Knowledge about Automotive Part Manufacturer

When you’re in the market to purchase automotive parts, it’s important to have knowledge about the manufacturer you’re buying from. There are numerous companies that produce automotive parts, but not all of them are equal in terms of quality and reliability.

Before making a purchase, it’s important to research the manufacturer to ensure that they are a reputable company with a track record of producing high-quality parts. Look for reviews and ratings from other customers and industry professionals to get an idea of the company’s reputation.

It’s also important to consider the type of parts the manufacturer produces. Some manufacturers specialize in a particular type of automotive part, such as brake pads or exhaust systems, while others produce a wide range of parts. Consider your specific needs and look for a manufacturer that can provide the parts you require.

When researching a manufacturer, look into their production facilities and quality control processes. The best manufacturers will have state-of-the-art facilities and rigorous testing procedures in place to ensure that their parts meet industry standards and are safe for use.

Another important factor to consider is the price of the parts. While it may be tempting to choose the cheapest option, it’s important to remember that quality comes at a cost. Cheaper parts may be less reliable and may need to be replaced more frequently, ultimately costing you more in the long run.

In addition to quality and reliability, consider the manufacturer’s customer service and warranty policies. A good manufacturer will stand behind their products and offer a warranty that provides peace of mind and protection for your investment.

In conclusion, having knowledge about the automotive part manufacturer is crucial for making an informed purchasing decision. By taking the time to research the manufacturer and their products, you can ensure that you’re getting high-quality parts that will meet your needs and last for years to come.

Various Types of Automotive Part Manufacturer

Automotive parts are the constituents that make up the various systems of vehicles. These parts range from engines, suspensions, brakes, tires, and other vital components that work together to ensure that vehicles operate efficiently. These parts are produced by a range of manufacturers who specialize in different aspects of automotive systems.

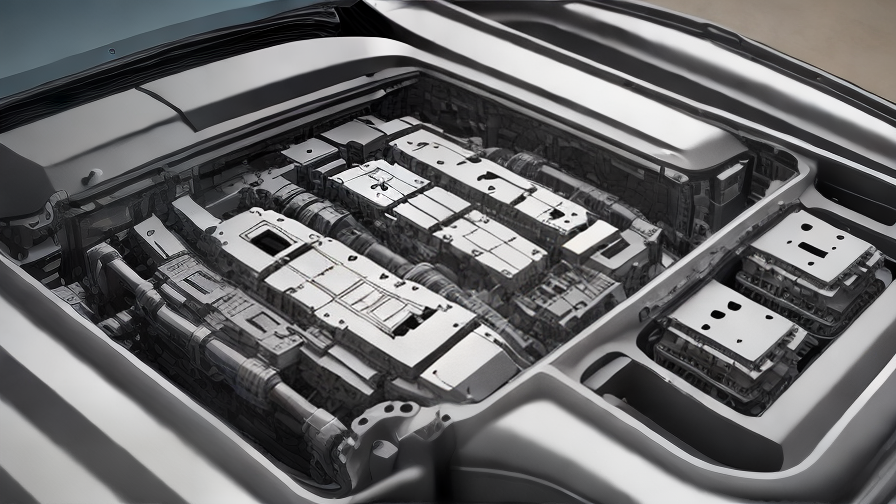

Original Equipment Manufacturers (OEMs) are the primary source of automotive parts in the market. These manufacturers produce parts that are designed to fit specific vehicles, and every part is made according to the exact specifications of the respective automaker. These manufacturers use sophisticated equipment and high-tech machinery to manufacture car parts that are reliable and of high quality.

Aftermarket manufacturers, on the other hand, produce replacement parts that are designed to fit vehicles from different automakers. These parts are not made to any specific automaker’s specifications; they are produced to a set of standards designed to ensure that they can be used in place of OEM parts. Aftermarket parts are cheaper than OEM parts, and they are often of similar quality.

