Benefits of Cement Brick Making Machine

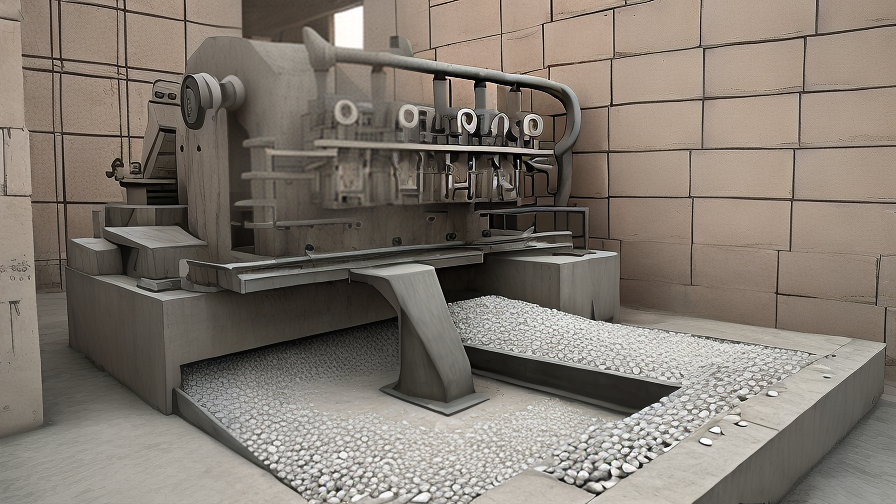

Cement brick making machines are becoming more popular in the construction industry today. They are used to make bricks and blocks that provide strength and durability to buildings. There are many benefits of using a cement brick making machine in construction that make it a must-have for any construction site.

Firstly, cement brick making machine is an efficient and effective way to produce bricks. Unlike manual brick making, cement brick making machines are automated, which makes brick production faster, easier, and consistent in quality. Also, they require less labor, and this reduces the cost of production for the brick manufacturer. This benefit makes buying a cement brick making machine an excellent investment.

Secondly, using a cement brick making machine results in higher quality bricks. The machines are designed to ensure that the bricks produced are uniform in size, shape, and texture. This consistency in quality ensures that the bricks are durable and able to withstand harsh weather conditions. It also makes it possible to produce different kinds of bricks to suit different construction needs.

Thirdly, cement brick making machines are eco-friendly. The machines use cement, sand, and water to produce bricks. Unlike traditional brick making techniques, they do not require the burning of wood or coal, which reduces air pollution. Moreover, the waste generated during production can be reused, and this eliminates the need for landfill sites.

Fourthly, cement brick making machines facilitate easy maintenance. The machines are designed to be durable and require minimal maintenance. This means that a small amount of time and money is needed to keep them operating effectively. Additionally, the machines come with safety features that make them safe to use, which reduces accidents in the workplace.

Finally, cement brick making machines are versatile, and they can make various shapes and sizes of bricks, including interlocking bricks. Also, they can produce bricks for different construction needs, such as load-bearing walls, non-load bearing walls, and boundary walls. This versatility makes them an excellent investment for any brick manufacturer.

In conclusion, cement brick making machines are gaining popularity in the construction industry due to their numerous benefits. They provide efficient and consistent production of high-quality bricks, are eco-friendly, require minimal maintenance, and are versatile. Investing in a cement brick making machine is a smart decision that can increase profits, reduce costs, and improve the quality of bricks produced.

Features of Cement Brick Making Machine

Cement brick making machines are mainly used for making various types of bricks and blocks for construction purposes. These machines are compact and efficient, using hydraulic pressure to produce high-quality bricks with minimal effort. Here are some of the features of cement brick making machines.

1. Automated Controls

Cement brick making machines come with advanced automated controls that make the manufacturing process faster, safer, and more efficient. These controls can be adjusted to meet specific production needs, ensuring flexibility and versatility.

2. High-Speed Production

Cement brick making machines can produce large quantities of bricks in a short amount of time. With the ability to produce up to 1000 bricks per hour, these machines can reduce the amount of time it takes to complete a construction project.

3. Eco-Friendly Design

Cement brick making machines operate on electricity or diesel, making them eco-friendly to use. These machines do not produce any harmful emissions and require minimal maintenance, making them a cost-effective option for sustainable construction.

4. Multiple Brick Sizes

Cement brick making machines can produce bricks in different sizes, including standard size, hollow blocks, interlocking, and paving bricks. This ability to produce various brick sizes makes these machines suitable for different types of construction projects.

