Knowledge about Bar Cutting Machine

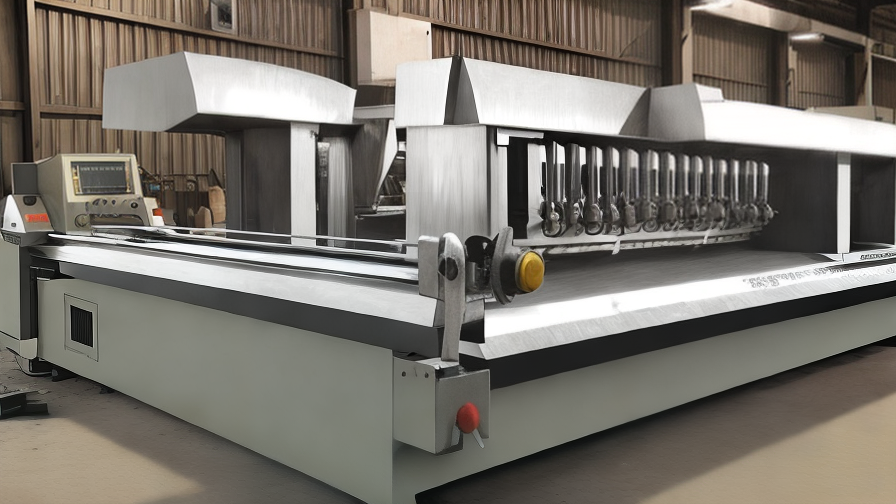

Bar cutting machine is an essential tool used in the construction industry for cutting steel bars into various sizes and lengths. This machine is popularly used for making reinforced concrete structures in various industries such as infrastructure, skyscrapers, bridges, dams, and more. In this article, we will discuss the significant knowledge about bar cutting machines.

Firstly, bar cutting machines come in two types: mechanical and hydraulic. The mechanical bar cutting machines work on a shearing principle, whereas hydraulic machines work on a hydraulic system. Hydraulic machines are more advanced and efficient as they require less human effort and can cut thicker bars.

Secondly, it is essential to determine the correct size of the bar that the machine can cut before purchasing. The bar cutting machines come in different sizes that have different capacities. It is crucial to select the bar cutting machine that can handle the bar size you require to use for construction.

Thirdly, the manufacturers of bar cutting machines provide manuals that explain the installation process, instructions for operation, and maintenance. It is crucial to follow the guidelines for optimal performance and prevent any operational errors that could lead to machine breakdown.

Fourthly, it is essential to ensure the safety of the operator and the surroundings while operating the machine. Before cutting the bars, the operator should wear protective gear such as gloves, goggles, and earplugs. The area around the machine should also be marked off as a no-entry zone to prevent accidents.

Lastly, maintenance is crucial to the longevity of the machine. Regular cleaning and lubrication of the machine can prevent damage and eliminate any risks of malfunctioning. If any parts require replacement, they should be done promptly.

In conclusion, bar cutting machine is an essential tool used in the construction industry. Knowledge of its workings, operations, and maintenance is essential for optimal performance, safety, and durability of the machine.

Various Types of Bar Cutting Machine

There are various types of bar cutting machines used in the construction industry. These machines are designed to cut bars of different diameters and lengths with precision and accuracy. Here we will discuss some of the most commonly found bar cutting machines in the market.

1. Manual Bar Cutting Machine: This type of machine is operated manually and is suitable for small construction projects. It is portable, easy to operate and inexpensive compared to other types of bar cutting machines.

2. Automatic Bar Cutting Machine: This machine is equipped with an automatic feeding system that can automatically feed the rods to the cutting blades. It can cut bars of different diameters with high precision and speed. It is suitable for medium to large-scale construction projects.

3. Hydraulic Bar Cutting Machine: This machine uses hydraulic pressure to cut bars of different diameters. It is fast, efficient and consumes less power. It is suitable for heavy-duty construction projects.

4. Pneumatic Bar Cutting Machine: This machine uses pneumatic pressure to cut bars of different diameters. It is fast, efficient and consumes less power than hydraulic machines. It is suitable for medium to heavy-duty construction projects.