Performance parts manufacturers produce parts for automotive enthusiasts who want to enhance their vehicles’ performance. These parts are specifically designed to boost horsepower, torque, and acceleration, among other things that improve vehicle performance. Performance parts are not compatible with all vehicles; therefore, it is essential to ensure that the performance part is compatible with your car before purchasing it.

Specialty parts manufacturers specialize in the production of specialized automotive parts that are not readily available in the market. These manufacturers produce parts such as custom suspension systems, steering wheels, and other parts that are designed to enhance a vehicle’s aesthetics, performance, or function.

In conclusion, automotive part manufacturers are essential in ensuring that vehicles operate efficiently. OEMs produce parts that are designed to fit specific vehicle models and are of high quality. Aftermarket manufacturers produce parts that are cheaper than OEM parts but are of similar quality. Performance parts manufacturers produce parts that enhance vehicle performance, while specialty parts manufacturers produce specialized parts that enhance a vehicle’s aesthetics, performance, or

FAQ sourcing Automotive Part Manufacturer manufacturer from China

Sourcing automotive parts from Chinese manufacturers has become a popular choice due to their competitive pricing and reliable quality. However, there are several concerns and questions that arise when it comes to selecting the right manufacturer for your business needs. To help simplify the process, we have compiled a list of frequently asked questions and multiple answers for you to consider:

1. What certifications should I look for in a Chinese automotive part manufacturer?

Ans: Look for manufacturers that have certifications such as ISO 9001 or TS 16949, as they indicate compliance with global quality standards.

2. How do I ensure the quality of the parts?

Ans: Conduct a factory audit, request samples, and ask for references from previous clients.

3. What is the typical lead time for automotive parts?

Ans: The lead time can vary depending on the complexity and quantity of the parts, but the average is between 4-12 weeks.

4. Can I customize parts according to my specifications?

Ans: Yes, most manufacturers offer customization options, but it may require additional costs and longer lead times.

5. What is the minimum order quantity (MOQ) for automotive parts?

Ans: It varies from manufacturer to manufacturer, but the MOQ for custom parts is typically higher than for standard parts.

6. How do I handle shipping and logistics?

Ans: You can either arrange your own shipping or request the manufacturer to handle it, but be mindful of the additional costs.

7. What payment methods are available?

Ans: Manufacturers usually accept payments through wire transfer, PayPal, or letter of credit.

In conclusion, sourcing automotive parts from Chinese manufacturers offers a cost-effective solution for businesses. By ensuring the manufacturer has the necessary certifications, conducting quality checks, and understanding lead times and customizations options, you can confidently select the right manufacturer for your needs.

Applications of Automotive Part Manufacturer

Automotive part manufacturers are vital players in the automotive industry. They provide a wide range of solutions for the production of high-quality vehicle parts. The industry has grown significantly, thanks to the demand for improved and complex car parts. Automotive manufacturers have increasingly turned to parts manufacturers to keep up with the market. The following are some of the applications of automotive part manufacturers.

Design and Development

Automotive part manufacturers have the expertise and technology to design and develop parts of varying complexities. They work closely with automakers to understand their requirements and develop parts that meet their specifications. They use advanced tools like CAD, CAM, and CAE to design and simulate parts’ performance to ensure they meet the required standards.

