Knowledge about Aluminium Manufacturer

Aluminium manufacturing involves the production of aluminium products from various raw materials such as bauxite and alumina. Top aluminium manufacturers typically have all the necessary resources and expertise to produce quality products that meet the needs of various industries.

One of the key knowledge areas to consider is the manufacturing process used by aluminium manufacturers. A typical production process involves mining the raw materials, refining bauxite into alumina, smelting alumina to produce aluminium, and then further processing the aluminium to create different products such as sheets, extrusions, and wires. Having knowledge around these stages of the manufacturing process can help stakeholders understand the quality of the finished products.

Another crucial area of knowledge is the quality standards upheld by aluminium manufacturers. High-quality standards are maintained by ensuring that the finished products meet the necessary requirements in terms of performance, safety, and durability. Quality standards can be tested through rigorous quality control processes, which usually involve mechanical testing, chemical analysis, and inspections.

Moreover, understanding the application of aluminium products in specific industries can also provide valuable insights into the manufacturing process. For instance, aluminium products are used in construction, transportation, packaging, and electrical industries, among others. Therefore, understanding the key properties required for these applications can help to inform the selection of appropriate raw materials and the production processes used.

In conclusion, having in-depth knowledge of aluminium manufacturers can help stakeholders to make informed decisions while procuring aluminium products. The knowledge areas that stakeholders should seek to understand include the manufacturing process, quality standards, and the application of aluminium products in various industries. With this knowledge, clients can be confident in the quality of the products they procure from top aluminium manufacturers.

Various Types of Aluminium Manufacturer

Aluminium is one of the most important materials in the modern era. It is used in a wide range of products, from packaging to transportation and construction. As a result, there are many different types of aluminium manufacturers, each with their own unique focus and expertise.

One type of aluminium manufacturer is the primary smelter. These companies specialize in producing pure aluminium from bauxite ore. Primary smelters are often large-scale operations that require significant capital investment and technology to produce high-quality aluminium.

Another type of aluminium manufacturer is the secondary smelter. These companies focus on recycling and reusing scrap aluminium to produce new products. Secondary smelters typically produce lower grade aluminium compared to primary smelters, but their production process is much more sustainable and environmentally friendly.

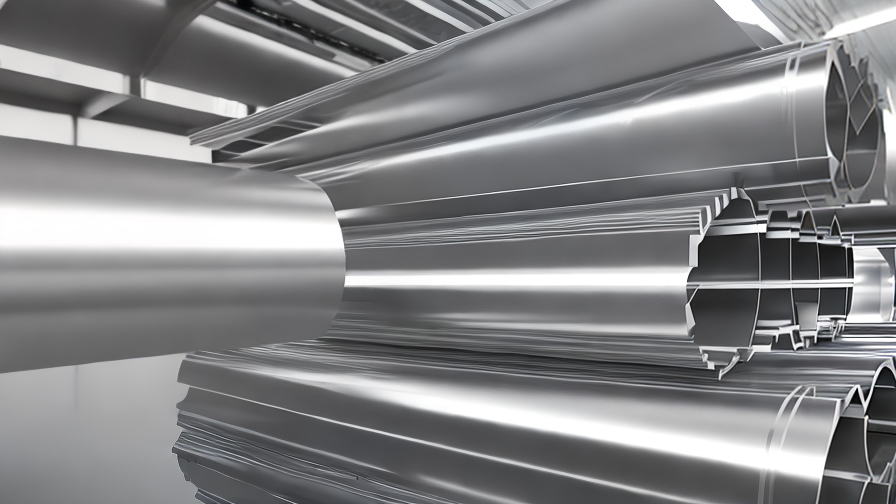

Next, there are aluminium extrusion manufacturers. These companies specialize in transforming aluminium into a wide range of profile shapes and sizes that are used in various applications, including construction, automotive, and transportation. Aluminium extrusion manufacturers can produce complex designs with tight tolerances to meet the requirements of specific applications.