5. Durable Build Quality

Cement brick making machines come with robust construction and are made from high-quality materials that can withstand heavy usage for years. These machines are built to last, ensuring that they can perform well under demanding conditions.

In conclusion, Cement brick making machines are essential tools for the construction industry. These machines provide high-quality bricks in different sizes at a faster rate and with minimal effort. With their eco-friendly and durable build quality, these machines are the perfect solution for sustainable construction projects.

Various Types of Cement Brick Making Machine

Cement brick making machines are essential tools in the construction industry. These machines help in producing high-quality cement bricks that are used in building homes, offices, schools, and other structures. There are various types of cement brick making machines available in the market, and each machine has unique features that make them suitable for different applications.

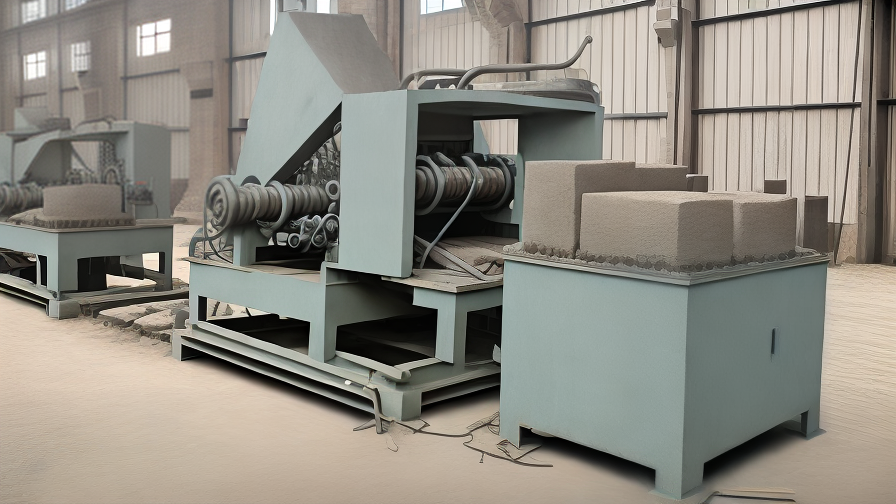

The first type of cement brick making machine is the hydraulic brick machine. This machine uses hydraulic pressure to compress the raw materials into high-density bricks. Hydraulic brick machines are durable and produce uniform bricks with precise dimensions.

Another type of cement brick making machine is the concrete brick machine. This machine uses a mixture of cement, sand, and water to produce concrete bricks. Concrete brick machines are easy to operate and are perfect for producing bricks for walls, pavements, and other applications.

The third type of cement brick making machine is the fly ash brick machine. This machine uses fly ash, a by-product of coal-fired power plants, to produce bricks. Fly ash brick machines are eco-friendly and produce bricks that are lightweight and strong.

The fourth type of cement brick making machine is the interlocking brick machine. This machine produces interlocking bricks that can be easily assembled without the need for mortar. Interlocking brick machines are perfect for producing bricks for landscaping, patios, and other outdoor applications.

Lastly, the cement brick making machine with an automatic system is becoming popular these days. This machine uses advanced technology and has a computerized system that controls the production process. This type of machine is efficient and requires less labor compared to other types of cement brick making machines.

In conclusion, cement brick making machines are available in various types and sizes, and each machine has unique features that make them suitable for different applications. With the use of these machines, producing high-quality cement bricks have become easier, efficient, and more affordable.

Applications of Cement Brick Making Machine

Cement brick making machines are becoming increasingly popular in the construction industry. They are useful in many ways and can help streamline the building process for builders and architects. There are many applications for cement brick making machines, and here are just a few:

1. Residential construction- Cement brick making machines can be used to create durable, strong bricks that are perfect for residential construction projects. These machines can make bricks of various sizes, shapes, and colors, which can be used to build homes.

2. Commercial construction- Cement bricks are also perfect for commercial construction projects. These bricks are weather-resistant, durable, and require less maintenance than other types of bricks. Cement brick making machines can produce bricks in large numbers, making them perfect for commercial buildings, such as offices, factories, and warehouses.

3. Landscaping- Cement bricks can be used in landscaping projects. They can be used to build retaining walls or create decorative features in outdoor spaces. They are perfect for creating pathways, garden borders or low walls.

