Benefits of Casing Manufacturer

A casing manufacturer could be the best investment for businesses that require high-quality, reliable and durable casings for their products. With the help of a casing manufacturer, one can ensure that their products are safe, hygienic and secure for the end-users. A casing manufacturer provides a variety of benefits for businesses operating in the food, pharmaceutical, medical, and other industries.

Firstly, casing manufacturers can provide customized casings that meet the unique specifications and requirements of each business. They can offer various materials, sizes, colors, and designs that can suit the needs and preferences of business owners, allowing them to create a packaging that best represents their brand.

Secondly, manufacturers can provide casings that are safe for different types of products, such as sausages, deli meats, cheeses, and other food items. They can manufacture casings that meet the food safety standards set by regulatory agencies, ensuring that the products are free from contamination and spoilage.

Thirdly, casing manufacturers can offer cost-effective solutions for businesses that need to produce a large number of products, as they can offer bulk discounts and other cost-saving measures. This way, businesses can save money while still producing high-quality products.

Fourthly, casing manufacturers can help businesses to reduce their environmental impact, by providing eco-friendly and biodegradable casings that are sustainable and recyclable.

Overall, partnering with a casing manufacturer can provide many benefits for businesses that require high-quality casings for their products. Customized casings that meet specific requirements, strict food safety standards, cost-effective solutions, and eco-friendly options are just a few benefits that manufacturers can offer. With a reliable and experienced casing manufacturer, businesses can ensure that their products are safe, secure, and appealing to customers, which can help them to grow their business and increase customer satisfaction.

Features of Casing Manufacturer

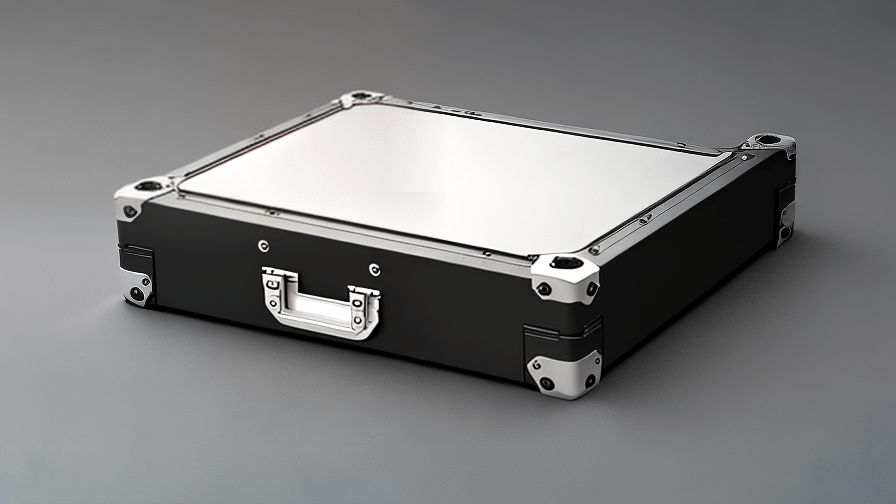

Casing manufacturers are companies that specialise in the production of protective casings for a wide range of products. These products can include electronic devices, tools, machinery and other items that require protection from the elements or physical damage. There are different types of casing manufacturers with varying levels of expertise and capabilities. Here are some key features of a reputable casing manufacturer.

