Benefits of Bowling Ball Drill Press

Bowling is a fun and challenging game that requires precision and accuracy. However, achieving these qualities can be difficult if you are not equipped with the right tools. One essential tool that every bowler should have is a bowling ball drill press. This machine not only creates custom finger holes that fit your hand perfectly but also provides various benefits that make it a valuable investment for any bowler.

One of the significant advantages of owning a bowling ball drill press is that it allows you to customize your ball to fit your hand comfortably. The process of drilling holes in a bowling ball requires precision and accuracy, which can be challenging to achieve with hand tools. However, with a drill press, you can ensure that the finger holes are drilled uniformly, accurately, and at the perfect depth. This precision means that you will be able to grip the ball comfortably and reduce the risk of injury or strain.

Secondly, a bowling ball drill press enables you to modify your ball’s weight distribution. A properly weighted ball can significantly enhance your performance by increasing your overall control and accuracy. The weight of a bowling ball is an essential factor, and by using a drill press, you can add or remove weight in specific areas of the ball to create an ideal balance that works for you.

Furthermore, a drill press is a time and cost-efficient tool. Instead of constantly buying new balls, you can reuse your old ones and get new life by altering the drilled hole layout. You can save yourself the hassle of getting new balls each time you need a different size or style. Additionally, you won’t have to pay for third-party modifications or re-drilling. You can easily make modifications to your current ball to enhance its performance and save money in the long run.

Lastly, owning a bowling ball drill press can contribute to improving your overall gameplay. With a custom-fit ball that has the perfect weight distribution, you will have better control over your throws and achieve greater accuracy. All these factors combined will help improve your confidence on the lanes, and you will be able to achieve consistent results with each throw.

In conclusion, investing in a bowling ball drill press is a smart decision for any bowler. The benefits of customization, weight distribution, cost-effectiveness, and improved gameplay make it a valuable tool that every bowler should have in their arsenal. Get yourself one today and take your game to the next level.

Features of Bowling Ball Drill Press

Bowling is a popular game played by many people. The game has evolved over the years, with the introduction of new rules and equipment. One of the most critical pieces of equipment required to play the game is the bowling ball. However, drilling a bowling ball requires a specific tool, the bowling ball drill press.

A bowling ball drill press is a machine designed explicitly for drilling bowling balls to customize them to the bowler’s specific requirements. It is a powerful machine that can drill holes at precise depths and angles. The following are features that make a bowling ball drill press unique:

1. Adjustable Speed and Direction: The drill press is designed with a feature that allows adjusting the speed of the drill bit. This enables the operator to control the speed of the drill bit based on the density of the ball core. Moreover, the drill press can drill holes in different directions and angles to customization.

2. Easy to Use: The drill press is user-friendly, and its simple design makes it easy to understand and operate. Most of the machines come with an instruction manual that provides a step-by-step guide on how to use the drill press successfully.

3. Efficient: The machine is designed to be efficient, allowing the operator to drill balls quickly and accurately. The drill press is powerful enough to drill through the hardest bowling balls and offers an efficient means to do the job.

4. Adjustable Table: The drill press comes fitted with an adjustable table that can be moved up and down to various heights. This feature is essential in ensuring that the bowler’s ball is adequately positioned while drilling. It also allows for the drilling of multiple balls at a time.

5. Dust Collection System: A bowling ball drill press produces a lot of dust while drilling. To ensure safety and maintain a clean workspace, the machine comes fitted with a dust collection system that ensures that the workspace is clean after the procedure.

In conclusion, a bowling ball drill press is an essential tool for any bowler in need of customized equipment. Its unique features make the drill press effective, efficient, and easy to use. A drill press guarantees safe customization of bowling balls, and operators are advised to follow the manufacturer’s instructions to ensure safety and maintain the machine’s durability.

Various Types of Bowling Ball Drill Press

A bowling ball drill press is an essential equipment used for customizing a bowling ball’s reaction. There are various types of drill presses for bowlers who prefer to drill their own bowling balls. These drill presses are catered to different skill levels and drilling needs.

