Introduce about acrylic machine cutter guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

The acrylic machine cutter guide is an essential tool used in the process of cutting acrylic sheets. It is designed to provide precise measurements and cutting paths, ensuring accurate and clean cuts every time. This guide is commonly used in various industries, such as signage, displays, and crafts.

In terms of quality, acrylic machine cutter guides are usually made of high-quality materials like durable plastics or metals. They are known for their sturdiness and ability to withstand repeated use without losing accuracy. The measurements and cutting paths provided by these guides are typically reliable and consistent.

When it comes to the cost of acrylic machine cutter guides, they can vary depending on the brand, material, and features included. Basic guides are generally more affordable, while those with advanced features and high-quality materials may be pricier. It is important to consider your specific needs and budget when choosing a guide.

There are numerous suppliers of acrylic machine cutter guides available in the market. It is advisable to choose a reputable supplier known for producing reliable and durable guides. Conducting research, reading customer reviews, and comparing prices can help identify trustworthy suppliers.

As far as certifications are concerned, some acrylic machine cutter guides may have certifications verifying their quality and performance standards. These certifications can provide assurance of the guide’s reliability and can be valuable when selecting a product.

The market for acrylic machine cutter guides is vast and diverse. They are widely used in industries and businesses that deal with acrylic sheets, contributing to their popularity and demand. Additionally, individuals engaged in DIY projects that involve acrylic cutting can also benefit from using these guides.

Here are some tips to consider when using an acrylic machine cutter guide:

1. Ensure the guide is securely attached to the cutting surface to avoid any movement during the process.

2. Double-check the measurements and cutting paths before initiating the cut to prevent any mistakes.

3. Use proper safety precautions such as wearing protective gloves and eyewear to minimize the risk of injuries.

Frequently Asked Questions (FAQ):

1. Can acrylic machine cutter guides be used for cutting other materials besides acrylic? Yes, these guides can be used for cutting various materials like thin plastics, wood, and even metals.

2. Are acrylic machine cutter guides suitable for both professional and DIY use? Absolutely, these guides are designed to cater to the needs of professionals and DIY enthusiasts alike.

3. Can acrylic machine cutter guides be customized to fit specific cutting requirements? Some suppliers offer customization options where guides can be tailored to specific measurements and cutting paths.

In conclusion, acrylic machine cutter guides are reliable tools used to achieve accurate and clean cuts in acrylic sheet applications. Their quality, cost, suppliers, certifications, and market demand should be duly considered when procuring these guides. Following tips and familiarizing yourself with FAQ can enhance your cutting experience.

Types of acrylic machine cutter

Acrylic machine cutters are widely used in various industries for cutting and shaping acrylic sheets. There are different types of acrylic machine cutters available, each with its unique characteristics and applications. Here are some popular types of acrylic machine cutters:

1. Table saw: Table saws are commonly used for straight cuts in acrylic sheets. They have a large flat surface with a rotating blade protruding from the center. The sheet is pushed against the blade, enabling precise and straight cuts.

2. Laser cutter: Laser cutters use a high-powered laser beam to cut through acrylic sheets. This type of cutter provides clean, precise cuts with minimal heat deformation. It is particularly suitable for complex and intricate designs.

3. Router: Routers use high-speed rotating bits to cut through acrylic sheets. They are versatile and can be used for straight or curved cuts. Routers are often used for creating detailed patterns or designs on the surface of acrylic sheets.

4. Bandsaw: Bandsaws have a continuous blade looped around two wheels, which moves up and down to cut through materials. They are suitable for cutting thicker acrylic sheets and are known for their ability to create curved cuts.

5. Guillotine cutter: Guillotine cutters consist of a hinged blade that moves vertically to cut through materials. They are used for quick and straight cuts in thin acrylic sheets. Guillotine cutters are commonly used in signage and small-scale acrylic fabrication.

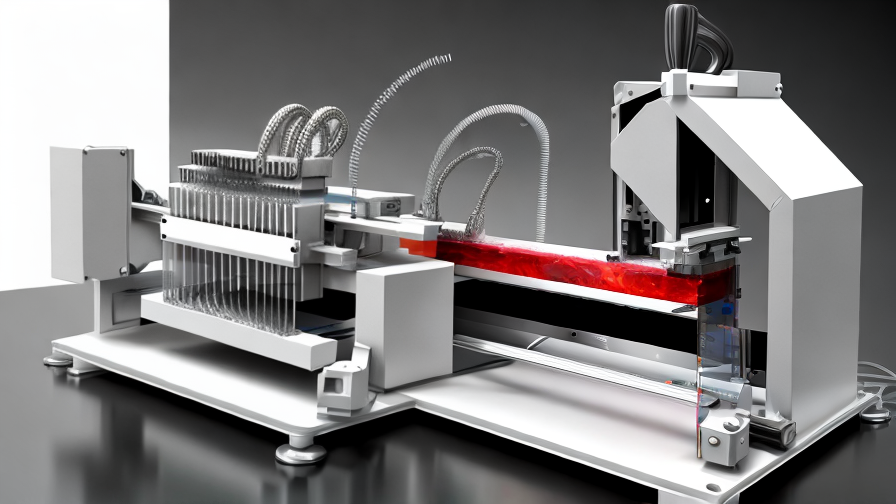

6. CNC machine: Computer Numerical Control (CNC) machines are automated cutting systems that use pre-programmed instructions to cut acrylic sheets accurately. They provide high precision and repeatability, making them ideal for mass production and complex designs.

It is important to choose the right type of acrylic machine cutter based on the desired cuts, sheet thickness, and level of precision required. Factors like cost, speed, and ease of use also need to be considered while selecting the appropriate acrylic machine cutter for a particular application.

Pros and Cons of Using acrylic machine cutter

Acrylic machine cutters, also known as laser cutters, offer a number of benefits and drawbacks. Below, we highlight some of the pros and cons of using these machines to help you make an informed decision.

Pros:

1. Precision: Acrylic machine cutters provide a high level of precision and accuracy, making it ideal for intricate and detailed designs. The laser beam allows for clean and precise cuts, resulting in sharp edges and smooth finishes.

2. Versatility: These machines can cut through various materials, including acrylic, wood, fabric, and metals. They can also etch and engrave designs onto surfaces, expanding the range of potential applications.

3. Speed: Laser cutters are generally faster than other cutting methods, enabling efficient production times. This is particularly beneficial for industries that require mass production or have tight deadlines.

4. Automation: Acrylic machine cutters are typically computer-controlled, allowing for automated processes. This reduces the need for manual labor, saving time and effort.

5. Minimal material wastage: The precision of laser cutting minimizes material wastage by cutting precisely along the desired outline. This ensures that you get the most out of your raw materials and helps to reduce costs.

Cons:

1. Initial cost: Acrylic machine cutters can be quite expensive to purchase initially, especially for high-quality models. This can be a significant investment for small businesses or individuals on a limited budget.

2. Training and expertise: Operating an acrylic machine cutter requires specialized training and expertise. Learning to use the software and calibrating the machine correctly can be time-consuming and may require additional training or hiring experienced operators.