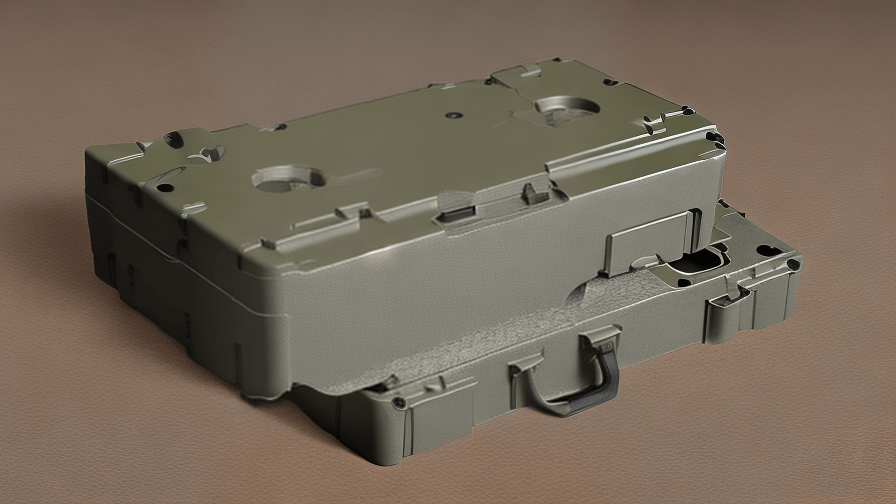

Quality and durability: A good casing manufacturer should produce high-quality cases that are durable and provide adequate protection for the products they are designed to hold. Quality control measures should be in place to ensure that every product leaving the factory meets the required standards.

Customisation and flexibility: Casing manufacturers should be flexible enough to accommodate the individual needs of clients. They should be able to provide customised solutions tailored to the specific requirements of the product and the user. They should also be able to accommodate changes in design, materials and production timelines.

Expertise and experience: A reputable casing manufacturer should have a team of experts with the necessary knowledge, skills and experience to design and produce high-quality casings. They should keep up to date with new technologies and materials to produce the best products possible.

Compliance with standards: Casing manufacturers should comply with industry standards and regulations. This includes production standards, product safety standards and environmental regulations. They should be transparent about their processes and certifications.

Proactive customer service: Casing manufacturers should be proactive in their approach to customer service. They should be able to provide prompt and effective communication to address any issues or concerns that clients might have. They should also be able to anticipate future needs and actively seek feedback to improve their products and services.

In conclusion, working with a reliable casing manufacturer can help ensure the protection of your products. A good casing manufacturer should produce high-quality casings that are durable and customised to your individual needs, compliant with industry standards, and supported by a proactive customer service team.

Various Types of Casing Manufacturer

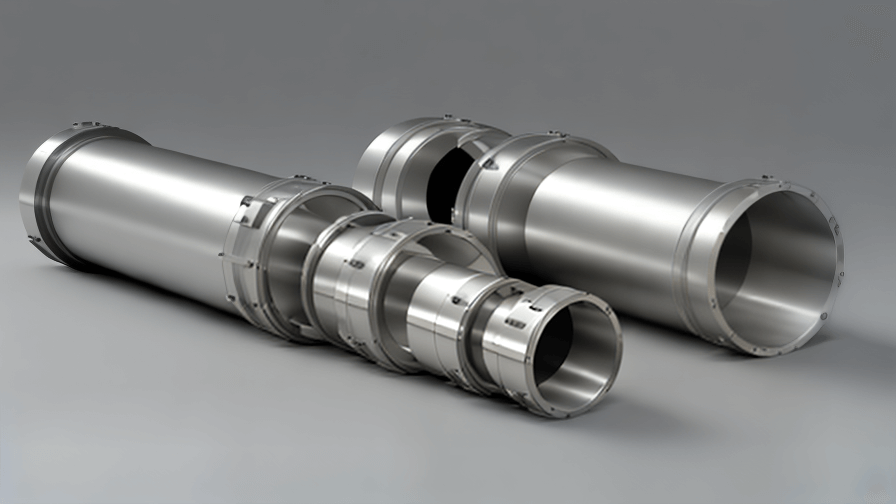

Casing is an essential component used in construction and many other industries such as oil and gas, mining, and agriculture. It is used to protect and support pipes and other materials and it plays a crucial role in the durability and safety of the project.

There are various types of casing manufacturers in the market, ranging from small local manufacturers to large international companies. Here are some of the most common types of casing manufacturers:

