Knowledge about Asphalt Distributor

Asphalt distributor is a vital piece of equipment in the road construction industry. It’s essential to know the necessary information about it, as it ensures that it’s operated efficiently.

To start with, an asphalt distributor is a machine designed to distribute asphalt over a surface uniformly. It is used to spray different sorts of surfaces such as roads, bridges, highways or any other surface which requires a smooth and even coat of asphalt.

Some of the crucial things to know about an asphalt distributor include its various components. These components include the distributor tank, the spray bar, the heaters, the hydraulic system, and the control system.

The distributor tank is the most fundamental part of the equipment, and it stores and distributes the asphalt. The spray bar is another important component that sprays the asphalt uniformly on the surface. The heaters warm the asphalt to make it easier to distribute while the hydraulic system controls the movement of the spray bar.

The control system is critical since it controls the functions of the machine. It allows the operator to adjust the speed, amount of asphalt being distributed, and the spray width to ensure that it’s done uniformly.

Safety is of great importance when operating an asphalt distributor. Some hazards that an operator should be aware of include hot asphalt, electrical hazards, and the risk of the machine tipping over.

Lastly, it’s essential to ensure the machine is well maintained. Regular maintenance will ensure that the equipment is in excellent working condition, and it’ll operate efficiently, thereby increasing productivity.

In conclusion, knowing the essential information about an asphalt distributor is crucial to ensure that the equipment is operated safely and efficiently. It’s crucial to ensure that the machine is in excellent working condition, and safety measures are taken when using it.

Various Types of Asphalt Distributor

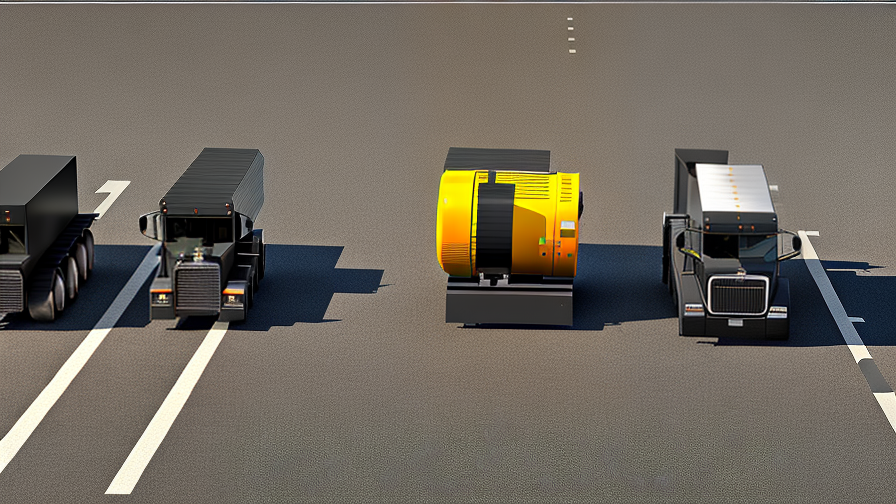

An asphalt distributor is a special vehicle that is used to apply liquid asphalt to road surfaces. The equipment is typically mounted on a truck chassis and has a tank that holds the liquid asphalt. The asphalt is then sprayed onto the road surface using a spray bar. There are various types of asphalt distributors that are used for different applications.

One of the most common types of asphalt distributors is the standard truck-mounted unit. This type of distributor is used for general-purpose applications and is designed to be easy to operate. The truck-mounted unit has a tank that can hold up to 2000 gallons of liquid asphalt and a spray bar that can cover up to 12 feet in width.

Another type of asphalt distributor is the shot distributor. This type of equipment is used for precise applications and is designed to provide accurate, controlled spraying of liquid asphalt. The shot distributor has a narrow spray bar that can cover a distance of up to 6 feet. This equipment is typically used for road maintenance and repair work.

A third type of asphalt distributor is the trailer-mounted unit. This equipment is designed to be towed behind a truck and is ideal for larger applications, such as highway construction. The trailer-mounted unit has a capacity of up to 5000 gallons and a spray bar that can cover up to 24 feet in width.

In addition to these types of asphalt distributors, there are also specialized units that are designed for specific applications. For example, there are units that are designed to apply a thin layer of liquid asphalt over a large area. There are also units that are designed to apply a thicker layer of asphalt over a smaller area.

