Knowledge about Carry Bag Making Machine

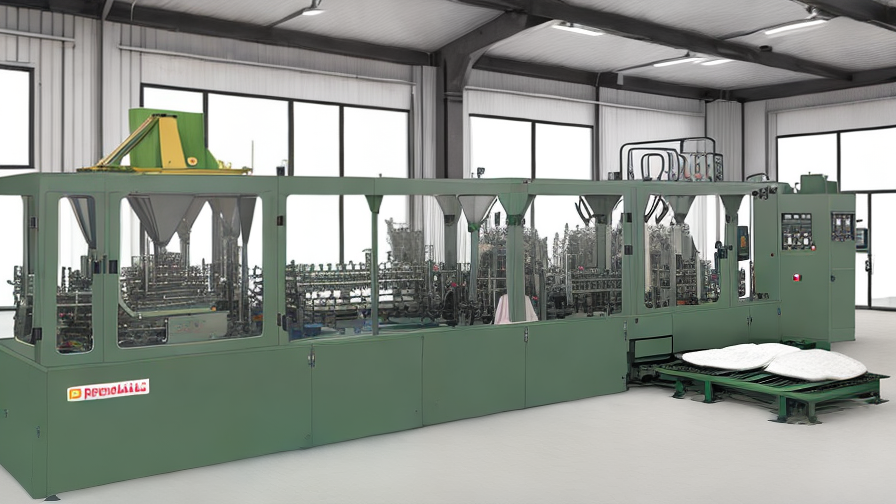

Carry bag making machine is an automatic machine that is used to produce carry bags of different sizes and shapes. These machines come in different models, with each model having unique features and capabilities. It is important to have a good knowledge about carry bag making machines if you plan to venture into the bag manufacturing business.

To begin with, the carry bag making machine is made of different parts, each playing a vital role in the bag-making process. Some of the parts include the unwinding unit, cutting unit, sealing unit, and feeding unit. The machine operates by feeding the raw material, mostly plastic rolls, through the unwinding unit to the cutting and sealing unit, where the bag is cut and sealed according to the desired size.

There are different types of carry bag making machines, including manual, semi-automatic, and fully automatic machines. The manual machine requires manual inputs for cutting, sealing, and feeding. The semi-automatic machine requires less human intervention but still needs an operator to control some of the functions. The fully automatic machine, on the other hand, requires no human intervention, as it operates fully automatically, with minimal supervision.

When purchasing a carry bag making machine, it is important to consider various factors, such as the productivity rate, quality of the bag produced, and machine maintenance cost. Choosing a machine with a high productivity rate and consistent quality bag production will ensure you meet market demands, maintain customer loyalty, and increase profits.

Finally, it is critical to have a good understanding of the machine’s operations to ensure proper maintenance and machine longevity. Regular check-ups and maintenance help detect any malfunction and address it before it becomes a bigger problem.

In conclusion, having good knowledge about carry bag making machines is essential for a successful bag manufacturing business. It is important to understand the different types, parts, and operations of the machine, as well as how to maintain them to ensure optimal production quality and productivity.

Various Types of Carry Bag Making Machine

Carry bags are a key component of modern life, with people relying on them to bring home their daily groceries, retail shopping, and other essentials. From small paper bags to large plastic bags, manufacturing these items can be done efficiently and economically with the help of various types of carry bag making machines.

First on the list is the non-woven bag making machine. This machine can make environmentally friendly bags made from spun bond non-woven fabric. It can produce bags with different colors, sizes and designs, making it a versatile choice for businesses of all sizes.

Secondly, there is the polythene bag making machine which creates bags out of polythene materials. This machine can produce bags of different shapes, sizes and thicknesses suitable for various purposes.

Thirdly, the paper bag making machine is a popular choice for creating paper bags. These machines offer features such as flexible size adjustments, high-speed production and automated operation, making them efficient and reliable for any paper bag production needs.

