Benefits of Carry Bag Machine

Carry bag machines have become an essential part of the packaging industry. They have multiple benefits that make them ideal for small to large-scale businesses. Here are some of the top benefits:

1. Cost-effective

The biggest advantage of having a carry bag machine is cost-effectiveness. It eliminates the need for manual labour, which saves time and money. A single machine can produce a large number of bags in a short amount of time.

2. Customization

With a carry bag machine, businesses can create custom-made bags with ease. This is an excellent branding opportunity for businesses to showcase their logos or unique design on their bags. It also enables them to produce bags of varying sizes and shapes depending on their products.

3. Environmentally Friendly

Carry bag machines are environmentally friendly as they reduce the need for non-biodegradable packaging material. These machines produce bags made of bio-degradable materials, which is a great step towards a more sustainable future.

4. Better Quality

Carry bag machines produce high-quality bags that are durable and resistant to wear and tear. This is crucial as it ensures that the products packed in those bags are safe and secure.

5. Speed and Efficiency

Carry bag machines can produce a large number of bags in a short amount of time, which increases productivity. This ensures that businesses can meet the demand of consumers promptly.

In conclusion, carry bag machines offer a range of benefits that make them ideal for businesses of all sizes. They are cost-effective, customizable, environmentally friendly, produce better quality bags and greatly improve the efficiency of the packaging process.

Features of Carry Bag Machine

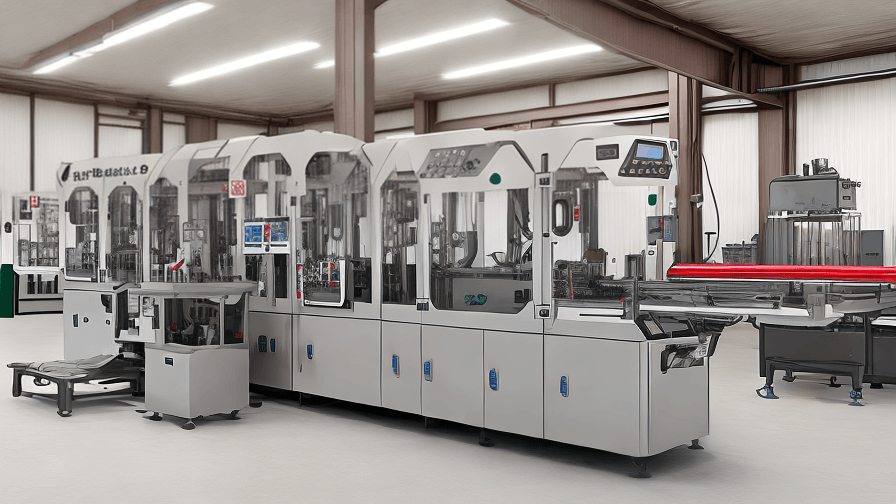

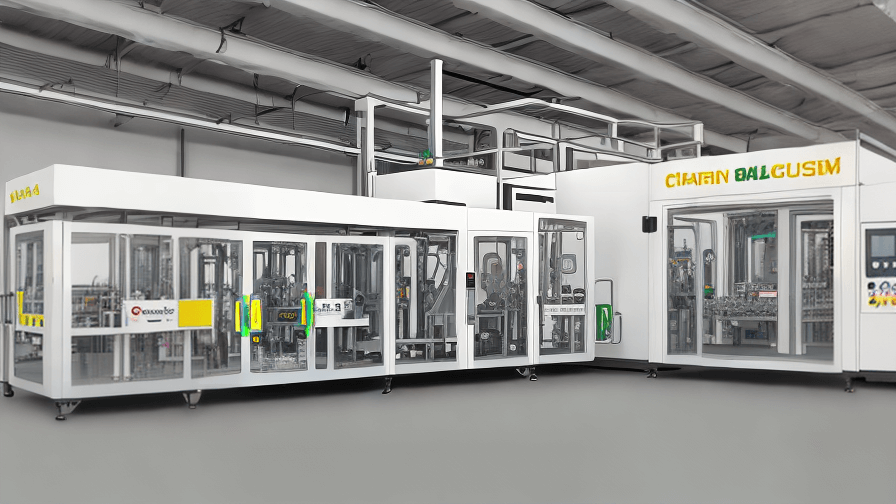

Carry bags are a fundamental item for customers, and the manufacturers are continually striving to make them more durable, customized, and cost-effective. To aid in this, various machines have been invented to manufacture carry bags. The carry bag machine is an advanced technology that is designed to improve and simplify the production process of carry bags. In this article, we will discuss some of the most essential features of a carry bag machine.

