Knowledge about Can Labeler

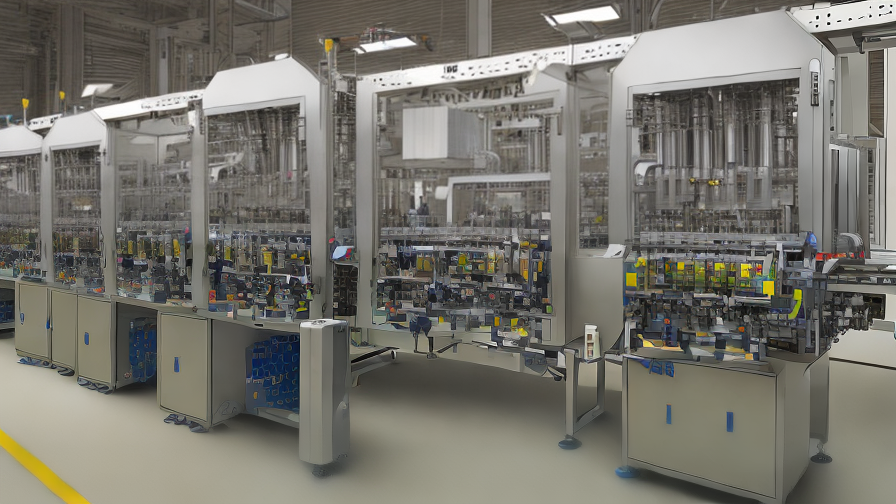

A can labeler is a machine used in the manufacturing industry to add labels to metal cans at a high rate. It is commonly used in the food and beverage industry where product labeling is a requirement by law. Can labelers can handle a wide range of can sizes and materials, including aluminum and steel.

There are different types of can labelers, including semi-automatic and fully automatic labelers. A semi-automatic can labeler requires human intervention to load, adjust and remove labeled cans. In contrast, a fully automatic labeler is a self-contained machine that can load, label, and remove cans without human intervention.

The labeling process involves printing and applying the label onto the can. The label is first printed with thermal transfer or direct thermal printing technology, and then it is applied to the cans using a label dispenser. Once applied, the label is securely fixed onto the can using pressure, heat or a combination of both.

Can labeling machines come in different designs and sizes, and can be customized to suit specific labeling requirements. Some can labelers have multiple labeling heads, allowing them to apply different labels on the same can. Others have features such as dust removal systems and can orientation sensors to ensure accurate labeling and prevent labeling errors.

Proper maintenance of a can labeler is essential for optimal performance and longevity. Routine maintenance activities include cleaning of label dispensers, lubrication of moving parts, and inspection of electrical components. Regular calibration of the machine is also recommended to ensure accurate labeling and prevent label misalignment.

In conclusion, a can labeler is a crucial component in the food and beverage industry for safe and efficient labeling of products. Understanding the different types, designs and maintenance requirements of a can labeler is essential for manufacturers to select the best machine for their needs and ensure smooth operations.

Various Types of Can Labeler

A can labeler is a type of machine that is used to apply labels on various types of cans. They are widely used in the food and beverage industry and have helped in increasing efficiency and productivity. There are several types of can labelers available in the market, each designed to cater to specific needs. Below are some of the various types of can labelers:

1. Semi-automatic can labeler – This type of can labeler uses manual feeding and requires an operator to place the cans onto the machine. It is ideal for small-scale production.

2. Automatic can labeler – As the name suggests, this type of can labeler is fully automatic and does not require an operator to place the cans. It can label up to 250 cans per minute and is ideal for larger-scale production.

3. Wrap-around can labeler – This type of labeler is designed to apply labels that wrap around the can. It is commonly used for labeling beer cans and can label up to 600 cans per minute.

4. Front and back can labeler – This type of can labeler is designed to apply two labels, one on the front and one on the back of the can. It is commonly used in the beverage industry for labeling soft drink cans.

5. Top and bottom can labeler – This type of can labeler is designed to apply labels on the top and bottom of the can. It is ideal for labeling cans of baked goods and soups.