3. Safety precautions: Working with laser machines carries certain safety risks, such as potential eye damage or fire hazards. Operators must strictly follow safety guidelines and wear protective gear to minimize these risks.

4. Material limitations: While acrylic machine cutters have a wide range of applications, there are certain materials that may not be compatible with the machine. Some materials, such as PVC or polycarbonate, may release toxic fumes when cut by a laser and should be avoided.

5. Maintenance and running costs: Acrylic machine cutters require regular maintenance to ensure optimal performance, including cleaning the lens and replacing consumables like laser tubes and filters. These maintenance tasks, as well as the electricity costs, add to the overall operational expenses.

In conclusion, acrylic machine cutters offer a plethora of benefits when it comes to precision, versatility, speed, automation, and material wastage reduction. However, they come with certain drawbacks, including the initial cost, training requirements, safety precautions, material limitations, and maintenance expenses. Evaluating these pros and cons will help you determine if an acrylic machine cutter is the right choice for your specific needs.

acrylic machine cutter Reference Specifications (varies for different product)

Acrylic machine cutters are versatile tools used in various industries for cutting acrylic sheets with precision. These machines are available in different models and specifications, catering to the diverse needs of users. The reference specifications of acrylic machine cutters may vary depending on the specific product, but some common features and specifications are typically found.

One important specification is the cutting capacity of the machine. This refers to the maximum thickness of acrylic sheets that the cutter can handle effectively. The cutting capacity can range from a few millimeters to several centimeters, allowing users to work with a wide range of acrylic sheet thicknesses.

Another key specification is the cutting speed. This refers to the rate at which the machine can cut through the acrylic sheet. Faster cutting speeds are desirable for high-volume production environments, while slower speeds may be more suitable for intricate and delicate cutting tasks.

Precision is a crucial aspect of acrylic cutting, and the accuracy specification determines how precisely the machine can cut the acrylic sheets. This specification is often measured in terms of tolerance, indicating the maximum permissible deviation from the intended cut line. Machines with high accuracy ensure clean and precise cuts.

The size of the working area or the cutting bed is another specification worth considering. The larger the cutting bed, the larger the acrylic sheets that can be accommodated for cutting. This is particularly important for users working with large-format acrylic sheets.

Additionally, some acrylic machine cutters may offer additional features such as automated material feed systems, laser alignment guides, or digital control panels for enhanced user experience and efficiency.

It is important to note that these reference specifications are indicative and can vary depending on the specific model and manufacturer. Therefore, it is advisable to review the product datasheet or consult with the manufacturer or supplier for precise specifications before making a purchase decision.

In summary, acrylic machine cutters are valuable tools for precise cutting of acrylic sheets. The reference specifications of these machines vary but typically include cutting capacity, cutting speed, accuracy, working area size, and additional features. Understanding these specifications helps users choose the right machine for their specific needs.

Applications of acrylic machine cutter

Acrylic machine cutters, also known as acrylic CNC machines or laser cutters, are powerful and versatile tools used in various industries and applications. These machines are specifically designed to cut, engrave, and shape acrylic sheets with a high level of precision and efficiency. Here are some of the key applications of acrylic machine cutters:

1. Advertising and Signage: Acrylic machine cutters are widely used in the advertising industry to create eye-catching signs, logos, and displays. The machines can cut intricate shapes and letters with smooth edges, allowing for the production of high-quality and professional-looking signage.

2. Architectural Models: Acrylic is a popular material in architectural model making. With an acrylic machine cutter, architects and designers can easily cut, engrave, and shape acrylic sheets to create accurate and detailed models of buildings, landscapes, and urban environments.

3. Industrial Prototyping: Acrylic machine cutters play a crucial role in rapid prototyping. Manufacturers and product designers can use these machines to quickly produce prototypes of new products, test their functionality, and make necessary adjustments before mass production. The precision and speed of acrylic machine cutters significantly reduce the time and cost associated with prototyping.

4. Arts and Crafts: Artists and hobbyists often use acrylic machine cutters to create intricate designs and patterns on various materials. These machines can engrave and cut acrylic, wood, leather, fabric, and even paper. The ability to create precise and detailed designs makes these machines ideal for creating customized artwork, jewelry, decorations, and other craft projects.

5. Awards and Trophies: Acrylic is a popular material for manufacturing awards and trophies due to its aesthetic appeal and durability. Acrylic machine cutters enable precise engraving and cutting of various designs, logos, and text onto acrylic surfaces, allowing for the production of unique and customized awards.

6. Packaging and Display: Acrylic machine cutters are employed in the production of packaging materials and display items. These machines can cut and shape acrylic sheets to create display stands, product holders, and packaging inserts that enhance the presentation and protection of various products.

In summary, acrylic machine cutters find applications in advertising, architecture, industrial prototyping, arts and crafts, awards manufacturing, and packaging/display production. The versatility, precision, and speed of these machines make them invaluable tools across multiple industries, enabling efficient and high-quality production of a wide range of acrylic products.

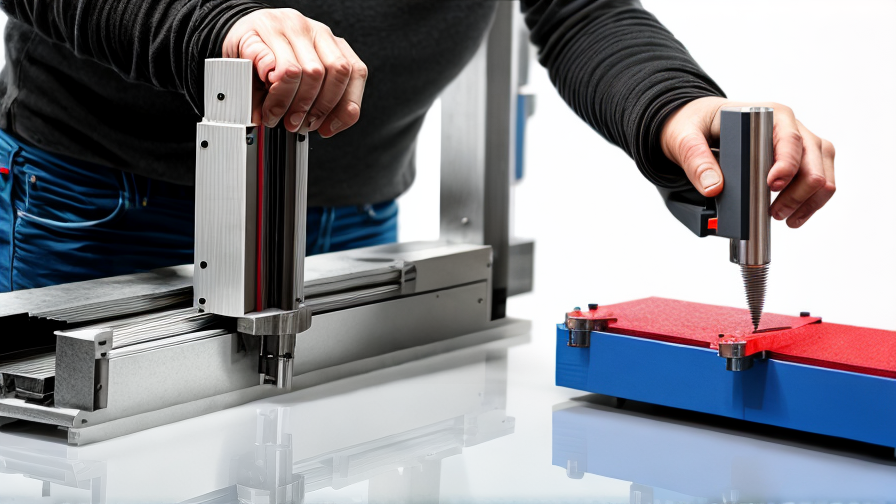

The Work Process and how to use acrylic machine cutter

The work process of using an acrylic machine cutter involves several steps. First, you need to set up the machine by ensuring it is properly assembled and all safety precautions are in place. This includes wearing protective gear such as gloves and goggles.

Next, you need to prepare the acrylic sheet that you want to cut. Measure and mark the desired dimensions on the acrylic sheet using a ruler and a marker. Ensure your measurements are accurate and the lines are straight.

Once the acrylic sheet is marked, place it on the cutting bed of the machine. Adjust the cutting bed and align the sheet so that the marked lines are aligned with the machine’s cutting head.