One of the primary features of a carry bag machine is its versatility. It can be used to produce different types and sizes of carry bags varying from small bags for single items or grocery bags to large bags used in supermarkets. Secondly, it has an automated system, which makes it easier to operate and requires fewer labor inputs. Once the machine is programmed, it can produce carry bags in a continuous manner, thus saving time and costs associated with manual labor.

The carry bag machine is made of high-quality materials that can withstand wear and tear, and it’s easy to maintain. The parts can be easily replaced in case of damage, therefore, reducing downtime and minimizing the cost of maintaining the machine.

Another crucial feature of a carry bag machine is its ability to print unique designs, patterns, and logos on the bags. This feature enables manufacturers to produce customized carry bags that are unique to their brand. This not only helps in building brand awareness but also attracts the attention of customers, thus improving sales.

Lastly, Carry bag machines are designed to be environmentally friendly. They utilize recyclable materials and reduce the amount of waste produced during the manufacture of carry bags. In addition, they use minimal energy and reduce carbon footprint emissions.

In conclusion, the features of the carry bag machine are geared towards improving the production of carry bags, saving time, reducing costs, and producing high-quality, cheap, and environmentally friendly carry bags. Therefore, it’s important for manufacturers to invest in carry bag machines to improve the quality of their products as well as increase their profit margins.

Various Types of Carry Bag Machine

Carry bags play a vital role in today’s society as they serve as a convenient option to carry our day-to-day essentials. The use of bags in various shapes and sizes has increased drastically over the past few years, which has encouraged the development of carry bag machines.

