Benefits of Bottle Shrink Wrap Machine

Bottle shrink wrap machines are essential equipment for businesses that package bottled products such as beverages, cleaning agents, and other liquids. These machines provide numerous benefits that help businesses improve their operations. Here, we outline some of the advantages of using a bottle shrink wrap machine.

1. Improved Product Protection

Bottle shrink wrap machines have the ability to protect products from contamination, damage, and tampering. The wrap tightly encases the bottle, providing a barrier against dust, moisture, and other contaminants that can affect the quality of the product. It also protects the bottle from breakage and ensures it arrives safely to its destination.

2. Enhanced Visibility of Products

Wrapping bottles in shrinkable film enhances the visibility of the product, thereby improving its appeal to customers. As the film brings out the color and texture of the product, it can entice potential customers to make a purchase.

3. Cost-Effective Packaging

By using a bottle shrink wrap machine, businesses can save money on packaging materials. Shrink wrap is an affordable alternative to traditional packaging materials, such as cardboard boxes and paper sleeves. Additionally, shrink wrap takes up less space, which is important for businesses looking to optimize their storage space.

4. Increased Efficiency

Bottle shrink wrap machines automate the packaging process, increasing the efficiency of the production line. This means businesses can package more products in a shorter amount of time, allowing them to meet customer demands efficiently. The machines also provide consistent wrapping quality, ensuring that products are presented in a consistent and professional manner.

5. Versatile Wrapping Options

A bottle shrink wrap machine can wrap bottles of different sizes, shapes, and materials. This flexibility enables businesses to use the machine for various products, reducing the need for multiple packaging machines.

In conclusion, a bottle shrink wrap machine provides ample benefits for businesses. From improved product protection to cost-effective packaging and increased efficiency, it is an essential tool for businesses looking to streamline their packaging operations.

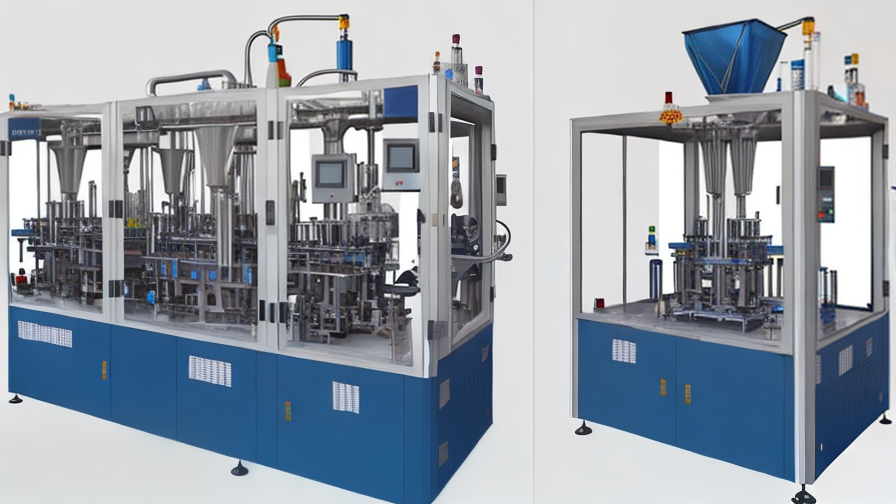

Features of Bottle Shrink Wrap Machine

A bottle shrink wrap machine is a device used in the packaging industry to wrap and seal bottles with a plastic film known as a shrink wrap. This machine is ideal for industries that manufacture and sell bottled products such as beverages, cosmetics, and medicines.

One of the key features of the machine is the automatic control system. The machine is fully automated, which makes it easy to use and operate. With this feature, it reduces the possibility of human error while ensuring efficient production.

The machine also has a high-speed wrapping system. It can wrap up to 100 bottles in a minute, which makes it ideal for high-capacity production. The speed of the machine can be adjusted to match the production requirements of each manufacturer.