5. Abrasive Bar Cutting Machine: This machine uses abrasive blades to cut bars of different diameters. It is fast and efficient and can cut through hard materials like steel and metal. It is suitable for heavy-duty industrial applications.

6. Portable Bar Cutting Machine: This type of machine is designed for on-site operations. It is lightweight, portable and can be easily moved from one place to another. It can cut bars of different diameters with high precision and speed.

In conclusion, bar cutting machines are essential tools for the construction industry. They come in various types and sizes, each designed for specific applications. Choosing the right type of machine depends on the project requirements and the materials to be cut.

FAQ sourcing Bar Cutting Machine manufacturer from China

Bar cutting machines play a crucial role in the construction industry. They are used to accurately cut bars of different sizes and shapes for various structures, including bridges, buildings, highways, and roads. With China being one of the leading manufacturers of bar cutting machines, it’s important to know how to source the right manufacturer for your needs. Here are some frequently asked questions (FAQs) regarding sourcing a bar cutting machine manufacturer from China with multiple answers:

Q: What are the factors to consider when sourcing a bar cutting machine manufacturer from China?

A: Some of the essential factors to consider include the manufacturer’s experience, reputation, quality of products, delivery time, pricing, and after-sales service.

Q: How do I verify the manufacturer’s quality of products?

A: You can ask for product samples or arrange for an on-site inspection of the manufacturer’s facility. You can also check for any certification or quality control processes that the manufacturer follows.

Q: What types of bar cutting machines are available from Chinese manufacturers?

A: Chinese manufacturers offer a wide range of bar cutting machines, including manual, semi-automatic, and fully automatic machines. The machines can cut bars of different sizes, shapes, and materials.

Q: How do Chinese manufacturers ensure timely delivery of products?

A: Most manufacturers have an efficient production and supply chain management system that helps them meet delivery deadlines. They also have a team dedicated to logistics and shipping to ensure smooth delivery.

Q: How do I communicate with the manufacturer effectively?

A: Most Chinese manufacturers have a team of English-speaking sales representatives to communicate with clients effectively. You can also use online communication tools like Skype, Zoom, or WeChat for video/audio calls and chat.

In conclusion, sourcing a bar cutting machine manufacturer from China requires careful consideration of several factors. By asking the right questions and doing thorough research, you can find a reliable and professional manufacturer to cater to your needs.

Applications of Bar Cutting Machine

A Bar Cutting Machine is a type of equipment that is widely used in the construction industry to cut steel bars of different sizes and shapes. This machine is used in various applications, including the construction of bridges, dams, buildings, and other infrastructure projects. Below are some of the applications of a Bar Cutting Machine.

Reinforcement Steel Cutting

The Bar Cutting Machine is primarily used to cut steel bars quickly, accurately and effortlessly. The machine is used to cut reinforcement steel of various sizes, including round bars, flat bars, and TMT bars. This helps in reducing the construction time, labour and cost.

Bridge Construction

Bar Cutting Machine is an essential tool in bridge construction, where large quantities of steel bars must be cut to specific length and sizes. The machine is ideal for cutting steel bars that are used in the construction of beams, columns, piles and other structural elements of the bridge.

Building Construction

Building construction is another application where Bar Cutting Machine is commonly used. This equipment helps in producing accurate cuts of steel bars which are used for the construction of walls, columns, and various other structural elements of the building.

Dam Construction

In dam construction, steel bars are used for reinforcing the concrete structure. Bar Cutting Machine is widely used in this application to cut steel bars of different sizes that are used in the foundation, walls, and other structural parts of the dam.

Conclusion

The Bar Cutting Machine is a critical equipment for the construction industry, and it helps in reducing both time and labour costs while also improving accuracy and efficiency. The above applications show that this machine is an essential tool in the construction of bridges, buildings, dams, and other infrastructure projects. Investing in a high-quality Bar Cutting Machine is, therefore, a prudent decision for contractors and construction companies to ensure that they meet their timelines and construction quality standards.