Overall, asphalt distributors are an essential piece of equipment for road construction and maintenance. Whether it is a standard truck-mounted unit or a specialized piece of equipment, asphalt distributors help ensure that roads are safe and well-maintained for drivers.

FAQ sourcing Asphalt Distributor manufacturer from China

Asphalt distributors are an essential part of any construction project involving the laying of asphalt. As a result, sourcing a reliable and efficient asphalt distributor manufacturer is paramount. In China, there are many options available. Here are some frequently asked questions and their answers that can help you in sourcing an asphalt distributor manufacturer from China.

Q: What is the general cost of an asphalt distributor from China?

A: The cost of an asphalt distributor may vary depending on the manufacturer, size, and features of the machine. Generally, asphalt distributors can be found in a price range of $10,000 to $200,000.

Q: What are the payment terms that manufacturers usually offer?

A: The payment terms offered by manufacturers may vary. However, most manufacturers usually offer a 30% deposit payment in advance, and the remaining balance is paid before delivery or shipment.

Q: What kind of warranty comes with the asphalt distributor?

A: Most good quality manufacturers will offer a warranty for at least one year. However, the warranty period may vary depending on the manufacturer.

Q: Do the manufacturers offer training on how to use the equipment?

A: Yes, most manufacturers offer training on how to use and maintain the asphalt distributor. Training usually takes up to one week and may be offered in the manufacturer’s factory or at the client’s location.

Q: How long does it take for the manufacturer to deliver the product after payment?

A: Delivery time may depend on factors such as the size of the order, distance, and availability of the machine. However, most manufacturers usually deliver within 30-60 days after receiving payment.

In conclusion, sourcing an asphalt distributor manufacturer from China can be a simplified process by knowing the right questions to ask. With proper research and due diligence, one should be able to find a manufacturer that can meet their specific needs and requirements.

Applications of Asphalt Distributor

An Asphalt Distributor is a specialty vehicle that is used to apply a thin layer of asphalt onto a particular surface. This piece of equipment is largely made up of a chassis, an insulated tank, a heat system, and a distribution system. Asphalt Distributors are commonly utilized in road construction and maintenance projects, but they can also have various other applications.

One of the main applications of Asphalt Distributors is in patching up potholes and cracks in roadways. By using an Asphalt Distributor, a contractor can apply a precisely measured amount of asphalt onto the damaged area, resulting in a seamless and durable repair. This application of the Asphalt Distributor helps extend the life of the road and reduces the likelihood of further damage.

Another use of the Asphalt Distributor is in the construction of parking lots. By using this piece of specialized equipment, contractors can lay a thin and even layer of asphalt, providing a smooth and level surface that is perfect for parking. Asphalt Distributors can also apply sealcoat to a parking lot surface, which helps protect against wear and tear caused by exposure to UV rays, water, and other damaging elements.

Asphalt Distributors are also utilized in industrial areas, such as airports and warehouses. The smooth and even surface provided by an Asphalt Distributor is ideal for heavy-duty equipment and vehicles. The high durability and long lifespan of the asphalt pavement created by an Asphalt Distributor make it an ideal choice for areas that are subject to heavy traffic and high weights.

Finally, Asphalt Distributors are used in residential settings as well. They can be used to pave driveways, walkways, and other areas around a home, creating a smooth and elegant surface. This application of the Asphalt Distributor can help enhance the curb appeal of a home and increase its value.

In conclusion, Asphalt Distributors are incredibly versatile pieces of equipment that can be used in a variety of applications. From repairing damaged roads to providing a smooth and level surface for industrial areas, Asphalt Distributors are an essential tool

Manufactured Products made of Asphalt Distributor

Asphalt distributor is a type of construction equipment that is primarily used for applying hot asphalt to a surface. It is a highly versatile machine that can be used for a wide range of applications, including road construction, pavement maintenance, and concrete repair. One of the key advantages of an asphalt distributor is that it allows for precise and efficient application of asphalt.

Manufactured products made of asphalt distributor include a range of construction materials used in the construction industry. These products typically include asphalt emulsions, asphalt cutbacks, and asphalt sealants. These materials are highly valued for their highly durable and waterproof characteristics, as well as their ability to withstand harsh weather conditions and heavy loads.

