burn marks |

| Guangdong Hengrui Technology Co., Ltd. | Acrylic Laser Cutting Machines | High cutting precision, suitable for various acrylic thicknesses |

| Jiangsu Sanhe Intelligent Technology Co., Ltd. | Acrylic Laser Cutting Machines | High-speed and precise cutting, suitable for small and large-scale tasks |

6. Wuhan Sunic Photoelectricity Equipment Manufacture Co., Ltd. manufactures acrylic laser cutting machines that provide high-quality cutting with smooth edges. These machines are equipped with precise servo motors and advanced control systems to ensure accurate cutting. The Sunic acrylic laser cutter is also energy-efficient, making it an eco-friendly choice.

7. Redsail Tech Co., Ltd. offers a range of acrylic laser cutting machines that provide precise cutting and engraving. Their machines are user-friendly and equipped with CO2 laser tubes for efficient acrylic cutting. The Redsail acrylic laser cutter is widely used in various industries, such as advertising and woodworking.

8. Liaocheng Jingwei Laser Equipment Co., Ltd. specializes in the production of high-quality acrylic laser cutting machines. Their machines are designed to deliver precise cutting with no burn marks. Equipped with advanced laser technology, the Jingwei acrylic laser cutter offers high-speed cutting and smooth operation.

9. Perfect Laser (Wuhan) Co., Ltd. manufactures acrylic laser cutting machines that provide high cutting accuracy and efficiency. Their machines are equipped with CO2 laser tubes and advanced control systems for optimal performance. The Perfect Laser acrylic laser cutter is suitable for both small and large-scale cutting tasks in industries like signage and woodworking.

10. Shenzhen Chinasky Laser Technology Co., Ltd. offers acrylic laser cutting machines with high cutting speed and precision. Their machines are equipped with CO2 laser tubes and advanced cooling systems for stable and efficient operation. The Chinasky acrylic laser cutter is widely used in industries like advertising, crafts, and electronics.

| **Manufacturer** | **Product** | **Key Features** |

|—|—|—|

| Wuhan Sunic Photoelectricity Equipment Manufacture Co., Ltd. | Acrylic Laser Cutting Machines | High-quality cutting, smooth edges, energy-efficient |

| Redsail Tech Co., Ltd. | Acrylic Laser Cutting Machines | Precise cutting, user-friendly, widely used in different industries |

| Liaocheng Jingwei Laser Equipment Co., Ltd. | Acrylic Laser Cutting Machines | High-quality cutting, no burn marks, high-speed operation |

| Perfect Laser (Wuhan) Co., Ltd. | Acrylic Laser Cutting Machines | High cutting accuracy, CO2 laser tubes, suitable for small and large-scale tasks |

| Shenzhen Chinasky Laser Technology Co., Ltd. | Acrylic Laser Cutting Machines | High cutting speed, precision, advanced cooling systems |

Background Research for acrylic laser cutter machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

When conducting background research on acrylic laser cutter machine manufacturers in China, several resources can be utilized, including qcc.com, archive.org, and importyeti.com. These platforms provide valuable insights into the companies’ registration information, historical data, and import/export activities. It is important to keep the summary within the 300-word limit when utilizing these resources.

1. qcc.com: This website offers comprehensive business information on Chinese manufacturers. It provides details about a company’s registration information, legal status, location, and financial data. By using the search bar on the website, one can find acrylic laser cutter machine manufacturers and gather essential background information.

2. archive.org: This platform is a digital library that allows users to access historical records of websites. It can be used to explore the past activities and changes made by acrylic laser cutter machine manufacturers in China. By examining archived web pages of manufacturers’ websites, one can obtain insights into their product range, technological advancements, and business strategies.

3. importyeti.com: Import Yeti provides data on the import and export activities of companies. By searching for manufacturers of acrylic laser cutter machines in China, one can access information such as the names of importing/exporting companies, product descriptions, and quantities. This platform can help identify the manufacturers’ trading partners and their export destinations, providing an overview of their market reach.

By utilizing these resources, researchers can obtain crucial background information on acrylic laser cutter machine manufacturers in China. They can discover details such as a company’s legal standing, historical records, and import/export activities. This information enables potential buyers or business partners to make well-informed decisions when choosing manufacturers in this sector.