6. Pressure-sensitive can labeler – This type of can labeler uses pressure to apply labels on the can. It is ideal for labeling cans that have irregular shapes.

In conclusion, can labelers have revolutionized the food and beverage industry by increasing efficiency and productivity. There are several types of can labelers available in the market, each designed to cater to specific needs. It is important to choose the right type of can labeler based on the production needs and the type of cans that need to be labeled.

FAQ sourcing Can Labeler manufacturer from China

When it comes to sourcing can labeler manufacturers from China, there are several frequently asked questions that potential buyers might have. Below are some of the most commonly asked questions about sourcing can labeler manufacturers from China and their answers.

1. How do I find a reliable can labeler manufacturer in China?

Finding a reliable can labeler manufacturer in China can be a bit of a challenge, but there are ways to ensure that you choose the right supplier. One way is to check their certifications and quality control systems, such as ISO 9001. You can also check their references and reviews from previous clients.

2. How much does a can labeler from China cost?

The cost of a can labeler from China depends on various factors, such as the type of labeler, capacity, and features. Generally, the price can start from around $1,000 and can go up to several thousand dollars.

3. How long does it take to receive a can labeler from China?

The lead time to receive a can labeler from China can vary from supplier to supplier, but usually, it takes around four to six weeks. Factors that can affect the lead time include customization requirements and the order quantity.

4. What are the payment terms for a can labeler from China?

Typically, Chinese manufacturers require a 30% deposit before production starts, with the remaining balance due after inspection and before shipping. Payment methods can include wire transfer, PayPal, or other secured payment options.

5. Will the can labeler have international certifications, such as CE?

Many can labeler manufacturers from China can offer international certifications such as CE, FCC or ROHS. However, it’s essential to check with the supplier if their product can meet your specific requirements.

In summary, if you’re considering sourcing a can labeler manufacturer from China, it’s crucial to do your due diligence and select a reliable supplier based on their certifications, references, and quality control systems. Keep in mind the price, lead

Applications of Can Labeler

A can labeler is an essential tool that is used to label cans with ease and precision. As the name suggests, it is designed to apply labels to cans automatically. It is an ideal option for manufacturers that need to label large cans in a short amount of time. The applications of can labeler are vast, and they include the following.

Food Processing Industry

The can labeler is widely used in the food processing industry. It is used to label various cans such as canned fruits, vegetables, soups, and other canned products. The machine ensures that the labels are applied to the cans accurately and within a short amount of time.

Pharmaceutical Industry

Can labelers are also used in the pharmaceutical industry. Pills and other medications are usually packaged in cans, and labeling them correctly is crucial. The can labeler ensures that the labels are applied correctly and that they adhere firmly to the cans.

Beverage Industry

In the beverage industry, can labelers are used to apply labels to cans containing soft drinks, beer, and other beverages. The machine ensures that the labels are applied without any errors, such as misalignment or incorrect placement.

Chemical Industry

The chemical industry is another area where can labelers find application. Various chemicals are usually packaged in cans, and labeling is crucial to ensure they are properly identified. The can labeler ensures that the labels are applied to the cans accurately, safely and with the highest level of precision.

Cosmetics Industry

The can labeler is increasingly used in the cosmetics industry to label cans containing beauty products such as hair sprays, moisturizers, and other beauty products. With the increasing demand in the beauty industry, the can labeler is becoming an indispensable tool for labeling cans.

In conclusion, the can labeler is a versatile and indispensable tool in various industries. Its precision, efficiency, and accuracy make it an ideal option for labeling cans. The machine has revolutionized the labeling process, making it faster, easier, and more accurate.

Manufactured Products made of Can Labeler

Can labeling machines have revolutionized the packaging industry as they offer efficient and accurate labeling solutions for various shaped cans. The machines are automated and designed to handle different sizes of cans and label them accordingly. These labeling machines have made it possible to produce high-quality, clear and readable labels on cans of different sizes and shapes.