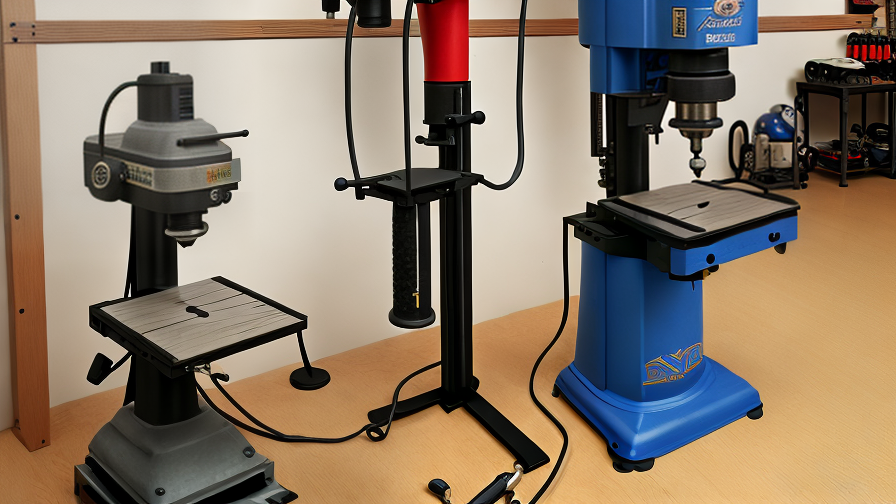

The first type of bowling ball drill press is the standard drill press. This type of press is usually used by beginners and those who only drill a few balls per year. The standard drill press is affordable and relatively easy to use, making it a popular choice for home use.

The second type is the mill/drill press, which is suitable for intermediate to advanced drillers. This type of drill press has more advanced features, including the ability to drill at different angles and depths. The mill/drill press is also much larger and more expensive than the standard drill press.

The third type is the CNC (Computer Numerical Control) drill press, which is the most advanced type of drill press. CNC drill presses are computer-controlled, allowing the user to input precise measurements and drill specifications. This type of press is most commonly used in professional pro shops and is quite expensive.

Another type of drill press is the portable ebonite drill press. This drill press is suitable for bowling ball manufacturers and those who travel frequently. Portable ebonite drill presses are compact and lightweight, making them easy to transport and set up.

Lastly, there is the vacuum cup-style drill press. This type of press uses a vacuum cup to hold the ball in place during drilling, allowing the user to drill with precision and accuracy. The vacuum cup-style drill press is suitable for home use and is relatively easy to operate.

In conclusion, understanding the various types of bowling ball drill presses is essential for bowlers who prefer to drill their own bowling balls. It is important to consider the skill level, drilling needs, and budget before investing in a drill press.

Applications of Bowling Ball Drill Press

Bowling Ball Drill Press applications go beyond just drilling holes into bowling balls. This type of press offers a variety of possibilities for bowling enthusiasts and professionals alike, making it an essential tool for the sport.

A bowling ball drill press is used to create the finger holes in a bowling ball, which is crucial for the bowler to have a good grip on the ball while throwing it down the lane. With a drill press, the finger holes can be customized to the bowler’s hand size and position, ensuring a comfortable and secure grip. This feature is especially important for professional bowlers who need to ensure their grip is perfect to deliver accurate shots.

Apart from this, bowling ball drill presses also offer other applications such as resurfacing the ball to maintain its optimum performance. The surface of a bowling ball can get scuffed, scratched or worn out over time, leading to a reduction in the ball’s hook potential, grip, and overall performance. Using a drill press, the surface of the ball can be gently sanded and polished to restore its smoothness and effectiveness, allowing for better hook potential and grip.

Bowling ball drill presses also offer a great range of customization options to enhance performance. The drill press can be used to create various layouts on the ball, which include different weights and positioning of finger holes to enhance the spin of the ball. This feature allows for a unique ball design suitable for the particular bowler’s style and preference, providing better performance on the lanes.