Production and Manufacturing

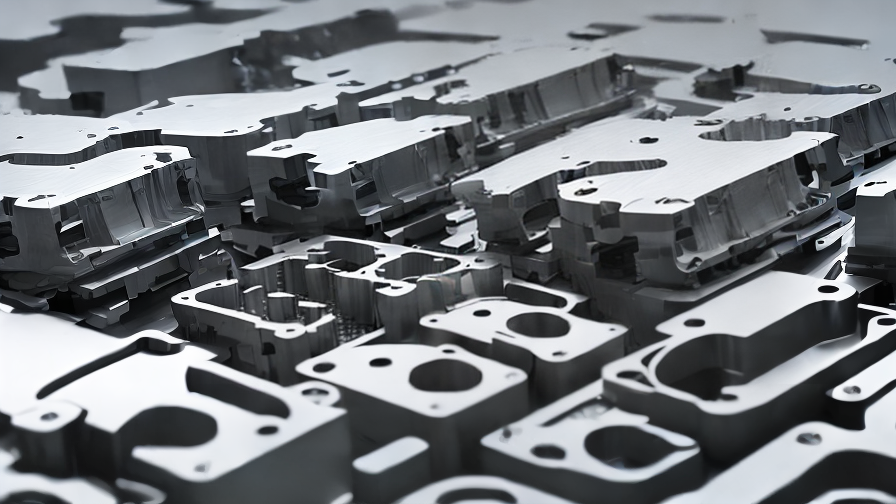

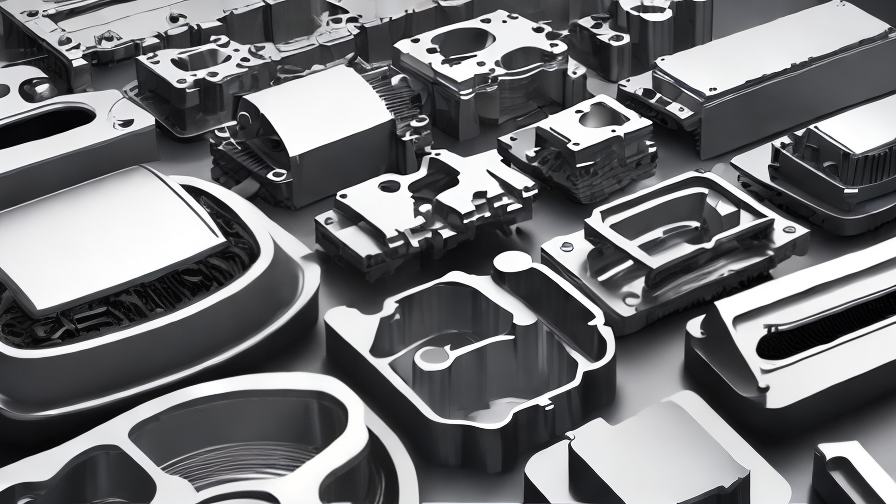

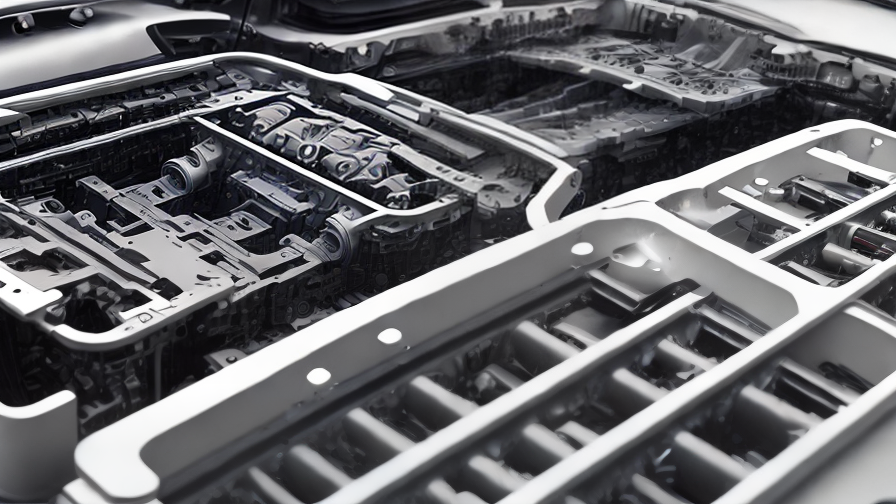

Automotive part manufacturers use state-of-the-art equipment and processes to produce high-quality parts. They use different types of metals, plastics, and other materials to manufacture parts ranging from small precision components to large structural parts. They use techniques like injection molding, casting, stamping, and extrusion to produce the desired shapes and sizes of parts.

Product Testing and Validation

Automotive parts manufacturers also provide product testing and validation services to ensure the parts meet the required standards. They use different testing methods like fatigue, durability, and crash testing to assess the parts’ performance under different conditions.

