Knowledge about Asphalt Milling Machine

Asphalt milling machines are essential equipment in the construction industry. These machines are used to remove the top layer of an existing pavement, allowing a new layer to be applied. However, not many people are knowledgeable about these machines.

First, asphalt milling machines come in different sizes, from the small millers that can fit in tight spaces to the larger ones that can work on highways. Additionally, they use different types of cutting tools, such as drum cutters and milling teeth, which are suitable for different types of materials and work environments.

Second, it’s important to note that asphalt milling machines are complex machines that require skilled operators. Operators need to have a good understanding of the equipment and its features, as well as the project specifications. Safety is also crucial, and operators need to be familiar with safety protocols and procedures.

Third, regular maintenance and servicing are crucial for the longevity and efficiency of the milling machines. The operator needs to inspect and replace the cutting tools regularly, lubricate the machine’s moving parts, and ensure that the hydraulic system is working correctly.

Fourth, technology has played a huge role in improving the efficiency of asphalt milling machines. Some machines have GPS technology that helps the operator to work with more precision while minimizing errors. Other machines have sensors that detect when there are obstacles in the way, preventing accidents and damage to the machine.

In conclusion, asphalt milling machines are crucial equipment in the construction industry. Knowing about their different sizes, cutting tools, safety protocols, maintenance needs, and technological advancements will help users operate them efficiently and safely.

Various Types of Asphalt Milling Machine

Asphalt milling machines are widely used in the construction industry for removing old asphalt pavements and preparing surfaces for new asphalt layers. These machines come in different shapes and sizes, each designed to perform a specific task. Here are some of the various types of asphalt milling machines in the market.

1. Half-lane milling machines – These machines are used to remove asphalt layers up to a depth of 8 inches. They are suitable for medium and large-scale road construction projects.

2. Small milling machines – Small milling machines are suitable for smaller road construction projects such as parking lots, sidewalks, and residential driveways. They can remove asphalt layers up to a depth of 4 inches.

3. Full-lane milling machines – Full-lane milling machines are designed to remove entire lanes of asphalt from highways and other major roadways. They are capable of removing asphalt layers up to a depth of 12 inches.

4. Cold milling machines – Cold milling machines are designed to remove asphalt layers without heating the asphalt material. They are suitable for removing damaged asphalt surfaces and preparing surfaces for new asphalt layers.

5. Profiling milling machines – Profiling milling machines are designed to create a particular profile on the asphalt surface. They are used for creating rumble strips, drainage patterns, and other surface textures.

In conclusion, asphalt milling machines are essential equipment in the construction industry. The different types of asphalt milling machines are designed to perform specific tasks and are suitable for different road construction projects. Contractors should carefully consider the size and depth of the asphalt layers to be removed before selecting an asphalt milling machine.

FAQ sourcing Asphalt Milling Machine manufacturer from China

Asphalt milling machines are essential equipment in the construction industry. They are widely used for removing the upper layer of the pavement, creating a smooth surface and improving the quality of roads. If you’re in the market for a high-quality asphalt milling machine from China, here are some frequently asked questions about sourcing from Chinese manufacturers:

Question 1: What are the advantages of sourcing Asphalt Milling Machine from China?

Answer: There are several advantages to sourcing asphalt milling machines from China. Firstly, Chinese manufacturers offer competitive pricing and high-quality products. You can also enjoy fast and reliable delivery times, as well as excellent customer service.

Question 2: How do I find a reputable manufacturer in China?

Answer: Research is key to finding a reputable manufacturer in China. Look for reviews and testimonials from previous customers at various forums and websites. Additionally, check the manufacturer’s reputation and certifications, such as ISO and CE.

Question 3: How do I know the quality of an Asphalt Milling Machine from China?

Answer: Quality assurance is essential when sourcing from China. You can request a sample of the machine to check the quality and test its performance. Also, consider selecting a manufacturer that provides comprehensive warranties and customer after-sales support.

Question 4: Can I customize the specifications of an Asphalt Milling Machine from China?