Fourthly, the woven bag making machine offers the ability to make bags from woven materials. This type of machine is commonly used for producing large bags such as sacks and containers, typically used for storing and transporting heavy items like grains, seeds, and cement.

Finally, the fully automatic carry bag making machine is one of the most advanced machines that can be used to make a variety of carry bags. It is capable of producing bags of different sizes, shapes, and designs with minimal human intervention. This makes it a highly efficient option for large scale manufacturing of carry bags.

In conclusion, the type of carry bag making machine one chooses will depend on their specific production needs. There are a variety of options available in the market with different features, capabilities, and price ranges. It is important to conduct a thorough analysis of one’s business requirements before selecting a machine to ensure that it fits their production needs and budget.

FAQ sourcing Carry Bag Making Machine manufacturer from China

Are you looking for a reliable carry bag making machine manufacturer from China? Here are some frequently asked questions and multiple answers to help you source the right supplier for your business needs.

Q: What types of carry bag making machines can I find from Chinese manufacturers?

A: You can find a variety of carry bag making machines such as non-woven bag making machines, plastic bag making machines, paper bag making machines, and more.

Q: What are the advantages of sourcing carry bag making machines from China?

A: China has a vast manufacturing industry that offers competitive pricing for quality products. Chinese manufacturers also have experience in exporting machines worldwide, offering after-sales service and support.

Q: How do I select a reliable manufacturer from China?

A: First, conduct research on the manufacturer’s reputation, history, and reviews. Second, request product samples or visit the manufacturer’s factory to inspect the quality and production process. Third, check the manufacturer’s certifications and compliance with international standards.

Q: Can I customize the carry bag making machine according to my specific requirements?

A: Yes, most Chinese manufacturers offer customized solutions to meet your business needs.

Q: What is the price range for carry bag making machines from Chinese manufacturers?

A: Prices vary depending on the type, capacity, and customization of the machine. Generally, prices can range from $5,000 to $50,000.

Q: How do I ship the carry bag making machine from China to my country?

A: Chinese manufacturers usually offer shipping services to customers worldwide. They can arrange shipping by air, sea, or land, depending on your preference and budget.

In conclusion, sourcing carry bag making machines from Chinese manufacturers can be a cost-effective solution for your business needs. By considering these frequently asked questions and multiple answers, you can find a reliable manufacturer that meets your specific requirements.

Applications of Carry Bag Making Machine

A carry bag making machine is a piece of equipment that is used to manufacture various kinds of carrier bags. These machines are widely used for producing bags of various sizes and shapes, depending on the requirements of the customers. These machines serve a variety of applications, including packaging and transportation of goods, stacking multiple items, and carrying groceries and other items.

One of the most significant applications of a carry bag making machine is in the packaging of goods. These machines can produce bags made of different materials such as plastic, paper, and jute. These bags can withstand the weight and pressure of the items inside, ensuring that they are protected during transportation. The bags are also durable and can be reused for other purposes, which makes them an eco-friendly option.

Another application of carry bag making machine is in the retail sector, where customized bags are produced according to the customers’ specifications. Depending on the size and shape of the products, different types of bags can be manufactured to ensure that the products are well displayed and easily accessible to the customers.

Moreover, carry bags are also used for storing and transporting clothes, books, and other items. They are spacious and can protect the items inside from dust, water, and other elements. For this purpose, carry bag making machines can produce bags made of different materials with varying thicknesses, ensuring that the bags are strong enough to hold a considerable amount of weight.

In conclusion, carry bag making machines are essential and have versatile applications across a variety of industries. With advancements in technology and innovation, these machines are continually evolving to produce better-quality bags that are more eco-friendly and cost-effective. Manufacturers can benefit from investing in these machines to maximize their production process and improve productivity.

Manufactured Products made of Carry Bag Making Machine

Carry bag making machine is an essential manufacturing tool that helps in the production of bags of various sizes and shapes. Many industrial enterprises nowadays have realized the benefits that come with the use of these machines, and the products that it produces have a high demand in the market.