Supply Chain Management

Automotive part manufacturers play a crucial role in the automotive supply chain. They ensure that the parts are delivered to the assembly line just in time to meet production deadlines. They also manage inventory levels to prevent shortages or excess stock.

Conclusion

Automotive part manufacturers play a critical role in the production of high-quality automotive parts. They have advanced technologies and expertise to design, develop, and manufacture parts of varying complexities. They also provide testing and validation services and manage the automotive supply chain. The industry is poised for growth, thanks to the increasing demand for high-quality and complex car parts.

Manufactured Products made of Automotive Part Manufacturer

Manufactured products made of automotive part manufacturer are the result of the collaboration between different industries. An automotive part manufacturer specializes in creating various automotive parts, such as engines, transmissions, suspensions, and brakes. These parts are then used by different automotive and vehicle manufacturers.

However, automotive part manufacturers are not limited to producing parts solely for the automotive industry. They also create various products that are used in the manufacturing of different consumer goods. Examples include power tools, home appliances, and construction equipment. These products are designed to offer the same quality and durability as their automotive counterparts.

Automotive part manufacturers have played an important role in the manufacturing process of different products. For instance, the creation of high-quality power tools would not be possible without the precision and quality of automotive parts manufacturers. These tools require accuracy and strength, and the materials used in their production need to withstand rough and regular use.

Similarly, home appliances such as refrigerators, washing machines, and air conditioning units require high-quality motors and compressors. Automotive part manufacturers can provide these parts, resulting in the production of durable appliances that can withstand regular use and wear and tear.

Another example is the use of automotive parts in the construction industry. Construction equipment like cranes, forklifts, and bulldozers require heavy-duty engines and transmissions. These parts need to resist dust, sand, and other environmental factors, making them ideal for construction use.

The use of automotive parts in the manufacturing of different products has resulted in high-quality and durable products. The precision, engineering, and materials used in the production of these parts have made them essential for different industries. The reliability of these parts has made them attractive to manufacturers, leading to increased demand for automotive part manufacturers.

In conclusion, automotive part manufacturers have played a significant role in the manufacturing process of different products. The use of their precision-engineered parts has resulted in durable and reliable products that can withstand regular use and wear and tear. Their importance has resulted in increased demand and an essential role

The Evolution history of Automotive Part Manufacturer

Automotive part manufacturing has come a long way since the early days of the automobile. In the early 1900s, parts were made by hand, with each component being individually crafted by skilled artisans. This method was not only time-consuming, but it also limited the number of parts that could be produced, making replacement parts expensive and hard to come by.

However, with the advent of mass production techniques such as the assembly line, the manufacturing of automotive parts became more efficient and cost-effective. The widespread adoption of these techniques allowed manufacturers to produce large quantities of parts quickly and at lower costs. This led to an exponential growth in the automotive industry, with manufacturers able to meet the growing demand for vehicles.

As the industry began to evolve, new technologies were introduced to streamline the manufacturing process even further. The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) made it possible for designers to create complex parts rapidly and to have these parts manufactured with precision and accuracy. This allowed manufacturers to reduce the time it takes to develop new parts and to improve the quality of these parts.