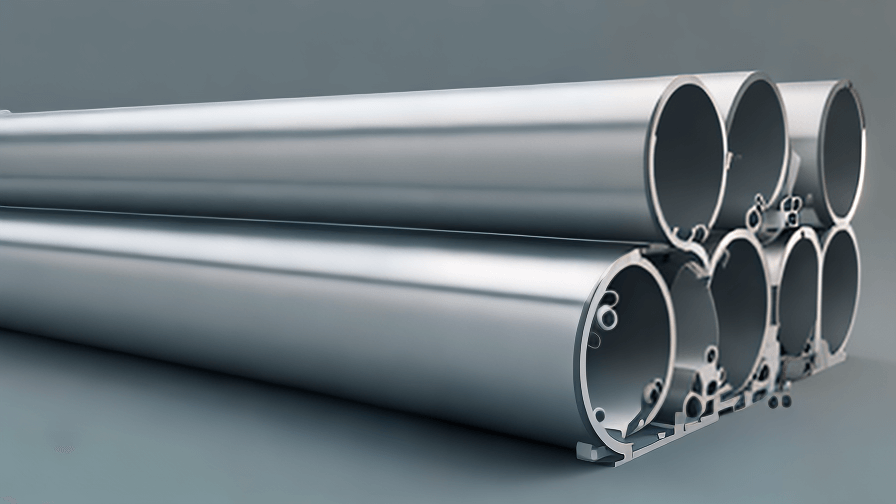

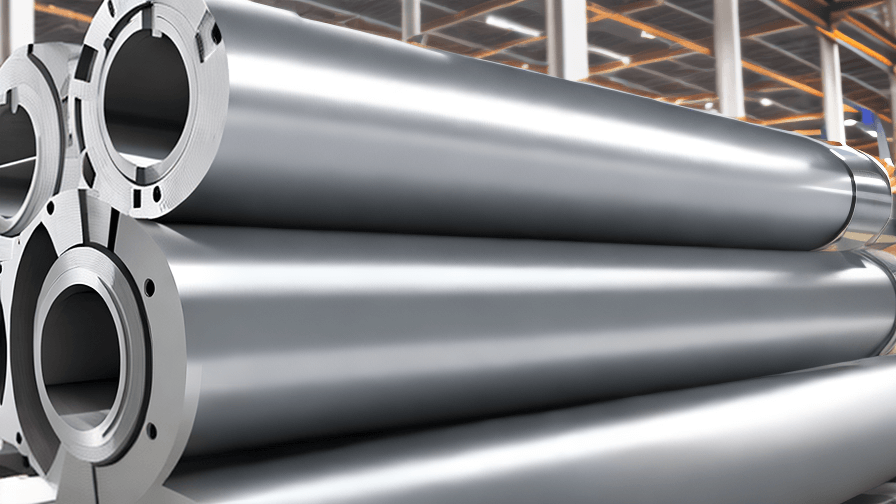

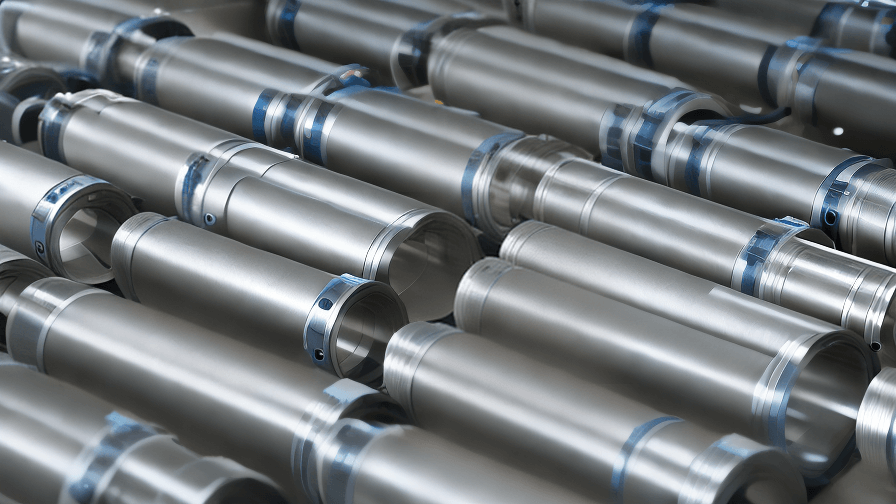

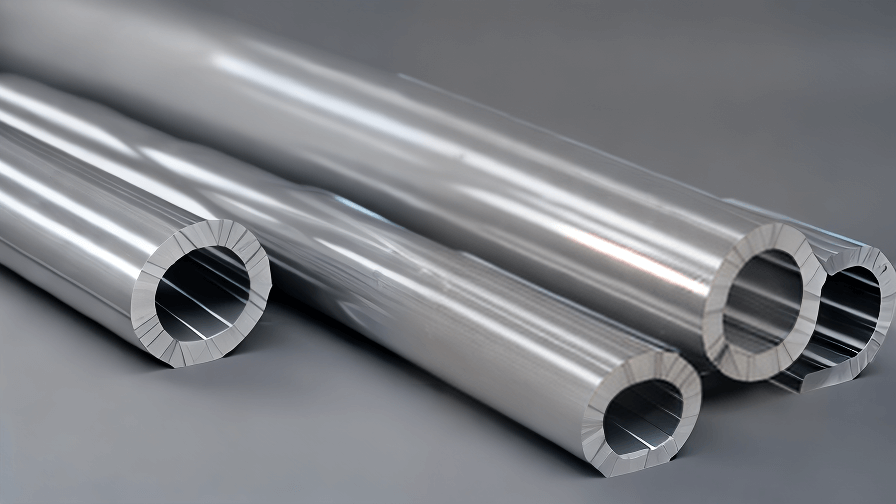

1. Steel Casing Manufacturers: Steel casing is a popular choice due to its strength and durability. Steel casing is used in a variety of industries, including construction and oil and gas. Steel casing manufacturers typically produce high-quality steel casing in various sizes and thicknesses to meet the needs of their customers.

2. PVC Casing Manufacturers: PVC casing is commonly used in irrigation, water supply, and drainage systems. PVC casing manufacturers produce high-quality, durable, and corrosion-resistant PVC pipes and casing in different diameters and thicknesses.

3. Concrete Casing Manufacturers: Concrete casing is commonly used in construction projects where strength and durability are necessary. Concrete casing manufacturers produce precast reinforced concrete pipes and casing in different sizes and shapes based on the project’s specifications.

4. Fiberglass Casing Manufacturers: Fiberglass casing is a durable and lightweight option in areas that require high resistance to corrosion. Fiberglass casing manufacturers produce Fiberglass Reinforced Plastic (FRP) pipes and casing in different sizes and thicknesses.

5. Composite Casing Manufacturers: Composite casing manufacturers produce casing made of two or more materials, usually designed to reduce costs and improve durability. Composite casing may be made of a combination of PVC, concrete, steel, or fiberglass.

In conclusion, casing manufacturers are essential to a wide range of industries, and the various types of casing manufacturers listed above specialize in producing high-quality casing materials for specific industries. With the right type of casing manufacturer, companies can ensure long-lasting and stable projects.

Applications of Casing Manufacturer

Casing manufacturer plays an integral role in several industries such as oil and gas, construction, and agriculture. The range of applications of casing manufacturer is vast and diverse, ranging from protecting valuable equipment to providing safe and secure foundation for buildings.