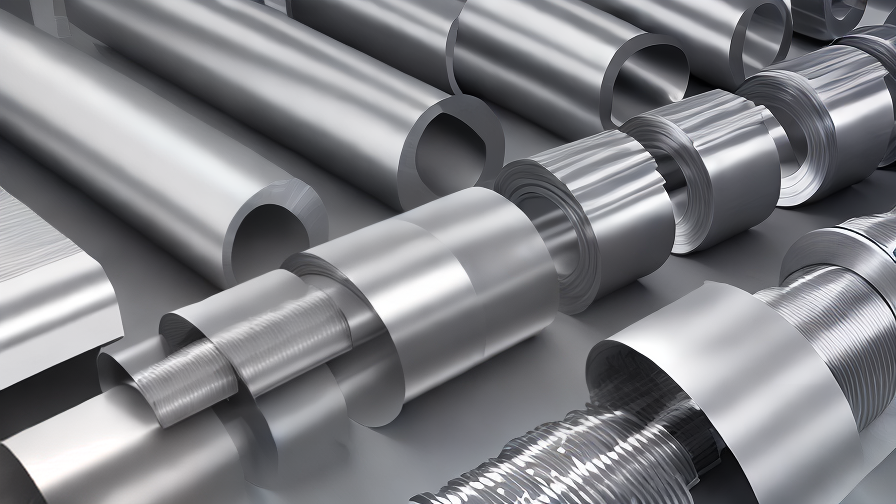

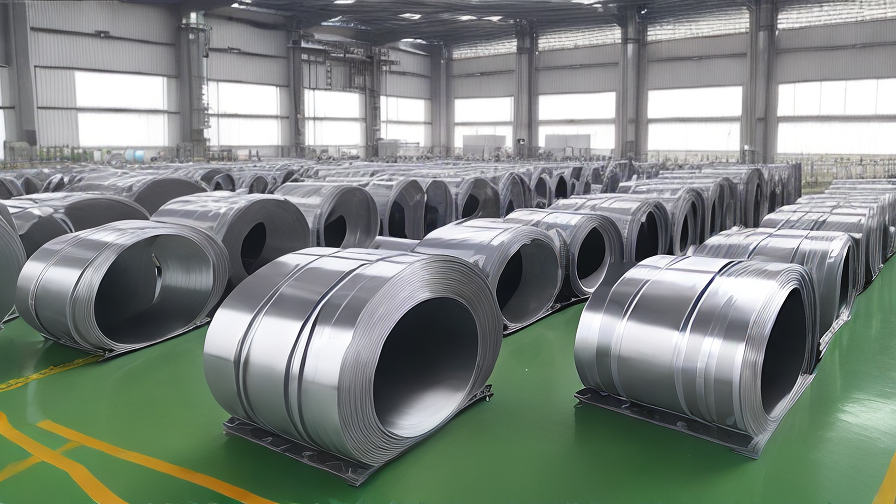

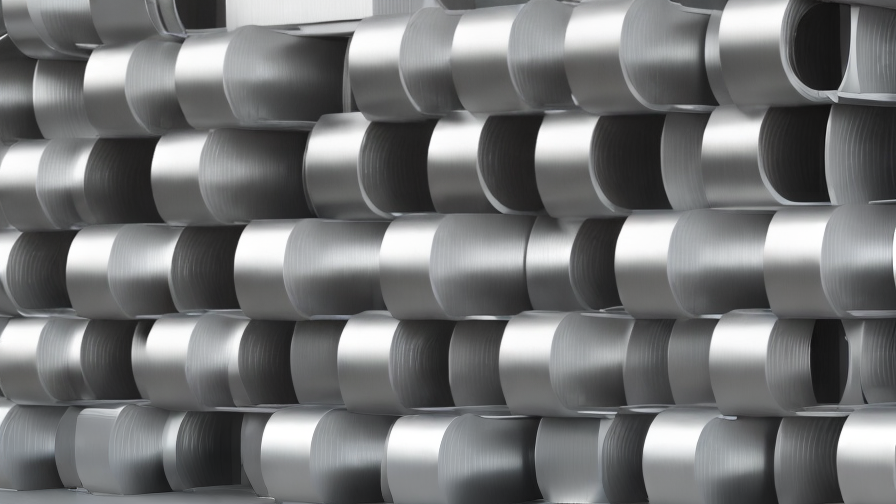

Another type of aluminium manufacturer is the rolling mill. These companies specialize in producing high-quality aluminium sheets, coils, and plates that meet the requirements of specific industries, such as aerospace and transportation.