Manufactured products made of can labeling machines include food and beverage packaging, cosmetics, and pharmaceutical labeling. The machine is specially designed to handle different types of label materials such as paper, plastic, or aluminum. The labeling machines work at high speed, making it possible to label thousands of cans in just an hour.

For food manufacturers, the labeling machines offer a streamlined process to help achieve regulatory compliance as required by the FDA. The label must include the nutrition information, ingredients, allergens, and any special instructions. The can labeling machine ensures that the information is legible and conforms to the regulatory requirements.

The can labeling machine can be customized to various sizes and shapes of cans, from tin cans, plastic jars, aluminum cans, and glass jars to bottles. The machine is efficient when handling round or rectangular shaped cans, and it can be adjusted to meet the customer’s requirements. The machine is also capable of printing graphics, logos, and barcodes, which is vital in the pharmaceutical and cosmetic industries, where product identification and tracking are of great importance.

In conclusion, the can labeling machine has transformed the packaging industry as it offers an efficient, fast, and accurate labeling solution for manufacturers who produce high volumes of products. The machine is used to produce labeled cans that meet regulatory requirements, ensuring that the customers have the correct information about the product. The customizable feature on the machine offers manufacturers the flexibility to adjust the machine to their needs, making it a valuable product for a range of industries.

The Evolution history of Can Labeler

The history of can labelers goes back to early 1900 when canning business began to boom. The early can labelers were simple machines that required manual feeding of labels, and they could only handle one size of cans. However, with time and advancements in technology, can labelers have undergone a significant evolution.

In the 1930s, the first automatic can labelers were introduced, and they greatly improved the productivity of canning companies. They were able to handle various sizes of cans, and they came equipped with sensors that could detect when a can was not properly aligned, hence reducing waste.

The 1970s saw the introduction of high-speed can labelers that could label over 800 cans per minute, and this greatly improved efficiency for large scale canning operations. With the emergence of coding technology, can labelers were integrated with coding systems that printed production dates, batch numbers, barcodes, and other product-related information on the label.

The current generation of can labelers, which feature automated and touch screen controls, has made the labeling process more streamlined and efficient. They can handle different can shapes and sizes, and most importantly, they can handle a wide range of label materials, including shrink sleeves, pressure-sensitive labels, and pre-cut labels.

The latest advances in can labeler technology are in response to the changing consumer preferences for personalized packaging, sustainability, and compliance with food safety regulations. Modern can labelers have incorporated innovative features such as application of compostable and recyclable labels, tamper-evident labels, and security labels that prevent counterfeiting.

In conclusion, the evolution of can labelers has been driven by the need for enhanced productivity, quality, and regulatory compliance. From manual label applicators to high-speed, automated machines with sophisticated controls, the future of can labelers is expected to be even more innovative, sustainable, and efficient.

The Process of Can Labeler

The process of can labeling is an essential part of the packaging of various goods. It is used to identify and provide information about the product in a quick and reliable way. It involves the use of a can labeler, which is a machine specifically designed to attach labels to the surface of cans, jars or bottles.

The can labeling process involves several steps that ensure the application of the right label to the correct product. The first step is to load the can labeler with the product to be labeled. This is done by placing the cans or bottles in the feeder system of the machine. The feeder system then moves the containers in a single file and positions them correctly in front of the label dispensing mechanism.

The next step involves the dispensing of labels onto the cans or bottles. The label dispensing mechanism usually consists of a series of rollers and brushes that pick up the labels from a roll and apply them to the container. The label is then pressed against the surface of the container to ensure that it adheres properly.

After the label has been applied to the container, the can labeler also has a system for checking the accuracy of the label application. This automated quality control system ensures that the label is applied correctly and that there are no defects or errors.

The final step of the can labeling process is the removal of the labeled container from the machine. The labeled products are then ready for packaging and shipment to their respective destinations.

Overall, the can labeling process is an efficient and reliable way to ensure that products are labeled correctly and consistently. The use of a can labeler also frees up human resources for other tasks, reducing production costs and increasing the efficiency of the overall production process.