Asphalt emulsions are one of the most popular materials made from an asphalt distributor. They are made by combining asphalt with water and a surfactant, which allows the asphalt to be suspended in water. Asphalt emulsions are highly versatile and can be used for a wide range of applications, including pavement maintenance, crack sealing, and soil stabilization.

Asphalt cutbacks are another popular product made from an asphalt distributor. They are made by mixing asphalt with a solvent, such as kerosene or diesel fuel, to create a more fluid asphalt mixture. This allows the asphalt to be easily applied to surfaces for sealing or coating. Asphalt cutbacks are widely used in the construction industry for sealing and waterproofing roofs, foundations, and other structures.

Finally, asphalt sealants are another popular product made from an asphalt distributor. These sealants are typically used to protect asphalt surfaces from water, sunlight, and other types of damage. Asphalt sealants are highly durable and can last for many years, making them a popular choice for roadways, parking lots, and other high-traffic areas.

Overall, the use of an asphalt distributor can lead to the production of high-quality, long-lasting materials that are highly valued in the construction industry. With its precise and efficient application, an asphalt distributor can help ensure that these materials are used effectively

The Evolution history of Asphalt Distributor

Asphalt distributor is a specialized piece of equipment used for spraying bitumen on the surface of a road. This piece of equipment has evolved over time to become more efficient and effective. The evolution history of asphalt distributor can be traced back to the early 1900s when crude oil was discovered in the United States.

The first asphalt distributor was invented by E.D. Etnyre in 1918. This machine was designed to spray hot asphalt on the road surface to improve its durability. It was a simple machine consisting of a tank, a pump, and spraying nozzles. The machine was mounted on a truck and was towed behind it. The operator would drive the truck and spray the hot asphalt on the road surface using the spraying nozzles.

In the 1920s, the asphalt distributor was improved significantly. The tank was made larger, and the spraying nozzle was made adjustable. This made it possible to vary the width of the spray pattern depending on the width of the road. The machine was also made more portable, and it became possible to mount it on a trailer and tow it behind a car.

The 1930s saw further improvements in the design of the asphalt distributor. The pump was made more powerful, and the tank was made larger still. The spraying nozzle was also made more efficient, and it became possible to spray asphalt at a faster rate.

In the 1940s, the asphalt distributor became more sophisticated. The machine was now mounted on a truck chassis, and it had a heating system to keep the asphalt at the correct temperature. The spraying nozzle was also improved, and it became possible to spray a more precise pattern.

Today, the asphalt distributor is a highly sophisticated piece of equipment. It is computer-controlled, and it has a GPS system that can accurately control the amount of asphalt sprayed on the road surface. The machine is also more efficient, and it consumes less fuel than its predecessors.

In conclusion, the asphalt distributor has evolved significantly over the

The Process of Asphalt Distributor

Asphalt distributor is a crucial piece of equipment used in road construction projects. It is a machine that is responsible for spraying asphalt at the right temperature on the surface of the road. The process of asphalt distributor includes several steps that are critical to the success of a road construction project.

The first step in the process of asphalt distributor is the preparation of the surface of the road. This involves cleaning the surface to ensure that it is free from any dirt or debris that may affect the quality of the asphalt. The next step is to apply a coat of primer to the surface of the road. The primer serves as a bonding agent between the existing pavement and the new asphalt, ensuring that the two surfaces adhere together.

The asphalt distributor machine is then loaded with hot liquid asphalt, which is heated to a temperature between 160ºC to 220ºC. The machine ensures that the asphalt is heated uniformly, to avoid any issues with the quality of the asphalt during the spraying process.

Once the asphalt is loaded, the machine is driven to the starting point of the road construction project. The operator of the machine then activates the spray nozzles, and the asphalt is sprayed onto the surface of the road. The asphalt is applied in a uniform layer at the right thickness, ensuring that the surface is smooth and even.

As the machine moves forward, the operator adjusts the speed and the flow of the asphalt to ensure that the layer is even and consistent. The process continues until the entire section of the road is covered with the asphalt.

After the spraying process is complete, the asphalt needs to be allowed to cool and cure before any vehicles are allowed back on the road. This is to ensure that the asphalt sets and bonds correctly to the surface of the road.

In conclusion, the process of asphalt distributor is an essential part of road construction projects. It is a process that requires precision and attention to detail, to ensure that the road surface is even and smooth. Proper maintenance of the asphalt distributor machine is crucial to

Benefits Advantages of Utilizing Asphalt Distributor

Asphalt distributors are specialized machines used in the construction industry to apply and distribute asphalt onto surfaces. The machines are designed to spray asphalt in liquid form, which is then spread evenly over a surface, providing a smooth and durable finish. Here are some of the benefits of using asphalt distributors.