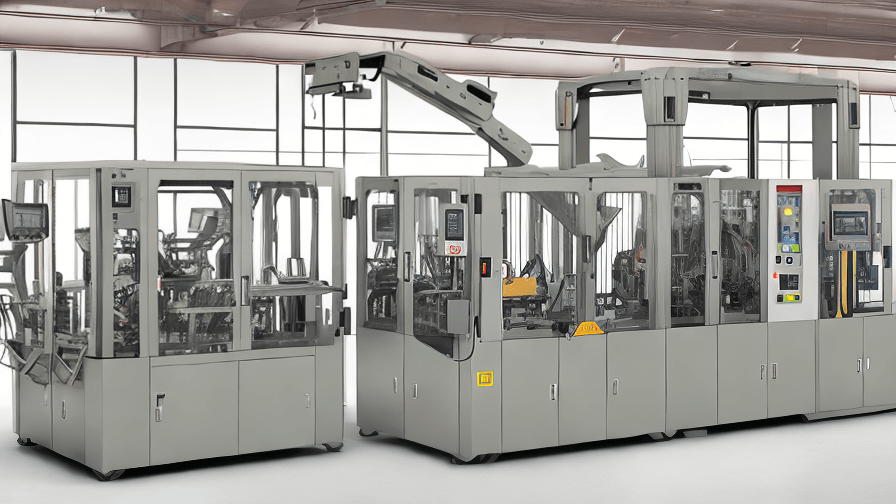

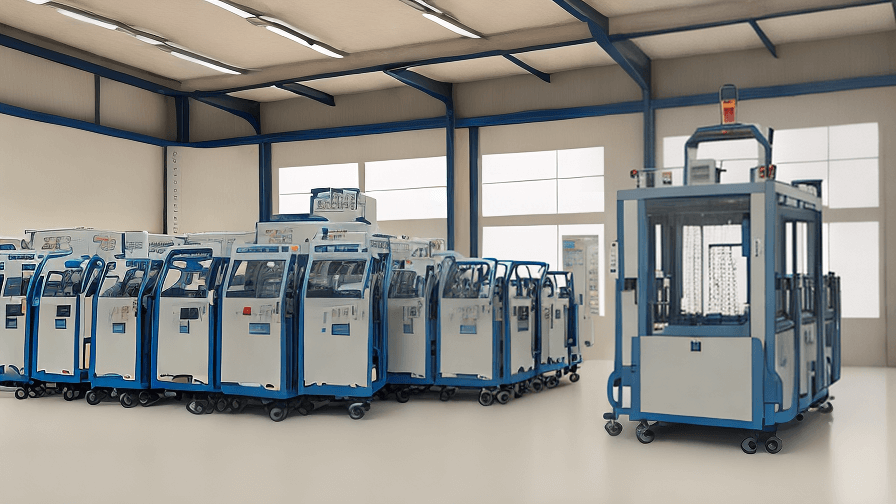

There are various types of carry bag machines available in today’s market, catering to different needs of customers. Some of the commonly used carry bag machines are:

1. Automatic Carry Bag Making Machine – This type of machine is widely used in the manufacturing industry. These machines are capable of producing bags of different sizes and thickness, making them ideal for custom orders.

2. Semi-Automatic Carry Bag Machine – As the name suggests, these machines require some manual labor and are budget-friendly options compared to automatic machines. They are best suited for limited production requirements.

3. Non-Woven Carry Bag Making Machine – These machines are eco-friendly as they use non-woven material to make bags. Non-woven bags are widely used as shopping bags, grocery bags, and packing bags.

4. High-Speed Side sealing Carry Bag Machine – This type of bag machine is known for its high production rate. It is capable of producing bags at a faster rate than other types of machines, making them the preferred choice in large scale productions.

5. Flexographic Printing Carry Bag Machine – These machines are used to print designs on bags. They are capable of printing high-quality images and designs, making them a preferred choice by companies for branding and advertisement purposes.

In conclusion, the use of carry bag machines has revolutionized the way we use bags in our day-to-day life. With various types of machines available in the market catering to different needs, businesses and individuals can choose the one that best suits their requirements. The machines not only help in the production of bags but also contribute to the environment in an eco-friendly way, which is a bonus feature.

Applications of Carry Bag Machine

Carry bag machines are becoming increasingly common in today’s world. They are commonly used in retail stores, supermarkets, and many other businesses. They are designed to produce high-quality and durable bags that can hold a large capacity of items. These machines come with numerous features and benefits that make them ideal for a range of applications.

One of the most significant applications of carry bag machines is in the retail industry. Retailers use them to produce eco-friendly bags that are designed to carry items like groceries, clothing, and other products. These machines are also commonly used in supermarkets to create bags for customers to use for their shopping. These bags are durable and can hold a large number of products, making them ideal for supermarkets.

Carry bag machines are also used in the manufacturing industry. They are used to create bags that are used for packaging goods such as food, pharmaceuticals, and other items. The bags can be designed to be airtight, waterproof, or tamper-evident, depending on the specific application. This makes them ideal for use in many different manufacturing environments.

Another application of carry bag machines is in the hospitality industry. They are used to create bags for guests’ luggage, making it easy for them to transport their items from one location to another. Bags can also be created for laundry services, allowing staff to transport dirty and clean laundry quickly and efficiently.

Finally, carry bag machines are used in the agricultural industry. Bags can be created for farmers to use for transporting crops and other agricultural products. These bags are designed to be durable and can handle heavy loads, making them ideal for use in the agricultural industry.

In conclusion, the applications of carry bag machines are numerous. They are used in a range of industries, from retail to agriculture, and provide numerous benefits. High-quality and eco-friendly bags can be produced quickly and efficiently, making them an essential machine for businesses that need to package and transport goods.