Lastly, there are aluminium foundries. These companies specialize in producing cast aluminium parts for various industries, including construction, automotive, and transportation. Aluminium foundries use a variety of processes, such as sand casting and die-casting, to produce complex parts with high precision and consistency.

In conclusion, there are many different types of aluminium manufacturers, each with their own unique focus and expertise. From primary and secondary smelters to extrusion manufacturers and rolling mills, the aluminium industry is diverse, adaptable, and crucial to the modern world.

FAQ sourcing Aluminium Manufacturer manufacturer from China

Sourcing Aluminium Manufacturer from China is becoming increasingly popular due to the cost-effectiveness of production in China. With numerous options available, it can be challenging to identify the right manufacturer for your business. Here, we address some frequently asked questions to guide your selection process:

Q. What quality standards should I expect from Chinese Aluminium Manufacturers?

A. Reputable suppliers in China often have ISO certifications indicating that they meet international quality standards. Additionally, they may also have ASTM, JIS, or GB standards certifications or test reports to ensure the products’ quality.

Q. How can I verify the manufacturer’s capabilities and qualifications?

A. It is advisable to conduct a factory audit before selecting a manufacturer. This ensures that the manufacturer has adequate facilities, equipment and skilled workers. You can also check references and online reviews.

Q. How can I ensure that the products are shipped on time?

A. Ensure that the supplier has efficient logistics systems, such as their own fleet of trucks, good relationships with shipping companies and customs clearances processes. Frequent communication with the supplier helps to guarantee timely delivery.

Q. How can I protect my Intellectual Property (IP) rights when sourcing from China?

A. It is essential to sign a Non-disclosure agreement (NDA) and request for the supplier’s IP policy. Also, register your IP in China and have a legal representative that can act on your behalf if any dispute arises.

Q. What are the payment terms?

A. Most suppliers require an initial deposit of 30-50% to start production, with the balance paid upon completion of goods. It is crucial to have a clear payment agreement in writing to avoid disputes.

In conclusion, doing business with Chinese Aluminium manufacturers requires due diligence, verification, and clear communication. Choose a supplier that offers value, reliability, quality and good customer support.

Applications of Aluminium Manufacturer

Aluminium is a highly versatile metal that is used in a range of applications due to its durability, lightweight properties, and resistance to corrosion. The applications of aluminium manufacturer have been expanding in recent years and an increasing number of industries are incorporating the metal into their products.

One of the most common applications of aluminium is in the manufacture of packaging materials. Aluminium is an excellent material for cans, foils, and containers due to its resistance to moisture, air, and light. It is also lightweight, which makes it an ideal material for transportation and storage of food and beverages.

In the automotive industry, aluminium is used to create lightweight and strong components. This reduces the overall weight of the vehicle, which in turn improves fuel efficiency and reduces emissions. Aluminium is also used in the construction of aircraft, as it is a strong and lightweight metal that can withstand high-altitude environments.

In the building and construction industry, aluminium has become increasingly popular due to its durability, flexibility, and low maintenance requirements. It is commonly used in roofing, windows, doors, and cladding, as it can withstand extreme weather conditions and is resistant to rust and corrosion.

Aluminium is also an important ingredient in the manufacture of electronics, as it is a good conductor of electricity and can be easily shaped into various components. It is commonly used in the production of computers, mobile phones, and home electronics.

In the medical industry, aluminium is used to create prosthetics and medical equipment. It is a biocompatible material that is safe for use in the body and can be easily molded to fit specific requirements.

In conclusion, the applications of aluminium manufacturer are vast and diverse, ranging from packaging to transportation, construction, and healthcare. As technology and innovation continue to advance, the demand for aluminium and its versatility is bound to continue to grow, making it an important material for many industries.