Firstly, asphalt distributors are highly efficient in their application of paving materials. They ensure that asphalt is distributed evenly and quickly, which saves time and reduces waste. The even application of asphalt also leads to a better quality finish, which is more durable and long-lasting.

Asphalt distributors are also very versatile machines that can be used in a variety of construction projects. They can be used to apply asphalt to roads, parking lots, driveways, and other surfaces. They can also be used to distribute other materials such as sealants, tack coats, and emulsions.

Another advantage of using asphalt distributors is that they are cost-effective. The machines are capable of applying materials at a much faster rate than manual labor, reducing the time and manpower required for a project. Additionally, the even application of materials ensures that there is no wastage, which reduces overall costs.

Asphalt distributors are also very safe machines to use. They are designed to prevent accidents and injuries on construction sites. They come with safety features such as protective shields and warning lights that prevent accidents and alert workers to potential dangers.

In conclusion, the use of asphalt distributors offers many benefits to the construction industry. They are efficient, versatile, cost-effective, and safe machines that ensure a high-quality finish on any project. With the demand for asphalt paving projects increasing, more construction companies are investing in asphalt distributors to keep up with the competition and meet the needs of their customers.

Disadvantages Asphalt Distributor

An Asphalt Distributor is a vital piece of equipment that is used in the construction industry to apply asphalt to roads, parking lots, and other paved surfaces. Its function is to evenly distribute the asphalt over the surface, creating a smooth and durable finish. However, like all machines, an Asphalt Distributor also has some disadvantages that should be considered before using it.

One of the main disadvantages of using an Asphalt Distributor is its cost. These machines are costly to purchase and maintain. Additionally, they require skilled personnel to operate, which can add to the overall cost of the project.

Another disadvantage of using an Asphalt Distributor is the environmental impact it has during its use. The process of distributing hot asphalt can release fumes, which can be harmful to the environment and the people nearby. These fumes can cause air pollution, which can be exacerbated by high temperatures and humidity levels.

Another issue with Asphalt Distributors is their limited capacity. These machines can only distribute a certain amount of asphalt at a time, making them unsuitable for large projects. This means that several trips may be required to complete the job, increasing the time and cost of the project.

Asphalt Distributors also require a significant amount of maintenance. They need to be properly serviced and maintained to ensure they operate effectively. Ignoring maintenance can lead to costly repairs or even the need for replacement.

Finally, the use of an Asphalt Distributor is limited in certain weather conditions. For instance, they cannot be used during heavy rainfall or cold weather conditions, as the asphalt will not adhere properly to the surface.

In conclusion, while an Asphalt Distributor is a useful and necessary machine for asphalt distribution, it is essential to consider its disadvantages. These include its cost, environmental impact, limited capacity, maintenance requirements, and weather restrictions. By acknowledging these limitations, contractors can make informed decisions about whether to use an Asphalt Distributor for their project or consider other alternatives.

Selecting the Ideal Manufacturer Asphalt Distributor

Asphalt distributors play a crucial role in the construction industry as they are responsible for the application of asphalt materials. Therefore, selecting the ideal manufacturer for an asphalt distributor is a critical decision that can impact the quality of the paving work. Here are some factors to consider when choosing the right manufacturer for your asphalt distributor needs:

Quality of Equipment:

One of the critical factors to consider when choosing an asphalt distributor manufacturer is the quality of their equipment. A reputable manufacturer will have state-of-the-art, dependable and durable equipment that is capable of delivering a high-quality product.

Price:

Price is another crucial factor to consider when selecting an asphalt distributor manufacturer. It is essential to compare prices from different manufacturers critically. This is because there are different prices depending on the level of sophistication, features, and size of the equipment. Choose a manufacturer that offers high-quality equipment at a competitive price.

Warranty:

Another significant factor to consider when choosing an asphalt distributor manufacturer is the warranty offered. You should opt for manufacturers that provide warranties with their equipment. Be sure to read and understand the warranty conditions before making a purchase.

Technical support:

Choose an asphalt distributor manufacturer that provides exceptional technical support. The manufacturer should have knowledgeable professionals who can offer reliable support and assistance when needed. This will help to ensure that any issues with the equipment are promptly resolved.