Manufactured Products made of Bar Cutting Machine

Bar cutting machines are essential tools for metal fabrication processes. They are widely used in manufacturing plants that require precision cutting of steel bars or any other forms of metal. These machines are designed to provide quick and accurate cutting of metals of different thicknesses and sizes, which makes them an ideal choice for construction and metalworking industries.

The products manufactured with the help of bar cutting machines are diverse and numerous. Some of the most common products made with these machines include reinforcing steel bars or rebar for use in construction sites, wire mesh used in the construction industry, and steel sections for use in various metalworking and industrial applications.

The reinforcing steel bars produced by bar cutting machines are essential building materials used in the construction of reinforced concrete structures such as bridges and buildings. These steel bars are known for their high tensile strength and are designed to provide structural support and improve the tensile strength of concrete.

Bar cutting machines are also used in the manufacturing of wire mesh products commonly used in the construction industry for various purposes such as reinforcing walls, providing security, and creating barriers. These wire meshes can be cut into different sizes and shapes to suit specific construction applications.

Furthermore, bar cutting machines are instrumental in the production of steel sections such as tube, pipe, and angle iron, which are widely used in metalworking and industrial applications. These products are used to construct basic structures, frames, machinery and as a supporting element in building structures like roofs.

Overall, bar cutting machines are essential tools for various metal fabrication processes. The products that are produced with these machines have significant importance in the construction and industrial sector. With the use of these machines, manufacturers can achieve high precision cuts, reducing scrap and material waste. This makes the manufacturing process more efficient and cost-effective.

The Evolution history of Bar Cutting Machine

Bar Cutting Machines have come a long way since its inception in the 1960s. Initially, Bar Cutting Machines were basic mechanical machines that used hydraulic power to cut bars. The machines’ cutting capacity was low, and the cutting time was long, making it difficult to keep up with the site’s dynamic pace. These bar-cutting machines were not very efficient and were largely obsolete.

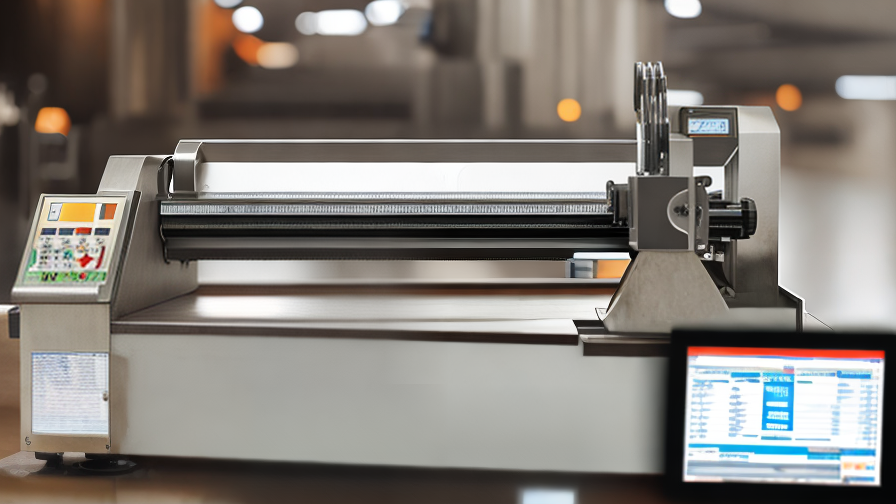

The bar cutting machine’s evolution gained momentum in the 1980s when Bar Bender and Cutter manufacturers began using electrical motors to power cutters. This implementation made the machines faster and more efficient, cutting down on project timelines significantly. In the 2000s, manufacturers started using CNC (computer numerical control) technology to operate Bar Cutting Machines. This innovation transformed Bar Cutting Machines into a more precise and accurate tool, minimizing wastage and increasing project quality.

Today, Bar Cutting Machines are equipped with several features like automatic lubrication, blade quality sensors, and touchscreen displays. These features make the machines more convenient and user-friendly, allowing even unskilled employees to operate them effectively.