In the oil and gas industry, casing manufacturer is utilized to construct the borehole of oil wells. It is used to line and stabilize the well, preventing any collapse of the well walls, and preventing any contamination of freshwater sources. The casing prevents any fluids from seeping out into the surrounding rocks, soil or water.

In construction, casing manufacturer is essential to create a secure foundation. Steel casings are used in deep foundation systems to protect from water infiltration and provide increased support to the structure. Casing manufacturer also plays an important role in urban construction projects where underground utilities are present and need to be protected from damage, making the system reliable and long-lasting.

Casing manufacturer is also used extensively in agriculture industry. Plastic casing, in particular, is used to provide a moisture barrier and protect plants from harmful environmental factors such as frost. In addition, plastic casings are used to construct tunnels for the growth of special varieties of fruits and vegetables.

Furthermore, casing manufacturer also plays an important role in manufacturing of consumer goods, such as electronic devices and household appliances. It provides durability and protection to these products while ensuring that they meet the highest safety standards.

The applications of casing manufacturer are varied and widespread, from protecting valuable infrastructure to providing protective measures to people and the environment. It is a crucial component to several industries and continues to grow in importance with the development of new technologies and materials.

The Process of Casing Manufacturer

Casing manufacturing is an intricate process that involves several steps from the selection of raw materials to the finished product. The process starts with the selection of high-quality raw materials like steel coils or aluminum sheets. The selected raw materials will then undergo various processes like cutting, shaping, and painting.