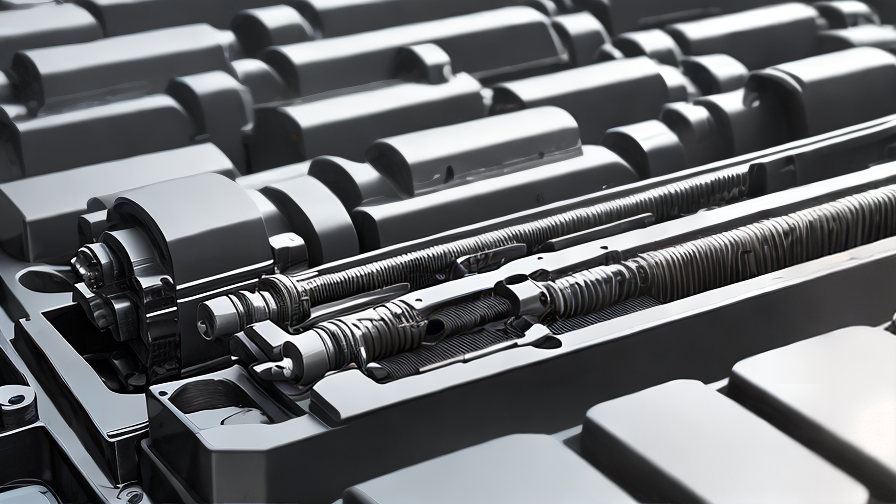

Another significant development in the automotive parts industry is the increasing use of automation. Modern manufacturing plants often make use of robots and other automated systems to perform repetitive tasks, such as assembly work and welding. This has not only increased production efficiency but has also made it safer for workers to work in these facilities as robots have taken over some of the more dangerous tasks.

Finally, the advent of 3D printing technology has opened up new horizons in automotive part manufacturing. With 3D printing, manufacturers can produce customized parts quickly and at a lower cost than traditional manufacturing methods. This has made it possible for manufacturers to offer more customized options to customers, resulting in a more personalized driving experience.

In conclusion, the history of automotive part manufacturing is one of constant evolution and innovation. From the early days of manual labor to the current age of automation and 3D printing, manufacturers have continued to

The Process of Automotive Part Manufacturer

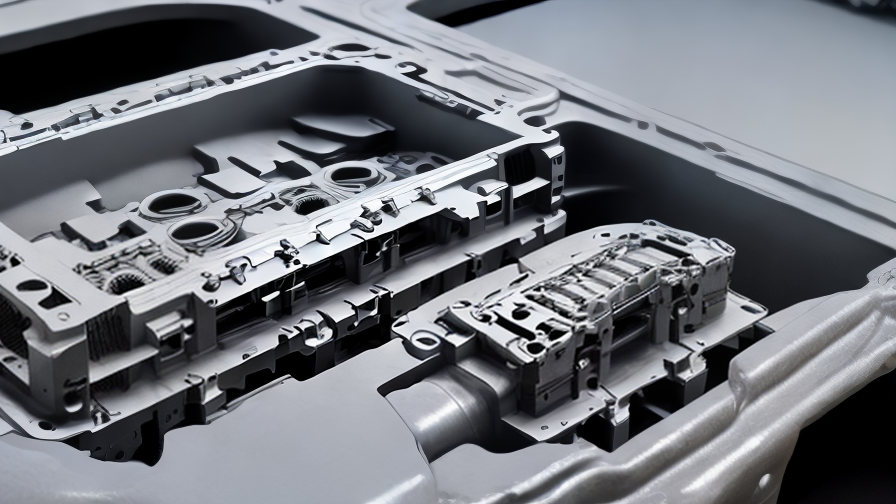

Automotive part manufacturing is a complex process that requires precision and accuracy. The process involves several stages, from design to production, quality control, and distribution.

The first stage is the design process, where the engineers create the blueprint of the automotive parts. This is followed by the development stage, where the engineering team creates prototypes of the parts. Once the prototypes are approved, the manufacturing process starts.

The manufacturing process usually starts with raw materials that are carefully selected based on their properties, such as strength, durability, and flexibility. The raw materials are then shaped and molded to the required size and shape using various tools and machines.

Next, the parts are assembled, which involves fitting various components together using specialized equipment. The parts are then tested for quality control purposes. This is done to ensure that they meet the required standards in terms of functionality, safety, and reliability.

Lastly, the finished parts are packaged and distributed to the respective suppliers or customers. The packaging is done in a manner that ensures the safety and security of the parts during transportation.

In summary, the process of automotive part manufacturing starts with design and development, followed by the selection of raw materials, shaping and molding of parts, assembly, quality control, and finally distribution. This process requires expertise, skill, and attention to detail to ensure that the parts produced are of the highest quality and meet the requirements of the customers.