Manufactured Products made of Aluminium Manufacturer

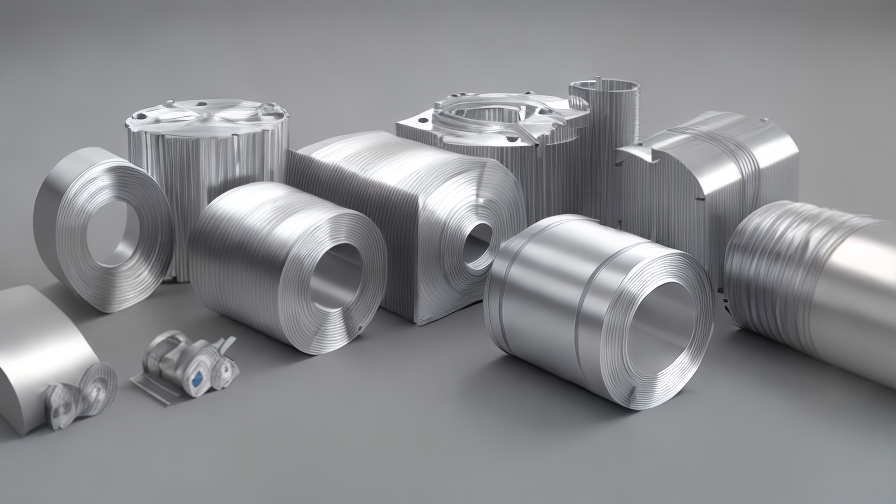

Manufactured products made of aluminium are becoming increasingly popular in various industries such as automotive, aerospace, construction, consumer goods, and packaging. Aluminium’s unique properties make it a versatile material, which can be easily transformed into various products that are lightweight, durable, and cost-effective.

Aluminium manufacturers are companies that specialize in producing and distributing aluminium products to these industries. They have the necessary expertise, equipment, and facilities to produce high-quality products that meet precise specifications and standards.

One of the significant advantages of using aluminium for manufacturing products is its excellent strength-to-weight ratio. This makes it an ideal choice for lightweight products such as automotive parts, aircraft components, and consumer electronics.

Additionally, aluminium’s high thermal and electrical conductivity, corrosion resistance, and malleability make it an attractive choice for a wide range of products. It can be easily formed, machined, and welded, making it a valuable material in diverse applications.

Manufactured products made of aluminium can be found in many everyday items such as beverage cans, cooking utensils, and even furniture. In the automotive sector, aluminium is used for car frames, engine parts, and wheels, while in the construction industry, it is used for windows, doors, and cladding.

As a result of its versatility and widespread use, the demand for manufactured products made of aluminium is continually growing. Aluminium manufacturers are continually improving their processes to enhance the durability, strength, and sustainability of their products.

In conclusion, manufactured products made of aluminium have become essential in a vast number of industries where durability, strength, and lightweight are essential. Aluminium manufacturers play a vital role in producing high-quality products that meet the needs of these industries. As demand for aluminium products continues to increase, manufacturers will remain essential in meeting the expectations of their clients.

The Evolution history of Aluminium Manufacturer

The history of aluminum manufacturing is quite interesting. It all started in the 1800s when scientists wanted to find new ways to extract aluminum from its ores. At that time, aluminum was considered a rare and precious metal and was even more expensive than gold.

In the late 1800s, technology improved, and a more efficient way of extracting aluminum was developed. The first aluminum factories were built in the United States, and it quickly became a popular choice for manufacturing products due to its lightweight and durable features.

During World War II, the demand for aluminum skyrocketed as it was needed for military aircraft and other wartime production. Many aluminum manufacturing plants were built to meet this demand.

Over the years, aluminum manufacturing has continued to evolve with new technologies and advancements. Today, aluminum is used in a wide range of products, from airplanes and cars to home appliances and packaging materials.

One of the significant changes in the aluminum industry was the development of recycling techniques. In the early days, aluminum was extracted from bauxite ores, but today, 75% of all aluminum produced is recycled from scrap. This has made aluminum an environmentally friendly and sustainable choice in manufacturing.

Another trend in the aluminum industry is the emphasis on energy efficiency. Many manufacturers are adopting clean energy methods such as solar or wind power to power their factories. This approach not only reduces carbon emissions but also helps companies save on energy costs.

In conclusion, the aluminum manufacturing industry has come a long way since its inception in the 1800s. Its lightweight, durable, and sustainable properties have made it a critical component in modern manufacturing. As the world continues to evolve, the aluminum industry must continue to adapt to new technologies and innovations.

The Process of Aluminium Manufacturer

The process of aluminum manufacturing involves several steps, starting with the mining and extraction of bauxite ore. Bauxite is collected, washed and crushed to a fine powder before being transported to an alumina refinery.