One of the significant advantages of using a carry bag making machine is that it allows manufacturers to create bags of different sizes and shapes according to the client’s specifications. The bags also come in different colors and designs to suit various industries’ needs. For instance, these machines can make bags for shopping, promotions, packaging, and so on.

The bags produced from carry bag making machines are high-quality and durable, made of materials such as LDPE, HDPE, and PP. This allows them to carry heavyweights without tearing or breaking and can be reused multiple times. These bags are eco-friendly, and many companies prefer to use them to fulfill their corporate social responsibility.

Another advantage of these machines is that they are easy to operate and require minimal human intervention. The machines also have features such as automatic feeding, cutting, and punching mechanisms, which further reduce the chances of errors occurring in the manufacturing process. Most models have an adjustable speed control function, allowing companies to produce large quantities of bags with ease.

The products that can be made using a carry bag making machine are numerous. For instance, you can produce grocery bags, gift bags, shopping bags, garbage bags, industrial packaging bags, and many more. These bags have a significant impact in our day to day life.

In conclusion, the benefits of using a carry bag making machine are numerous, and the products it produces have a high demand in the market. With advanced technology, the manufacturing process is now more efficient, with less wastage and improved quality. Companies can save significant resources by using these machines and produce bags that meet the customer’s specific needs.

The Evolution history of Carry Bag Making Machine

Carry bags are one of the most commonly used items all over the world. In the past, carry bags were made by hand with natural materials like leaves, bark and twigs. However, as technology advanced, the carry bag making machine was invented to simplify the process and cater to the increasing demand for bags.

The evolution of carry bag making machines can be traced back to the early 19th century when the first mechanical machine for producing bags was invented. This was a wooden contraption that used a hand crank to produce bags from paper. With time, the machine was improved to include a feeder, which made it more efficient.

In the mid-20th century, advancements in technology led to the invention of the first electrically powered carry bag making machine. It was capable of producing bags at a much faster rate, and with greater precision. Plastic bags were also introduced during this period, and the machine was adapted to produce them.

In the 1970s, the first fully automatic bag making machine was developed. This machine used computer technology to create precise and consistent bags at a much faster rate than previous models. It was also capable of producing bags in different sizes and shapes, making it a versatile option for manufacturers.

In recent years, environmental concerns have led to the development of eco-friendly bag making machines. These use bio-based materials like corn-based polymers and biodegradable additives to produce bags that are less harmful to the environment.

In conclusion, the evolution of carry bag making machines has been marked by significant advancements in technology, leading to the production of faster, more efficient and eco-friendly machines. As the world continues to embrace sustainability, manufacturers will continue to innovate and produce more environmentally friendly carry bag making machines.

The Process of Carry Bag Making Machine

Carry bag making machines are a significant innovation in the packaging industry. They are capable of making bags from various materials such as plastic, paper, and non-woven fabric. The goal of the carry bag making machine is to simplify the production of bags, making them easier, faster, and more efficient.

The process of carry bag making begins with raw materials such as roll sheets of plastic, paper, or non-woven fabric. The raw materials are loaded into the machine, and the machine then goes through several stages to turn the raw material into a finished product.

First, the raw material is fed through a feeding system where it is measured and cut to size. The cut material then enters the sealing and cutting station. Here, the material is cut into the desired shape and size, and the edges are sealed to prevent it from fraying.

After sealing and cutting, the material enters the folding and gluing station. In this stage, the material is folded to form the shape of the bag, and the sides are glued together to create the final product.

Once the bag is formed, it enters the printing station. Here, the bag is printed with logos, designs, or promotional messages based on customer requirements.

Finally, the bags go through the delivery station where they are counted, stacked, and delivered for packing and shipping to respective locations.

Carry bag making machines are highly efficient and adaptable to various customer needs. They can produce different bag sizes, shapes, colors, and materials based on customer requirements. The use of carry bag making machines in packaging production has reduced production costs and increased production efficiency.

In conclusion, the process of making carry bags using the carry bag making machines has simplified the production process, making it faster and more efficient. It has also enabled the production of customizable bags to suit various customer needs.