Benefits Advantages of Utilizing Automotive Part Manufacturer

Utilizing an automotive part manufacturer has numerous benefits and advantages, especially for those involved in the automobile industry. These manufacturers are experts on producing high-quality parts and components that conform to strict standards and regulations set by the government and industry.

One of the main benefits of utilizing an automotive part manufacturer is that they offer a wide range of products designed according to the customer’s specific requirements. They employ skilled and specialized personnel that utilize cutting-edge technology and equipment to produce products that meet or exceed expectations. This ensures that customers can get exact parts needed for their automobile without having to look far and wide.

In addition, automotive part manufacturers typically offer cost-effective solutions, saving customers significant amounts of money. They have established relationships with suppliers of raw materials and other necessary components, which enables them to purchase materials at favorable prices. This, coupled with their efficiency and expertise, makes their products very affordable.

Automotive part manufacturers often have rigorous quality control systems in place to ensure that the products they produce are of the highest quality. They thoroughly test and inspect every component before release to the market to help ensure that they meet essential quality benchmarks. When customers purchase such products, they are assured of top-notch value, durability, and longevity.

Finally, automotive part manufacturers typically have excellent customer support systems. Customers can contact them at any time of the day and get the necessary assistance. They offer support services such as installation, maintenance, and repair assistance, providing customers with even greater peace of mind.

In summary, leveraging the services of an automotive part manufacturer comes with numerous benefits, including cost-effectiveness, quality control, specialized products, and exceptional customer support. Customers are assured of value for money and can rest easy knowing that they have the right components for their automobiles.

Disadvantages Automotive Part Manufacturer

The automotive industry is one of the largest industries in the world, with millions of vehicles being produced every year. While automotive part manufacturers play a vital role in this industry, there are several disadvantages that they face.

Firstly, automotive part manufacturers require significant investments in equipment, facilities, and highly skilled labor. This means that setting up a manufacturing plant can be a costly and time-consuming process. These costs can be prohibitive, especially for small manufacturers, making it difficult for them to compete with larger companies.

Secondly, automotive part manufacturers are highly dependent on the automotive industry. Any fluctuations or changes, such as a decrease in demand for vehicles or changes in regulations, can significantly affect the industry’s profitability. This makes it challenging for manufacturers to plan and invest in the future since any shifts in the market can result in significant financial losses.

Thirdly, automotive part manufacturers are subject to strict quality standards and regulations. This is due to concerns around safety and reliability, as well as the high expectations of automotive companies and consumers. Meeting these standards can be time-consuming and expensive, requiring significant resources and investments.

Finally, automotive part manufacturers face the challenge of global competition. This means that they may need to compete with manufacturers from different countries, each with their own strengths and cost advantages. For example, Chinese manufacturers are known for their low-cost production, making it difficult for manufacturers in countries with higher labor costs to compete.

In conclusion, while automotive part manufacturing is a crucial part of the automotive industry, it comes with several challenges and disadvantages. These challenges include high costs, market fluctuations, strict quality standards, and global competition. Despite these challenges, manufacturers continue to innovate and invest in new advances in technology and processes to stay competitive and meet the demands of the industry.

Selecting the Ideal Manufacturer Automotive Part Manufacturer

When it comes to selecting the ideal automotive part manufacturer, it is crucial to do your research and choose a company that meets your specific requirements. Here are some key factors to consider when selecting an automotive part manufacturer:

1. Quality: Quality is always important when it comes to automotive parts. Look for a manufacturer that has a reputation for producing high-quality parts that meet or exceed industry standards.

2. Experience: An experienced manufacturer will have a better understanding of your needs and will be able to provide you with better solutions. Look for a company that has been in business for several years and has a history of producing quality parts.

3. Price: Price is always a consideration when selecting an automotive part manufacturer. However, it is important to keep in mind that the cheapest option may not always be the best. Look for a manufacturer that offers competitive pricing for high-quality parts.

4. Customer Service: Good customer service is essential when working with a manufacturer. Look for a company that is responsive to your needs and has a reputation for excellent customer service.