The Process of Carry Bag Machine

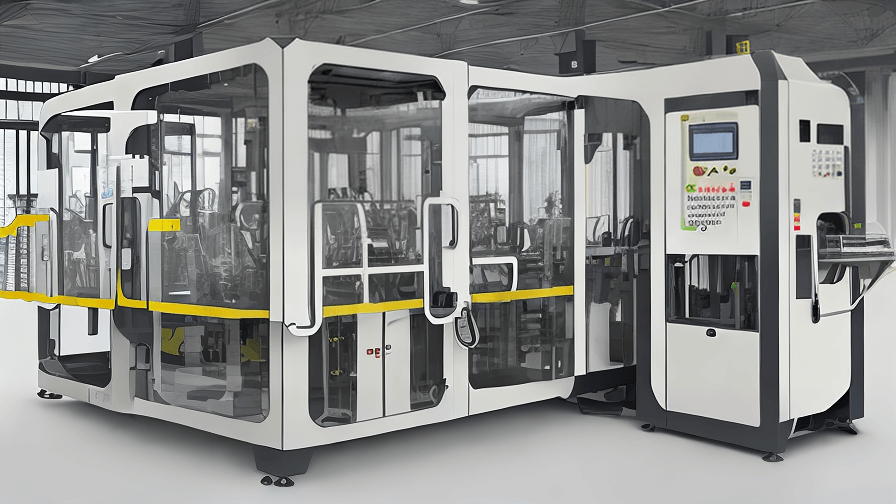

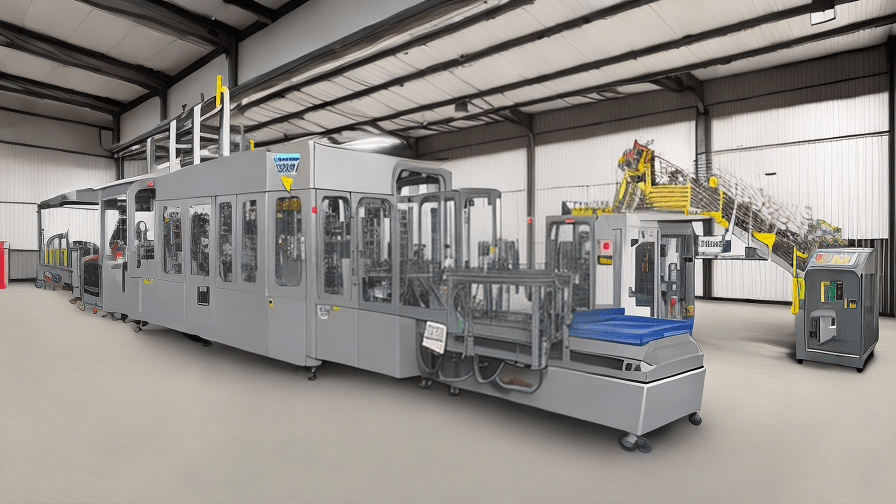

The process of a carry bag machine is an essential part of the packaging industry. It involves a series of steps that ultimately create the carry bag that we use to transport goods. The process is automated, efficient, and highly precise, ensuring that the bags are made to meet industry standards.

The first step in the process of a carry bag machine is the feeding of raw materials. The machine is fed with rolls of polyethylene material, which are then passed through a series of rollers and cutters. These rollers and cutters ensure that the polyethylene film is of the right size and shape, ready for the next step.

The next step is the sealing process. The machine heats the edges of the polyethylene film, allowing it to stick together, creating the sides of the bag. The bags’ bottom is then sealed to form the base of the bag, which is important for ensuring that it can hold weight without tearing.

Once the sides and base of the bag are sealed, it is then passed through a series of rollers and cutters to create the handles. The handles are made by punching holes through the sealed sides of the bag using a cutter. This process is automated, and the machine can produce thousands of bags in a matter of hours.

After the handles have been punched, the machine then folds and cuts the bags to their final size. The bags can be customized to meet different customer requirements, such as the size and color of the bag.

The final step in the process of a carry bag machine is the packaging of the bags. Once the bags have been created, they are stacked and packed into boxes, ready for transportation. The machine can produce bags in large quantities, making it more efficient and cost-effective than manual bag-making processes.

In conclusion, the process of a carry bag machine involves feeding raw materials, sealing the sides and base of the bag, creating the handles, folding, and cutting the bags to their final size, and packaging them. The machine is highly automated, efficient, and precise, ensuring that the bags meet industry standards. The carry bag machine has revolutionized the packaging industry, making it easier to produce high-quality bags in large quantities.

How to use Carry Bag Machine

Carry bag machines are a great addition to any business that sells items that require packaging. These machines automate the process of creating bags, reducing the need for pre-made bags and saving time and resources in the long run. Here is how to properly use a carry bag machine:

1. Set up the machine – First step is to set up the machine on a flat surface, ensuring that it is stable and secure. Plug the machine into a power source and ensure that all necessary attachments are in place.