Switch on the machine and select the appropriate cutting speed and depth settings based on the material thickness and type. Most acrylic machine cutters have adjustable settings that allow you to control the cutting parameters.

Slowly lower the cutting head onto the acrylic sheet, making sure it is aligned with the marked lines. Start the cutting process by pressing the start button or triggering the cutter mechanism.

The machine will then move along the marked lines, cutting through the acrylic material. Ensure you maintain a steady hand and keep an eye on the cutting process to make sure it is going smoothly.

Once the cutting process is complete, switch off the machine and inspect the cut edges for smoothness and accuracy. You may need to make some post-processing adjustments like removing any burrs or rough edges using sandpaper or a file.

Remember to always follow safety guidelines and refer to the specific instructions provided by the manufacturer of your acrylic machine cutter. Practice caution and make sure to clean and maintain your machine regularly to ensure optimal performance and longevity.

Quality Testing Methods for acrylic machine cutter and how to control the quality

When it comes to quality testing methods for acrylic machine cutters, several techniques can be employed to ensure optimum performance and accuracy. Here are a few commonly used methods:

1. Visual Inspection: A visual examination of the machine cutter is crucial to identify any visible defects or abnormalities. Inspectors check for flaws like cracks, chips, or uneven surfaces, which may affect the cutter’s performance.

2. Dimensional Inspection: This technique involves measuring the key dimensions of the acrylic machine cutter using precision instruments like calipers or micrometers. Comparing the measured values against the required specifications helps identify any deviations that may impact the cutter’s functionality.

3. Cutting Efficiency Testing: Testing the efficiency and precision of the machine cutter involves running it through various cutting tasks. Inspectors observe the cutter’s performance in terms of accuracy, speed, and consistency while cutting acrylic materials. Any deviations or errors in the cutting process suggest a quality concern.

4. Durability Testing: To determine the cutter’s longevity and resistance to wear, durability testing is essential. This involves subjecting the cutter to repetitive, challenging cutting tasks to assess its ability to withstand prolonged usage without significant deterioration.

To effectively control the quality of acrylic machine cutters, the following measures can be implemented:

1. Establishing Clear Quality Standards: Clearly defining the required specifications for the machine cutter’s design, dimensions, and performance is crucial to ensure consistency in quality control.

2. Supplier Evaluation: Thoroughly evaluating the suppliers of acrylic machine cutters is essential. Assessing their manufacturing processes, quality control measures, and reputation in the industry can help choose reliable suppliers who prioritize quality.

3. In-process Inspections: Implementing regular inspections throughout the manufacturing process allows for early detection of potential issues. This helps prevent defective products from progressing further, saving time and resources.

4. Final Inspection: Conducting a comprehensive final inspection on each acrylic machine cutter before shipment ensures that only products meeting the defined quality standards are released to customers.

5. Continuous Improvement: Continually reviewing and improving the quality control processes based on feedback, customer reviews, and technological advancements is crucial to maintain the long-term quality of acrylic machine cutters.

By employing these quality testing methods and control measures, manufacturers can uphold high standards for acrylic machine cutters, ensuring customer satisfaction and reliable performance in various applications.

acrylic machine cutter Sample Policy and Post-Purchase Considerations for acrylic machine cutter from China

Sample Policy:

1. Sample Availability: Ensure that the supplier provides samples of the acrylic machine cutter before making a purchase. This allows you to evaluate the product’s quality, functionality, and compatibility with your requirements.

2. Sample Cost: Clarify whether the supplier charges for samples and the associated shipping costs. It is advisable to negotiate for free or discounted samples, especially if you intend to place a bulk order.

3. Sample Delivery Time: Discuss the estimated time required for sample delivery. Prompt sample delivery demonstrates the supplier’s efficiency and commitment to customer service.

4. Customization: Inquire whether the supplier offers customization options for the acrylic machine cutter. This ensures that the product aligns with your specific needs and preferences.

Post-Purchase Considerations:

1. Quality Inspection: Conduct a thorough inspection of the received acrylic machine cutter to verify its quality, including the material used, construction, and overall workmanship. Report any discrepancies or defects to the supplier immediately.

2. Warranty: Confirm the warranty period provided by the supplier for the acrylic machine cutter. Ideally, a reasonable warranty should be offered to cover any manufacturing defects or malfunctions.

3. After-Sales Support: Ensure that the supplier offers after-sales support, including technical assistance, spare parts availability, and repair services. Prompt and reliable after-sales support is essential for the smooth functioning and longevity of the machine cutter.

4. Shipping and Delivery: Monitor the shipping process closely, ensuring that the supplier arranges efficient and secure transportation for the acrylic machine cutter. Communicate any concerns regarding packaging or shipping delays promptly.

5. Feedback and Reviews: Leave a detailed review or provide feedback to the supplier, sharing your experience with the acrylic machine cutter. Positive feedback encourages the supplier to maintain their quality standards, while constructive criticism helps them improve their products and services.

By following this sample policy and considering the post-purchase aspects mentioned, you can ensure a smooth procurement process and a satisfactory purchase experience for the acrylic machine cutter from China.

Sourcing acrylic machine cutter from China: Opportunities, Risks, and Key Players

Sourcing acrylic machine cutters from China can offer various opportunities for businesses. Firstly, China is known for its cost-effective manufacturing capabilities, allowing companies to obtain acrylic machine cutters at competitive prices. This can significantly reduce production costs and increase profit margins for businesses in the acrylic industry. Additionally, China has a vast network of manufacturers specializing in acrylic machinery, providing a wide range of options for buyers to choose from.

However, there are certain risks associated with sourcing acrylic machine cutters from China. One major risk is substandard quality. As the market is flooded with numerous suppliers, it can be challenging to ensure consistent quality standards across all manufacturers. Conducting thorough due diligence and engaging in careful supplier selection processes can help mitigate this risk. Additionally, communication and language barriers may pose challenges during the negotiation and manufacturing processes. It is crucial for businesses to establish clear and effective communication channels to avoid misunderstandings and ensure production meets their specifications.

When it comes to key players in the acrylic machine cutter industry in China, several manufacturers stand out. Some prominent companies include Han’s Laser, Unikonex Technologies, and Jinan JinQiang Laser CNC Equipment Co., Ltd. These manufacturers have extensive experience in producing acrylic machinery and have gained a reputation for their reliable and high-quality products. Engaging with these key players can provide businesses with assurance of quality and after-sales support.

In conclusion, sourcing acrylic machine cutters from China can offer cost-effective solutions and a wide range of options for businesses. However, mitigating risks associated with quality and communication is crucial. Engaging with key players in the industry, such as Han’s Laser, Unikonex Technologies, and Jinan JinQiang Laser CNC Equipment Co., Ltd., can help ensure a successful sourcing process.

How to find and select reliable acrylic machine cutter manufacturers in China,use google search manufacturers and suppliers

When searching for reliable acrylic machine cutter manufacturers in China, using Google search can be an effective method. Here are some steps to follow:

1. Start by entering relevant keywords into the Google search bar, such as “acrylic machine cutter manufacturers” or “acrylic machine cutter suppliers in China.”