5. Turnaround Time: The turnaround time for manufacturing and delivering parts is an important factor to consider. Look for a manufacturer that has a fast turnaround time, especially if you need parts quickly.

6. Technology: Technology is constantly advancing in the automotive industry, and it is important to work with a manufacturer that stays up-to-date with the latest technology. Look for a company that invests in the latest equipment and software to ensure quality and efficiency.

In conclusion, selecting the ideal automotive part manufacturer requires careful consideration and research. By taking into account the factors outlined above, you can find a manufacturer that meets your specific needs and provides high-quality parts at a competitive price.

Things to Consider When Purchasing Automotive Part Manufacturer

When it comes to purchasing automotive parts, choosing the right manufacturer is crucial for the quality and reliability of the parts you receive. With countless automotive part manufacturers to choose from, it’s important to consider the following factors before making a final decision:

1. Reputation – Look for a manufacturer with a good reputation in the industry. Consider reading reviews and checking out their track record in terms of quality and customer satisfaction.

2. Expertise – Check that the manufacturer has the necessary expertise to produce the parts you need. Look for a manufacturer that specializes in the specific type of part you require.

3. Quality Control – Ensure that the manufacturer has a stringent quality control process in place. This will guarantee that the parts produced are of high quality and meet industry standards.

4. Cost – Compare prices among different manufacturers to find a cost-effective option without compromising on quality.

5. Customer Service – A manufacturer with excellent customer service will provide prompt responses and be readily available to assist with any inquiries or issues.

6. Delivery Time – Check that the manufacturer can deliver the parts in a timely manner to avoid delays in the repair or maintenance of your vehicle.

7. Warranty – Find out if the manufacturer provides a warranty for their parts. This will provide peace of mind that any defects will be repaired or replaced.

By considering these factors when purchasing automotive parts, you can ensure that your vehicle is equipped with high-quality, reliable parts that will keep it running smoothly.

Properties of Automotive Part Manufacturer

Automotive part manufacturers can be described as companies that specialize in the production of automotive components, parts, and accessories. These manufacturers are tasked with the responsibility of producing various types of automotive parts, both large and small. The properties of a good automotive part manufacturer are critical in ensuring the quality of the parts produced.

One of the properties of a competent automotive part manufacturer is a robust and sophisticated manufacturing process. A high-quality manufacturing process ensures that the parts produced are of high quality and meet customer specifications. This includes the use of high-quality equipment, well-trained personnel, efficient production processes, and effective quality control mechanisms.

Additionally, a good automotive part manufacturer must possess strong research and development capabilities. The ability to innovate and develop new products is critical in an industry that is constantly evolving. A manufacturer that can provide cutting-edge solutions and adapt to emerging market needs will be able to stay ahead of the competition.

Another crucial property of a good automotive part manufacturer is the ability to provide excellent customer service. Manufacturers must be available to address any questions or concerns their customers may have. This includes a comprehensive warranty program, prompt delivery, and after-sales support.

Finally, a good automotive part manufacturer must have a strong commitment to sustainability. The production of automotive parts has significant impacts on the environment, and manufacturers must take steps to reduce their carbon footprint. This includes investing in eco-friendly production processes, using recycled materials, and reducing waste.

In conclusion, the properties of a good automotive part manufacturer are crucial in ensuring the quality of the parts produced. The ability to offer excellent customer service, strong research and development capabilities, a sustainable manufacturing process, and a commitment to quality and efficiency are critical in meeting the dynamic needs of the industry. With these properties, manufacturers can produce high-quality automotive parts that meet the needs of their customers and drive their success in the marketplace.

How to use Automotive Part Manufacturer

Using an automotive manufacturer for your parts can be an efficient and cost-effective way of ensuring that your vehicles or machinery are up to date with the latest technology and innovations that the market has to offer.

The first step in using an automotive part manufacturer is to identify the specific components that you require. There are a variety of manufacturers who specialize in different types of parts, so it is important to do your research and find the one that most closely fits your needs. Once you have identified the manufacturer, it is important to ensure that they have the capability to produce the components that you require, in the quantities that you need.