Benefits Advantages of Utilizing Carry Bag Making Machine

Carry bag making machines are highly beneficial in the packaging industry these days. They are widely used in the manufacturing processes of carry bags. These machines come in various sizes and models which are highly energy-efficient, cost-effective and highly productive. Here are some of the benefits and advantages of utilizing carry bag making machines.

Efficient Production

Carry bag making machines increase the production rate significantly. This means you can manufacture a large number of bags in a very short run. This guarantees fast delivery of the bags, which ultimately leads to satisfied customers, higher cash flow and overall company growth.

Energy Efficiency

Modern carry bag making machines are highly energy efficient. They are designed to use the minimum amount of energy while working at maximum productivity. This reduces your company’s carbon footprint, lowers your energy costs, and thus results in a positive effect on the environment.

Cost Savings

Carry bag making machines automate the production process, which increases the overall efficiency and productivity of the company. This leads to a reduction in labour costs and an increase in profit margins. Moreover, bulk purchases of raw materials and other manufacturing supplies can also be done at reasonable prices, making the overall cost of production economical.

Customization

Carry bag making machines are highly customizable. The machines allow you to produce bags of different colors, sizes, patterns, and materials according to your customer’s requirements. This means you can cater to the specific needs of your customers and improve overall customer satisfaction.

Overall, carry bag making machines offer numerous benefits and advantages. They are highly efficient, energy-efficient, cost-effective and customizable machines that improve the production rate, performance and profitability of the manufacturing companies. Therefore, these machines should be considered by anyone involved in the packaging industry as they assist in achieving the best results.

Disadvantages Carry Bag Making Machine

Carry bag making machines are widely used in the paper and plastic bag manufacturing industry. These machines make the process of bag production faster, more efficient, and reduce labor costs. However, as with any type of machine, carry bag making machines have their own set of disadvantages.

Firstly, carry bag making machines can be expensive to purchase and maintain. The initial investment required for a high-quality machine can be significant, and the cost of repairs can also be substantial. This can make it difficult for small businesses to afford these machines, limiting their ability to compete with larger companies.

Secondly, carry bag making machines require skilled operators to run them. While computerized controls have made operation easier, it still requires a level of expertise to set up and operate the machine. This can make it challenging for companies that struggle to find skilled workers or cannot afford to invest in training their employees.

Thirdly, carry bag making machines can be extremely loud and create a significant amount of noise pollution. This can be a problem for both workers and neighboring businesses. In addition, the vibrations from the machine can cause damage to nearby structures or equipment.

Fourthly, carry bag making machines can produce a large amount of waste, particularly in the form of scraps or rejected bags. This can result in added costs for disposal, as well as environmental concerns.

Finally, carry bag making machines may not be as flexible as manual bag production. While they offer high production capacity, they may not be able to produce customized or unique bags as easily as manual methods. This can limit a company’s ability to meet specific customer demands.

In conclusion, while carry bag making machines offer many advantages, they are not without their drawbacks. Before investing in one of these machines, companies must carefully consider the cost, the need for skilled operators, noise pollution, waste production, and flexibility.

Selecting the Ideal Manufacturer Carry Bag Making Machine

When choosing a manufacturer carry bag making machine, it’s essential to consider several factors to ensure you get the best possible equipment for your business. With so many different types of machines available in the market, it can be challenging to select the ideal one.

First, consider the type of bags you intend to produce. Depending on their size and features, some bags require specific machinery to make them. Therefore, ensure the machine you choose can accommodate the bag specifications you require.

The machine’s output speed is another essential factor to consider. Machines that produce more bags per minute will increase productivity, resulting in higher returns on investment. However, these machines may require more space to operate and may be more expensive.

It’s also critical to consider the machine’s quality output. The ideal machine should produce bags that meet your desired standards consistently. Low-quality bags can lead to loss of profits, negative reviews, and unsatisfied customers.