Another feature is the precision shrink wrapping system. The machine uses precise heat control to ensure that the shrink wrap perfectly conforms to the shape of the bottle. This feature ensures that the products are well presented, thus increasing the appeal to potential customers.

The machine is also versatile in operation. It can be used to wrap bottles of various shapes and sizes. This feature makes the machine suitable for multiple industries such as bottled water, soft drinks, and medicines, among others.

The bottle shrink wrap machine also has a compact design, making it space-efficient and easy to install. It does not require a lot of floor space and can be easily transported from one location to another.

In conclusion, the bottle shrink wrap machine is a valuable tool in the packaging industry. Its many features make it efficient, reliable, and versatile in operation. This machine ensures that products are well-presented to clients, and therefore it is an excellent tool for enhancing the market appeal of bottled products.

Various Types of Bottle Shrink Wrap Machine

A bottle shrink wrap machine is an essential part of the packaging process. Shrink wrapping is a popular method of packaging that involves sealing and heating plastic film around a product, providing a tight and secure seal. There are different types of bottle shrink wrap machines in the market, and each one is designed to serve a particular purpose. In this article, we’ll discuss the various types of bottle shrink wrap machines.

Semi-automatic shrink wrap machines are the most common type in the market. As the name suggests, these machines require human input to operate. Once the bottle is placed in the film, the operator activates the sealing and shrinking process. Semi-automatic machines come in different sizes and have different levels of automation.

Fully automatic shrink wrap machines are designed to streamline the packaging process. These machines are suitable for high volume production and don’t require human input. Once the bottle is placed in the machine, the machine seals and shrinks the film automatically.

L-Bar shrink wrap machines are designed for products of different shapes and sizes. These machines use an L-Shaped sealing bar that can accommodate bottles, boxes, and other products that require shrink wrapping.

Shrink tunnels are specialized machines used for high volume production of shrink-wrapped products. These machines are designed to work with fully automatic systems and can shrink wrap up to 2000 bottles per hour.

In conclusion, when choosing a bottle shrink wrap machine, it is essential to consider your production needs. Whether you need a semi-automatic or fully automatic machine, it’s important to make sure that the machine you choose fits your production requirements. Therefore, understanding the various types of bottle shrink wrap machines and choosing the right one for your business can save time, money, and effort in the long run.

Applications of Bottle Shrink Wrap Machine

Bottle shrink wrap machines are useful for products that need flexible, durable and protective packaging. From beverage bottles to pharmaceutical products, this technology has found its place in various industries in recent years.

The main application of this machinery is to encase a product in a clear film and shrink-wrap it tightly using heat. This process provides a tamper-evident seal that protects the product from dust, moisture, and damage during shipping.

One of the most significant benefits of the bottle shrink wrap machine is its ability to reduce material waste. The tight fit ensures that minimal materials are needed during the packaging process. This is especially crucial for companies that are looking to reduce their carbon footprint.

Another advantage of using shrink wrap technology is its flexibility and versatility. This machine can be adjusted to fit different bottle sizes and shapes. This allows manufacturers to use a single machine for multiple products, saving them time and money.

The bottle shrink wrap machine is used in the food and beverage industry to safely pack products such as water bottles, soda cans, and energy drinks. The tight seal provided by the shrink wrap protects the products from contamination and extends their shelf life.

In the pharmaceutical industry, shrink wrap technology is used to package medicines and medical devices. The tight seal ensures that these products are protected from environmental factors that could compromise their efficacy.

Shrink wrap machines are also used in the cosmetic industry to package various products, including shampoos, conditioners, and lotions. The clear film allows customers to see the product inside, making it more appealing and attractive.

In conclusion, the bottle shrink wrap machine has several applications across various industries. This technology is environmentally friendly, versatile and efficient. It provides an opportunity for manufacturers to protect their products during shipping and enhance their visibility to customers.

The Process of Bottle Shrink Wrap Machine

Bottle shrink wrap machines have become increasingly popular in packaging industries. They are a great investment as they automate the packaging process and increase production rates. The process of bottle shrink wrap machines involves several steps as follows:

Step 1: Load Bottles

The first step is to load bottles onto the machine. The bottles are loaded onto a conveyor belt which feeds them into the shrink wrap machine.