The latest evolution of Bar Cutting Machines is the move to adopt hybrid technology, combining electrical motors with hydraulic power. The hybrid machines are faster, more powerful, and produce less noise, making them ideal for use in noise-sensitive sites.

In conclusion, the Evolution history of Bar Cutting Machines is a testament to human innovation and technology’s possibilities. From basic hydraulic-powered machines to the current hybrid technology, the Bar Cutting Machine’s transformation has been remarkable, making it a tool of choice for construction professionals worldwide.

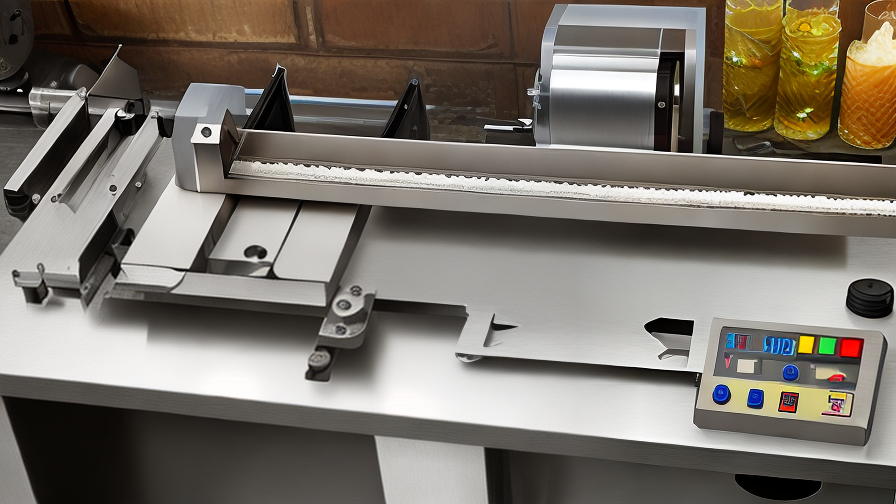

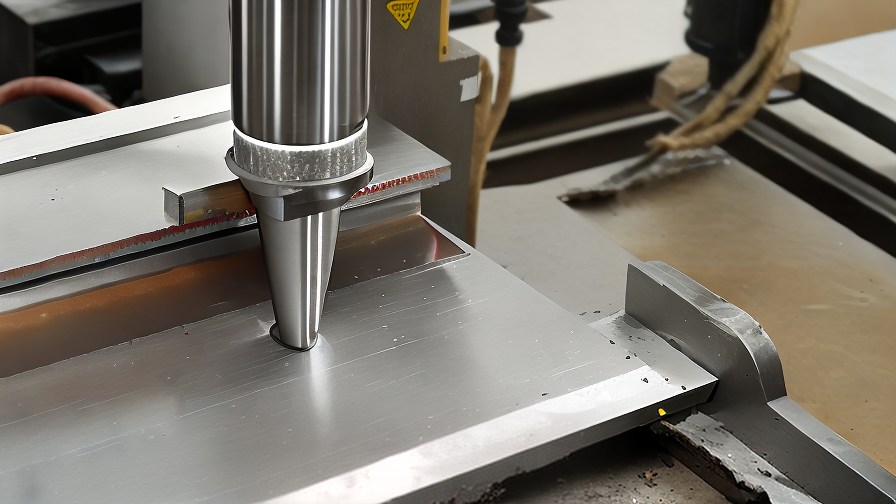

The Process of Bar Cutting Machine

Bar cutting machine is widely used in the construction industry to cut steel bars of different sizes and lengths efficiently. The process of bar cutting machine involves several steps that ensure precise and accurate cuts are made every time.

The first step in the process is to select the correct blade for cutting the steel bars. The blade material and thickness depend on the type of steel and the desired cutting speed. Once the blade is selected, it is installed onto the bar cutting machine.

The second step is to set the length of the bar to be cut. This can be done manually or by using a digital display. The bar is then placed onto the machine’s cutting bed, with the end that needs to be cut in the appropriate position.

The third step is to activate the machine’s cutting mechanism. This is done by pressing a button or foot pedal. The blade moves across the bar, cutting it cleanly and precisely. After the cut is made, the machine’s hold-down mechanism releases the newly cut bar from the cutting bed.