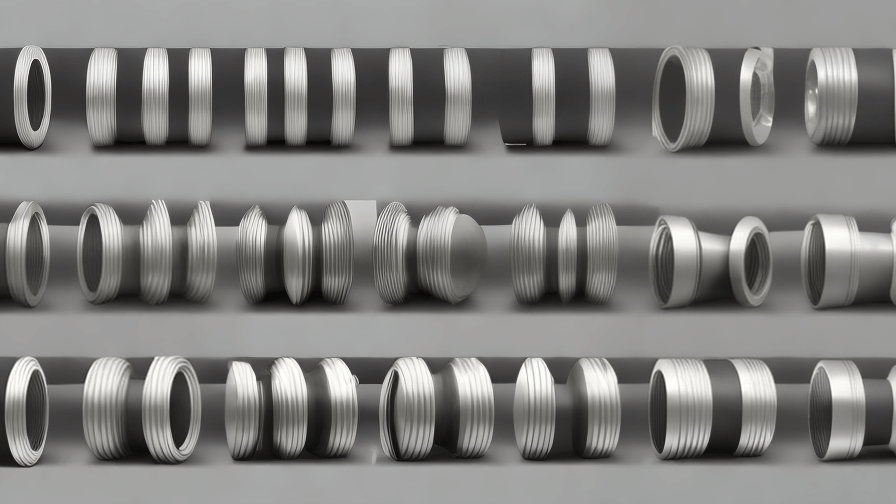

The next step is the stamping process, where metal sheets are pressed and shaped into the desired shape and size with the help of stamping dies. This process gives the casing its required shape and dimensions.

After stamping, the casing is subjected to cleaning and polishing to remove any blemishes, rust, or dirt. It is then coated with a layer of paint or powder to provide a protective layer and enhance its visual appeal.

The final stage involves the installation of necessary features and accessories like handles, locks, and hinges. This process requires precision, as any error can compromise the performance and functionality of the casing.

Quality control is an integral part of the entire manufacturing process. A series of tests are conducted to ensure that the casing meets the required standards and specifications. The finished product is then inspected for any defects or imperfections before it is packaged and shipped to the customer.

In conclusion, casing manufacturing is a complex process that requires attention to detail, precision, and expertise. The quality of the final product depends on the selection of high-quality raw materials, rigorous manufacturing processes, and strict quality control measures. This process ensures that the final product is durable, functional, and aesthetically appealing, meeting the diverse needs and demands of customers.

How to use Casing Manufacturer

When it comes to manufacturing, there are numerous parts and pieces to consider. In particular, casing plays a significant role in the process. From electronics to machinery, casing is required to protect the inner components of many devices and systems. Fortunately, there are numerous casing manufacturers that can help you acquire the proper casing for your needs. Here are some tips on how to use a casing manufacturer.

First, determine what type of casing is needed for your device or system. There are many different materials and designs available, such as plastic, metal, or rubber. Consider the environment the device or system will operate in; for example, if it will be exposed to extreme temperatures or moisture, a more durable and protective casing may be necessary.

Next, research different casing manufacturers to find one that can meet your requirements. Look for a manufacturer that has experience working with the material and design you need, and has a good reputation for quality and reliability. Don’t be afraid to ask for samples or references to ensure that the manufacturer is capable of meeting your needs.

Once you’ve selected a casing manufacturer, work with them to finalize the design of the casing and obtain a quote. Be sure to provide accurate and detailed specifications to ensure that the manufacturer can produce the desired casing. If necessary, work with the manufacturer to make adjustments and modifications to the design.

After the design is finalized and the quote is agreed upon, the manufacturer will begin producing the casing. Be sure to communicate any specific delivery or timeline requirements to the manufacturer. Once the casing is complete, inspect it to ensure that it meets your specifications and requirements.

In conclusion, working with a casing manufacturer can help ensure that your device or system is properly protected and functioning. By following these tips, you can successfully use a casing manufacturer to obtain the necessary casing for your needs.