2. Review the search results, focusing on the websites of manufacturers or suppliers listed on the first few pages. These are more likely to be well-established and reliable companies.

3. Visit the websites of the top search results and gather information about their experience, expertise, certifications, and product range. Look for manufacturers with a proven track record and positive customer reviews.

4. Check if the company has their own manufacturing facilities or if they outsource the production. Manufacturers with in-house facilities are generally more reliable, as they have better control over quality and production processes.

5. Look for any certifications or qualifications mentioned on the websites, which can be an indication of adherence to international quality standards, such as ISO 9001.

6. Make sure the manufacturer has experience specifically in producing acrylic machine cutters. This expertise ensures that the products are manufactured using appropriate materials and techniques.

7. Contact the shortlisted manufacturers to get more information about their acrylic machine cutters. Inquire about their production capacity, lead times, customization options, and pricing.

8. Request samples if possible, so you can assess the quality of their acrylic machine cutters firsthand. This will allow you to see if their products meet your requirements.

9. Lastly, compare the information gathered from different manufacturers and suppliers to make an informed decision. Consider factors such as quality, pricing, lead times, and customer service.

By following these steps and conducting thorough research, you can find and select reliable acrylic machine cutter manufacturers in China using Google search. Remember to exercise due diligence and perform background checks to ensure the chosen supplier meets your standards and requirements.

How to check acrylic machine cutter manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of an acrylic machine cutter manufacturer’s website, you can follow these steps using Google Chrome and SEOquake:

1. Install SEOquake: Visit the Google Chrome Web Store and search for SEOquake. Install the extension to your browser.

2. Open the manufacturer’s website: Access the website of the acrylic machine cutter manufacturer you want to check.

3. SEOquake toolbar: Once the website is loaded, you will see the SEOquake toolbar on your browser. It provides various data about the website’s SEO, traffic, and more.

4. Check Ranking: Look for the “Google Index” section in the SEOquake toolbar and find the numerical value next to “Rank.” If this value is within the top 10 million, it indicates that the website has decent popularity or traffic.

5. Analyzing data: Proceed to examine other data provided by the SEOquake toolbar, such as the Alexa Rank, which gives an estimate of the website’s traffic volume, and the Pages Indexed, which indicates the number of pages from the website that are present in Google’s index.

6. Website reputation: While SEO ranking and traffic data indicate popularity, it’s also essential to evaluate the overall reputation of the manufacturer, product quality, and customer reviews. Consider reviewing feedback from existing customers, checking social media platforms, and consulting other trusted sources for a comprehensive assessment.

7. Length of content: Although it is not directly related to the website’s reliability, you can also check if the website provides sufficient, relevant, and informative content on their product, company, and policies. Make sure the content is not too brief or excessively filled with marketing jargon.

8. Trust signals: Look for trust signals on the website, such as secure payment options, SSL certificates, customer testimonials, and any official certifications or affiliations.

Remember to exercise discretion and apply critical thinking when evaluating website reliability, as the ranking alone may not guarantee authenticity or quality.

Top 10 acrylic machine cutter manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. ASL Laser Equipment Co., Ltd. specializes in manufacturing acrylic machine cutters for various applications such as signage, jewelry, and crafts. Their high-precision laser cutting machines offer fast and efficient cutting with minimum material wastage. ASL machines are equipped with advanced technology and provide excellent cutting quality, accuracy, and stability. They also offer customization options to meet specific customer requirements.

2. Jinan Senfei Technology Co., Ltd. is a leading manufacturer of acrylic machine cutters in China. Their range of products includes CNC routers and laser engraving/cutting machines that are suitable for acrylic and other materials. These machines ensure high-quality and precise cutting, making them ideal for various industries such as advertising, woodworking, and plastics.

3. Shandong Leiming CNC Equipment Co., Ltd. is renowned for its acrylic machine cutters, offering superior cutting performance and durability. Their CNC routers are designed to handle acrylic sheets of different sizes and thicknesses, delivering precise cuts with smooth edges. Leiming CNC Equipment also provides fast and reliable after-sales support.

4. Guangzhou Dragon Diamond Technology Co., Ltd. manufactures a wide range of acrylic machine cutters, including laser engraving/cutting machines and CNC routers. These machines are known for their high-speed processing, efficiency, and accuracy. Dragon Diamond’s products are widely used in industries such as advertising, woodworking, and model making.

5. Jinan Blue Elephant CNC Machinery Co., Ltd. offers advanced acrylic machine cutters that are suitable for both small businesses and large-scale production. Their CNC routers ensure precise cutting, high efficiency, and long life. Blue Elephant also provides a comprehensive warranty and reliable technical support.

6. Perfect Laser (Wuhan) Co., Ltd. is a leading manufacturer of acrylic machine cutters, providing laser cutting and engraving machines of various sizes and power options. Their machines deliver excellent cutting speed and precision, specifically designed to handle acrylic with ease. Perfect Laser also offers customization services according to customer needs.

7. Jinan Rhino CNC Equipment Co., Ltd. is known for its premium quality acrylic machine cutters. Their CNC routers deliver precise and clean cuts on acrylic sheets of different thicknesses. Rhino CNC Equipment’s machines are highly reliable, easy to operate, and offer excellent value for money.

8. Shandong Chencan Machinery Incorporated Company specializes in manufacturing CNC routers for acrylic cutting purposes. These machines offer high-speed cutting, exceptional precision, and smooth finishes. Chencan Machinery’s acrylic machine cutters are widely used in industries such as advertising, woodworking, and plastic fabrication.

9. Jinan Upgoal Mechanical Equipment Co., Ltd. provides a range of acrylic machine cutters, including laser engraving/cutting machines and CNC routers. Their machines ensure high-quality acrylic cutting with accuracy and efficiency. Upgoal Mechanical Equipment offers exceptional customer service and technical support.

10. Qingdao Steeler Woodworking Machinery Co., Ltd. manufactures high-performance CNC routers for acrylic cutting applications. These machines are designed to handle various thicknesses of acrylic with precision and speed. Steeler Woodworking Machinery is known for its durable and reliable products, backed by comprehensive after-sales service.