Reputation:

When choosing an asphalt distributor manufacturer, consider the reputation of the company. Look for manufacturers with positive reviews and feedback from customers who have used their equipment. This will give you an idea of their level of expertise and the quality of their equipment.

In conclusion, when selecting an asphalt distributor manufacturer, ensure to consider the quality of equipment, price, warranty, technical support, and reputation. By considering these factors, you can be able to choose the ideal manufacturer that will meet your specific needs effectively.

Things to Consider When Purchasing Asphalt Distributor

When it comes to purchasing an asphalt distributor, there are several things to consider before making a purchase. An asphalt distributor is an important investment, and purchasing the right one can save you time and money in the long run. Here are some important things to consider when purchasing an asphalt distributor.

First, you need to consider the size of the distributor. The size of the distributor will depend on the size of the job you are working on. If you are working on small projects, you may not need a large distributor. However, if you are working on larger projects, you will need a larger distributor to be able to complete the job effectively.

Another thing to consider is the type of distributor you need. There are several types of distributors available, including manual, hydraulic, and gooseneck distributors. Each type has its own advantages and disadvantages, so it is important to do your research to determine which one is right for your needs.

You should also consider the material the distributor is made of. Asphalt distributors are typically made of steel, but there are other materials such as aluminum and fiberglass available as well. Steel is the most popular choice due to its durability, but aluminum and fiberglass may be a better choice if weight is a concern.

The price is another important consideration when purchasing an asphalt distributor. Prices can vary widely depending on the size and type of distributor, as well as the features it offers. It’s important to have a clear understanding of your budget before you start shopping, so you can compare prices and features to find the best option for your needs.

In addition to these considerations, it’s important to choose a reputable manufacturer or dealer when purchasing an asphalt distributor. Look for a company with a good reputation in the industry and a track record of providing quality products and excellent customer service.

In conclusion, purchasing an asphalt distributor requires careful consideration of several important factors. By considering the size, type, material, price, and reputation of the manufacturer or dealer, you can find the right asphalt distributor to

Properties of Asphalt Distributor

Asphalt distributor is a vital machine in the construction industry. It is used for spraying bitumen over the surface of the road during the asphalt laying process. It is critical for ensuring uniform application of the binder and achieving high-quality results. Asphalt distributors have different properties that enable them to perform their tasks effectively. This article will discuss some of the essential properties of asphalt distributors.

Capacity: The capacity of the asphalt distributor varies from machine to machine. The capacity of the tank determines the amount of bitumen that can be carried and sprayed on a road surface. The capacity ranges from 1000 liters to 12000 liters. The higher the capacity, the more significant the area that can be covered.

Spray Bar: The distributor has a spray bar that is used for the application of bitumen. The spray bar can be adjusted to different widths to cover a broader surface area. The spray bar consists of nozzles that are strategically placed to ensure even distribution of the binder.

Pump: The distributor also has a pump that provides pressure to the spray bar. The pump should be strong enough to ensure that bitumen is sprayed at the correct pressure for optimal results. A well-functioning pump ensures that the bitumen is sprayed evenly and at the correct thickness.

Heat System: The asphalt distributor has a heat system that is used to maintain the temperature of the bitumen. Bitumen needs to be kept at the correct temperature to ensure that it remains in a liquid state. The heat system is essential to ensure that the bitumen flows smoothly through the spray bar.

Controls: Asphalt distributors have controls that enable operators to control the flow and pressure of bitumen. The controls should be easy to operate to enable the operator to control spraying from the cab quickly.

In conclusion, asphalt distributors play a significant role in the road construction industry. The properties discussed above are essential for an effective asphalt distributor. The machine should have a large capacity, adjustable spray bar, strong pump, heat system, and easy-to-use controls

How to use Asphalt Distributor

An asphalt distributor is a heavy-duty machine used to apply hot asphalt material on road surfaces. It is an essential equipment in road construction that ensures an even and uniform layer of asphalt is laid, which improves road grip and durability. Here is a straightforward guide on how to use an asphalt distributor.

1. Know the Machine

The first step on how to use an asphalt distributor is to familiarize yourself with its components, controls, and operations. Ensure you read the manufacturer’s manual and understand each part and how they work.