2. Load the film roll – Take the film roll and insert it into the machine according to the manufacturer’s instructions. Once loaded, ensure that it is properly aligned and secured in place.

3. Select the bag size – Check the machine to see if it has options to select the bag size. If so, choose the appropriate size for the item you intend to package.

4. Turn on the machine – Once set up, switch on the power button, and check the LCD panel to ensure that the machine has powered on and is ready to use.

5. Insert the item – Take the item you want to package, and insert it into the opening of the machine from where the bag will be created.

6. Collect the bag – As the machine produces the bag, ensure that it is collecting the bag correctly. You can adjust the tension according to the thickness of the item being packaged.

7. Remove the bag – Once the bag has been created, remove it from the machine and repeat the process for the next item.

In summary, a carry bag machine is an efficient and effective way to package items, reducing the need for pre-made bags and increasing productivity in the long run. Following these instructions will ensure that the machine is used correctly, producing high-quality bags that are both secure and functional.

Selecting the Ideal Manufacturer Carry Bag Machine

When selecting a manufacturer for your carry bag machine, there are various factors that you need to consider to ensure you choose the ideal machine for your business. Here are some tips to help you with the selection:

1. The type of machine: Different carry bag machines are designed to handle different bag types and sizes. You must select the one that best suits your business needs. Also, consider the capacity of the machine in terms of the number of bags it can produce in a given period.

2. The manufacturer’s reputation: It is best to work with a manufacturer that has a good reputation in the industry. Browse their website, read reviews from previous customers and check if they have any awards or accolades that prove their quality.

3. Cost: Consider your budget before making any purchases. You don’t want to overspend and limit your ability to invest in other areas of your business. On the other hand, it’s not advisable to go for the cheapest option available because the quality may not meet your expectations.

4. Involve your staff in the selection process: Your machine operators and other staff will be using the machine daily. It’s wise to involve them in the selection process, so they can provide their input on the practicality and ease of use of different models.

5. Maintenance and support: Your machine needs regular maintenance to function optimally. Find out what type of maintenance is required and how often it should be done. Also, check if the manufacturer provides any maintenance support to ensure the longevity of the machine.

In conclusion, selecting the ideal manufacturer carry bag machine involves careful consideration of various factors. By taking the time to evaluate your needs and the options available, you can find a machine that is efficient, cost-effective, and provides long-term value to your business.

list FAQ with answer about Carry Bag Machine

Q: What is a carry bag machine?

A: A carry bag machine is a machine used to produce carry bags, typically made of plastic or paper, for commercial use.

Q: What types of carry bag machines are there?

A: There are two main types of carry bag machines: those that produce and seal plastic bags, and those that produce and fold paper bags.

Q: What sizes of carry bags can be produced by a carry bag machine?

A: The size of the carry bags produced by a carry bag machine depends on the specific model being used, but generally, these machines can produce bags in a range of sizes, from small produce bags to large shopping bags.

Q: How long does it take to produce a batch of carry bags using a carry bag machine?

A: The time it takes to produce a batch of carry bags using a carry bag machine can vary depending on the model and the size of the bag being produced, but generally, it takes only a few minutes to produce several dozen bags.

Q: Can carry bag machines be operated manually or automatically?

A: Yes, there are carry bag machines that can be operated manually, typically using a foot pedal or hand lever, as well as machines that are fully automatic and require no manual intervention.

Q: What materials can be used to produce carry bags using a carry bag machine?

A: The materials used to produce carry bags using a carry bag machine can vary depending on the specific machine, but generally, plastic and paper are the most common materials used.

Q: How much does a carry bag machine cost?

A: The cost of a carry bag machine varies widely depending on the specific model, but typically ranges from several hundred to several thousand dollars.

Q: What are the maintenance requirements for a carry bag machine?

A: Depending on the specific model, the maintenance requirements for a carry bag machine can vary, but generally, keeping the machine clean and well-oiled, replacing worn parts as needed, and performing regular maintenance checks are all important steps to ensure optimal performance.

Things to Consider When Purchasing Carry Bag Machine

When it comes to purchasing a carry bag machine, there are a few important things to consider. This type of machine is used to produce plastic or paper bags that can then be used to carry items such as groceries, clothing, and more. Here are some key factors to keep in mind:

1. Capacity: One of the most important things to consider is the capacity of the machine. How many bags can it produce in a certain period of time? Make sure to choose a machine that meets your production needs.