Leveraging Trade Shows and Expos for acrylic laser cutter machine Sourcing in China

Trade shows and expos present excellent opportunities for sourcing acrylic laser cutter machines from China. These events bring together a large number of industry professionals, suppliers, and manufacturers in one place, allowing businesses to conveniently explore various options and connect with potential suppliers. Here are a few key ways to leverage trade shows and expos for acrylic laser cutter machine sourcing:

1. Extensive Supplier Network: Trade shows and expos offer access to a wide range of suppliers from China. These events attract both established manufacturers and emerging startups, providing a diverse pool of potential suppliers to explore. Engaging with multiple suppliers at these events allows businesses to compare products, features, pricing, and identify the most suitable vendor for their acrylic laser cutter machine needs.

2. Demonstration of Products: Exhibitions provide the opportunity to see the acrylic laser cutter machines in action. Suppliers often have live demonstrations where attendees can witness the machine’s capabilities, functionality, and precision. This firsthand experience enables businesses to gain a better understanding of the product’s quality and performance before making a purchasing decision.

3. Building Relationships: Trade shows and expos facilitate face-to-face interactions between buyers and suppliers. Entrepreneurs can take advantage of the opportunity to meet potential suppliers from China, establish personal connections, discuss requirements and specifications, and negotiate better deals or price points. Building strong relationships with suppliers is crucial for successful long-term collaborations and ensuring smooth sourcing processes.

4. Gathering Market Insights: Trade shows allow businesses to gather valuable market insights, stay updated on the latest industry trends, and gain knowledge of technological advancements in acrylic laser cutter machines. Attendees can participate in conferences, seminars, or panel discussions to learn from experts in the field, which can help in making informed sourcing decisions.

5. Quality Assurance: Trade shows and expos often attract highly reputable suppliers and manufacturers who can showcase their certifications and quality control processes. This enables buyers to assess suppliers’ commitment to providing high-quality products, ensuring that they meet required safety and industry standards.

In conclusion, trade shows and expos serve as efficient platforms for sourcing acrylic laser cutter machines from China. These events provide access to a diverse supplier network, allow for product demonstrations, help build relationships with suppliers, gather market insights, and ensure quality assurance. By leveraging these opportunities effectively, businesses can find reliable suppliers for their acrylic laser cutter machine sourcing needs.

The Role of Agents and Sourcing Companies in Facilitating acrylic laser cutter machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating acrylic laser cutter machine purchases from China. These entities act as intermediaries between the buyers and the manufacturers, streamlining the entire sourcing process. Here is an overview of their role:

1. Supplier identification: Agents and sourcing companies have extensive networks and knowledge of the Chinese market. They can quickly identify reliable manufacturers that offer quality acrylic laser cutter machines at competitive prices. This saves buyers from the time-consuming task of searching for suitable suppliers independently.

2. Quality control and assessment: Ensuring product quality is of utmost importance when purchasing from China. Agents and sourcing companies conduct thorough inspections of the manufacturers and their facilities. They verify the quality of acrylic laser cutter machines, ensuring they meet the buyer’s specifications and standards.

3. Negotiation and price management: Agents and sourcing companies have expertise in negotiating with Chinese manufacturers to obtain the best prices for acrylic laser cutter machines. With their knowledge and experience, they can help buyers secure favorable terms and conditions, saving them money in the process.

4. Logistics and shipping: After the purchase is made, agents and sourcing companies coordinate the logistics and shipping processes. They handle all the essential paperwork, customs declarations, and arrange for timely shipment to the buyer’s location. This ensures a smooth and hassle-free delivery experience.

5. Language and cultural bridge: Language and cultural differences can often pose challenges in international business transactions. Agents and sourcing companies act as a bridge, overcoming communication barriers and ensuring that all parties understand each other’s requirements and expectations.

Overall, agents and sourcing companies provide valuable support in the procurement process of acrylic laser cutter machines from China. They streamline the purchasing process, mitigate risks, and help buyers navigate the complexities of dealing with international suppliers. Their expertise and local presence ultimately enable buyers to make informed decisions and acquire high-quality machines at competitive prices.