Finally, bowling ball drill presses can also be used to create unique designs or logos on the balls. This customization option adds to the aesthetics of the ball and makes it stand out from the others, providing a sense of pride, ownership and identity for the bowler.

In conclusion, a bowling ball drill press is a highly versatile tool that has various applications, apart from drilling finger holes in bowling balls. Its customization options diversify its uses, and its benefits enhance a bowler’s performance, providing them with the tools to achieve better results in their sport.

The Process of Bowling Ball Drill Press

The process of bowling ball drill press involves several steps to ensure precision and accuracy. The first step is to select the appropriate drill bit size for the desired hole diameter. The drill bit size varies based on the ball’s weight and the desired hole size.

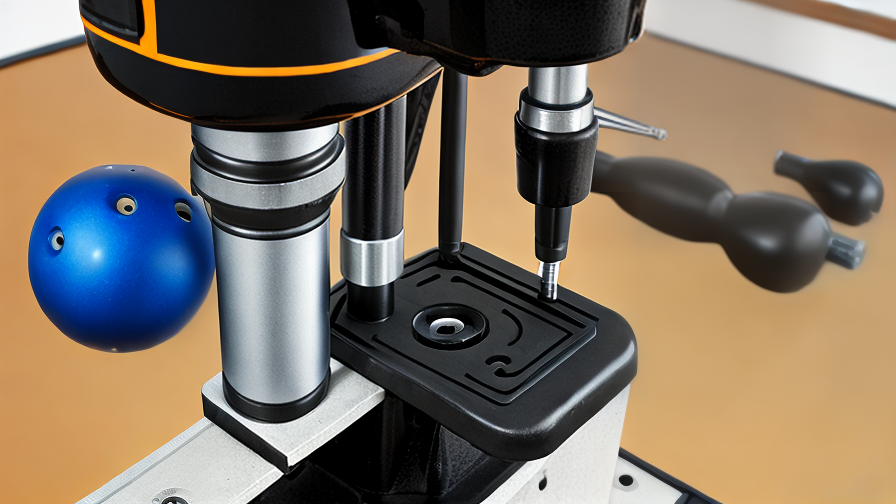

Once the correct drill bit size is selected, the ball is inserted onto the drill press. The ball is then secured onto the drilling jig with clamps to prevent it from moving during the drilling process.

After the ball is secured, the drill is turned on, and the bit begins to cut into the surface of the ball. The drill bit is carefully guided by the operator through the pre-determined drill path.

It is essential to ensure that the drill bit is correctly aligned to prevent any mistakes in the drilling process. The operator must also monitor the drill bit’s progress to ensure that the holes are drilled to the correct depth and diameter.

The bowling ball drill press also features various accessories that allow for specific drilling techniques. For example, a ball spinner allows the operator to smooth out the holes’ edges, while a vacu-jig assists in aligning the ball and provides a more stable drilling surface.

Finally, after the drilling process is complete, the ball is removed from the jig and carefully inspected for any defects or irregularities. The holes are then smoothed and polished using sandpaper or a polishing wheel to ensure a smooth and even surface.

In conclusion, the process of bowling ball drill press is a crucial aspect of bowling that allows players to customize their balls to fit their unique preferences and playing style. It involves precision and accuracy, and each step must be carefully monitored to ensure a perfect result.

How to use Bowling Ball Drill Press

Are you tired of unsatisfactory drilling of your bowling balls? The ideal solution to a perfect drill is the use of a bowling ball drill press. This machine has been designed specifically to help you drill your balls accurately and with ease.