Table:

| Manufacturer | Specialization | Key Features |

| —————————————- | ———————————————————————– | ————————————————————————————————————————— |

| ASL Laser Equipment Co., Ltd. | Laser cutting machines for signage, jewelry, and crafts | High precision, excellent cutting quality, customization options |

| Jinan Senfei Technology Co., Ltd. | CNC routers and laser engraving/cutting machines | High-quality cutting, suitable for various industries |

| Shandong Leiming CNC Equipment Co., Ltd. | CNC routers for acrylic sheets | Precise cuts, smooth edges, reliable after-sales support |

| Guangzhou Dragon Diamond Technology Co. | Laser engraving/cutting machines and CNC routers | High-speed processing, efficiency, widely used in advertising and woodworking industries |

| Jinan Blue Elephant CNC Machinery Co. | CNC routers for small businesses and large-scale production | Precise cutting, high efficiency, reliable technical support |

| Perfect Laser (Wuhan) Co., Ltd. | Laser cutting and engraving machines for acrylic | Excellent cutting speed, precision, customization options |

| Jinan Rhino CNC Equipment Co., Ltd. | CNC routers for acrylic cutting | Precise and clean cuts, excellent value for money |

| Shandong Chencan Machinery Inc. | CNC routers for acrylic cutting | High-speed cutting, exceptional precision, smooth finishes |

| Jinan Upgoal Mechanical Equipment Co. | Laser engraving/cutting machines and CNC routers | High-quality cutting, accuracy, exceptional customer service |

| Qingdao Steeler Woodworking Machinery Co.| CNC routers for acrylic cutting | Precise and speedy cutting, durable products, comprehensive after-sales service |

In conclusion, these ten acrylic machine cutter manufacturers based in China offer a variety of products including laser cutting machines, CNC routers, and laser engraving/cutting machines. With varying specializations, they provide high-quality, precise, and efficient cutting solutions for acrylic sheets. Customers can choose based on their specific requirements, such as customization options, industry suitability, technical support, and after-sales service.

Background Research for acrylic machine cutter manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to searching for acrylic machine cutter manufacturers in China, several websites can be utilized to gather relevant information. This background research can be conducted using sources such as qcc.com, archive.org, and importyeti.com.

Qcc.com is a comprehensive business information database that provides details about Chinese companies. It allows users to search for specific manufacturers and acquire essential information such as contact details, company profile, and production capabilities. This platform is widely used to validate the credibility and reputation of potential manufacturers.

Archive.org is a valuable tool that allows users to access archived versions of websites. This can be particularly useful when seeking historical information about manufacturers or checking the evolution of a company’s website over time. By browsing through the past versions of a manufacturer’s website, researchers can gain insights into their previous products, client base, and market positioning.

Importyeti.com is an import-export trade records database that provides information on companies involved in international trade. This platform can help researchers identify Chinese acrylic machine cutter manufacturers based on their exporting activities and the countries they export to. By analyzing trade records, researchers can gain insights into a manufacturer’s production capacity, customer base, and market reach.

In conducting the background research, it is important to be concise and clear. Therefore, summarizing the findings in not more than 300 words can help to ensure a succinct report.

Leveraging Trade Shows and Expos for acrylic machine cutter Sourcing in China

Trade shows and expos can be highly effective for sourcing acrylic machine cutters in China. These events bring together manufacturers, suppliers, and industry professionals, providing a platform for showcasing products and connecting buyers with potential suppliers.

Attending trade shows and expos in China allows buyers to meet face-to-face with multiple suppliers, evaluate their offerings, negotiate deals, and establish long-term business relationships. These events also present an opportunity to learn about the latest trends, technologies, and innovations in the acrylic machine cutter industry.

To make the most of these events, buyers should thoroughly research and identify the trade shows and expos relevant to the acrylic machine cutter industry in China. Some popular trade shows in China for this sector include the Canton Fair, China International Machine Tool Show (CIMT), and China Hi-Tech Fair.

Prior to attending, buyers should set clear objectives, such as the desired quantity, quality, and price range of acrylic machine cutters they are looking for. It is important to bring detailed specifications and requirements for the desired product to ensure effective communication with suppliers.

During the trade shows and expos, buyers should allocate time to visit various booths and engage in conversations with suppliers. It is advisable to take note of suppliers’ credentials, production capabilities, product samples, and any certifications they possess. Asking relevant questions about manufacturing processes, lead times, and pricing will help buyers assess the suitability of each supplier.

After the trade shows and expos, buyers should narrow down the list of potential suppliers and follow up with them. This can include requesting formal quotations, conducting factory visits, or arranging product samples for testing. It is crucial to thoroughly evaluate the shortlisted suppliers before making a final decision.

In conclusion, trade shows and expos in China offer an excellent opportunity to source acrylic machine cutters. By conducting thorough research, setting clear objectives, and engaging in effective communication with suppliers, buyers can leverage these events to find the most suitable and reliable suppliers for their business needs.

The Role of Agents and Sourcing Companies in Facilitating acrylic machine cutter Purchases from China

Agents and sourcing companies play a crucial role in facilitating acrylic machine cutter purchases from China. With their deep understanding of the Chinese market, language proficiency, and extensive networks, they provide valuable assistance to businesses looking to import these products.

One of the key roles of agents and sourcing companies is to identify and vet reliable manufacturers or suppliers in China. They have a thorough knowledge of the local industry and can pinpoint the most suitable options based on the specific requirements of the buyers. This saves time and resources for businesses by eliminating the need for extensive research and verification.

Furthermore, agents and sourcing companies negotiate on behalf of the buyers to get the best possible prices for acrylic machine cutters. They are well-versed in the art of negotiation and use their expertise to secure competitive deals, ensuring that buyers obtain the most value for their investment.

Agents and sourcing companies also have a vital role in ensuring product quality and compliance with international standards. They conduct factory audits and inspections to assess manufacturers’ capabilities and determine if they meet the required quality standards. This mitigates the risk of receiving substandard products and helps maintain the buyers’ reputation for providing high-quality goods.

Additionally, agents and sourcing companies handle all the logistics and documentation involved in the import process. They oversee the shipping, customs clearance, and other legal requirements, ensuring smooth and hassle-free transportation of the purchased acrylic machine cutters. This streamlines the entire purchasing process for the buyers, allowing them to focus on their core business activities.

In conclusion, agents and sourcing companies play a vital role in facilitating acrylic machine cutter purchases from China. They leverage their market knowledge, negotiation skills, and extensive networks to identify reliable manufacturers, negotiate favorable deals, ensure product quality, and handle logistics. Their involvement greatly simplifies the purchasing process and enables businesses to import these products with confidence.

Price Cost Research for acrylic machine cutter manufacturers Companies in China, use temu.com and 1688.com

When it comes to finding acrylic machine cutter manufacturers in China, two popular online platforms that offer a comprehensive database of suppliers are temu.com and 1688.com. These platforms can assist in conducting price cost research to identify suitable manufacturers for acrylic machine cutters.

Temu.com is an online B2B platform that allows users to access a wide range of suppliers for various products. By performing a search for acrylic machine cutter manufacturers on temu.com, users can browse through the available options and obtain information such as company profiles, product descriptions, and pricing details. The platform also facilitates communication with the manufacturers, allowing users to inquire about specific price quotations and negotiate deals directly.

Another useful platform for price cost research is 1688.com, which is a leading wholesale marketplace in China. This platform provides a vast database of suppliers and is particularly popular among domestic businesses. Users can search for acrylic machine cutter manufacturers on 1688.com and access price and product information. While the platform is primarily in Chinese, using translation tools or seeking assistance from a sourcing agent can overcome any language barriers.

When conducting price cost research on these platforms, it is important to consider various factors such as the manufacturer’s credibility, product quality, and pricing competitiveness. Reading reviews and ratings from other buyers can provide insights into a manufacturer’s reputation. Additionally, reaching out to multiple manufacturers and comparing their price quotations can help in making an informed decision.