The fourth step is to inspect the cut bar for any deformities or imperfections. This is important to ensure that the bar will be safe to use in construction applications.

Finally, the cut bars are stacked and moved to the next stage of the construction process. The entire process of bar cutting machine is fast, efficient and precise, making it an essential tool for construction projects of any size.

In conclusion, bar cutting machine is a crucial tool that plays a significant role in the construction industry. By following the steps mentioned above, the machine can be operated safely and effectively, resulting in clean, precise and accurate cuts every time.

Benefits Advantages of Utilizing Bar Cutting Machine

A bar cutting machine is an essential tool used in construction and metalworking industries for cutting steel bars with accuracy and precision. It has several benefits and advantages, which include:

1. Saves Time and Money: One of the significant benefits of utilizing a bar cutting machine is that it saves time and money. Manual cutting of steel bars is a tedious and time-consuming process that requires a significant amount of effort. A bar cutting machine, on the other hand, can cut multiple bars in a matter of minutes, thereby saving time and reducing labor costs.

2. High Precision: Accuracy and precision are essential factors in the construction and metalworking industries. With a bar cutting machine, you can achieve the desired length and shape of the steel bars accurately and precisely. This eliminates the need for additional work to correct errors and ensures that the bars fit perfectly in the project.

3. Improved Efficiency: Bar cutting machines can handle a large volume of work, making them highly efficient. They can cut different sizes and shapes of steel bars easily and quickly, which increases productivity and allows workers to focus on other critical aspects of the project.

4. Enhanced Safety: Manual cutting of steel bars poses a risk of injury to workers due to the use of sharp tools and the physical effort required. A bar cutting machine eliminates this risk by providing a safe cutting process that operates automatically with minimal human intervention.

5. Versatility: Bar cutting machines are versatile tools that can cut different types of steel bars. They can handle different shapes, sizes, and thicknesses of steel bars, making them suitable for use in various construction and metalworking projects.

In summary, bar cutting machines are innovative tools that offer several benefits and advantages to the construction and metalworking industries. They save time and money, provide accurate and precise cuts, enhance safety, improve efficiency, and are versatile. Therefore, utilizing a bar cutting machine is a worthwhile investment for any construction or metalworking project.

Disadvantages Bar Cutting Machine

Bar cutting machines are used extensively in the construction and steel industries to cut long steel bars accurately and efficiently. These machines are popular due to their speed, precision, and ease of use. However, like any other machine, bar cutting machines also come with disadvantages that can have significant implications on work quality, workers’ safety, and overall efficiency.

The first disadvantage of bar cutting machines is their high initial investment cost. These machines can be expensive to purchase and maintain, especially for small businesses that may not have the funds to invest in them. This high cost is a barrier to entry for new companies looking to adopt the technology, and it may force them to stick to manual methods, which may not be as efficient.

The second disadvantage is the risk of injury posed to workers when operating the machine. Bar cutting machines use sharp blades that can cause severe injuries if not handled correctly. Workers who are not adequately trained on how to use the machine or who do not follow safety procedures are at high risk of getting injured on the job site.

The third disadvantage of the bar cutting machine is its high maintenance cost. These machines require regular maintenance to function correctly, and the cost can be high if not properly managed. The maintenance costs can add up over time, making the machine uneconomical to run.

Another disadvantage is the limited versatility of the machine. Bar cutting machines can only cut straight bars, and cannot handle complex shapes or curved cuts. This limitation means that companies need to invest in other machines to handle these specialized tasks, leading to additional costs and space requirements.

In conclusion, bar cutting machines are a valuable asset to the construction and steel industries. However, they come with several disadvantages that companies should consider before investing in them. These disadvantages include high initial investment costs, worker safety risks, high maintenance costs, and limited versatility. Despite these drawbacks, bar cutting machines remain an essential tool for companies looking to improve the efficiency and reliability of their operations.