At the refinery, the bauxite powder is mixed with caustic soda and heated to high temperatures in large furnaces. This results in the formation of alumina, which is separated from the remaining solids and sent to an aluminum smelter.

In the smelter, alumina is dissolved in a bath consisting of molten cryolite and other additives before being electrolyzed. The electrolysis process separates the positively charged aluminum ions from the negatively charged oxygen ions, which then settle at the bottom of the bath.

The liquid aluminum is then drawn off from the bottom and transferred to a holding furnace, where it is further purified and cast into ingots or extruded into various shapes.

The final step involves the fabrication of aluminum products, which includes the cutting, machining, welding, and coating of the metal to meet specific customer requirements.

Overall, the process of aluminum manufacturing is complex and involves several stages of refining, smelting, and fabrication. However, it is a highly efficient and sustainable process with numerous applications across various industries.

Benefits Advantages of Utilizing Aluminium Manufacturer

Aluminium manufacturers have been helping businesses of all sizes meet their needs for many years. Utilizing these manufacturers has become increasingly popular due to the many benefits and advantages they provide.

One of the most significant benefits of utilizing aluminium manufacturers is the level of precision they provide. These manufacturers use specialized machines and techniques to ensure that the final product is of the highest quality. This precision translates into a reduction of waste and improved efficiency in the production process, which is reflected in lower costs for businesses.

Another benefit of utilizing aluminium manufacturers is their ability to create custom products. Businesses can collaborate with these manufacturers to create a product that is tailored to their specific needs. This level of customization allows for a more efficient and effective production process, as well as a higher level of customer satisfaction.

Aluminium manufacturers also provide a level of expertise that is valuable to businesses. These manufacturers have a deep understanding of the properties and characteristics of aluminum and can recommend the best solutions for a business’s specific needs. Additionally, they stay up-to-date with the latest industry trends and technologies, which allows them to provide innovative and efficient solutions.

The use of aluminium in manufacturing also provides several other advantages. Aluminium is lightweight, yet strong, making it an excellent choice for products that need to be durable, yet easy to handle. It is also corrosion-resistant, which makes it ideal for products that will be exposed to harsh environments.

In conclusion, utilising aluminium manufacturers has several benefits and advantages for businesses. These manufacturers provide precision, customised products, expertise and recommendations, as well as the advantages of using aluminium in manufacturing. By choosing to collaborate with an aluminium manufacturer, businesses can achieve higher quality products and a more efficient production process, ultimately leading to increased profits.

Disadvantages Aluminium Manufacturer

As with any manufacturing process, there are certain disadvantages associated with the production of aluminium, particularly in terms of both its health and environmental impacts.

For starters, the process of extracting aluminium from bauxite ore requires a significant amount of energy. This energy-intensive process releases large amounts of carbon dioxide, which contributes to global climate change. Additionally, the production of aluminium increases greenhouse gases and other pollutants, such as nitrogen oxides, which are known to cause respiratory problems.

Another disadvantage of aluminium manufacturing is the toxicity of the chemicals used in the process. The production of aluminium involves the use of harsh chemicals like cryolite, sodium hydroxide, and aluminum fluoride, which are all harmful to the environment, and can have severe health impacts, particularly for the workers involved in the manufacturing process.

Furthermore, the mining of bauxite, the primary source of aluminium, can lead to the displacement of local communities and destruction of ecosystems, causing long-term environmental damage.

Aluminium manufacturing also generates huge amounts of waste, both solid and liquid, which can pollute groundwater and other water bodies, leading to environmental degradation and health problems.

Finally, aluminium, like all metals, is nonrenewable, meaning that once it is extracted from the earth, it cannot be replaced.

While aluminium has numerous advantages, the disadvantages of its manufacturing process must be considered. To address these issues, manufacturers must adopt sustainable and responsible production practices to minimize the impact of their operations on the health and environment. Likewise, consumers must emphasize the demand for sustainably produced aluminium to hold manufacturers accountable for their actions.

Selecting the Ideal Manufacturer Aluminium Manufacturer

When selecting an aluminium manufacturer, it is important to consider several key factors to ensure that you are getting the best quality aluminium products. Here are some tips to help you find the ideal aluminium manufacturer for your needs.