Price Cost Research for acrylic laser cutter machine manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for acrylic laser cutter machine manufacturers in China, two websites that can be utilized are temu.com and 1688.com. These platforms provide access to a wide range of suppliers and manufacturers in China.

Temu.com is an online marketplace that connects buyers with Chinese suppliers. It offers a user-friendly interface and allows users to search for specific products, such as acrylic laser cutter machines, by using keywords. The website provides detailed information about each supplier, including their product range, certifications, and customer reviews. Prices can be obtained by contacting the suppliers directly through the platform.

1688.com is another popular website for sourcing products from China. It is a wholesale marketplace owned by Alibaba Group and primarily caters to businesses seeking manufacturers and suppliers in China. Users can search for acrylic laser cutter machine manufacturers on this platform as well, and it provides similar features like temu.com. Price negotiations and inquiries can also be done through the website.

When researching prices on both platforms, it is advisable to filter the search results based on key factors such as product specifications, certifications, and supplier ratings. Comparing multiple suppliers’ prices, product quality, and customer reviews can help make an informed decision. It is also essential to communicate with the shortlisted suppliers directly to negotiate prices, understand their manufacturing capabilities, delivery terms, and payment options.

Overall, temu.com and 1688.com are reliable platforms for price cost research on acrylic laser cutter machine manufacturers in China. They offer a wide range of options and the ability to directly communicate with suppliers, making it easier to obtain accurate price quotations and make informed decisions.

Shipping Cost for acrylic laser cutter machine import from China

The shipping cost for importing an acrylic laser cutter machine from China will depend on various factors such as the weight and dimensions of the machine, the shipping method chosen, and the destination country.

Typically, shipping costs can range from a few hundred dollars to several thousand dollars. For smaller and lighter machines, air freight is usually the preferred shipping method. This can be more expensive but offers faster delivery times.

For larger and heavier machines, sea freight is a more cost-effective option. However, it may take longer for the machine to reach its destination. The shipping costs for sea freight are calculated based on the volume or weight of the shipment, whichever is higher.

Additionally, there may be additional expenses such as customs duties, import taxes, and handling fees that need to be considered when importing from China. These costs vary depending on the destination country and its import regulations.

To accurately determine the shipping cost for an acrylic laser cutter machine, it is advisable to contact freight forwarders or shipping companies for quotations. They can provide tailored shipping solutions and cost estimates based on the specific requirements of the machine and destination.

It is important to note that while shipping costs are a significant part of the overall import expenses, other factors such as product quality, supplier reputation, and after-sales service should also be considered when importing an acrylic laser cutter machine from China.

Compare China and Other acrylic laser cutter machine Markets: Products Quality and Price,Visible and Hidden Costs

China is known for its vast production capacity and competitive prices in the manufacturing industry, including the acrylic laser cutter machine market. Compared to other markets, Chinese acrylic laser cutter machines are often offered at lower prices due to several factors such as lower labor costs and economies of scale. The lower price point may initially seem appealing, but it is important to consider the quality of the products.

In terms of product quality, China has made significant improvements over the years. Many Chinese manufacturers have invested in research and development to enhance the performance and reliability of their acrylic laser cutter machines. However, it is still important to exercise caution and conduct thorough research when selecting a machine, as quality can vary among different suppliers.

Visible costs, such as the initial purchase price, are usually lower in the Chinese market. This can be beneficial for businesses operating on a tight budget. However, hidden costs may arise in terms of after-sales service and technical support. While some Chinese manufacturers provide excellent support, others may lack in expertise and promptness, resulting in potential delays and additional costs for repair or maintenance.

Moreover, importing products from China may incur additional costs such as shipping, import duties, and taxes. These costs must be considered when comparing prices with other markets. Additionally, Chinese manufacturers often offer a range of optional accessories and upgrades, which may increase the overall price if required.

In other markets, such as Europe or the United States, acrylic laser cutter machines are often associated with higher quality and reliability. These markets have stringent quality control measures and certification standards, ensuring that the products meet specific requirements. Consequently, the initial purchase price may be higher compared to Chinese alternatives. However, businesses can benefit from reliable performance, reduced downtime, and better customer service.