Benefits Advantages of Utilizing Can Labeler

A can labeler is a highly automated and efficient labeling machine that is used in the packaging and labeling of a wide range of products, including food and beverages, cosmetics, and pharmaceuticals. There are several benefits and advantages that come with utilizing can labeler machines, including increased productivity, efficiency, and accuracy.

One of the primary advantages of using can labelers is increased productivity. With this machine, you can label multiple cans at once, which significantly reduces the time spent on manual labeling. In addition, the machine operates at optimal speeds, ensuring that you meet your production targets within a shorter period.

Can labeler machines are designed with high accuracy levels that guarantee consistency in labeling. Unlike manual labeling, which is prone to errors, a can labeler ensures that every can is labeled with precision, conforming to the set standards.

Another benefit of using can labelers is improved efficiency. This machine comes with an automated system that self-adjusts to the size of the can, ensuring that every label is correctly placed. This eliminates the need for manual adjustments or modifications, which can be time-consuming and costly.

Can labeler machines are designed to handle different can sizes and shapes, making them versatile and suitable for various labeling needs. By investing in a can labeler, you can label different can sizes and shapes with ease, regardless of the label’s size or material.

Lastly, can labeler machines are designed for long-term use and require minimal maintenance. This translates to lower operating costs, as you do not have to worry about frequent repairs or replacements.

In conclusion, utilizing can labeler machines has numerous benefits and advantages, including increased productivity, efficiency, accuracy, and versatility. With a can labeler, you can achieve high-quality labeling quickly and with minimal manual input, making it a worthy investment for businesses looking to improve their packaging and labeling processes.

Disadvantages Can Labeler

Can labeling machines are designed to help you label cans quickly and easily. These machines can be very helpful in speeding up your production process, but they also have a number of disadvantages that you need to be aware of.

Firstly, can labeling machines can be quite expensive to purchase and maintain. They require regular maintenance, including cleaning and lubrication, which can be time-consuming and costly. Additionally, if the machine breaks down, you’ll need to call in a professional to repair it, which can be even more expensive.

Secondly, can labeling machines can be difficult to use. They require a lot of skill and experience to operate, which means that you may need to invest in training for your employees. This can also be time-consuming and costly, especially if you have a large number of employees who need to be trained.

Thirdly, can labeling machines can be prone to errors. If the machine is not properly calibrated, the labels may not be applied in the right location or at the right angle. This can result in wasted materials and time, as well as a lower quality product.

Finally, can labeling machines can be limited in terms of their capabilities. They may not be able to handle all types of cans or labels, which means that you may need to purchase multiple machines to meet your needs. This can be very expensive, and can also take up a lot of space in your facility.

In summary, while can labeling machines can be useful tools for increasing efficiency and productivity, they also have a number of disadvantages that you need to be aware of. These machines can be expensive to purchase and maintain, difficult to use, prone to errors, and limited in their capabilities. Before investing in a can labeling machine, it’s important to carefully consider these factors and make an informed decision based on your specific needs and circumstances.

Selecting the Ideal Manufacturer Can Labeler

Selecting the ideal can labeler is an important decision for any manufacturing business. With so many options available, it can be overwhelming to make the correct choice. Here are some things to consider when selecting the right can labeler for your business.

The first thing to consider is the type of cans your business needs to label. Different can labelers are designed to handle different sizes and materials of cans. Some machines can only label cylindrical cans, while others can also label oval and square shapes. Make sure to choose a labeler that is compatible with the type of cans you need to label.

Next, consider the volume of cans your business will be labeling. Some labelers are designed for smaller batches, while others are designed for higher-volume production lines. If you have a small business, a less expensive option may be the best choice. If you have a high-volume production line, investing in a higher-end machine may be necessary.

Another factor to consider is the label material. Different machines are designed to handle different types of labels- paper, vinyl, or plastic. You need to choose a machine that is compatible with the label material you plan to use for your cans.

Ease of use is also important. You want to make sure that the machine is easy to operate and requires minimal training. The machine should be user-friendly so that any employee can quickly learn how to operate it.