Step 2: Shrink Wrap Film

The second step involves the shrink wrap film. The film is unwound from a roll of plastic and passed through a heating system. The heating system warms the film, making it more malleable and ready for wrapping.

Step 3: Wrap Bottles

With the film warmed up, the machine wraps the bottles individually. Once wrapped, the edges of the film are sealed using a heating element. This sealing helps keep the film in place, creating a secure and professional-looking packaging.

Step 4: Shrink

With the bottles wrapped and sealed, the machine then shrinks the film around the bottles. The heating system used in step two is again utilized at this stage to ensure the film shrinks tightly around the bottle, creating a tight and secure seal.

Step 5: Cooling

Once the bottles have been shrunk, they are passed through a cooling station. The cooling process helps to solidify and set the film, making it retain its shape and form on the bottle.

Step 6: Unload Bottles

The final step involves unloading the bottles. Once the bottles have passed through the cooling station, they exit the machine ready for labeling, shipping, and storing.

In conclusion, the process of bottle shrink wrap machine is a simple but highly automated process that increases production rates and improves packaging quality. The use of bottle shrink wrap machines has become an essential investment for packaging industries looking to optimize packaging processes and stay ahead of the competition.

How to use Bottle Shrink Wrap Machine

Bottle shrink wrap machines are an efficient way to package and protect your bottles. They work by using heat to shrink a plastic film around a bottle, conforming to its shape and keeping it secure. Here’s how to use a bottle shrink wrap machine:

1. Prepare the machine: Make sure the shrink wrap machine is plugged in and the heat shrink bar is in the correct position for the product you are packaging. Adjust the machine to fit the size of your bottle.

2. Place the bottle in the center of the plastic film: Adjust the film rollers so the plastic film is centered over the bottle. Make sure there is enough film to cover the entire bottle.

3. Secure the bottle: Use a heat gun to shrink the film around the top and bottom of the bottle. This will help to secure the bottle in place.

4. Activate the shrink wrap machine: When you’re ready to begin, press the button to start the machine. The machine will use heat and pressure to shrink the plastic film around the bottle.

5. Remove the bottle: Once the shrinking process is complete, remove the bottle from the machine. The plastic film will now be tightly wrapped around the bottle, ensuring its safety during transport.

In conclusion, using a bottle shrink wrap machine is a simple process that can save you time and money while ensuring the safety of your products. By following these five steps, you can easily and efficiently package your bottles with ease.

Selecting the Ideal Manufacturer Bottle Shrink Wrap Machine

When it comes to selecting the ideal manufacturer bottle shrink wrap machine, there are several factors that must be taken into consideration. These machines are an essential part of the bottle packaging process, and they can be used for different types of bottles such as plastic, glass, metal, and even industrial drums.

Firstly, the capacity of the machine is a significant factor in selecting an ideal manufacturer bottle shrink wrap machine. Depending on the size of your production line, you will need to select a machine that can handle the production volume of your business.

Secondly, the type of bottle being packaged should also be considered. Different shrink wrap machines are designed for different types of bottles, so it is important to choose a machine that is compatible with the specific bottles that you intend to package.

In addition, the features and capabilities of the machine are also important. Modern shrink wrap machines come with various additional features that make the packaging process more efficient and effective. These features include automatic cut-off systems, adjustable temperature controls, and more.

The reputation of the manufacturer also matters when deciding on the ideal manufacturer shrink wrap machine. You want to work with a manufacturer with a good reputation for producing high-quality machines that have been tested and proven to be reliable.

Finally, the costs involved in purchasing and maintaining the machine should also be taken into consideration. The cost of the machine should be justifiable based on the production volume of your business, and the maintenance requirements of the machine should also be reasonable.