Answer: Yes, you can customize the specifications of the asphalt milling machine to meet your unique needs. However, you must ensure that the manufacturer you select has the appropriate technology and expertise to produce the machine according to your specifications.

Question 5: Is it possible to get technical support after receiving an Asphalt Milling Machine from China?

Answer: Yes, the manufacturer must offer technical support to all customers. Look for manufacturers who have a dedicated customer service team that provides technical support and can troubleshoot any issues that may arise.

In conclusion, Chinese manufacturers offer high-quality asphalt milling machines at a competitive price. Be sure to select a reputable manufacturer by conducting thorough research and validating their reputation and certifications.

Applications of Asphalt Milling Machine

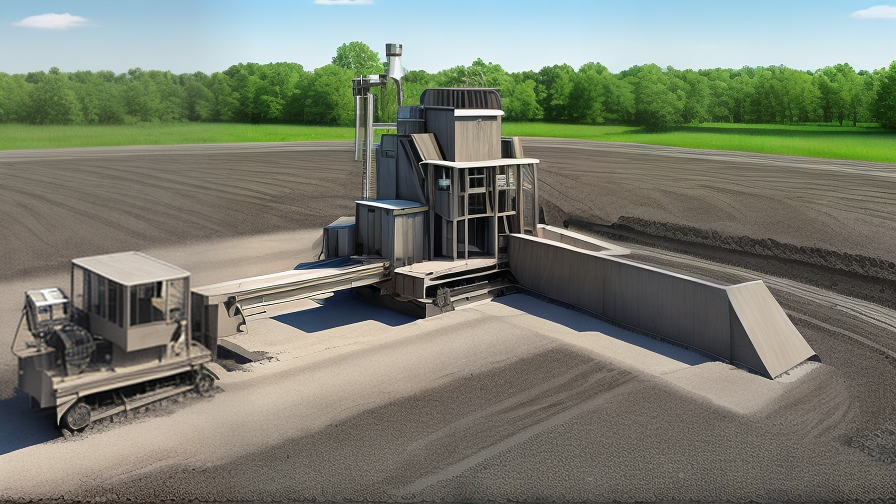

An asphalt milling machine is a versatile tool used for removing pavement layers, grading surfaces, and preparing the base of a road for a new layer of asphalt. The machine is equipped with high-powered drums lined with strategically placed teeth that grind and remove the pavement surface. The milling machine is a key player in the construction industry and offers numerous applications.

One of the primary uses of an asphalt milling machine is to remove damaged pavement layers. By removing the damaged surface layer, the machine creates a surface that is ready for repair or resurfacing. Once the damaged layer is removed, the milling machine grades and smooths the surface to prepare for a new layer of asphalt.

Another application of an asphalt milling machine is to create a surface with the desired gradient. The machine can create varying levels of depth to ensure water flows correctly throughout the road. This ability to create a slope is key in reducing standing water on roads, which lowers the risk of accidents or road damage.

Asphalt milling machines are also used for creating rumble strips. These safety features are designed to alert drivers to slow down, avoid shoulder areas, or indicate a change in road conditions. Rumble strips can be machined along the shoulder or center line of the road, depending on the intended purpose.

Finally, an asphalt milling machine is also used for preparing road surfaces for paving. The machine is ideal for flattening out and grading a roadbed to ensure that asphalt paving is even and the road surface is smooth. This can extend the life of the new pavement and improve the overall safety of the road.

Overall, the asphalt milling machine offers numerous applications in the construction industry. Whether removing damaged pavement layers, creating a slope for better water drainage, adding safety features, or preparing road surfaces for paving, the machine is a key tool for any construction professional.

Manufactured Products made of Asphalt Milling Machine

Asphalt milling machines have been used for decades to remove layers of deteriorated asphalt roads for repair or to create new roads. However, these machines have also paved the way for the production of some amazing products.