Selecting the Ideal Manufacturer Casing Manufacturer

Selecting the ideal manufacturer casing manufacturer is essential for achieving a successful product. The casing serves as the outer cover of the product, protecting it from external factors such as dust, heat, and moisture. Choosing the right manufacturer ensures that the casing is durable, functional, and cost-effective. Here are a few factors to consider when selecting the ideal manufacturer casing manufacturer:

Experience and Expertise: Look for a manufacturer with extensive experience in the field and a proven track record of producing high-quality casings. Ensure that the company has a team of knowledgeable engineers and designers who can help you select the right material and design for your product.

Cost: Price is always a crucial factor to consider when selecting a manufacturer. Look for a manufacturer who offers affordable prices without compromising on quality. A good manufacturer will work with you to find a cost-effective solution that meets your needs and budget.

Material: The material used in manufacturing casings can vary significantly. Some of the most popular materials are plastic, metal, foam, and wood. Know the nature of your product and select a manufacturer that can help you choose the right material to protect it and make it stand out from the competition.

Customization: Different products require different types of casings. Look for a manufacturer who offers customization options to meet your specific product needs. A good manufacturer should be flexible in meeting your product requirements and have the capability of producing casings in different shapes, sizes, and colors.

Quality Control: Choosing a manufacturer who follows stringent quality control measures is essential. Ensure that the manufacturer has a robust quality control process in place, including testing and inspection of the casings to guarantee that they meet the required standards and specifications.

In conclusion, selecting the ideal manufacturer casing manufacturer is a crucial step for any product development process. Consider experience, expertise, cost, material, customization, and quality control when choosing a manufacturer to ensure that you get the best value for your money and a superior quality product.

list FAQ with answer about Casing Manufacturer

As a consumer looking to purchase a casing for your device, it’s essential to have some understanding of the options available. In this article, we will answer some of the most frequently asked questions regarding casing manufacturers, giving you all the information you need to make an informed decision.

Q: What are the most popular casing materials available?

A: The most common materials used for casings are plastic, silicone, metal and leather. Each of these materials provides varying levels of protection and style and is readily available from most casing manufacturers.

Q: What factors should I consider before selecting a casing?

A: Primarily, you should consider the level of protection you require and the style you prefer. A rugged case will offer more protection but may be less appealing aesthetically.

Q: Are all cases created equal?

A: No, not all cases are created equal. Some manufacturers may use cheaper materials or skimp on features, leading to a subpar product. It’s important to research the manufacturer before choosing a case.

Q: How can I tell if a casing is of good quality?

A: Look for reviews from other customers and check the manufacturer’s reputation within the industry. More established brands with a proven track record of delivering quality products are a safer bet.

Q: What are some reputable casing manufacturers?

A: There are many reputable manufacturers to choose from, including Otterbox, Spigen, Case-Mate, and UAG (Urban Armor Gear). Each of these manufacturers offers a range of products tailored to different devices and use cases.

In conclusion, choosing the right casing manufacturer is an essential part of protecting your device adequately. Consider your needs and preferences, research your options, and select a reputable manufacturer that delivers on quality.

Things to Consider When Purchasing Casing Manufacturer

When it comes to purchasing casing for your project, there are a few things that you should consider before choosing a manufacturer. Here are some factors to keep in mind:

1. Quality: The quality of the casing is the most important factor to consider when making a purchase. You want to make sure that the casing is made from high-quality materials and meets industry standards.

2. Price: Price is also an important factor to consider when purchasing casing. You want to make sure that you are getting a fair price for the product. However, you also want to make sure that you are not sacrificing quality for a lower price.

3. Reputation: The reputation of the manufacturer is also important to consider. You want to choose a manufacturer who has a good reputation for producing high-quality products and providing excellent customer service.

4. Availability: You want to make sure that the casing manufacturer has the products that you need in stock and can deliver them in a timely manner.

5. Customer Service: Good customer service is essential when purchasing casing. You want to choose a manufacturer who is responsive to your needs and can answer any questions you may have.

6. Customization: If you need customized casing for your project, you want to choose a manufacturer who can provide this service. Make sure to ask about their customization options before making a purchase.

In conclusion, when purchasing casing, it is important to consider the quality, price, reputation, availability, customer service, and customization options of the manufacturer. By keeping these factors in mind, you can choose a manufacturer that will provide you with the best product for your needs.