Another important consideration when using an automotive part manufacturer is the quality of their products. It is essential that the parts are manufactured to the highest standards and are of the correct specification. This not only ensures that your vehicles or machinery perform at their best, but also reduces the risk of costly breakdowns or accidents occurring.

When dealing with an automotive manufacturer, it is also important to establish a good working relationship. Building a strong partnership with your manufacturer can help to ensure that your products are delivered on time and to your specifications. It is important to communicate regularly with your manufacturer and provide them with any necessary feedback or updates on your requirements.

Finally, it is important to consider the cost of using an automotive part manufacturer. While there may be a larger initial investment in using a manufacturer, the long-term benefits of improved efficiency and reduced downtime can more than compensate for this cost. By working closely with your manufacturer and negotiating prices, you can ensure that you get the best possible deal on your components.

Overall, using an automotive part manufacturer can be an excellent way to ensure that your vehicles or machinery are fitted with the latest and most innovative components on the market. By following these simple steps, you can ensure that you get the best possible products and build a strong and successful partnership with your manufacturer.

Glossary Terminology Terms for Automotive Part Manufacturer

As an automotive part manufacturer, it’s essential to have a comprehensive understanding of the language and terminology used in the industry. Here are some glossary terms that every automotive part manufacturer should be familiar with:

1. CAD: Computer-Aided Design is a software tool used to design, simulate, and test automotive parts.

2. CAM: Computer-Aided Manufacturing is a software tool used to control and automate the manufacturing process.

3. CNC: Computer Numerical Control is a technology used in the manufacturing process to control the movement and operation of machines.

4. Injection Molding: This is a manufacturing process that involves injecting molten material into a mold to produce finished parts.

5. Die Casting: This is a manufacturing process that involves using a metal mold to produce finished parts.

6. Sheet Metal Fabrication: This is a manufacturing process that involves cutting, bending, and shaping metal sheets to produce finished parts.

7. Quality Control: This is the process of ensuring that finished parts meet the required specifications and standards.

8. Assembly: This is the process of joining different parts to form a finished product.

9. OEM: Original Equipment Manufacturer is a company that produces parts for other companies to use in their products.

10. Aftermarket: This is the market for parts and accessories that are sold after the vehicle has been manufactured.

Understanding these terminologies is critical in the automotive industry to ensure that the manufacturing process is efficient, and the finished products are of high quality. It also helps in ensuring that the language used in discussions is accurate and descriptive, and clear communication is maintained between different stakeholders.

Automotive Part Manufacturer Price

The price of automotive parts is an important consideration for every car buyer. This is because the price will affect the overall cost of owning a car, including the cost of maintenance and repair. The automotive part manufacturer price can vary depending on several factors, including the quality of materials used, the complexity of the manufacturing process, and the location of the manufacturing facility.

One of the main factors that impact automotive part manufacturer price is the quality of materials used in the manufacturing process. High-quality materials are more expensive, but they will result in parts that are more durable and reliable. Manufacturers who prioritize the use of high-quality materials will often charge higher prices for their products.

The complexity of the manufacturing process can also impact the cost of automotive parts. Parts that require a more complex manufacturing process will often require the use of more advanced machinery and technology, which can drive up the cost of production. This can be especially true for parts that are custom-designed for specific makes and models of cars.

Another factor that can impact the price of automotive parts is the location of the manufacturing facility. Manufacturers who operate in countries with lower labor costs and less strict environmental regulations can produce parts at a lower cost than those operating in countries with higher labor costs and stricter regulations. This can result in significant price differences for the same part produced by different manufacturers.

In conclusion, the price of automotive parts is influenced by several factors, including the quality of materials used, the complexity of the manufacturing process, and the location of the manufacturing facility. Car buyers should consider these factors when purchasing parts to ensure that they are getting the best value for their money. While price is an important consideration, it should not be the only factor when choosing a manufacturer. Quality, durability, and reliability should also be taken into account to ensure that the parts will provide safe and effective performance for years to come.