One of the most popular products made from asphalt milling machines is recycled asphalt pavement (RAP). RAP is created by grinding up old asphalt and mixing it with new asphalt cement to create a durable and cost-effective paving material. This significantly reduces waste and conserves resources, making it an environmentally-friendly solution for road construction.

Another product that can be made from asphalt milling machines is cold mix asphalt. This is a pre-mixed blend of asphalt and aggregate that can be used for road repair and patching. It can be produced on site which means quicker repair times and less traffic disruption.

Asphalt millings can also be used as a base for new construction projects. The fine-grained, crushed pieces of asphalt can be compacted to create a stable and durable base for new roads, parking lots or other construction projects. This is a sustainable and cost-effective solution compared to traditional gravel bases.

Beyond traditional construction projects, asphalt milling machines have even been used to create unique, artistic products. For example, artists have used asphalt millings to create sculptures, garden pathways or even furniture. The material is versatile and durable, allowing for a wide range of creative ideas to come to life.

Overall, the use of asphalt milling machines has transformed the construction industry and paved the way for the creation of innovative and useful products. With their efficiency and versatility, asphalt milling machines will continue to shape the way we think about road construction and beyond.

The Evolution history of Asphalt Milling Machine

Asphalt milling machines have come a long way since their inception. The first machine was invented in the early 1900s to remove the excess material and debris left behind after a roadway was paved. However, these early machines were clumsy and inefficient, requiring multiple workers to operate and even more to maintain. With advancements in technology and engineering, these machines have evolved into powerful, effective tools for today’s road maintenance crews.

One significant innovation was the addition of a conveyor system, allowing the machine to continuously move forward while removing material to avoid creating patches that could cause damage. Another was the inclusion of a drum with better cutting teeth, increasing speed and efficiency. Finally, electronic sensors and real-time feedback systems allow for precise control over the machine’s operation and ensure a more even and thorough cut.

In recent years, manufacturers have also focused on making these machines more environmentally friendly. Newer models use less fuel and produce lower emissions, helping to reduce the carbon footprint of road maintenance. Increased automation and technology integration have also helped reduce human error and enhance worker safety.

Overall, the evolution of asphalt milling machines mirrors the technological advancements seen in many industries. These machines have become faster, more efficient, and more advanced, providing smoother and safer roads for drivers. With continued investment and innovation, it is likely that these machines will continue to evolve and meet the needs of future road maintenance crews.

The Process of Asphalt Milling Machine

Asphalt milling is the process of removing a portion of the top layer of pavement. This process is carried out using an asphalt milling machine. The milling machine removes the damaged or deteriorated pavement and grinds it into small pieces. The resulting material is then recycled and used to repair the pavement surface.

The process of asphalt milling begins with the preparation of the area to be milled. The area is marked and cleared of any debris and obstacles that may hinder the milling machine’s operation. The milling machine is then positioned on the pavement surface to be milled.

The milling machine has a large rotating drum that grinds the pavement surface. The drum is fitted with carbide-tipped teeth that move across the pavement to remove the top layer. The depth of the cut can be adjusted to remove only the damaged or deteriorated portion of the pavement.

As the milling machine moves forward, it grinds the pavement surface into small pieces. These pieces are then conveyed by a conveyor system to a waiting truck. The truck then transports the material to a recycling facility for processing.

Once the milling process is complete, the surface is then cleaned to remove any debris or loose material. This is usually achieved using a broom or street sweeper. The repaired surface is now ready for resurfacing.

Asphalt milling is a cost-effective way to repair damaged or deteriorated pavement. It is also an environmentally friendly process as the materials are recycled and reused, reducing waste and pollution. It also helps to prolong the life of the pavement surface, reducing the need for extensive repairs in the future.

In conclusion, the process of asphalt milling is an essential process in the repair and maintenance of pavement surfaces. It is a cost-effective and environmentally friendly way to repair damaged or deteriorated pavement surfaces. The use of advanced milling machines has improved the efficiency and accuracy of the process, making it a viable option for repairing pavement surfaces in a timely and effective manner.