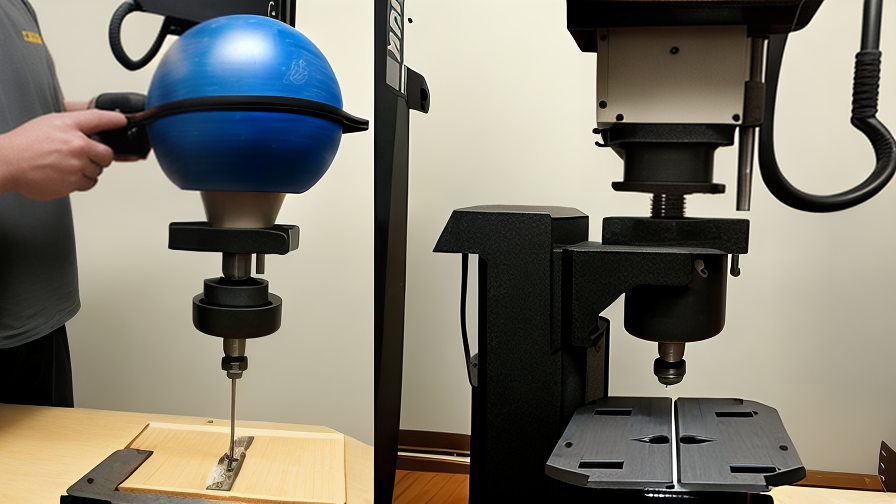

To begin, ensure that your drill bits are of high quality according to your specifications. Adjust the drill press height and set the bit to your desired size.

Place your bowling ball securely in the fixture provided by the drill press, ensuring you’ve marked the spot you want to drill precisely.

You can then start the drill press, which can be manually or electrically operated. Gradually lower the drill bit while applying light pressure to the ball to avoid putting too much stress on it. You can use a lubricant to reduce heat while drilling and also help produce smooth edges.

With bowling ball drill presses, you can also drill finger holes with ease. Ensure that you’ve marked the desired finger spots on the ball using several different methods, such as attaching a piece of tape. You can then use the finger hole jig to mark your finger holes evenly, ensuring perfect hand placement every time.

After drilling has been completed, it’s important to clean the edges of the holes to ensure a smooth finish. This can be done using sandpaper or a specifically designed rubbing compound.

Using a bowling ball drill press takes much less time and requires less energy, as opposed to using handheld drilling machines. It’s also very efficient, allowing for a much more accurate line to the point of the ball’s drilling.

In conclusion, drilling your ball with a bowling ball drill press guarantees a precise and smooth drilling process. All you need is the correct specifications, quality bits, and concentration while drilling.

Selecting the Ideal Manufacturer Bowling Ball Drill Press

When it comes to drilling your bowling balls, having the right equipment is essential. One of the most important pieces of equipment you will need is a bowling ball drill press. With so many options available in the market, selecting the ideal manufacturer bowling ball drill press can be overwhelming. Here are some tips to help you find the perfect one for your needs.

First, consider the type of drill press you need. There are two main types; the mechanical press and the electronic press. Mechanical presses are operated by hand while electronic presses are automated. If you are a beginner or prefer a hands-on approach, a mechanical press would be ideal. However, if you want to save time and get more precise results, then an electronic press would be your best bet.

Another important factor to consider is the number of holes you require. If you are only drilling one or two holes, a basic drill press will do the job just fine. However, if you want to drill multiple holes for a variety of grip patterns, then look for a drill press that can handle multiple holes at once.

When selecting a manufacturer, research their reputation, and read customer reviews to find out if they offer quality products and reliable customer service. A reputable manufacturer will provide a warranty for their drill presses, ensuring that you are protected in case of any defects or malfunctions.

Finally, think about your budget. Drill presses can range from a few hundred to several thousand dollars depending on the features they offer. Choose a manufacturer that offers a drill press that falls within your budget while still providing the features that you need.

In conclusion, selecting the ideal manufacturer bowling ball drill press requires careful consideration of your needs, the type of press you require, the manufacturer’s reputation, and your budget. By taking these factors into account, you can ensure that you find a high-quality drill press that will help you achieve the perfect grip on your bowling balls.

list FAQ with answer about Bowling Ball Drill Press

Looking to drill your bowling ball with a drill press? Here are some frequently asked questions and answers about bowling ball drill presses.