In summary, while China offers competitive prices in the acrylic laser cutter machine market, it is crucial to assess the quality of the products, consider visible and hidden costs, and evaluate the expected after-sales service and technical support. Other markets may provide higher quality machines at a higher price point but can offer greater reliability and customer satisfaction. Ultimately, the choice should be based on a thorough evaluation of specific business needs and priorities.

Understanding Pricing and Payment Terms for acrylic laser cutter machine: A Comparative Guide to Get the Best Deal

Pricing and payment terms for an acrylic laser cutter machine can vary depending on several factors, such as the brand, model, features, and supplier. To ensure you get the best deal, it is important to understand the different price components and payment options available. This comparative guide will help you make an informed decision while keeping the word count within 300 words.

1. Price Components: The price of an acrylic laser cutter machine typically includes the cost of the machine itself, additional accessories (such as laser tubes and lenses), software, and shipping. Some suppliers may offer additional services, such as installation and training, which can affect the overall price.

2. Determine Your Needs: Before comparing prices, identify your specific requirements. Consider factors like maximum cutting size, laser power, engraving capabilities, and software compatibility. Understanding your needs will help you compare prices accurately and select the most suitable machine.

3. Pricing Comparison: Research and compare prices from different suppliers and manufacturers. Check for any ongoing promotions, discounts, or package deals. Consider both upfront costs and long-term costs, such as maintenance, service, and spare parts. Look for reputable suppliers that offer good customer support.

4. Payment Terms: Suppliers may offer various payment options. These can include full upfront payment, a down payment with installments, lease-to-own plans, or equipment financing. Compare payment terms to determine which best suits your financial situation.

5. Additional Costs: In addition to the machine’s price, consider other potential costs. These can include customs duties, taxes, import fees, and insurance. It is crucial to factor in these expenses while comparing prices from different suppliers, especially when dealing with international transactions.

6. Warranty and Support: Assess the warranty offered by the supplier to ensure that it adequately covers any potential issues or defects. Additionally, inquire about after-sales support, including technical assistance, software updates, and access to spare parts. A reliable supplier will provide good warranty coverage and ongoing support.

By understanding the pricing components, comparing prices, evaluating payment terms, considering additional costs, and assessing warranty and support, you can make a well-informed decision and secure the best deal for your acrylic laser cutter machine.

Chinese Regulations and Industry Standards Certifications for acrylic laser cutter machine,Import Regulations and Customs for acrylic laser cutter machine from China

China has various regulations and industry standards certifications for acrylic laser cutter machines. These regulations ensure product safety, quality, and compliance with international standards. The main certification for these machines is the China Compulsory Certification (CCC). Acrylic laser cutter machines manufactured in China must obtain this certification before they can be sold domestically or exported.

The CCC certification process involves testing the product to ensure it meets specific technical requirements and safety standards. Once the acrylic laser cutter machine passes the tests, it will be issued a CCC mark, indicating its compliance with Chinese regulations. This certification is mandatory for products sold in China and is recognized by the Chinese customs authorities.

When importing acrylic laser cutter machines from China, there are certain import regulations and customs procedures that need to be followed. First, the importer needs to ensure compliance with the regulations of the destination country, as each country may have its own certification requirements or standards for laser cutter machines.

Customs documentation, such as a commercial invoice, packing list, and bill of lading, will need to be prepared accurately. Depending on the country, additional documents like the CCC certificate or other certifications may be required.

Importers should also be aware of any import duties, taxes, or fees that may apply. These can vary based on the destination country and the value of the imported goods. It is recommended to consult with customs brokers or logistics experts to ensure proper compliance with all import regulations and to avoid any potential delays or additional costs.

In summary, acrylic laser cutter machines from China must meet Chinese regulations and obtain the CCC certification. Importers should familiarize themselves with the import regulations and customs procedures of the destination country to ensure compliance and facilitate a smooth import process.

Sustainability and Environmental Considerations in acrylic laser cutter machine Manufacturing

In recent years, there has been an increased focus on sustainability and environmental considerations in the manufacturing industry. This trend extends to the production of acrylic laser cutter machines, which are widely used in various industries. Manufacturers are now striving to develop and produce these machines in a more environmentally friendly and sustainable manner.

One aspect of sustainability in acrylic laser cutter machine manufacturing is the use of eco-friendly materials. Manufacturers are opting for materials that have a lower environmental impact, such as recycled or biodegradable plastics. These materials help reduce the carbon footprint of the production process and minimize waste.