In conclusion, temu.com and 1688.com are valuable resources for conducting price cost research for acrylic machine cutter manufacturers in China. By exploring the available suppliers on these platforms and considering factors such as credibility, quality, and pricing competitiveness, businesses can find suitable manufacturers for their acrylic machine cutter needs.

Shipping Cost for acrylic machine cutter import from China

The shipping cost for importing an acrylic machine cutter from China depends on several factors such as the weight and dimensions of the machine, the shipping method chosen, and the destination.

For small to medium-sized machines, air freight is generally the preferred shipping method. The cost can vary between $5 to $10 per kilogram, and it typically takes around 5 to 10 days for the machine to arrive at the destination port. The shipping cost is also influenced by the distance between China and the destination country.

If the acrylic machine cutter is larger and heavier, sea freight may be a more cost-effective option. The cost of sea freight can range from $30 to $50 per cubic meter, and the transportation time is longer compared to air freight, usually taking around 20 to 40 days.

It’s crucial to consider additional expenses such as customs duties, taxes, and import fees that may be applicable when importing from China. These costs vary depending on the destination country and the classification of the machine. Importers should research and consult with customs brokers or freight forwarders to determine the exact fees and requirements.

To minimize shipping costs, it’s recommended to work with reputable shipping companies, compare quotes from different service providers, and consider consolidating multiple orders into one shipment to take advantage of price breaks.

Please note that the shipping costs mentioned here are rough estimates and can vary depending on the specific details of the acrylic machine cutter and the shipping arrangements. It’s advisable to contact shipping professionals for accurate and up-to-date information based on your unique requirements.

Compare China and Other acrylic machine cutter Markets: Products Quality and Price,Visible and Hidden Costs

China is known for its diverse and extensive acrylic machine cutter market. It offers a wide range of products with varying quality levels, catering to different customer needs. While some products meet high-quality standards and are comparable to those found in other markets, others may have lower quality due to a lack of strict regulation.

In terms of price, China is known for competitive pricing. The abundance of manufacturers and vendors in the country leads to intense competition, which drives prices down. As a result, customers can often find acrylic machine cutters at more affordable prices compared to other markets. This factor has contributed to China’s dominance in the global acrylic machine cutter market.

However, it’s important to consider both visible and hidden costs when purchasing from China. Visible costs include the product price, shipping fees, and import taxes. Many manufacturers and vendors offer competitive pricing but charge extra for shipping or have minimum order quantities, which can significantly impact the final cost. Hidden costs, on the other hand, include the risk of product defects, inconsistent quality, and the need for additional quality control measures, such as third-party inspections.

Other markets, such as Europe or the United States, may offer acrylic machine cutters with higher initial prices compared to China. However, they often come with higher quality assurance and stricter regulations, ensuring better product quality and consistency. These markets may have lower hidden costs as the risk of defects or inconsistent quality is reduced.

In conclusion, China’s acrylic machine cutter market offers a wide range of products with varying quality levels at competitive prices. While some products meet high-quality standards, others may require additional quality control measures. Customers should carefully consider both visible and hidden costs when comparing China to other markets, taking into account the trade-off between price and product quality.

Understanding Pricing and Payment Terms for acrylic machine cutter: A Comparative Guide to Get the Best Deal

When looking to purchase an acrylic machine cutter, understanding the pricing and payment terms is crucial to ensure you get the best deal. Here is a comparative guide to help you navigate through the process.

Pricing for acrylic machine cutters can vary significantly depending on factors such as brand, model, specifications, and additional features. It is essential to compare prices from different suppliers and manufacturers to determine the average market price range. This will give you an idea of what to expect and enable you to negotiate better terms.

Keep in mind that cheaper options may compromise on quality, so it’s essential to find a balance between price and functionality. Look for reputable brands known for their durability and performance to avoid potential issues in the long run.

In addition to the initial cost, it is crucial to consider other payment terms. Some suppliers may offer financing options, allowing you to pay for the machine cutter in installments over a period. This can be beneficial if you have budget constraints or prefer not to make a lump sum payment.

Another aspect to consider is warranty and after-sales service. Ensure that the machine cutter comes with a warranty period, which can range from a few months to several years. This will provide you with peace of mind in case of any defects or malfunctioning. Additionally, inquire about the availability of technical support and maintenance services, as this can greatly impact the machine’s lifespan and overall efficiency.

When comparing prices and payment terms, make sure to factor in any additional costs such as shipping and handling fees. These costs may vary depending on your location and the supplier’s policies. Additionally, check if the supplier offers any discounts, promotions, or package deals that can further reduce the overall cost.

Finally, don’t forget to read and understand the terms and conditions of the purchase agreement before making any commitments. Pay attention to clauses regarding returns, refunds, and cancellation policies to protect yourself in case of any unforeseen circumstances.

In conclusion, understanding pricing and payment terms for acrylic machine cutters is vital to secure the best deal. Research, compare prices, consider payment options, and assess warranty and after-sales services. By doing so, you can make an informed decision and ensure a smooth and satisfactory purchase experience.

Chinese Regulations and Industry Standards Certifications for acrylic machine cutter,Import Regulations and Customs for acrylic machine cutter from China

In China, the regulations and industry standards certifications for acrylic machine cutters fall under various authorities and organizations. One of the key regulatory bodies is the China National Accreditation Service for Conformity Assessment (CNAS), which is responsible for accrediting certification bodies and laboratories.

To meet the industry standards, acrylic machine cutter manufacturers in China need to comply with specific certifications like the ISO 9001:2015 for quality management systems. This certification ensures that the manufacturer follows stringent quality control processes in the production of acrylic machine cutters.

Additionally, certain industry standards such as the GB/T 3880-2012 for machining precision and GB/T 14710-2009 for safety requirements provide guidelines for acrylic machine cutter manufacturers to adhere to. These standards ensure that the machines meet the necessary precision and safety specifications to guarantee optimal performance and user protection.

For import regulations and customs procedures for acrylic machine cutters from China, it is essential to adhere to the customs requirements of the destination country. Importers need to provide relevant documentation such as invoices, bill of lading, and packing lists to clear customs and comply with local regulations.

Furthermore, importers should be aware of any applicable customs duties, taxes, or import restrictions that may apply when bringing acrylic machine cutters into their respective countries. They should consult with local customs authorities or import clearance agents to ensure compliance with all necessary procedures and legal requirements.

In conclusion, acrylic machine cutter manufacturers in China must obtain certifications such as ISO 9001:2015 and adhere to industry standards like GB/T 3880-2012 and GB/T 14710-2009. Importers need to consider the customs regulations and import requirements of their respective countries, ensuring compliance with documentation and payment of applicable duties and taxes.

Sustainability and Environmental Considerations in acrylic machine cutter Manufacturing

In today’s industrial landscape, sustainability and environmental considerations play a crucial role in every manufacturing process, including acrylic machine cutter manufacturing. Manufacturers are increasingly recognizing the importance of minimizing their environmental impact and adopting sustainable practices to meet the growing demand for eco-friendly products.