Benefits Advantages of Utilizing Asphalt Milling Machine

Asphalt milling machines are equipment designed to remove asphalt pavement layers from the road surface. The machines have become increasingly popular in recent years, thanks to their numerous benefits and advantages. They offer an efficient and cost-effective way of removing damaged pavement layers without disrupting the underlying foundation.

One significant benefit of utilizing asphalt milling machines is the reduced cost of road construction or repair. It is more cost-effective to remove the damaged layer only and replace it with fresh asphalt, rather than replacing the entire road surface. This saves time and money, which can be used to enhance other areas of road repair or construction.

Another advantage of these machines is that they are eco-friendly. Asphalt milling machines use a process called cold milling, which crushes and grinds the asphalt pavement into small pieces. The crushed asphalt is then recycled for future use, reducing the amount of waste material that ends up in landfills. This is highly beneficial for the environment, as it promotes sustainability and reduces carbon footprint.

Additionally, asphalt milling machines provide a safe way of removing damaged road surface layers. With the right operator, the machines can easily excavate and remove the asphalt layer without damaging the underlying foundation. This is important because it reduces the risk of accidents and improves overall road safety.

Asphalt milling machines are versatile and can be used for a wide range of road construction and repair tasks. They offer a fast and efficient way of removing damaged pavement layers, and can also be used to cut channels, remove concrete, and grind surfaces. This versatility makes them highly useful for a wide range of tasks, helping road contractors to complete projects quickly and efficiently.

In conclusion, utilizing asphalt milling machines has numerous benefits and advantages. These machines provide a safe, eco-friendly, cost-effective, and efficient way of removing damaged pavement layers, making them highly useful in road construction and repair projects. By utilizing these machines, road contractors can save time, money, and resources, while also promoting sustainability and safety.

Disadvantages Asphalt Milling Machine

Asphalt milling machines are essential for the construction industry. They are used to remove layers of pavement and ensure that the surface is level before new pavement is laid. However, as with any piece of equipment, there are disadvantages to using asphalt milling machines.

One disadvantage of asphalt milling machines is that they are incredibly noisy. The noise level can reach up to 120 decibels, which can cause permanent hearing damage. To combat this, workers must wear proper hearing protection, and the machine must be used in areas where noise levels won’t cause disruption.

Another disadvantage is that asphalt milling machines can produce large amounts of dust, which can cause respiratory problems for workers. The dust produced during the milling process contains harmful chemicals and substances that can be hazardous to people’s health. To prevent this, safety measures need to be taken to ensure that the workers are not exposed to dangerous levels of dust.

Asphalt milling machines are often expensive, making it challenging for small construction companies to afford them. As a result, they may rely on renting equipment, which can be costly and eat into the company’s profits. Additionally, the maintenance and repair of the machines can also be costly, especially if they break down frequently.

Lastly, asphalt milling machines can be dangerous if not operated correctly. Workers need to undergo proper training to ensure that they know how to operate the equipment safely. Failure to do so can result in injuries or even death.

In conclusion, while asphalt milling machines are essential for the construction industry, they do have their disadvantages. They generate high levels of noise, produce hazardous dust, and can be costly for smaller construction companies. Additionally, they can be dangerous if not operated correctly. It is critical to take the necessary safety measures to ensure that workers are not harmed while using this equipment.

Selecting the Ideal Manufacturer Asphalt Milling Machine

Selecting the ideal manufacturer for an asphalt milling machine is essential for any construction company or road maintenance department. A good machine can make all the difference in the efficiency and quality of your project. When choosing a manufacturer, there are several factors to consider.

First, consider the quality of the machine. Look for a manufacturer that produces durable and reliable equipment. Read up on reviews and ask around in your industry for recommendations.

Next, consider the manufacturer’s experience and expertise in the industry. A manufacturer with a long history in producing asphalt milling machines will likely have more knowledge and experience in producing high-quality equipment.