2. Clean the Distributor

Before using the machine, ensure that it is clean and free from debris that may clog the spray nozzle. Ensure that the tank is cleaned and refilled with the right amount of hot asphalt material.

3. Adjust the Spray Bar

Next, adjust the spray bar to the required spread width and height. This is done by loosening the locking pin on the spray bar and adjusting the height and side-to-side spread of the nozzle to suit the road’s width.

4. Adjust the Pump

Check the pump motor and adjust the pressure to the recommended level for your road construction project. The pump’s pressure should be steady and within the manufacturer’s specifications to ensure an even application of hot asphalt material.

5. Test the Spray

Before starting the work, test the spray system to ensure it is working correctly. The worker is required to walk behind the machine to check the spray nozzle and adjust the pressure, as necessary.

6. Start Pouring

Finally, start pouring the hot asphalt material on the road surface. Start from one end of the road and work your way towards the other end, ensuring an even and uniform layer of asphalt is applied. Always note the required thickness of the asphalt and check it regularly to ensure you achieve the ideal thickness.

In conclusion, using an asphalt distributor requires proper preparation and knowledge of its parts and operations. With the above guidelines, you will understand how to use the machine correctly, leading to a smooth and even

Glossary Terminology Terms for Asphalt Distributor

Asphalt distributor is a mechanical device used for applying hot tar or asphalt on the road surface to prevent the occurrence of potholes or cracks. The process involves the use of a tank truck that carries the asphalt and a number of equipment including spray nozzle, pump and distributor bar. There are certain terminologies related to the asphalt distributor that one must be aware of:

1. Asphalt Tank: A large container used for storing asphalt.

2. Distributor Bar: A rod with spray nozzles that distributes asphalt evenly on the road surface.

3. Spray Nozzles: Nozzles located on the distributor bar that spray the asphalt out onto the road.

4. Pump: A device that pumps asphalt from the tank to the distributor bar.

5. Heating System: A system that heats up the asphalt to the right temperature for application.

6. Control System: A system that regulates the flow of asphalt from the tank to the distributor bar.

7. Pressure Gauge: A device that measures the pressure of the asphalt being sprayed out.

8. Safety Equipment: Equipment such as gloves, goggles and respirators that are worn by the operator to prevent exposure to the fumes and hot asphalt.

9. Calibration: The process of adjusting the flow rate of asphalt to ensure uniform distribution.

10. Asphalt Emulsion: A mixture of asphalt and water used for surface treatment.

Knowing and understanding the various terminologies related to the asphalt distributor is crucial for the operator to effectively apply asphalt while ensuring road safety. Maintaining the equipment and following the standard operating procedures of the asphalt distributor is also essential to ensure the accurate and efficient application of asphalt, ultimately leading to a well-maintained road surface.

Asphalt Distributor Price

Asphalt distributor is a heavy-duty construction equipment that is used to apply liquid asphalt material on roads, highways, parking lots, and other surfaces. It is designed to distribute the asphalt material evenly and efficiently, saving time, and reducing labor costs. The price of an asphalt distributor varies depending on the size, capacity, brand, and features.

The average price range for an asphalt distributor is between $40,000 to $150,000. The size and capacity of the equipment affect its price. The larger and bigger capacity equipment is more expensive than the smaller ones. The brand and reputation of the equipment also play a crucial role in its price. Well-known and established brands are more expensive than less-known ones.

Asphalt distributors come with various features that increase their efficiency and performance. Features such as computer controls, GPS systems, and multiple spray bars can increase the price of the equipment. The more advanced the features, the higher the price. However, these features can add value to the equipment and provide better output and performance.

Other factors that affect the price of an asphalt distributor are the type of material used to build the equipment, maintenance requirements, and warranty coverage. Equipment made from high-quality materials and with minimal maintenance requirements tend to have a higher price tag. Warranty coverage also affects the price, as equipment with longer and more extensive warranties cost more.

When choosing an asphalt distributor, it’s essential to consider the specific needs of the job and how the equipment will be used. Depending on the project’s size and scope, a smaller or larger capacity equipment may be more practical and cost-efficient. It’s also advisable to research various brands and features, and compare prices to ensure the best value for money.

In conclusion, the price of an asphalt distributor varies depending on several factors. Size, capacity, brand, features, material, maintenance requirements, and warranty coverage all affect the price of the equipment. Choosing the right equipment for the job and comparing various brands and features ensures the best value for money.