Selecting the Ideal Manufacturer Bar Cutting Machine

Selecting the Ideal Manufacturer Bar Cutting Machine

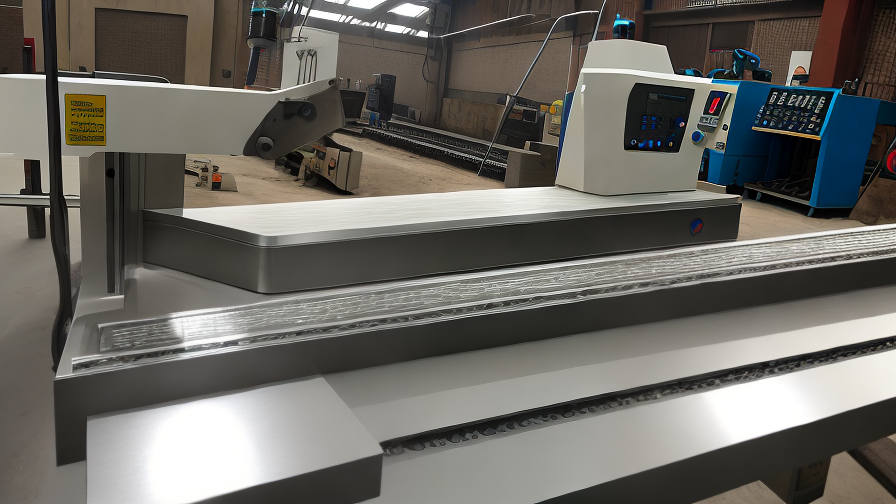

Bar cutting machines are tools used for cutting steel bars into different lengths and sizes for construction projects. With the demand for construction projects on the rise, it is essential to have a reliable bar cutting machine that can handle the workload efficiently. When selecting an ideal manufacturer bar cutting machine, there are a few key factors to keep in mind.

First, it is important to consider the cutting capacity of the machine. The cutting capacity will determine the maximum size of the steel bars that can be cut using the machine. You should choose a machine that has a cutting capacity that aligns with the size of the steel bars you frequently work with.

Secondly, the level of automation is crucial. Manual bar cutting machines require the operator to physically cut the steel bars, while automated machines have motorized features that make the cutting process more efficient. It is important to consider the workload of your project and your budget when selecting the level of automation you require.

Thirdly, the durability and reliability of the machine should be evaluated. A machine made of high-quality materials will last longer and require fewer repairs. Ensure that the machine’s warranty policy also covers any issues that may arise over time.

Fourthly, it is important to consider the safety features of the machine. Bar cutting machines can be dangerous when not handled properly. A machine with safety features such as emergency stop buttons and protective shields will ensure that the operator and other workers around the machine remain safe.

Finally, the after-sales support of the manufacturer should not be overlooked. It is important to ensure that the manufacturer offers technical support, spare parts, and customer service to ensure that the machine is kept in good condition and lasts longer.

In conclusion, selecting the ideal manufacturer bar cutting machine requires consideration of factors such as the cutting capacity, level of automation, durability, reliability, safety features, and after-sales support. By taking these critical factors into account, you can select a bar cutting machine that will meet your needs and enable you to

Things to Consider When Purchasing Bar Cutting Machine

When it comes to investing in a bar cutting machine, there are a few factors to consider so that you can make the best decision and meet your needs. In this article, we will discuss some of the main things to consider when purchasing a bar cutting machine.

1. Type of Cutting Machine: The type of cutting machine depends on the material you are planning to cut. You should determine the size, shape and type of material to ensure that the machine you go for caters to your needs.

2. Quality and Durability: Make sure you invest in a machine that offers a long lifespan and efficiency. This is to ensure you get your money’s worth, as you do not want to keep replacing the machine every time.

3. Ease of Use: Look for a machine that is user-friendly and easy to handle. It is always better to choose a machine with simple controls and comprehensive user manuals for easier operation.

4. Cost: Ensure the machine is within your budget. It is always advised to choose a machine with a price range that caters to your needs and offers quality services.

5. Maintenance: Look for a machine that has spare parts readily available in the market in case the machine requires a repair. Always enquire if the manufacturer of the machine offers maintenance services or if they can assist in sourcing spare parts.