Lastly, consider the overall durability and maintenance needs of the machine. It is important to look for a machine that is built to last and will require minimal maintenance. This will ensure that your business can rely on the labeler for years to come.

In conclusion, choosing the right can labeler requires careful consideration of several factors. The best labeler will depend on the specific needs and requirements of your business. By taking into account the can size, volume, label material, ease of use, and maintenance needs, you can find a labeler that will meet the demands of your business and help to increase productivity and efficiency.

Things to Consider When Purchasing Can Labeler

When it comes to packaging of canned goods, labeling is an essential aspect that determines product branding, safety, and consumer safety. A can labeler is a perfect tool for achieving this. However, choosing the right can labeler can be a daunting task. Here are some things to consider when purchasing a can labeler.

Firstly, you need to consider the level of automation you require. There are manual, semi-automatic, and automatic labelers. Manual labelers are suitable for small-scale operations, are affordable and easy to use. Semi-automatic labelers, on the other hand, are perfect for medium-scale operations, require human intervention in feeding cans and labels, and are general-purpose machines. Automatic labelers are suitable for large-scale operations, have high production rates, and require minimal human intervention.

Secondly, consider the label size and shape of the label. Ensure that the selected can labeller can handle different label sizes, shapes and materials. If you are dealing with multiple products, you may need a labeller that can accommodate various bottles or cans of different sizes and shapes. Be sure also to consider quantities and how fast the label changes that you need to make.

The third factor to consider is the speed of the can labeler. The speed of the can labeler is an important aspect to ensure maximum production efficiency. The higher the production rates, the more expensive the can labeler is likely to be. Therefore, evaluate the production needs of your business and select a labeller that best meets your needs.

Fourthly, consider the level of accuracy of the can labeler. The labeling process is critical in determining product branding, safety, and consumer safety. Accuracy in the labeling process is necessary to avoid product recall, costly rework, or rejection of finished products by retailers.

Lastly, consider the durability and quality of the can labeler. You need a labeller that requires minimal maintenance, is durable, and of high quality. Ensure that you select a manufacturer with a proven track record

Properties of Can Labeler

In the food and beverage industry, can labelers are an essential tool for labeling cans. Can Labelers function to provide efficient labeling of cans with a wide variety of labels including branding, nutrition facts, and warning labels. They come in different designs depending on the size of the cans they can label.

One of the main properties of can labelers is their high speed. Can labelers can label up to 60 cans per minute, depending on the machine’s model. This makes them an ideal tool for companies that need to label many cans in a short period.

Can labelers also have automatic feeding mechanisms, which allows them to handle cans of different shapes and sizes. This ensures that companies can label a range of cans without the need to switch machines or parts.

The precision afforded by can labelers during their labeling process is produced by a combination of electromechanical systems, software, and sensors. This ensures that the label is accurately placed on the can such that it conforms to regulatory standards. This is an important property especially in the food and beverage industry, which is heavily regulated.

Can labelers are designed to be easy to operate and maintain. They have simple user interfaces that require minimal training for users. They require minimal maintenance, which results in low maintenance costs, and satisfies the need for effortless cleaning.

Finally, can labelers are designed to be adaptable. This ensures that they can incorporate different features that can help companies meet their labeling needs. For instance, a company may need labeling machines that use specific materials like biodegradable or recyclable labels. In this case, a can labeler can be adapted to use such labels.

In conclusion, can labelers are essential tools in the food and beverage industry. They are designed to be high-speed, precise, adaptable, easy to operate and maintain. By incorporating these properties, can labelers help companies ensure that their cans are labeled efficiently and effectively.

How to use Can Labeler

Can labeling can be a daunting task, especially when you have plenty of cans to label. The good news is that you can simplify this process using a can labeling machine. Can labelers are designed to label cans precisely and accurately, saving you time and resources. Here’s a simple guide on how to use a can labeler.