1. Quality- Look for a manufacturer who has a reputation for producing high-quality and durable aluminium products. Check their certifications and accreditations to ensure that they meet the required standards.

2. Experience- Choose a manufacturer who has been in the industry for a long time. This will indicate that they have extensive knowledge and are experienced in producing high-quality aluminium products.

3. Customer Service- Consider the manufacturer’s customer service. They should be able to offer excellent customer service and be responsive to your needs.

4. Efficient Shipping- Choose a manufacturer who offers efficient and prompt shipping services to ensure that you receive your products on time.

5. Pricing- Look for a manufacturer that offers competitive pricing without sacrificing quality. It is important to get value for your money.

6. Variety- Choose a manufacturer who offers a wide range of aluminium products to choose from. This will enable you to find the perfect product to suit your specific needs.

7. Customization- Consider a manufacturer who offers customized aluminium products to meet your unique requirements.

In conclusion, selecting the ideal aluminium manufacturer requires careful consideration of the factors mentioned above. By taking the time to do your research, you will be able to find a reputable manufacturer who can provide high-quality and durable aluminium products that meet your specific needs.

Things to Consider When Purchasing Aluminium Manufacturer

When it comes to purchasing aluminium products, it can be challenging to know which manufacturer to choose. There are a few things to consider before making a final decision, including the quality of their products, their pricing, and their level of experience.

One of the most critical factors to consider when purchasing aluminium products is the quality of the manufacturer’s products. You want to make sure that the manufacturer you choose produces high-quality products that are durable and long-lasting. Look for a manufacturer that offers a warranty on their products, as this can be a good indication of their product’s quality.

Pricing is another essential consideration when choosing an aluminium manufacturer. You want to find a manufacturer whose products are reasonably priced and offer good value for money. Look for a manufacturer that offers transparent pricing, with no hidden costs or fees.

Experience is also crucial when choosing an aluminium manufacturer. You want to choose a company that has been in the industry for a while and has a track record of providing excellent customer service. An experienced manufacturer will have a good understanding of the industry and will use this knowledge to produce high-quality products.

Customer service is also an important consideration when selecting an aluminium manufacturer. You want to choose a manufacturer that is responsive and easy to work with. Look for a manufacturer that offers excellent communication channels and is always available to answer your questions.

In conclusion, when purchasing aluminium products, there are several things to consider before making a final decision. Quality, pricing, experience, and customer service are all crucial factors when choosing an aluminium manufacturer. By keeping these in mind, you can find a reliable and trustworthy manufacturer that can meet your needs and deliver high-quality products at a reasonable price.

Properties of Aluminium Manufacturer

Aluminium is one of the most widely used metals in the manufacturing industry. Properties of Aluminium Manufacturer have made it a popular choice for many applications. Aluminium is lightweight, strong, and resistant to corrosion, which has significantly increased its use in various sectors. In this article, we will look at the properties of aluminium that make it an ideal choice for various applications.

1. Lightweight: Aluminium is a lightweight metal that makes it useful in various applications such as transportation, aerospace, and automobile industries. It is three times lighter than iron or steel, yet it has comparable strength, making it an ideal metal to use when weight is a critical factor.

2. High Strength-to-Weight Ratio: Despite its low weight, aluminium has excellent strength-to-weight ratio, making it ideal for applications that require load-bearing capacity. Its strength-to-weight ratio makes it ideal for use in lightweight constructing applications.

3. Corrosion Resistance: One of the most significant properties of aluminium is its excellent resistance to corrosion. It forms an oxide layer over its surface, which protects it from rust, making it ideal for outdoor use.

4. Thermal Conductivity: Aluminium conducts heat efficiently, making it a popular choice in applications that require thermal management. The thermal conductivity of aluminium is nearly twice that of copper, allowing it to dissipate heat more effectively.

5. Recyclable: Aluminium is a highly recyclable metal that can be reused repeatedly without losing its properties. This characteristic makes it eco-friendly and sustainable, reducing the impact on the environment.

In conclusion, the properties of aluminium make it an ideal metal for many applications. Its combination of high strength, low weight, resistance to corrosion, and efficient thermal conductivity gives it a significant advantage over other metals. Aluminium is an essential metal used in airplanes, automobiles, construction, packaging, and many other industries due to its unique characteristics. Whether you are looking for a lightweight and durable material or a sustainable one, aluminium is an excellent choice.