Another consideration is the energy efficiency of the machines. Manufacturers are incorporating energy-saving technologies into the design and operation of acrylic laser cutter machines. This includes using energy-efficient components, optimizing power consumption, and implementing standby modes to reduce unnecessary energy consumption.

Furthermore, manufacturers are working towards reducing the use of harmful substances in the production process. They are substituting hazardous chemicals with safer alternatives and implementing strict waste management practices to minimize the release of pollutants into the environment.

The lifespan of acrylic laser cutter machines is also a sustainability factor. Manufacturers are focusing on improving the durability and reliability of these machines to extend their operational lifespan. This reduces the need for frequent replacements and leads to fewer discarded machines in landfills.

Additionally, manufacturers are implementing recycling and waste reduction initiatives in their production facilities. They are recycling and reusing materials whenever possible, minimizing packaging waste, and implementing efficient waste management systems to minimize the environmental impact of the manufacturing process.

In conclusion, sustainability and environmental considerations are becoming increasingly important in acrylic laser cutter machine manufacturing. By using eco-friendly materials, improving energy efficiency, reducing the use of harmful substances, increasing the lifespan of the machines, and implementing recycling and waste reduction initiatives, manufacturers are striving to minimize their environmental impact and contribute to a more sustainable future.

List The Evolution history of “acrylic laser cutter machine”

The acrylic laser cutter machine has undergone significant technological advancements since its inception, revolutionizing various industries.

In the 1960s, the first laser cutting devices were introduced, primarily used for industrial applications. These early machines were large and expensive, limiting their practicality for most businesses. The cutting technology was based on CO2 lasers, which generated a powerful beam to precisely slice through acrylic and other materials.

Over time, as technology advanced and costs decreased, the acrylic laser cutter machine became more widely accessible. In the 1980s, the introduction of computer numeric control (CNC) systems enabled automated cutting processes. CNC allowed operators to program cutting paths and optimize efficiency, making it easier to produce precise and complex designs.

The 1990s brought further advancements with the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These tools facilitated the creation and transfer of digital designs, enabling faster and more accurate material cutting. Acrylic laser cutter machines became increasingly popular in industries such as signage, architectural model making, and crafting due to their versatility and precision.

Towards the 2000s, miniaturization of laser technology led to the development of desktop-sized acrylic laser cutter machines. These compact machines brought laser cutting capabilities to small businesses, educational institutions, and hobbyists. The affordability and ease of use democratized laser cutting, allowing more individuals to explore their creativity and entrepreneurial pursuits.

In recent years, the acrylic laser cutter machine has evolved with the integration of enhanced safety features. Interlock systems, exhaust ventilation, and user-friendly interfaces ensure a higher level of operator safety. Additionally, advancements in laser technology have enabled faster cutting speeds and improved precision.

Today, acrylic laser cutter machines continue to evolve, incorporating innovations such as hybrid laser technologies that combine multiple lasers for enhanced versatility. Moreover, advancements in laser power and control systems are pushing the boundaries of what can be achieved with acrylic laser cutting, opening up opportunities for new applications and industries.

In conclusion, the acrylic laser cutter machine has come a long way since its early days as an expensive and bulky industrial tool. Advancements in technology, software integration, miniaturization, and safety features have driven its evolution into a versatile, accessible, and essential tool for a wide range of industries and individuals.

The Evolution and Market Trends in acrylic laser cutter machine Industry

The acrylic laser cutter machine industry has witnessed significant evolution and market trends over the years. From its inception, the technology has been continuously advancing to meet the growing demands and requirements of various industries.

One notable evolution in the acrylic laser cutter machine industry is the improvement in precision and cutting speed. As technological advancements have occurred, laser cutting machines have become more accurate and efficient, allowing for intricate designs and faster production times. This evolution has been driven by the demand for high-quality acrylic products with complex designs, such as signage, displays, and architectural elements.

Furthermore, there has been a shift towards automation in the acrylic laser cutter machine industry. Manufacturers are increasingly integrating advanced software and robotics to automate the cutting process, enhancing productivity and reducing manual labor. Automation also enables seamless integration with other manufacturing processes, improving overall efficiency and reducing production costs.