The machine’s versatility is also crucial. The best machines can make different types of bags, meaning you can expand your product range without the need for additional equipment. In addition, you should consider the machine’s maintenance needs and availability of spare parts.

Lastly, the cost of the machine should be within your budget, and also consider the energy consumption of the machine.

In conclusion, choosing the ideal manufacturer carry bag making machine depends on several factors. Ensure the machine can produce the type of bags you require, has high output speeds, produces quality output, is versatile, easy to maintain, and is affordable. Investing in the right machinery will ultimately result in higher productivity, better returns, and a more efficient manufacturing process.

Things to Consider When Purchasing Carry Bag Making Machine

Purchasing a carry bag making machine can be a significant investment for your business. Before investing in such equipment, there are some essential factors that you must consider to ensure that you get the best machine for your requirements.

1. Production output: Before purchasing the machine, assess your production needs and requirements. This will help you determine the production output capacity required from the machine.

2. Quality of the machine: Always consider the quality of the machine before purchasing it. Quality plays a significant role in the longevity and performance of the machine.

3. Ease of operation: Ensure that the machine has simple and easy to understand operation. This will save time and money spent on training personnel to operate the machine.

4. Cost: Cost is a critical factor to consider before purchasing the machine. Compare prices from different manufacturers and choose one that matches your budget and specifications.

5. After-sales service: Always research the supplier’s reputation and after-sales service to ensure that you get reliable and prompt assistance for any issues or maintenance needs.

6. Machine flexibility: Ensure that the machine can produce bags of different sizes and shapes to match your customer’s requirements.

7. Material compatibility: The machine must be suitable for the type of material you intend to use, such as paper or plastic.

8. Safety features: Ensure that the machine comes with all the necessary safety features and meets the required safety standards.

In conclusion, when purchasing a carry bag making machine, take time to consider these factors to get the best value for your investment. Always purchase from a reputable supplier to ensure quality and reliability. Investing in the right carry bag making machine can be a game-changer for your business and help you meet customer demands efficiently.

Properties of Carry Bag Making Machine

Carry bag making machines are widely used in the packaging industry to produce different types of bags including grocery bags, shopping bags, and zipper bags. These machines come with many properties that make them highly efficient and reliable. In this article, we will discuss some of the most important properties of carry bag making machines.

1. Automation: Modern carry bag making machines are fully automated, which means that they can operate without human intervention. This increases productivity, reduces labor costs, and improves overall product quality.

2. Precision: Carry bag making machines are designed to produce bags with precise measurements and dimensions. This ensures that the bags are the right size and shape to hold the intended products, and reduces waste.

3. Versatility: Carry bag making machines can produce a wide range of bag types and sizes. They can also be customized according to the needs of the user, making them highly versatile and adaptable to different production requirements.

4. Speed: Carry bag making machines are capable of producing large volumes of bags quickly and efficiently. This allows manufacturers to meet customer demand and increase profitability.

5. Durability: Carry bag making machines are built to last, with high-quality materials and components that withstand frequent use and wear and tear.

6. Reliability: Carry bag making machines are designed to work consistently and reliably, with minimal downtime and maintenance requirements. This reduces the risk of costly errors and production delays.

In conclusion, carry bag making machines are essential tools for the packaging industry, providing efficient, precise, and versatile bag production. When choosing a carry bag making machine, it is important to consider these properties in order to select the best option for your particular production requirements.

How to use Carry Bag Making Machine

Carry bags are the most commonly used packaging materials for products sold in retails stores. These bags are very easy to produce and come in a wide variety of sizes, colors, and materials. With the help of carry bag making machines, producing these bags has become easier, efficient, and cost-effective. Below are some guidelines on how to use a carry bag making machine.

1. Assemble the machine: Begin by assembling your bag making machine according to the manufacturer’s instructions. Ensure that all parts are connected securely and the machine is firmly fixed to the surface.

2. Load the material: Load the roll of material onto the machine spool. This material can be of various types such as paper, plastic, or cloth. Ensure that the material is in a straight line, and that the end is fixed securely to the take-up spindle roller.