One of the primary environmental concerns in acrylic machine cutter manufacturing is the use of raw materials. Acrylic, also known as polymethyl methacrylate (PMMA), is derived from non-renewable fossil fuels. To address this issue, manufacturers can explore alternative materials such as bio-based or recycled acrylic. Using bio-based acrylic, which is derived from renewable sources like plants, helps reduce dependence on fossil fuels and lowers carbon emissions.

Additionally, energy consumption during the manufacturing process is an area of environmental focus. Manufacturers can employ energy-efficient technologies and practices to minimize energy usage and reduce greenhouse gas emissions. This can include utilizing energy-efficient machinery, employing efficient production techniques, and optimizing the manufacturing process to eliminate wastage.

Waste management is another aspect of sustainability in acrylic machine cutter manufacturing. Reducing waste generation and implementing effective recycling programs are crucial in minimizing environmental impact. Manufacturers should aim to optimize material usage, minimize scrap generation, and ensure proper disposal of waste materials.

Adopting sustainable packaging practices is another vital step towards environmental consideration. Manufacturers should strive to use eco-friendly packaging materials, such as recyclable or biodegradable options. This reduces the overall environmental footprint by minimizing waste generation and promoting responsible disposal.

Finally, it is essential to consider the life cycle of acrylic machine cutters to ensure long-term sustainability. Manufacturers can design products for durability, ease of repair, and eventual recycling. Implementing a cradle-to-cradle approach allows for the reuse or recycling of materials, reducing the need for virgin resources and minimizing waste generation.

In conclusion, sustainability and environmental considerations in acrylic machine cutter manufacturing are of paramount importance. By utilizing alternative materials, adopting energy-efficient practices, managing waste effectively, using sustainable packaging, and considering product life cycle, manufacturers can reduce their environmental impact and contribute to a more sustainable future.

List The Evolution history of “acrylic machine cutter”

The history of the acrylic machine cutter can be traced back to the development of early cutting tools and machinery. In the late 19th century, the invention of the vertical milling machine revolutionized the cutting process by allowing for precise and automated cutting of materials. This technology formed the foundation for the future development of the acrylic machine cutter.

However, it wasn’t until the mid-20th century that acrylic, a thermoplastic material, gained popularity and became widely used in various industries. As the demand for acrylic products increased, there arose a need for efficient and precise cutting methods.

In the 1960s, companies started experimenting with the use of laser technology for cutting acrylic. Lasers provided a clean and accurate cutting process, reducing the need for post-processing. This innovation marked a significant step forward in the evolution of acrylic machine cutters.

Throughout the 1970s and 1980s, advancements in computer numerical control (CNC) technology further enhanced the capabilities of acrylic machine cutters. CNC systems enabled the automation of cutting processes, allowing for higher precision and productivity. These machines could follow complex designs programmed through computer software, increasing the versatility of acrylic cutting.

In the 1990s, waterjet cutting technology began gaining traction in the acrylic industry. Waterjet cutters utilized a high-pressure stream of water mixed with abrasive materials to cut through acrylic and other materials with precision. This technology offered advantages in terms of reduced heat generation, eliminating the risk of melting or warping the acrylic during the cutting process.

In recent years, the evolution of acrylic machine cutters has been driven by advancements in robotics and artificial intelligence. Robotic cutting systems equipped with AI capabilities can analyze and adapt to different cutting conditions in real-time, delivering optimal results consistently. This technology has allowed for further optimization of acrylic cutting processes, reducing waste and enhancing overall production efficiency.

Today, the acrylic machine cutter has evolved into a sophisticated tool, incorporating various cutting technologies and automation capabilities. With continued advancements in materials science and technology, it is likely that the future will bring even more innovative developments to further enhance the acrylic cutting process.

The Evolution and Market Trends in acrylic machine cutter Industry

The acrylic machine cutter industry has experienced significant evolution and market trends over the years. Initially, acrylic machine cutters were bulky, expensive, and required skilled operators to use them effectively. However, with advancements in technology, these machines have become more compact, affordable, and user-friendly.

One of the key trends in the acrylic machine cutter industry is automation. Manufacturers are incorporating advanced features such as computer numerical control (CNC) systems, which enable precise cutting and increased production efficiency. Automation also reduces the need for manual labor and minimizes the chances of human errors, leading to higher quality output.

Another important trend is the integration of laser technology in acrylic machine cutters. Laser cutters offer higher precision and can cut acrylic sheets of different thicknesses with ease. Additionally, laser cutting machines allow for intricate and complex designs that were previously challenging to achieve. This trend has opened up new possibilities in various industries, including signage, furniture, automobile, and electronics.

The market for acrylic machine cutters has also witnessed notable growth. The demand for acrylic products such as signage, displays, and retail fixtures has been steadily increasing due to their durability, versatility, and aesthetic appeal. To meet this demand, manufacturers have been introducing a wide range of acrylic machine cutters to cater to the diverse needs of different industries.

Furthermore, sustainability has become a critical factor driving market trends in the acrylic machine cutter industry. With the increasing emphasis on environmental conservation, manufacturers are focusing on developing machines that optimize energy consumption and reduce waste. Additionally, eco-friendly materials and processes are being implemented to align with sustainability goals.

In conclusion, the acrylic machine cutter industry has evolved significantly due to advancements in technology, automation, the integration of laser technology, and the growing market demand for acrylic products. The industry’s focus on sustainability has also shaped market trends, leading to the development of eco-friendly machines and processes. As the industry continues to innovate, it is expected to witness further growth and transformation in the coming years.

Custom Private Labeling and Branding Opportunities with Chinese acrylic machine cutter Manufacturers

Chinese acrylic machine cutter manufacturers offer custom private labeling and branding opportunities for businesses looking to expand their product lines and establish their own unique brands. With their expertise and advanced manufacturing capabilities, these manufacturers can help bring your vision to life.

By partnering with Chinese acrylic machine cutter manufacturers, businesses can have their branding and logo applied directly onto the products. This allows for a consistent and professional look across all items, enhancing brand recognition and customer loyalty.

Additionally, these manufacturers often offer a wide range of customization options, such as different sizes, shapes, and colors, to cater to specific branding requirements. This flexibility allows businesses to create a product line that showcases their unique identity and meets the needs of their target market.

Chinese acrylic machine cutter manufacturers also possess extensive knowledge and experience in the industry. They stay up-to-date with the latest trends and technology, ensuring that the products they produce are of the highest quality. This commitment to excellence helps businesses establish a reputation for providing superior products and strengthens their brand image.

Furthermore, partnering with Chinese manufacturers provides cost-effective solutions. The production costs are typically lower compared to other regions, allowing businesses to achieve a higher profit margin. Moreover, the competitive nature of the market drives manufacturers to continuously improve their offerings, resulting in better quality products at affordable prices.