In conclusion, selecting the ideal manufacturer bottle shrink wrap machine requires careful consideration of several factors such as machine capacity, type of bottle, features and capabilities, reputation of the manufacturer, and costs involved. By taking these factors into account, you can be sure to select the best machine for your business.

list FAQ with answer about Bottle Shrink Wrap Machine

A Bottle Shrink Wrap Machine is a piece of packaging equipment designed to wrap containers with a shrinkable plastic film. This type of packaging is commonly used to protect products from damage, enhance the product’s visual appeal, and ensure product safety during shipping and storage.

In this article, we will answer some frequently asked questions about Bottle Shrink Wrap Machines.

Q: What types of machines are available?

A: There are several types of Bottle Shrink Wrap Machines on the market, including manual, semi-automatic, and fully automatic machines. The machines can handle various bottle sizes and shapes, including round, square, and rectangular containers.

Q: What film materials are used?

A: The most commonly used shrink films for Bottle Shrink Wrap Machines are polyolefin and PVC. They are both cost-effective and provide strong seals.

Q: What are the benefits of using a Bottle Shrink Wrap Machine?

A: Bottle Shrink Wrap Machines offer numerous benefits, including increased product protection and shelf life, reduced product contamination, enhanced visual appeal, and improved product branding.

Q: What factors should I consider when purchasing a Bottle Shrink Wrap Machine?

A: When purchasing a Bottle Shrink Wrap Machine, you should consider factors such as the desired film material, rate of production, product size and shape, and overall equipment investment.

Q: How do I properly maintain my Bottle Shrink Wrap Machine?

A: Proper maintenance is crucial to ensuring the longevity and performance of a Bottle Shrink Wrap Machine. Routine maintenance should include cleaning the machine after each use, frequent inspections of the equipment, and replacing worn components as needed.

In conclusion, Bottle Shrink Wrap Machines are an essential piece of packaging equipment used to shrink wrap containers for increased product protection, shelf life, and visual appeal. Understanding the available types of machines, film materials, and maintenance requirements will help increase the effectiveness and longevity of the equipment.

Things to Consider When Purchasing Bottle Shrink Wrap Machine

A bottle shrink wrap machine is an indispensable piece of equipment for businesses that require large-scale packaging of bottled products. These machines come in different sizes and types, each designed to cater to specific needs. When purchasing a bottle shrink wrap machine, it is essential to consider several factors to ensure you make an informed choice.

Firstly, you need to consider the size and shape of your products. A bottle shrink wrap machine should fit your product size and shape to ensure optimal performance. It is essential to choose a machine with adjustable settings to accommodate varying bottle sizes.

Secondly, you need to consider the production output of the machine. Different machines have varying production capabilities per hour. Choose a machine that can keep up with your production needs. It is advisable to go for a high-speed machine if you need to package a large number of bottles per hour.

Thirdly, consider the type of shrink wrap material you need. The material you choose depends on the type of product you are packaging. Some machines are designed to handle different shrink films, while others only work with specific types of shrink wrap.

Fourthly, consider the durability of the machine. Choose a machine made from high-quality materials to ensure longevity. A durable machine can withstand the harsh environmental conditions in a manufacturing environment.

Lastly, consider the cost of the machine. The price of the machine should match its performance capabilities. Do not skimp on quality when purchasing a bottle shrink wrap machine.

In conclusion, purchasing a bottle shrink wrap machine is a significant investment for any business. Thoroughly considering the aforementioned factors before making a purchase can help you make an informed decision. Choose a machine that can efficiently package your products, withstand the harsh manufacturing environment, and provide value for your money.

Properties of Bottle Shrink Wrap Machine

A bottle shrink wrap machine is a device commonly used for wrapping bottles with shrink films. They come in a variety of designs, sizes, and specifications, and they all possess different properties that make them unique.

One of the essential properties of a bottle shrink wrap machine is its speed. A good machine should be able to wrap several bottles efficiently within minutes. This feature is important to companies that require massive production of finished goods. It helps to save time and increase productivity.

Another critical property of a bottle shrink wrap machine is its durability. A high-quality machine should be made from sturdy materials to withstand the rigors of daily use. This will help to guarantee longevity and reduce downtime.