3. Set the machine parameters: After loading the material, set the machine parameters based on the specifications of the bag to be produced. This includes the size of the bag, thickness of the material, handle length, and heat-sealing temperature.

4. Start the machine: Once you have set the machine parameters, it’s time to start the machine. Turn on the machine and the material will start to move through the machine. The machine will automatically cut and seal the material, forming a bag.

5. Monitor the machine: It’s essential to monitor the machine during the bag-making process. Ensure that the bag is formed correctly, and the heat sealer is sealing the bag tightly. Check for any defects in the bags during the process and adjust the machine settings accordingly.

6. Collect the bags: As the bags are produced, collect them on a table or in a container. Ensure they are stacked in neat piles for easier handling.

In conclusion, carry bag-making machines are efficient and cost-effective for the production of carry bags of different sizes and materials. However, it’s crucial to follow the manufacturer’s instructions and guidelines to operate the machine accurately

Glossary Terminology Terms for Carry Bag Making Machine

The manufacturing of carry bags is an essential part of the packaging industry. With the increasing demand for eco-friendly packaging, there has been a surge in the use of carry bag making machines. These machines help in producing high-quality bags in huge quantities. Listed below are some useful glossary terminology terms for carry bag making machines.

1. Bag cutting machine: This machine is used for cutting the plastic film or sheet into the required sizes to make bags.

2. Bag sealing machine: It is used to seal the edges of the bags to prevent spills and leakages.

3. Bag making machine: This machine is used to make bags of different sizes and shapes. It can produce bags for a variety of purposes such as shopping bags, garbage bags, and more.

4. T-Shirt bag making machine: This machine is used to make T-Shirt bags which are widely used in the retail industry for carrying items.

5. Loop handle bag making machine: This machine is used to produce bags with loop handles which are comfortable to hold and easy to carry.

6. Side seal bag making machine: This machine is mostly used for producing bags for packaging food items. These bags are sealed from the sides to prevent any kind of contamination.

7. Bottom seal bag making machine: This machine is used to produce bags with a sealed bottom which provides better support and prevents spillage.

8. Hot cutting machine: This machine is used to cut plastic films or sheets using heat.

9. Punching machine: It is used for making holes or punches in bags.

In conclusion, these are some of the useful glossary terminology terms for carry bag making machines. The packaging industry is constantly evolving, and these machines are playing a crucial role in meeting the demands of the market. By understanding the basics of these machines and the terminology, manufacturers can produce high-quality bags efficiently and effectively.

Carry Bag Making Machine Price

A carry bag making machine is a type of machine used for mass-producing carry bags made out of various kinds of materials like paper, fabric, or plastic. In the present world, carry bags are an essential commodity used in almost all areas of our daily lives, such as shopping, travelling, and groceries. Hence, there is a huge demand for carry bag making machines. The price of these machines depends on various factors such as the features it offers, the material it can produce, and its speed.

The price of a carry bag making machine starts from around $10,000 and can go up to several thousand dollars based on its features and other specifications. However, the price of the machine also depends on its capacity, which ranges from low to high.

The low capacity machines are less expensive and are ideal for small-scale businesses or startups that can start with a limited budget. These machines have a lower production rate of about 200-300 bags per hour and can produce bags made of paper or non-woven fabric.

The high capacity carry bag making machines are more expensive and suitable for established businesses with high production demands. These machines can produce over 1000 bags per hour and are capable of producing bags made out of various materials such as plastic, woven fabric, and paper.

With the advancement of technology, manufacturers have included new features and functions to the carry bag making machines, which also contributes to its price. Some of the features that are available in modern-day carry bag making machines include automatic printing, automatic cutting, and folding. These features are essential for carrying out the production process without any human intervention.

In conclusion, the price of a carry bag making machine varies depending on its capacity, features, and specifications. Therefore, it’s essential to check the features of a machine before making a purchase to determine the one that suits your production requirements and fits your budget.