In conclusion, Chinese acrylic machine cutter manufacturers offer excellent opportunities for custom private labeling and branding. By leveraging their expertise, businesses can create a unique product line that resonates with their target market. The superior quality, cost-effectiveness, and flexibility of these manufacturers make them an ideal choice for businesses looking to expand their brand presence.

Tips for Procurement and Considerations when Purchasing acrylic machine cutter

1. Determine the specific requirements: Before purchasing an acrylic machine cutter, it is important to clearly define the specific requirements for the machine. Consider factors such as the desired cutting size, cutting speed, precision, and any additional features required for your particular application.

2. Research reputable suppliers: Conduct thorough research to identify reputable suppliers of acrylic machine cutters. Look for suppliers with a proven track record of delivering high-quality machines and excellent customer service. Check customer reviews and testimonials to get an idea of their reputation in the market.

3. Compare prices and features: It is recommended to obtain multiple quotes from different suppliers to compare prices and features. However, price should not be the sole determining factor. Consider the overall value for money by evaluating the features, reliability, durability, and after-sales services offered by each supplier.

4. Assess cutting capacity and precision: Acrylic machine cutters come in various sizes and cutting capacities. Ensure that the chosen machine has the capacity to handle the desired thickness and size of acrylic sheets you will be working with. Additionally, assess the precision of the cutting machine to ensure it meets your requirements for accurate and clean cuts.

5. Compatibility with software and materials: Check if the acrylic machine cutter is compatible with the design software you plan to use. Compatibility is crucial for seamless integration and efficient operation. Additionally, check if the machine can handle different types and thicknesses of acrylic materials commonly used in your industry.

6. Consider ease of use and maintenance: Look for a machine that is user-friendly and easy to operate. Consider the level of skills required to operate the machine and whether it will require specialized training for your personnel. Additionally, inquire about the maintenance requirements and availability of spare parts for the machine.

7. Warranty and after-sales support: Ensure that the chosen acrylic machine cutter comes with a warranty and reliable after-sales support. A warranty will provide peace of mind, while good after-sales support ensures prompt assistance in case of any issues or breakdowns.

8. Seek recommendations: Reach out to industry peers or experts for their recommendations or experiences with specific brands or models of acrylic machine cutters. Their insights can prove valuable in making an informed purchasing decision.

In summary, when purchasing an acrylic machine cutter, it is essential to determine specific requirements, research reputable suppliers, compare prices and features, assess cutting capacity and precision, consider compatibility, evaluate ease of use and maintenance, and ensure warranty and after-sales support. Seek recommendations from industry peers to make a well-informed decision.

FAQs on Sourcing and Manufacturing acrylic machine cutter in China

1. Why should I consider sourcing acrylic machine cutters from China?

China is known for its cost-effective manufacturing capabilities, making it a popular choice for sourcing products. The country has a wide range of factories specializing in acrylic production, providing a vast selection of machine cutters to choose from. Additionally, Chinese manufacturers often offer competitive pricing and flexible customization options to meet varying customer requirements.

2. How do I find reliable manufacturers of acrylic machine cutters in China?

Finding reliable manufacturers requires thorough research and due diligence. Online B2B platforms such as Alibaba, Made-in-China, and Global Sources provide extensive supplier databases. Check supplier profiles, ratings, and customer reviews to gauge their reputation and reliability. It is essential to communicate directly with potential manufacturers to discuss product specifications, quality standards, and ensure they have the capability to meet your specific requirements.

3. What should I consider when selecting an acrylic machine cutter supplier in China?

Apart from product quality and pricing, consider evaluating the supplier’s manufacturing capabilities, certifications, and production capacity. Ensure the manufacturer possesses the necessary expertise and equipment to produce high-quality acrylic machine cutters. Request product samples to evaluate their performance and durability. It is also beneficial to choose a supplier who can provide additional services like packaging, customization, or even shipping arrangements.

4. How can I ensure the quality of the acrylic machine cutters from China?

Quality control is crucial when sourcing from China. Start by requesting a detailed product specification sheet from potential suppliers. You may also ask for certifications such as ISO 9001 or similar quality standards. Communicate your quality expectations clearly and request product samples for testing before placing a bulk order. Conduct inspections during production and final inspections before shipment. Consider hiring a third-party quality control agency to ensure the product meets your standards.

5. What is the typical lead time for manufacturing acrylic machine cutters in China?

The lead time for manufacturing acrylic machine cutters varies depending on factors such as order quantity, complexity, and customization requirements. Generally, it can range from a few weeks to a few months. Ensure to discuss the manufacturing timeline with your supplier early on to plan for any potential delays and adjust your production schedule accordingly.

6. How can I handle shipping and logistics when sourcing acrylic machine cutters from China?

You can choose between various shipping methods, such as air freight, sea freight, or express courier services, depending on your requirements and budget. It is advisable to work closely with your supplier to negotiate shipping terms and choose a reliable freight forwarder. Consider factors like transportation time, cost, and import duties when deciding on the shipping method. Properly labeling the shipments and ensuring compliance with the destination country’s regulations is also crucial.

7. Are there any potential challenges or risks associated with sourcing acrylic machine cutters from China?

Language barriers, cultural differences, and geographic distance may pose challenges during communication and establish a smooth business relationship. Quality control issues, counterfeit products, and intellectual property rights violations are also risks to consider. Conduct thorough research, verify supplier credentials, and establish legal agreements to mitigate such risks. Collaborating with experienced agents or consultants well-versed in Chinese manufacturing processes can help navigate these challenges effectively.

Why contact sourcifychina.com get free quota from reliable acrylic machine cutter suppliers?

Sourcifychina.com obtains a free quota from reliable acrylic machine cutter suppliers for several reasons. Firstly, offering a free quota allows Sourcifychina.com to attract potential customers and build trust with them. By receiving a free quota, customers can evaluate the services and quality of the acrylic machine cutter suppliers without any financial commitment.

Secondly, providing a free quota enables Sourcifychina.com to showcase its expertise and knowledge in the field of acrylic machine cutters. By analyzing the customer’s requirements and providing a tailored quota, Sourcifychina.com proves its ability to understand the specific needs of customers and deliver accurate results. This creates a positive impression and increases the likelihood of customers choosing Sourcifychina.com for their sourcing needs.

Furthermore, a free quota serves as a marketing strategy for Sourcifychina.com. It allows the company to showcase its partnership with reliable acrylic machine cutter suppliers, highlighting the quality and reliability of the products they offer. This strengthens the position of Sourcifychina.com as a trusted sourcing platform, attracting more potential customers and enhancing its reputation in the market.

Moreover, offering a free quota from reliable suppliers demonstrates Sourcifychina.com’s commitment to providing value-added services to its customers. It portrays the company as customer-centric, driven by the goal of helping clients find the best suppliers for their specific requirements. This approach builds loyalty among customers and promotes long-term relationships.

Overall, by offering a free quota from reliable acrylic machine cutter suppliers, Sourcifychina.com aims to attract and build trust with potential customers, showcase its expertise, strengthen its marketing strategy, and provide value-added services. This approach ultimately contributes to the company’s growth and success in the sourcing industry.