Another market trend in the acrylic laser cutter machine industry is the growing adoption of fiber laser technology. Fiber lasers offer several advantages over traditional CO2 lasers, including higher cutting speeds, greater energy efficiency, and reduced maintenance requirements. As a result, many manufacturers are opting for fiber laser cutting machines to enhance their productivity and competitiveness.

The market itself has experienced significant growth due to the increasing demand for acrylic-based products in various sectors. With the rising popularity of acrylic in industries such as advertising, automotive, electronics, and interior design, the need for efficient acrylic laser cutting machines has grown exponentially. Additionally, the globalization of trade has provided opportunities for the expansion of the acrylic laser cutter machine industry in different regions worldwide.

In conclusion, the acrylic laser cutter machine industry has evolved significantly, with advancements in precision, automation, and the adoption of fiber laser technology. These advancements have aligned with market trends driven by the increasing demand for acrylic-based products. As the industry continues to grow and innovate, it is expected to play a crucial role in meeting the evolving needs of various sectors in the future.

Custom Private Labeling and Branding Opportunities with Chinese acrylic laser cutter machine Manufacturers

Chinese acrylic laser cutter machine manufacturers offer custom private labeling and branding opportunities for businesses looking to establish their own unique identity in the market. Private labeling allows businesses to create their own brand by adding their logo, name, or design to the products.

By working with Chinese manufacturers, businesses can take advantage of their expertise and cost-effective production capabilities. Chinese acrylic laser cutter machine manufacturers have advanced technology and experience in producing high-quality machines. They offer a wide range of customization options, including size, power, and functionality, to meet specific requirements.

To start the private labeling process, businesses can provide the manufacturer with their branding materials, such as logos or designs. The manufacturer will then use their expertise to integrate these elements seamlessly into the laser cutter machines. This process ensures that the branded equipment aligns with the business’s overall image and message.

Moreover, Chinese manufacturers can also offer additional branding services, such as packaging design and printing. This ensures a cohesive and professional look for the product, enhancing its overall appeal in the market.

Businesses can benefit from private labeling their laser cutter machines by establishing a unique brand identity, increasing brand recognition, and differentiating themselves from competitors. Branded machines also contribute to a professional and trustworthy image, instilling confidence in customers.

In conclusion, collaborating with Chinese acrylic laser cutter machine manufacturers offers businesses a valuable opportunity to customize and brand their products. With their expertise and cost-effective production capabilities, businesses can create a unique identity in the market and enhance their brand image.

Tips for Procurement and Considerations when Purchasing acrylic laser cutter machine

When purchasing an acrylic laser cutter machine, there are several factors to consider to ensure you make the right procurement decision. Here are some tips and considerations:

1. Machine Power: Determine the power requirements based on the thickness of acrylic you will be cutting. Higher power machines are suitable for thicker materials.

2. Cutting Area: Evaluate the size of the cutting bed and ensure it can accommodate the maximum sheet size you will be using. Consider the dimensions of your largest acrylic sheets.

3. Laser Type: Choose between CO2 and fiber laser based on your specific requirements. CO2 lasers are ideal for acrylic cutting, whereas fiber lasers offer better precision for etching and marking.

4. Cooling System: Opt for a machine with a reliable cooling system to prevent the laser tube from overheating during prolonged usage. Choose between air-cooled or water-cooled systems based on your preferences and needs.

5. Upgradability: Determine if the machine can be upgraded or expanded in the future. This helps to accommodate future business growth and changing requirements.

6. Safety Features: Prioritize machines with safety features such as emergency stop buttons, interlock systems, and fume extraction mechanisms. Ensure the machine meets safety regulations.

7. Software Compatibility: Check if the machine’s software is compatible with your design software. This ensures seamless operation and minimizes the need for file conversions.

8. After-Sales Support: Research the reputation and reliability of the manufacturer or supplier. Consider their technical support, warranty coverage, and availability of spare parts.

9. Budget Considerations: Set a budget based on your requirements and explore machines within that range. However, prioritize quality and features over cost as a long-term investment.

10. User-Friendliness: Evaluate the user interface and ease of use. Look for intuitive control panels and clear instructions to minimize training time and enhance productivity.