2. Durability: The machine should be made from high-quality materials and be designed to withstand heavy use. It’s important to choose a machine that is reliable and long-lasting to ensure that you get the most out of your investment.

3. Ease of use: The machine should be easy to operate and maintain, even for those who are not experienced in using this type of equipment. Look for a machine that comes with clear instructions and training materials.

4. Customization: Do you need to be able to customize the bags that the machine produces? If so, make sure to choose a machine that offers this feature.

5. Safety: Always prioritize safety when purchasing any type of machinery, including carry bag machines. Look for models that come with safety features such as emergency stop buttons, guards, and more.

6. Price: Of course, price is a consideration when making any purchase. Consider your budget and choose a machine that offers the features you need at a price point that you can afford.

In summary, purchasing a carry bag machine requires careful consideration of capacity, durability, ease of use, customization, safety, and price. By keeping these factors in mind, you can select a high-quality machine that meets your needs and helps you produce the bags you need efficiently and effectively.

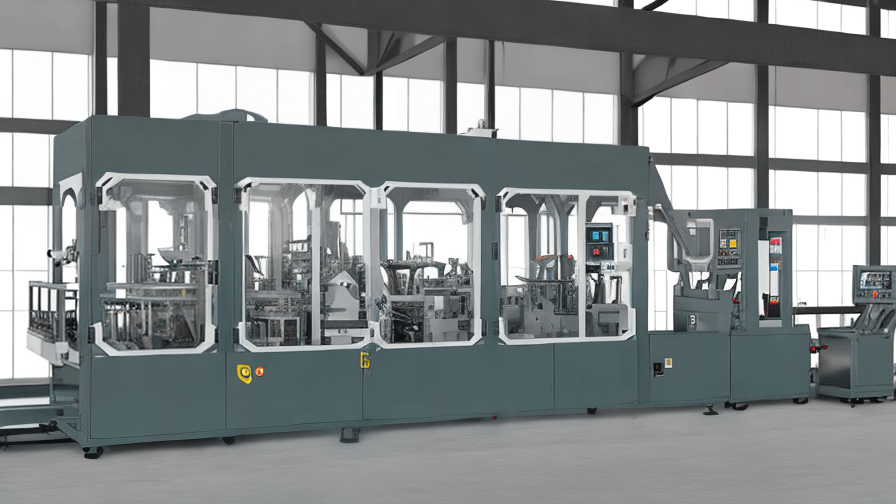

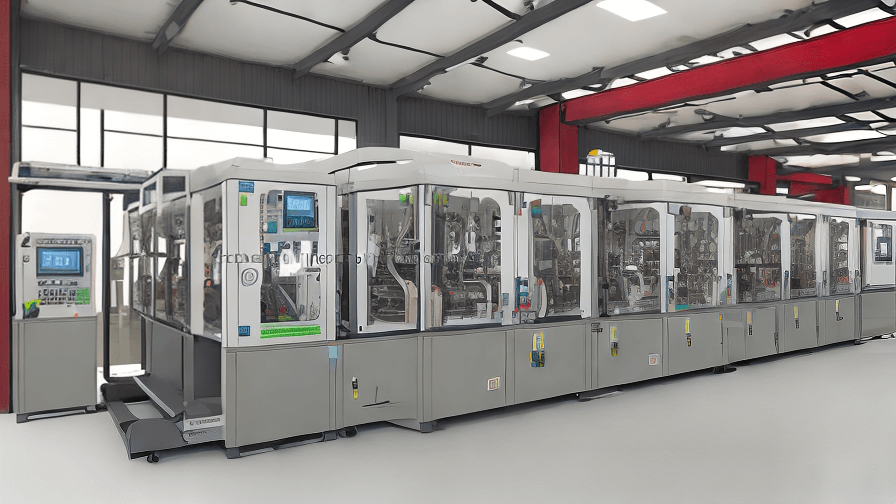

Properties of Carry Bag Machine

Carry bag machines are used to manufacture a variety of bags that are intended for use in businesses, grocery stores, and even homes. These machines are designed with a range of features that allow them to produce bags of different sizes, colors, and thicknesses. Here are some of the properties of carry bag machines that make them popular among businesses and manufacturers.