6. Safety Features: It is essential to choose a machine with safety features such as safety cut-off switches, safety guards, and emergency stop buttons for prevention of accidents.

Ultimately, it is important to choose a bar cutting machine that meets your requirements, considering the type of materials you need to cut, quality, durability, ease of use, cost, maintenance, and safety features. By keeping these things in mind, you can choose the best bar cutting machine for your needs.

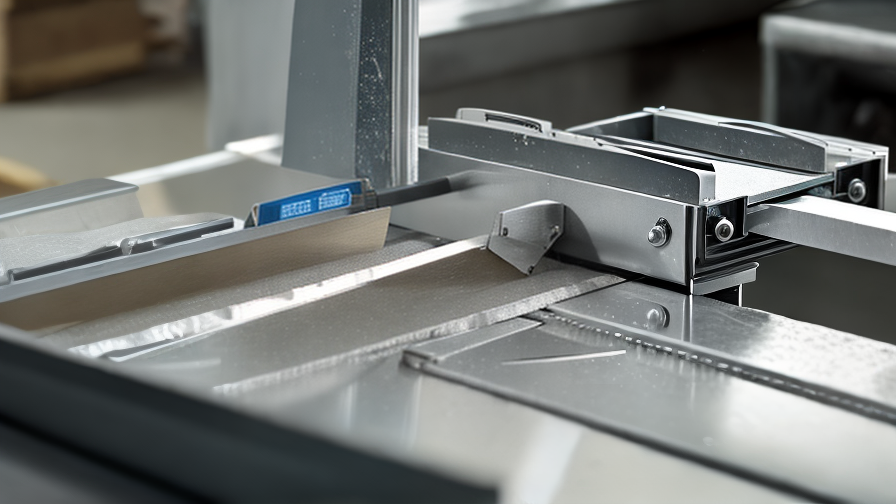

Properties of Bar Cutting Machine

Bar cutting machines are used in construction industries to cut the bars of steel and other metals. These machines are different from other cutting machines, as they are designed to cut heavy-duty bars used in construction. They have a specific set of properties that make them unique and efficient in their functions.

One of the essential properties of a bar cutting machine is its cutting capacity. To cut heavy bars, the machine should have a good cutting capacity. This means that the machine must be capable of cutting bars of different diameters and lengths. A high-quality bar cutting machine should be able to cut bars of up to 40mm diameter or more with ease.

The accuracy of the cut is another important property of the bar cutting machine. In construction, accuracy is essential as the bars need to be cut to precise measurements. A good bar cutting machine should be able to cut the bars accurately, which means the cuts should be straight and without deformities.

The safety of the machine is also an important property that cannot be ignored. Bar cutting machines are powerful machines and can cause harm if not used carefully. A good bar cutting machine should have safety features that help to prevent accidents, such as automatic shut-off and emergency stop buttons.

The speed is another property that is significant in a bar cutting machine. In construction, time is money, and the efficiency of the machine depends on its cutting speed. A high-quality bar cutting machine should be able to cut the bars quickly and smoothly, saving time and improving productivity.

The durability of the machine is also essential. A bar cutting machine is an investment, and a durable machine will last longer, provide better value for money, and require less maintenance.

In conclusion, the properties of a bar cutting machine are essential to ensure its effectiveness and efficiency. The cutting capacity, accuracy, safety, speed, and durability are essential traits that should be considered when purchasing a bar cutting machine. A high-quality and efficient bar cutting machine will improve the productivity and profitability of any construction project.

How to use Bar Cutting Machine

Bar cutting machines are used in the construction industry to cut rebar or steel bars. These machines are an essential tool for contractors and builders who need to cut these bars to specific sizes for their projects. This article will discuss the steps on how to use a bar cutting machine.

Step 1: Preparation

The first step is to prepare the area where you will use the machine. Make sure that the work area is clean and free from any obstacles that may interfere with the operation of the machine.

Step 2: Choose the right blade

Choose the right blade for the job. The blade should be sharp enough to cut through the steel bars easily.