4. Infrastructure- Cement brick making machines are also used in infrastructure projects. Roads, bridges, and other infrastructure projects often require bricks that are durable and strong enough to withstand the elements.

Overall, cement brick making machines have many applications in the construction industry. They are useful for creating durable and strong bricks that can be used in residential and commercial construction projects, as well as in landscaping and infrastructure projects. With the increasing demand for quality building materials, cement brick making machines are becoming an essential tool for builders and architects.

The Process of Cement Brick Making Machine

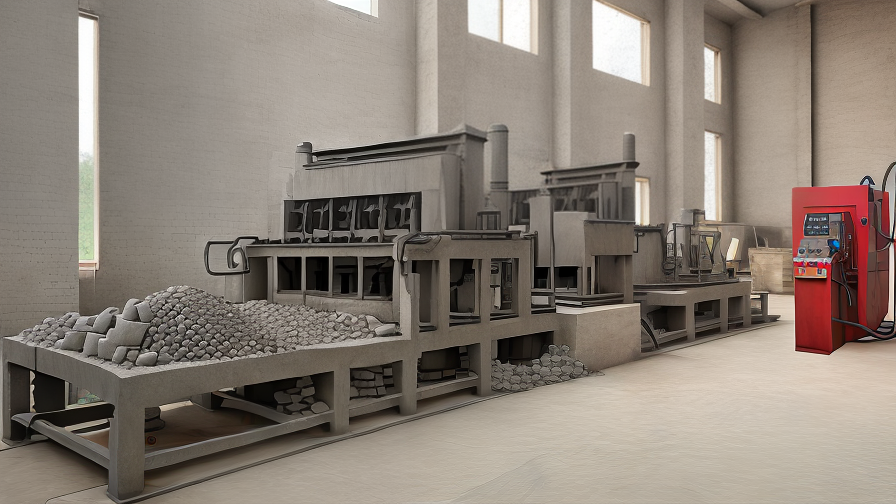

Cement brick making machines are widely used in the construction industry as they enable fast and efficient production of high-quality bricks. The process of cement brick making involves several steps, which are described below.

Step 1: Raw Materials Preparation

The first step in the process of cement brick making is preparing the raw materials. This involves mixing cement, sand, and water in the desired proportions to form a paste that will bind the materials together. The quality of the raw materials used will determine the strength and durability of the bricks.

Step 2: Molding

Once the raw materials are mixed, the paste is poured into a brick molding machine. The machine uses a hydraulic system to compress the paste into a mold and then releases it to form a brick shape. The mold can be customized to produce bricks of different sizes and shapes.

Step 3: Curing

After molding, the bricks need to be cured to gain strength and durability. This involves placing the bricks in a humid and warm environment for a few days. This allows for the chemical reaction between the cement and water to take place and for the bricks to harden.

Step 4: Drying

Once the bricks are cured, they need to be dried to remove any excess moisture and to prevent cracking during transport and storage. This is usually done in a drying chamber or under the sun.

Step 5: Packaging

The final step in the process of cement brick making is packaging. The bricks are stacked neatly and wrapped in plastic or other protective material for transport and storage.

In conclusion, the process of cement brick making involves several steps from preparation of raw materials to packaging the final product. The use of a brick molding machine enables fast and efficient production of high-quality bricks that are essential in the construction industry.

How to use Cement Brick Making Machine

Cement brick making machines are an effective way to make bricks at a large scale. If you plan on using them, there are certain guidelines you should follow to ensure optimal performance of the machine. In this article, we will discuss the steps you should take when using a cement brick making machine.

To start with, make sure that the machine is on a flat and stable surface, preferably on concrete. It’s important that the machine is level to avoid any vibration when it is operating. This will help to maintain the accuracy of the final bricks and reduce wear and tear on the machine.

Next, fill the hopper with the required amount of cement, sand, and water in the required proportions. Make sure to mix the materials thoroughly before putting them in the hopper. The machine will mix the materials further, but an initial mix will ensure a smoother process.

Once the hopper is filled with the materials, switch on the machine. The motor will generate the power required for the drum to rotate, mixing the materials. The mixture will then automatically move from the hopper through the mold.

The mold plays a vital role in creating the shape of the bricks. It’s important to choose a mold that suits your purpose – depending on the size and shape of the brick that you want to produce. Once the mixture is in the mold, the hydraulic pressure will shape the brick.