1. What is a bowling ball drill press?

A bowling ball drill press is a machine used to drill holes into a bowling ball to fit personalized finger grips and to change the ball’s core layout.

2. Can I use a regular drill press to drill my bowling ball?

No, a regular drill press is not suitable for drilling bowling balls. Bowling ball drill presses have specialized features such as adjustable speed and precision measurement tools that regular drill presses do not have.

3. How much does a bowling ball drill press cost?

The cost of a bowling ball drill press varies depending on the brand and model, with prices ranging from $800 to $6,000.

4. Can a beginner use a bowling ball drill press?

It is recommended that only experienced professionals use a bowling ball drill press. Without proper knowledge and training, it can be dangerous and result in injury or damage to the equipment.

5. What safety precautions should be taken when using a bowling ball drill press?

Always follow the manufacturer’s instructions and wear safety goggles, gloves, and a dust mask. Use appropriate clamps to secure the ball, and never place your hands near the drill bit while it is in motion.

6. Can I rent a bowling ball drill press?

Some pro shops and bowling facilities offer rental opportunities, but it is generally more cost-effective to have your ball drilled by a professional or invest in your own drill press if you plan to drill multiple balls.

7. What should I look for when purchasing a bowling ball drill press?

Consider the size and weight of the machine, the number of spindles or drill heads it has, and the accuracy and precision of its measurements. It is also crucial to purchase from a reputable retailer with a good warranty and customer service.

In conclusion, a bowling ball drill press is a specialized tool that requires proper training and safety precautions when in use. When considering purchasing or using a drill press, it is important to carefully weigh the financial, logistical, and safety factors involved.

Things to Consider When Purchasing Bowling Ball Drill Press

When it comes to drilling a bowling ball, having the right equipment is crucial. The bowling ball drill press is a necessary tool in every bowler’s arsenal, but purchasing one can be overwhelming. Here are some things to consider before making a purchase:

1. Size of the Drill Press

Drill presses come in various sizes, and it’s important to choose the right one for your needs. A small press will work for most standard drilling, but if you’re looking to do advanced drilling techniques like axis migration or finger/thumb inserts, you may need a larger press.

2. Motor Power

The motor is the heart of the drill press, and the higher the power, the faster and smoother the drilling process will be. A motor with a minimum power of 1/2 horsepower is recommended for bowling ball drilling purposes.

3. Spindle Travel

The spindle travel is the distance that the drill bit can move up and down, and it’s important to choose a drill press with enough spindle travel to accommodate the drilling depths and angles you need.

4. Chuck Size

The chuck is the part of the drill press that holds the drill bit, and it’s important to choose one that can accommodate the size of the drill bit you’ll be using. A 5/8″ chuck should work for most standard drilling, but larger chucks are needed for advanced techniques.

5. Brand and Price

Lastly, consider the reputation of the brand you’re purchasing and the price point. While a higher-end drill press may be more expensive, it may also have more features and last longer. However, if you’re on a budget, there are still many affordable options available.

In conclusion, when purchasing a bowling ball drill press, it’s important to consider the size, motor power, spindle travel, chuck size, brand, and price. By doing your research and choosing the right drill press, you can ensure a smooth and successful drilling process.

Properties of Bowling Ball Drill Press

A bowling ball drill press is a machine that is designed specifically for the purpose of drilling holes into the surface of a bowling ball. The process of drilling holes is an essential part of customizing a bowling ball, as it can help to improve grip and control for the bowler. The properties of a bowling ball drill press can have a significant impact on the quality of the drilling process, and the effectiveness of the end result.

One of the most important properties of a bowling ball drill press is its accuracy. Since drilling holes requires the machine to make precise measurements and cuts, any inaccuracies in the drill press can result in a poorly drilled ball. Most modern drill presses are designed with high-level precision features, including digital displays and measurement tools, to help ensure that each hole is precisely drilled to the desired specifications.