1. Choose the right can labeler

There are several types of can labelers, and you need to choose one that best suits your needs. Some labelers are designed for specific can sizes, shapes, and materials. Ensure that you select a can labeler that works with the types of cans you will label.

2. Preparing the cans

Cans that are dusty, oily or have residues can affect the adhesion of the label. You need to ensure that your can surfaces are clean and dry when you start labeling. You can wipe the surfaces with a clean, dry cloth or use a cleaning solution.

3. Load the labels

Load the labels onto the machine; ensure that the labels are in the right orientation. The label orientation should be such that the adhesive side faces outward.

4. Set the machine

Most can labelers have manual settings, which allow you to adjust the label placement and orientation. Nozzle positioning can also be adjusted. You can use a test can to confirm the accuracy of the label placement before starting the machine.

5. Start the labeling process

When you start the machine, the labeler will apply the labels onto the cans. Ensure that the cans move smoothly, and the labels are applied correctly. It’s essential to monitor the labeling process and make adjustments if necessary.

6. Check and verify the labels

Once the labeling process is complete, check the labels to ensure they are correctly applied. Verify the label orientation, text positioning, and any other specific requirements.

In conclusion, can labeling can be straightforward if you have the right can labeler and follow these simple steps. Can labeling machines can save time and resources and

Glossary Terminology Terms for Can Labeler

A can labeler is an essential piece of equipment for any manufacturing or packaging plant that deals with canned goods. However, the terminology used in the canning industry can be quite specific and might be confusing for those new to the field. In this article, we will introduce you to some of the glossary terminology terms used for can labelers.

1. Labeler – A labeler is a machine used to apply adhesive labels onto can products.

2. Front panel – This is the main area of the can label where the product name and brand are usually displayed.

3. Back panel – This is the area of the label on the opposite side of the can, where nutrition information or a barcode is usually placed.

4. Orientation – This term refers to the direction in which the label is applied to the can. A label can be oriented in a vertical or horizontal position.

5. Register – Register refers to the process of aligning the label with the can surface. This is important to ensure there are no wrinkles or bubbles in the finished product.

6. Overlapping – This term refers to how much of the label overlaps onto the front and back of the can.

7. Roll diameter – This is the size of the roll of labels that fits onto the machine. The diameter can vary depending on the size of the label and the machine used.

8. Dispenser – A dispenser is a device that feeds a roll of labels through the can labeler machine.

9. Sensor – Sensors detect the presence of cans on the conveyor belt and communicate with the labeler, so it knows where to apply the label.

10. Print head – A print head is a component of the labeler that prints information such as expiration dates or batch numbers on the label.

In summary, the terminology used in a can labeler can be quite specific, but understanding these terms is essential for a smooth and efficient labeling process in a canning facility. Knowing the terminology used in can labelers can also help you make

Can Labeler Price

A labeler price can vary depending on various factors such as brand, features, technology, and capacity. The average price range for a basic labeler starts from $100 up to $500, while a sophisticated labeler can cost up to thousands of dollars.

The labeler’s brand name is a significant factor affecting the price range. Popular and well-known brands for labelers like DYMO, Brother, and Avery, require a higher cost for their products due to their brand reputation and quality assurance.

Features and technology are also some factors that affect the price. Thermal transfer or Direct thermal technology, high-resolution printing, color printing, and software compatibility are some of the additional features that are cost-intensive. These additional features provide accuracy, precision, and speed, which can increase productivity in the labeling process, essentially making it easier and more efficient to use.

Capacity is another factor. This refers to the amount of labeling a machine can perform in a certain period, the label width, and roll size. Consequently, labelers with high capacity will have a steep price compared to a basic labeler with limited capacity.

The price of a labeler can also vary depending on where the buyer purchases it. Buying from an authorized dealer or reseller often comes with special deals, promotional discounts, and additional benefits like warranty, replacement, repair, and maintenance.

In conclusion, the labeler price ranges based on various factors, including brand name, features, technology, and capacity. As a buyer, one must assess their labeling needs and determine what features they need before making a purchase to determine if the product is worth the price.