Once molding is complete, release the hydraulic pressure and open the mold. The brick will slide out of the mold and onto a tray. Leave the bricks aside to dry for a few days before using them.

Finally, after using the machine, turn it off and clean it. Make sure to remove any leftover material from the machine to ensure that it remains in a good working condition for years to come.

In conclusion, a cement brick making machine can significantly reduce the time and effort required to make bricks on a large scale. By following these simple steps, you can make the best use of the machine and ensure that it is always in optimal condition.

Selecting the Ideal Manufacturer Cement Brick Making Machine

The process of choosing the ideal cement brick making machine involves considering a range of factors. This includes the capacity of the machine, its power source, the level of automation, and the level of customization. When looking for a cement brick making machine, it is important to do some research on the various models available in the market.

One important factor to consider when selecting a cement brick making machine is its capacity. The capacity of the machine will determine the quantity of bricks that can be produced in a given time frame. It is important for the buyer to determine how many bricks they need to produce in a day or week before selecting a machine.

Another factor to consider is the power source of the machine. There are cement brick making machines that are powered by electricity, diesel, or gasoline, and the choice will depend on the availability of the power source in the area where the machine will be operated. Electric-powered machines are more environmentally friendly but are only suitable in areas where electricity is stable and readily available.

Automation is another important factor to consider when choosing a cement brick making machine. Fully automated machines are more expensive but are more efficient in terms of production time and labor. Semi-automated machines require more labor but are more affordable.

Customization is also a crucial aspect to consider when selecting a cement brick making machine. The machine should be customizable to produce different sizes and shapes of bricks. The machine should also be adaptable to different types of soils.

In conclusion, selecting the right cement brick making machine requires careful consideration of various factors such as capacity, power source, automation, and customization. The right machine will ensure efficiency, productivity, and profitability in the brick-making business.

list FAQ with answer about Cement Brick Making Machine

Cement brick making machines are highly innovative machines that have revolutionized the construction industry. They are highly efficient, durable, and eco-friendly, making them the perfect choice for individuals looking to get into the brick-making business. Here are some frequently asked questions and answers that will help you understand more about Cement Brick Making Machines.

Q: What is a Cement Brick Making Machine?

A: A Cement Brick Making Machine is a machine that produces cement bricks. It is a machine that uses pressure to ensure that the materials are well mixed and that the bricks are formed.

Q: What is the raw material used in making Cement Bricks?

A: The raw materials used in making Cement Bricks are cement, sand, and water. The proportion of each material will depend on the desired strength and quality of the bricks.

Q: What is the capacity of Cement Brick Making Machines?

A: The capacity of a Cement Brick Making Machine depends on its size and model. Small machines can produce around 4400 bricks per day, while larger machines can produce up to 64,800 bricks per day.

Q: What is the cost of a Cement Brick Making Machine?

A: The cost of a Cement Brick Making Machine varies depending on the size, capacity, and technology used. Generally, prices for small manual machines start at $1000, while fully automatic machines can cost up to $200,000 or more.

Q: Can you make different types of bricks with a Cement Brick Making Machine?

A: Yes, you can make different types of bricks with a Cement Brick Making Machine. By changing the mold, you can create various shapes and sizes of bricks.

In conclusion, Cement Brick Making machines are a great investment for anyone looking to get into the brick-making business. With their efficiency, durability, and eco-friendliness, they are the perfect solution for producing top-quality bricks at a reasonable cost.

Things to Consider When Purchasing Cement Brick Making Machine

Cement brick making machines are essential for construction and infrastructure development. However, purchasing the right machine requires thorough considerations to guarantee efficiency, quality, and durability. The following are some of the key factors to keep in mind when selecting the best cement brick making machine.

First of all, consider the production capacity of the machine. It should match your production needs as well as to cater to future expansion plans. Determine the machine’s maximum output capacity and ensure that it aligns with your goals.

Secondly, examine the cost of the machine. Cement brick making machines come at different prices depending on their features, performance, and brands. Besides the upfront cost, consider the maintenance and repair cost implications over time.

Thirdly, evaluate the machine’s specifications concerning raw materials such as cement, sand, and water. Check the machine’s compatibility with different raw materials, their quality, and availability in the local market.

Fourthly, consider the machine’s power consumption and its impact on energy bills. Opt for machines with energy-saving features like automatic shutdown when idle and electric motor products with high-efficiency levels.

Another crucial aspect to consider is the machine’s reliability and durability. Check the machine’s build and material quality to ensure it can withstand heavy-duty usage and weather exposure.