Another important property of a bowling ball drill press is its versatility. Different bowlers have different preferences when it comes to hole placement and orientation, so a machine that can accommodate a wide range of drilling options is essential. This may include different types of drill bits and hole layouts, as well as adjustable angles and positions to ensure that each ball is drilled to the bowler’s exact preferences.

The durability and reliability of a bowling ball drill press is another key property to consider. These machines are typically used in high-volume environments, such as pro shops and bowling alleys, so they need to be robust enough to stand up to frequent use. High-quality materials, heavy-duty construction, and reliable motors and mechanical components are essential to ensuring that a bowling ball drill press can withstand the demands of regular use.

Overall, the properties of a bowling ball drill press can have a significant impact on the quality of the drilling process and the final product. Accuracy, versatility, durability, and reliability are all key considerations when selecting a machine for this purpose, and investing in a high-quality drill press can help bowlers achieve the best possible results on the lanes.

Technical Parameters Terms for Bowling Ball Drill Press

When it comes to bowling, having the right equipment is essential for optimal performance. One important tool for bowlers is a bowling ball drill press. This machine allows bowlers to customize their bowling balls to meet their specific needs and preferences. However, in order to effectively operate a bowling ball drill press, it is important to understand the technical parameters involved.

Here are some important technical terms to know when it comes to bowling ball drill presses:

1. RPM: RPM stands for rotations per minute, and refers to the speed at which the drill press is spinning. Different materials and ball sizes require different RPMs, so it is important to adjust the speed accordingly.

2. Depth of cut: Depth of cut refers to the amount of material being removed from the ball with each pass of the drill bit. This parameter affects how quickly or slowly the drill bit can be fed into the ball.

3. Feed rate: Feed rate refers to how quickly the drill bit is moved through the ball. This parameter can be adjusted to make the drilling process faster or slower, depending on the desired result.

4. Clamping pressure: Clamping pressure refers to the amount of pressure applied to the ball to hold it in place while it is being drilled. It is important to use the right amount of clamping pressure to avoid damaging the ball.

5. Drill bit size: The drill bit size determines the size of the hole that is drilled into the ball. It is important to use the correct size for the desired drilling pattern.

By understanding these technical parameters of a bowling ball drill press, bowlers can effectively customize their bowling balls to meet their needs and preferences. However, it is important to note that proper training and education in using the drill press is crucial to ensure the safety of both the operator and the ball.

Bowling Ball Drill Press Price

Bowling ball drill presses are necessary machines for drilling bowling balls to cater to a bowler’s specific needs. Whether you’re a professional bowler, coach or just a bowling enthusiast who likes to customize balls, having a drill press is crucial. These machines are specially designed to make it easy for bowlers to achieve their preferred ball specifications.

When shopping for a bowling ball drill press, the price is one of the critical considerations. The cost of a drill press can vary depending on the brand, model, and size. Prices can range from $1,000 to $10,000 or more, depending on your needs and budget.

Bowling ball drill presses typically come in two types: floor-standing models and tabletop models. Floor-standing models are larger and heavier, making them ideal for shops or bowling alleys that frequently drill bowling balls. Tabletop models are smaller and portable, making them ideal for personal use or small shops.

The cost of a bowling ball drill press is also affected by the quality of the machine. High-end models often have more features, such as multiple speed settings, more substantial motors, and digital displays. These features can make the drilling process more accurate and efficient, but they also drive up the cost of the machine.

On the lower end of the price scale, the tabletop models come with fewer features but still offer a good bang for your buck. The ATE Pro. USA Mini Benchtop Drill Press is an affordable option for those looking for a tabletop model, costing roughly around $100. This model has a 110V motor and a 5-speed setting that is perfect for drilling bowling balls.

In conclusion, the price of a bowling ball drill press is determined by several factors, such as the model, the brand, the size, and the quality. When shopping for a drill press, it’s essential to consider your needs and budget to find the right one for you. Whatever your pick, investing in a drill press is a considerable, long-term investment for people passionate about bowling.