1. Production Output

Carry bag machines are known for their high production output. They can produce thousands of bags in a single hour, depending on the size and type of bag being manufactured. This high output makes it ideal for manufacturers who need to produce a large volume of bags in a short amount of time to meet their customers’ demands.

2. Versatility

Carry bag machines are highly versatile. They can produce bags in different sizes, thicknesses, colors, and materials, making them ideal for use in various industries. The ability to produce different bags also allows manufacturers to offer their customers more options, increasing customer satisfaction.

3. Automated

Carry bag machines are often automated, which reduces the need for manual labor, streamlining the production process, and increasing efficiency. Automated machines also improve the accuracy and consistency of the bags produced, reducing the risk of errors or defects.

4. Easy to Operate

Carry bag machines are easy to operate, and training is generally minimal. Most machines come with user manuals and software that allows operators to control the production process easily. This ease of use can help save time and reduces the risk of errors from operator mistakes.

In conclusion, carry bag machines are versatile and efficient machines that make it possible for businesses to produce bags of different sizes, colors, and thicknesses. They are highly automated, easy to operate, and can produce bags in high volumes, making them popular among manufacturers. With the increasing demand for bags, carry bag machines are becoming more important now than ever before.

Technical Parameters Terms for Carry Bag Machine

Carry bag machines are automated machines that simplify the production of carry bags. These machines can produce carry bags in different shapes, sizes, and materials such as paper, non-woven, and plastic. To choose the right carry bag machine, it’s essential to understand the technical parameters involved in the machine.

The technical parameters include:

1. Bag width and length: The bag size is an essential factor when choosing a carry bag machine. The bag width and length determine the maximum size of bags the machine can produce.

2. Production capacity: The production capacity is the number of bags the machine can produce per hour. It is essential to consider the production capacity of the machine to meet the production demands.

3. Bag material: The machine can produce different carry bag materials, such as paper, non-woven, and plastic. The machine’s production capacity and bag size vary based on the type of materials used.

4. Power consumption: Power consumption is an important consideration when selecting a carry bag machine. The power consumption determines the operating cost the machine incurs.

5. Control system: The control system is crucial for the machine’s operation and productivity. A machine with an efficient and user-friendly control system can ensure higher productivity.

6. Machine dimensions: The machine’s dimensions determine the amount of space needed to accommodate the carry bag machine.

7. Weight: The machine’s weight determines its level of portability and ease of transportation.

In conclusion, choosing the right carry bag machine requires a thorough understanding of the various technical parameters involved. It is essential to consider the machine’s bag size, production capacity, material, power consumption, control system, machine dimensions, and weight. By doing so, the machine can ensure a higher level of productivity, cost-effectiveness and meet customers’ needs.

Carry Bag Machine Price

Carry Bag Machine Price

Carry bags are an essential commodity in our daily lives. As the number of shopping trips increases, so does the need for carry bags. Carry Bag Machines are used to manufacture these bags.

The price of the Carry Bag Machine varies depending on the brand and features. There are various options available in the market, and selecting the right one is crucial to have a smooth manufacturing process.

The Carry Bag Machine typically comes in two varieties: automatic and semi-automatic. Both machines have their pros and cons, but automatic machines are more expensive than semi-automatic machines due to the advanced features they offer. Semi-automatic machines are suitable for small scale industries, while automatic machines are ideal for large scale operations.

Another factor that affects the price of the Carry Bag Machine is the type of bag it produces. Machines that produce simple plastic bags are cheaper than those that manufacture biodegradable bags, which are currently in demand due to environmental concerns.

The price of the Carry Bag Machine also depends on the production capacity. Machines with a higher production capacity have a higher price tag because they can make more bags in less time. However, investing in a higher capacity machine is a one-time expense that can boost profitability in the long run.

The price of the Carry Bag Machine varies from manufacturer to manufacturer. It is essential to research and compare the prices before making a purchase. A high price does not always guarantee good quality, so it is necessary to check the reviews and ratings of the manufacturer.

In conclusion, the price of the Carry Bag Machine depends on factors such as brand, features, bag type, and production capacity. It is essential to select a machine that best fits the business requirements to ensure smooth operations and increase profitability.