Lastly, weigh the after-sales support from the manufacturer. They should be responsive to breakdowns, spare part requests, and general technical support.

In summary, purchasing a cement brick making machine requires proper research and analysis. Evaluate the production capacity, cost, raw materials specifications, power consumption, reliability and durability, and after-sales support before making a purchase.

Properties of Cement Brick Making Machine

A cement brick making machine is a tool used to make bricks from various raw materials like cement, sand, gravel, and water. These machines are ideal for producing high-quality bricks that are stronger and more durable than traditional bricks. The machine is easy to operate and has several properties that make it efficient in brick making:

1. High production capacity: The cement brick making machine can produce a large number of bricks in a short amount of time. This property makes the machine ideal for large-scale production of bricks.

2. Low energy consumption: The machine requires minimal energy to operate, making it an efficient option for brick production. This property makes the machine ideal for small businesses and individuals who want to produce bricks without incurring high energy costs.

3. Easy operation: The cement brick making machine is easy to operate and requires minimal training. The operator only needs to load the raw materials into the machine and press a button to start the production process.

4. Durable construction: The machine is made of high-quality materials that are resistant to wear and tear. This property ensures that the machine can withstand heavy-duty use for an extended period, making it a reliable option for brick production.

5. Versatility: The cement brick making machine can produce different types of bricks, including interlocking bricks, paving bricks, and solid bricks. This property makes the machine ideal for use in construction projects that require different types of bricks.

In conclusion, the cement brick making machine is an excellent tool for brick production. Its high production capacity, low energy consumption, easy operation, durable construction, and versatility make it an efficient and reliable option for brick making. Individuals and businesses looking to produce high-quality bricks should consider investing in a cement brick making machine.

Technical Parameters Terms for Cement Brick Making Machine

When it comes to choosing a cement brick making machine, it’s crucial to have a basic understanding of technical parameters. These parameters are essential for ensuring that the machine performs optimally, and that it meets your specific needs. Let’s take a look at some of the key technical parameters you need to know.

Production Capacity: This parameter refers to the number of bricks the machine can produce per hour. It’s important to choose a machine that has a production capacity that aligns with your production needs.

Power Rating: This refers to the amount of power consumed by the machine. It’s generally expressed in kilowatts (kW). Choose a machine that has a power rating that you can conveniently afford and that your facility can accommodate.

Vibration Force: This parameter refers to the force that the machine uses to vibrate the mould. This force is directly linked to the quality and durability of the bricks produced. A higher vibration force means that the bricks will be more compact and have fewer defects.

Moulding Cycle: This refers to the time it takes for the machine to complete one moulding cycle, which includes filling, pressing, and demoulding. The shorter the moulding cycle, the more bricks the machine can produce in a day.

Brick Size: Different machines are designed to produce bricks of different sizes. Ensure that you choose a machine that can produce the size of bricks you need.

Weight: This parameter refers to the total weight of the machine. It’s advisable to choose a machine that’s easy to move around and that can be easily transported from one location to another.

In conclusion, understanding the technical parameters of the cement brick making machine is crucial when selecting the right one for your business. With the above parameters in mind, you can choose a machine that suits your budget, production needs, and operational space.

Cement Brick Making Machine Price

A cement brick making machine is a critical investment for any construction business. It is a machine that helps to produce cement bricks in large quantities with minimal effort. The machine is designed to use natural materials such as cement, sand, and water to create bricks of various sizes and shapes.

One of the most significant factors that influence the purchase of a cement brick making machine is the price. The price of a cement brick making machine varies depending on various factors, such as the model, capacity, and features. Generally, the prices range from $1000 to $30,000.

The size of the machine is one of the primary determinants of the price. The larger the machine, the higher the price. The larger capacity machines can produce up to 5000 bricks per hour, while the smaller capacity machines can produce up to 1000 bricks per hour.

The level of automation is another factor that determines the price of the machine. Automated machines are more expensive than their manual counterparts. The automated machines require minimal human intervention and are more efficient, producing higher quantities of bricks.

The features of the machine also influence the price. Some of the features that may affect the price include the number of molds, cement feeding system, and the quality of the machine’s components.

In conclusion, the price of a cement brick making machine varies based on several factors. It is essential to compare different machines’ prices, models, and features to make an informed decision for your business. Investing in a high-quality machine is critical, as it will help you save time and effort while producing high-quality cement bricks.