Properties of Casing Manufacturer

A casing manufacturer is a company that specializes in the production of casings for various industrial applications such as pipelines, oil & gas drilling, geothermal drilling, and mining. The properties of a casing manufacturer are critical to the quality of the casings produced.

One important property of a casing manufacturer is its manufacturing process. The best casing manufacturers invest in modern and state-of-the-art technologies to ensure that they produce the highest quality casing products that can withstand harsh environmental conditions such as extreme temperatures, high pressure, and corrosive substances.

Another property is the materials used in casing manufacturing. A reputable casing manufacturer only uses high-grade materials such as carbon steel, stainless steel, and alloy steel. These materials are carefully chosen based on the application, and the manufacturer ensures that each casing meets industry standards and specifications.

The ability to customize casing products to specific industry requirements is also an essential property of a casing manufacturer. They should be able to develop custom solutions for special applications that require unique casing properties such as high ductility, high tensile strength, and resistance to abrasion.

The quality of customer service offered by the casing manufacturer is also a critical property. A good casing manufacturer should be able to provide expert guidance on material selection, design, and installation. They should also have an efficient support team that can provide timely response and resolution to any issues that arise.

In conclusion, the properties of a casing manufacturer are crucial to the quality of their casings. The manufacturing process, materials used, ability to customize, and customer service quality are the essential properties to consider when selecting a casing manufacturer. Proper casings are critical to the functioning of various industrial applications, and it is, therefore, important to choose a reliable casing manufacturer for your business needs.

Technical Parameters Terms for Casing Manufacturer

When it comes to casing manufacturer, there are several technical parameters that need to be taken into consideration. These parameters play a crucial role in ensuring that the manufactured casing meets the required standards. Here are some of the critical technical parameters that casing manufacturers should consider.

Firstly, manufacturers should consider the tensile strength of the casing. Tensile strength refers to the maximum force that a casing can withstand without breaking or cracking. In selecting a casing material, it is essential to choose one with a high tensile strength to ensure that it can withstand the pressure and weight of the materials it is intended to contain.

Another important technical parameter to consider is the thickness of the casing. The thickness of the casing impacts its overall strength and durability. A thicker casing will be stronger and more durable as compared to a thinner casing.

Manufacturers should also factor in the yield strength of the casing material. This is the degree of deformation that a casing material can withstand before it begins to exhibit permanent deformation. Choosing a casing material with high yield strength reduces the possibility of the casing cracking or becoming compromised during use.

The Hardness of the casing is another important technical parameter that manufacturers should consider. It refers to the resistance of the casing material to indentation. A harder casing material is better because it can resist wear and tear better than a softer one.

Finally, the corrosion resistance of the casing should be considered. Corrosion can lead to the degradation of the casing, reducing its ability to contain materials effectively. Choosing a casing material with good corrosion resistance reduces the possibility of the casing becoming compromised.

To sum up, the technical parameters discussed above are essential considerations for casing manufacturers. By taking into account these factors, manufacturers can produce high quality, durable and safe casing for their clients.

Casing Manufacturer Price

A casing manufacturer’s price is an important consideration when considering potential suppliers. The cost of casing can vary significantly between manufacturers, and it is important to evaluate the cost in terms of its return on investment.

When considering casing manufacturer prices, it is important to look at the overall cost of production. This includes the cost of raw materials, labor, transportation, and overhead costs. The quality of the casing should also be taken into consideration, as lower-priced casings may not be as durable or reliable as those that are more expensive.

Even though the price of casing is crucial, it should not be the only factor to consider. The timeliness, quality, and customer service of the manufacturer are equally important. A manufacturer that offers a low price but has poor customer service or consistently misses deadlines may end up costing more in the long run.

It is also important to evaluate the value that a casing manufacturer brings to the table. This includes their ability to customize products, improve product quality, and reduce production costs. Manufacturers that are willing to work with customers and provide outstanding support can provide a significant competitive advantage in today’s global market.

In summary, when considering casing manufacturer price, it is important to look beyond the bottom line. The overall cost of production, quality of casing, and value provided should be evaluated to determine the true cost of doing business with a particular manufacturer. By taking all of these factors into account, businesses can make informed decisions that are in their best interest.