Step 3: Set the machine

Set up the bar cutting machine according to the manufacturer’s instructions. Most machines are easy to set up, and the process usually involves locking the rebar or steel bars in the machine’s jaws.

Step 4: Cut the bar

Once you have properly set up the machine, you can start cutting the bar. Turn on the machine, and slowly lower the blade onto the bar. Make sure that the blade is perpendicular to the bar, and cut through the bar slowly and steadily.

Step 5: Clean up

After cutting the bar, turn off the machine and clean up the area. Remove the cut pieces of the bar and dispose of them properly.

Conclusion

Bar cutting machines are an important tool for contractors and builders who need to cut steel bars or rebar to specific sizes. By following these simple steps, you can safely and efficiently operate a bar cutting machine. Remember to always wear protective gear, such as gloves and eye protection, when using this machine.

Glossary Terminology Terms for Bar Cutting Machine

Glossary Terminology Terms for Bar Cutting Machine

Bar cutting machines are widely used in the construction industry for cutting metal bars to the required length and size. These machines come with different types of blades and tools that can perform various types of cutting operations. Here are some glossary terminology terms related to bar cutting machines that you should know:

1. Cutting Capacity: The maximum thickness and diameter of the metal bar that a bar cutting machine can cut.

2. Blade Speed: The speed at which the blades of the machine rotate while cutting the metal bar.

3. Cutting Speed: The speed at which the bar cutting machine can cut the metal bar.

4. Cutting Angle: The angle at which the blade cuts the metal bar.

5. Cutting Length: The length of the metal bar that can be cut by the machine in one operation.

6. Blade Material: The material used to make the blades of the machine.

7. Blade Type: The type of blade used for cutting the metal bar, such as circular blade, guillotine blade, or shear blade.

8. Blade Life: The lifespan of the blade before it needs to be replaced or sharpened.

9. Control Panel: The panel on the machine that allows the operator to control the cutting process, such as adjusting the blade speed, cutting angle, and cutting length.

10. Safety Features: The features of the machine designed to ensure safe operation, such as emergency stop button, blade guard, and overload protection.

Understanding the glossary terminology terms for bar cutting machines is crucial for operators to operate and maintain the machine properly. By knowing the terminology, operators can communicate effectively with technicians and understand the manual instructions better. Additionally, when buying or renting a bar cutting machine, it is essential to ask for detailed information about the machine’s specifications and features to ensure that it meets the requirements for the job at hand.

Bar Cutting Machine Price

If you are involved in the construction industry or any related field, you must know about bar cutting machines. They are essential equipment for cutting steel bars, which are commonly used in construction sites for various purposes like reinforced concrete structures, columns, beams, etc. During the manufacturing process, the steel bar is created in large sizes that need to be cut into smaller sizes per the requirement. Bar cutting machines are used for this purpose.

The price of a bar cutting machine is influenced by factors like the brand, model, capacity, and features of the machine. Here are some factors that affect the bar cutting machine price:

1. Machine capacity – The machine’s capacity primarily determines the machine’s price. If you require a high-capacity machine, you will need to pay more than what you would have to pay for a low-capacity bar cutting machine.

2. Cutting speed – The speed of the cutting machine depends on the motor used in the machine. The faster the cutting speed, the more advanced the motor, and the higher the machine’s price.

3. Durability – When it comes to bar cutting machines, it is essential to invest in durable machines to ensure optimum performance and minimal maintenance costs.

4. Brand and model – The brand and model of a bar cutting machine can influence its price. More reputed brands tend to price their machines higher for quality assurance.

The cost of a bar cutting machine ranges from $500 to $5000, depending on the type of machine and its features. Portable bar cutting machines are the most affordable, ranging between $500 to $1000. Whereas, large-sized machines can cost up to $5000. These machines have high accuracy and precise cutting that can cut larger steel bars with ease.

In conclusion, the price of a bar cutting machine is determined by various factors. However, it is essential to invest in a high-quality machine, regardless of the price, to ensure optimum efficiency, safety, and minimal maintenance costs.