It’s also important to consider the manufacturer’s customer service and support. Look for a manufacturer that provides excellent support before and after your purchase. This includes providing training on how to operate the machine and offering timely and effective customer service if any issues arise.

When selecting a manufacturer, don’t forget to consider the cost. While a more expensive machine may be of higher quality, it’s important to find a machine that fits within your budget. Be sure to compare prices from multiple manufacturers and consider any additional costs, such as shipping or maintenance.

Finally, consider the manufacturer’s warranty and guarantee. A manufacturer that offers a strong warranty and guarantee can give you peace of mind that your investment is protected.

In summary, selecting the ideal manufacturer for an asphalt milling machine requires consideration of the quality of the machine, the manufacturer’s experience and expertise, customer service and support, cost, and warranty and guarantee. By taking these factors into account, you can find the right manufacturer for your needs and ensure a successful project.

Things to Consider When Purchasing Asphalt Milling Machine

Asphalt milling machines are essential for contractors who want to remove old asphalt surfaces and recycle the materials. These machines are designed to grind, scrape and remove asphalt pavement, leaving behind a clean surface for resurfacing. If you are in the market for an asphalt milling machine, here are the things to consider:

1. Size: You need to determine the size of your project so that you can purchase the right size of the milling machine. For smaller projects, a smaller milling machine may be adequate, while larger projects may require a larger machine.

2. Power: The power of the milling machine is another critical factor to consider. The power of the machine will depend on the size of the project and the type of pavement being removed. You need to match the power output of the machine to the type of work to be performed.

3. Price: Asphalt milling machines come in different price ranges, so you need to determine your budget. You should consider the upfront cost of the machine, the cost of maintenance and repairs, and the cost of fuel and other operating expenses.

4. Durability: A milling machine is a significant investment, so you want to ensure that you purchase a durable machine that will last for a long time. Look for machines with high-quality parts and materials that can withstand the rigors of heavy-duty use.

5. Brand: The brand of the milling machine is another important factor to consider. Choose a reputable brand that is known for producing high-quality machines that perform well and have a long lifespan.

In conclusion, purchasing an asphalt milling machine requires careful consideration of several factors. You need to evaluate your project needs, budget, and the machine’s size, power, durability, and brand to make an informed decision. By doing so, you can ensure that you purchase a machine that will help you complete your projects efficiently and effectively.

Properties of Asphalt Milling Machine

Asphalt milling machines are powerful tools used for removing old paving materials, such as asphalt and concrete. They play a crucial role in construction and maintenance projects. Asphalt milling machines come in different sizes and types and offer several properties that make them efficient in performing their activities.

One of the essential qualities of an asphalt milling machine is its power. These machines can grind up to 12 inches of asphalt in a single pass, enabling quick and efficient removal of old pavements. They also come with various horsepower engines to handle tough asphalt, rocks, and other materials.

Another property of asphalt milling machines is their versatility. They can perform a range of tasks apart from milling, such as line removal, rumble strip installation, and curb cutting. Some models also convert into a skid steer or a loader, making them useful for other construction applications.

Asphalt milling machines also come with advanced features like enhanced dust suppression systems to keep the jobsite clean and prevent workers’ exposure to hazardous materials. These features make the machines safe and environmentally friendly.

Finally, asphalt milling machines have a long lifespan, which means they can serve a company for decades. They are durable, low-maintenance machines built to handle harsh weather conditions and heavy loads.

In conclusion, asphalt milling machines are essential tools in the construction industry, offering powerful capabilities, versatility, advanced features and durability. With these properties, they can perform their tasks efficiently, safely, and for a long time, helping to reduce construction downtime and costs.

How to use Asphalt Milling Machine

Asphalt milling machines are heavy-duty equipment used for removing old, damaged or worn-out asphalt pavements from roads and highways. This equipment is perfect for construction companies looking to save money on road repairs by recycling existing materials. In this article, we will discuss how to use an asphalt milling machine in a few easy steps.