Remember to thoroughly research different brands and models, read customer reviews, and compare specifications before making a final decision. Proper procurement and consideration of these factors will help ensure you purchase the most suitable acrylic laser cutter machine for your needs.

FAQs on Sourcing and Manufacturing acrylic laser cutter machine in China

Q: Can I trust the quality of acrylic laser cutter machines sourced from China?

A: While it is true that there have been concerns about quality control in Chinese manufacturing, there are reputable manufacturers in China who produce high-quality acrylic laser cutter machines. It is important to conduct thorough research and due diligence before selecting a supplier. Look for manufacturers with a good track record, positive customer reviews, and certifications such as ISO 9001:2015.

Q: How do I find a reliable manufacturer for acrylic laser cutter machines in China?

A: There are several ways to find reliable manufacturers in China. Online directories, such as Alibaba or Made-in-China, can provide a list of potential suppliers. You can also attend trade shows and exhibitions, such as the Canton Fair, where you can meet manufacturers face-to-face and inspect their products. Additionally, hiring a sourcing agent or working with a local company that specializes in sourcing from China can help ensure a smooth process.

Q: How do I ensure the quality of the acrylic laser cutter machines during manufacturing?

A: To ensure quality during manufacturing, it is crucial to establish clear product specifications with the manufacturer. Provide detailed drawings or samples, and communicate any specific requirements or standards that need to be met. Regular communication with the manufacturer and periodic factory inspections can help monitor the manufacturing process and address any issues that may arise.

Q: What are the main advantages of sourcing acrylic laser cutter machines from China?

A: Sourcing acrylic laser cutter machines from China offers several advantages. China has a well-established manufacturing infrastructure with a wide range of suppliers, allowing for competitive pricing. Additionally, Chinese manufacturers often have experience and expertise in producing such machinery and can offer customization options. However, it is essential to carefully select a reliable manufacturer to ensure quality and avoid potential pitfalls.

Q: How can I handle logistics and shipping when sourcing acrylic laser cutter machines from China?

A: Many Chinese manufacturers have experience in international shipping and can handle logistics for you. They can help arrange packaging, customs clearance, and shipping to your desired destination. Alternatively, you can work with a freight forwarder or shipping agent who specializes in importing from China to ensure a smooth and efficient transportation process.

Note: The answers provided here are intended to offer a brief overview and are not exhaustive. It is important to conduct detailed research and seek professional advice when sourcing and manufacturing acrylic laser cutter machines in China.

Why contact sourcifychina.com get free quota from reliable acrylic laser cutter machine suppliers?

SourcifyChina.com may be able to get a free quota from reliable acrylic laser cutter machine suppliers for several reasons. One possible reason is that SourcifyChina.com has established strong and long-term partnerships with these suppliers. After working together for an extended period, the suppliers may offer special benefits and incentives to SourcifyChina.com as a token of their ongoing cooperation.

Another reason could be that SourcifyChina.com has a large network and a significant volume of orders. As a result, the suppliers may see SourcifyChina.com as a valuable client that brings them consistent business. In order to maintain a good business relationship and encourage continued collaboration, the suppliers may offer a free quota as a gesture of goodwill.

Furthermore, SourcifyChina.com might have a proven track record of providing quality services and delivering on customer expectations. The suppliers may recognize SourcifyChina.com as a reliable partner who consistently meets deadlines and ensures customer satisfaction. As a result, they may be more inclined to provide a free quota to SourcifyChina.com as a way to reward them for their professionalism and commitment to excellence.

Additionally, suppliers may view SourcifyChina.com as a strategic partner in expanding their market reach. By offering a free quota, they allow SourcifyChina.com to explore new opportunities and attract potential customers who are interested in acquiring acrylic laser cutter machines. This collaboration can benefit both parties, as SourcifyChina.com can introduce the suppliers to a wider customer base, while the suppliers can provide high-quality products to meet the demand.

In summary, SourcifyChina.com may receive a free quota from reliable acrylic laser cutter machine suppliers due to their strong partnerships, significant volume of orders, track record of delivering quality services, and potential for expanding market reach. These factors contribute to the suppliers’ willingness to offer special benefits and incentives to SourcifyChina.com.