How to use Aluminium Manufacturer

Aluminium is one of the most commonly used metals in the world, owing to its lightweight, durability, and versatility. As a result, aluminium manufacturers are highly sought after. Here are a few tips on how to use aluminium manufacturers.

Firstly, identify the type of aluminium you need. This could be in the form of bars, sheets, tubes or sections. Once you’ve determined your requirement, research potential aluminium manufacturers who can provide you these products.

Secondly, look for a reputed aluminium manufacturer who has experience producing high-quality aluminium products. Check their certifications, quality standards, and whether they adhere to industry regulations. You don’t want to compromise on quality when it comes to aluminium products.

Thirdly, assess the aluminium manufacturer’s production capacity. If you need a large quantity of aluminium products, ensure the manufacturer has the infrastructure to handle bulk orders. You don’t want to be left with insufficient stock during peak production periods.

Fourthly, check whether the aluminium manufacturer creates customised products. You may require your aluminium products to have specific dimensions or a particular finish, and it’s important to find an aluminium manufacturer who can cater to these requirements.

Finally, consider the costs of the aluminium products. Compare prices from various aluminium manufacturers and look for value for money. Don’t choose a manufacturer purely on price, but consider the quality of the products and the level of customer service they offer.

In conclusion, using an aluminium manufacturer requires careful consideration to ensure you get high-quality products at competitive prices. By taking the time to assess your requirements, research potential manufacturers and compare prices, you’ll find the best aluminium manufacturer for your needs.

Glossary Terminology Terms for Aluminium Manufacturer

When it comes to the world of aluminium manufacturing, there is a whole set of terminology that is important to understand. Here are some important glossary terms:

1. Aluminium extrusion – This is the process of creating an object by pushing aluminum through a die, creating a uniform shape.

2. Die – This is the device used in the extrusion process. It is a shaped opening that determines the final shape of the aluminum product.

3. Billet – A billet is a solid block of metal that is heated and then used to create an extruded product.

4. Alloy – An alloy is a combination of two or more metals. Aluminium alloys are used in manufacturing to improve strength, durability, and other attributes.

5. Anodizing – This is a process where a surface layer of the metal is oxidized. This creates a harder, corrosion-resistant surface and can also add color to the product.

6. Extrusion press – This is the machine used to push the aluminum through the die and create the final product.

7. Finish – The finish of a product refers to its surface appearance, which might be smooth, textured, or shiny.

8. Heat treatment – Heat treatment is a process used to harden the metal and tailor its properties to specific applications.

9. Profile – This refers to the specific shape of the extruded aluminum product.

10. Tolerance – The tolerance refers to the allowable variation in the dimensions of the product, which is important for ensuring quality control.

By understanding these important glossary terms, manufacturers can better communicate with their suppliers and ensure that their products meet the required standards.

Aluminium Manufacturer Price

Aluminium is one of the most widely used metals in the world, and this is largely due to its unique combination of properties. It is lightweight, strong, corrosion-resistant, and highly conductive, making it ideal for a wide range of applications. However, the cost of aluminium can vary significantly depending on a number of factors.

The price of aluminium is determined by a complex range of factors, including global supply and demand, production costs, and geopolitical factors such as tariffs and trade restrictions. In recent years, the price of aluminium has been affected by a number of geopolitical issues, such as the US-China trade war, which saw the imposition of tariffs on aluminium imports.

In addition to geopolitical factors, the cost of producing aluminium can also affect its price. For example, the cost of energy is a major factor in aluminium production, as it requires a large amount of electricity to produce. Labour costs, raw material costs, and transportation costs also play a significant role in determining the final price of aluminium.

Despite these challenges, many aluminium manufacturers are focused on finding ways to reduce production costs and improve efficiency. This can include investing in new technologies or processes, improving supply chain management, and implementing sustainable practices to reduce energy consumption and waste.

Overall, the price of aluminium can be difficult to predict, as it is affected by a range of complex factors. However, it is clear that the global demand for aluminium will continue to grow, driven by its many unique properties and growing use in a wide range of industries. As such, manufacturers and consumers alike must remain vigilant when it comes to monitoring the latest trends and developments in the aluminium market.