Step One: Preparation

Before using an asphalt milling machine, be sure to conduct a thorough inspection to ensure that it’s ready to be used. Check the fuel, oil, coolant levels, and hydraulic fluids to ensure that they’re all at the proper levels. Inspect the machine’s tires and tracks for wear and tear, and make sure that any loose parts are tightened or replaced.

Step Two: Choosing the Right Cutting Depth

The depth of cut refers to how deeply the milling machine will cut into the asphalt. This depth is measured in inches and can be adjusted depending on the project’s specifications. To set the cutting depth, adjust the leveling equipment according to the desired depth.

Step Three: Operating the Machine

After completing the pre-operation check and setting the cutting depth, it’s time to start up the machine. Ensure that the engine is running at the required speed, and engage the cutting head into the pavement. Move the machine forward, allowing the teeth of the cutting head to mill the asphalt. Take care to avoid any obstacles in the pavement or areas where the pavement is too thick to be milled.

Step Four: Save the Milled Material

The milled asphalt material can be recycled and used in other projects. To do this, simply collect the milled material into a dump truck or other container to be transported to a recycling facility.

Conclusion

Operating an asphalt milling machine is not as difficult as it may seem. By following these simple steps, you can successfully operate the equipment for efficient and cost-effective road repairs. Remember to take proper safety precautions and wear protective gear when operating the machine. With the right equipment and knowledge, you can help your company save money

Glossary Terminology Terms for Asphalt Milling Machine

Asphalt milling machines are essential equipment for road construction, and those involved in the industry need to be familiar with the terminology used. Here are some common terms associated with asphalt milling machines.

1. Drum- This is the cylindrical component of the milling machine that removes the existing asphalt surface.

2. Milling Teeth- These are the cutting tools attached to the drum that remove the asphalt surface.

3. Conveyor- A belt system that transports the milled asphalt to a trailer or dump truck.

4. Differential- A component that allows one drum to rotate faster than the other, helping the machine to maintain a constant cutting depth.

5. Depth Control- A mechanism that controls the depth to which the milling teeth cut into the asphalt surface.

6. Crawler Tracks- The wheels or tracks that help the milling machine move across the road surface.

7. Skis- Pieces of metal that guide the machine along curbs and gutters.

8. Vacuum- A component that removes dust and debris from the milled asphalt.

9. Grade Control- A measurement system that ensures the milling machine cuts the asphalt surface to the correct level.

10. Wirtgen- One of the leading manufacturers of asphalt milling machines.

By understanding the terminology associated with asphalt milling machines, operators can communicate with each other effectively and make sure that everyone is on the same page when it comes to the task at hand. It also helps teams to identify and solve problems more quickly, reducing downtime and increasing productivity.

Asphalt Milling Machine Price

Asphalt milling machines are essential equipment in road construction and maintenance projects. They are used to remove the top layer of asphalt pavements, revealing a smooth surface that is ready for resurfacing. The cost of these machines varies depending on various factors, such as size, brand, and features.

On average, the price of an asphalt milling machine ranges from $30,000 to $500,000. The smaller machines used for residential driveways and small parking lots cost between $30,000 and $80,000. For larger projects such as highways and airports, the price can go up to $500,000. However, the size of the machine is not the only factor that affects the price.

Brand and features are also significant determinants of the cost of an asphalt milling machine. Renowned brands such as Caterpillar and Wirtgen often come at a premium price, but their machines are known for their durability and efficiency. Machines with advanced features such as automated controls and dust suppression systems also cost more.

Another factor that affects the price of an asphalt milling machine is the availability of the equipment in the market. During peak construction periods, the demand for such equipment is often high, leading to an increase in prices. On the other hand, during off-peak seasons, the prices can be lower due to low demand.

Finally, the cost of maintenance and repairs should also be considered when purchasing an asphalt milling machine. The machine’s durability, ease of maintenance, and availability of spare parts should factor in the buying decision.

In conclusion, the price of an asphalt milling machine varies depending on various factors, including size, brand, features, and demand. It is essential to consider these factors when making a buying decision to ensure the value for money.