The machine should also be versatile. It should be able to handle different types and sizes of bottles. This feature is crucial for companies that produce a wide range of products. It enables them to switch quickly from one product to another, thus enhancing efficiency.

Another important property is its ease of use. A good bottle shrink wrap machine should be user-friendly. It should have clear instructions on how to operate and maintain the device. This helps to avoid technical complications that can lead to downtime or wastage of film.

The ability to conserve energy is also essential. A machine that consumes less power will help to reduce running costs and promote environmental conservation.

Lastly, a machine that is easy to maintain and service is vital. It should have readily available spare parts and easy to access components for easy repair and replacement.

In conclusion, when selecting a bottle shrink wrap machine, it is important to consider the above properties to ensure cost-effectiveness and efficiency.

Technical Parameters Terms for Bottle Shrink Wrap Machine

When it comes to the world of packaging, bottle shrink wrap machines are an essential tool for businesses to streamline their operations and increase efficiency. However, to understand these machines fully, it is important to understand the technical parameters terms associated with them.

The first technical parameter is the Power Supply Voltage. The machine needs electricity to function, and every machine requires a different power supply voltage; therefore, it is important to ensure that the power supply voltage matches the machine’s requirements before purchasing it.

The second parameter is the Production Capacity. This refers to the number of bottles a machine can pack in a given time frame. It is essential to match the machine’s production capacity with the production needs of the business.

The third technical parameter is the Width of the Sealing Blade. This refers to the size of the sealing blade used by the machine to seal the wrapped bottles. The width of the sealing blade is crucial as it determines the width of the bottles that can be wrapped.

The fourth parameter is the Tunnel Size. This refers to the size of the tunnel used by the machine to shrink the plastic wrap. It is crucial to match the bottle size to the tunnel for an effective shrink wrap.

The fifth parameter is the Conveyor Speed. This refers to the speed at which the conveyors move and transport the bottles to the tunnel. It is important to match the conveyor speed with the machine’s production capacity to ensure efficiency.

Lastly, the Coefficient of Friction is also an important technical parameter. This refers to the force required to move the bottles over the conveyor. It is essential to ensure that the coefficient of friction matches the machine’s specifications to prevent damage to the bottles.

In conclusion, understanding the technical parameters associated with bottle shrink wrap machines is essential when it comes to purchasing and operating these machines effectively. Matching the machine’s technical parameters to the business’s production needs will ensure a proper production process.

Bottle Shrink Wrap Machine Price

Bottle shrink wrap machine is a vital tool for businesses that deal with bottling products. It is used to shrink and seal the plastic films on bottles, making them more durable and visually appealing. The prices of these machines vary depending on several factors.

One of the primary factors that affect the price of a bottle shrink wrap machine is the type of machine. There are manual, semi-automatic, and fully automatic machines. The manual machines are the most affordable and generally cost between $300 to $1000. Semi-automatic bottle shrink wrap machines cost between $1500 to $5000, while fully automatic machines cost between $7000 and $30000.

The size of the machine also affects its price. Machines designed for smaller bottles are typically cheaper than those that handle larger bottles. The number of bottles that a machine can process per hour is also a determining factor in its price. Machines that can handle a higher volume of bottles per hour are typically more expensive.

The materials used to make the machine also determine its price. Machines made of high-quality materials such as stainless steel and aluminum tend to be more expensive than those made of other materials.

Other factors that affect the price of a bottle shrink wrap machine include its brand, the country of manufacture, and the seller. High-end brands tend to have a higher price tag compared to less popular brands. Machines made in countries such as the USA, Germany, and Italy are generally more expensive than those made in China or India. The seller also affects the price of the machine, with some sellers offering discounts or financing options to buyers.

In conclusion, the price of a bottle shrink wrap machine varies depending on several factors, including type, size, materials used, brand, country of manufacture, and seller. It is essential to consider these factors when shopping for a machine to ensure that you get a quality machine that meets your needs.