Knowledge about Centrifugal Dryer

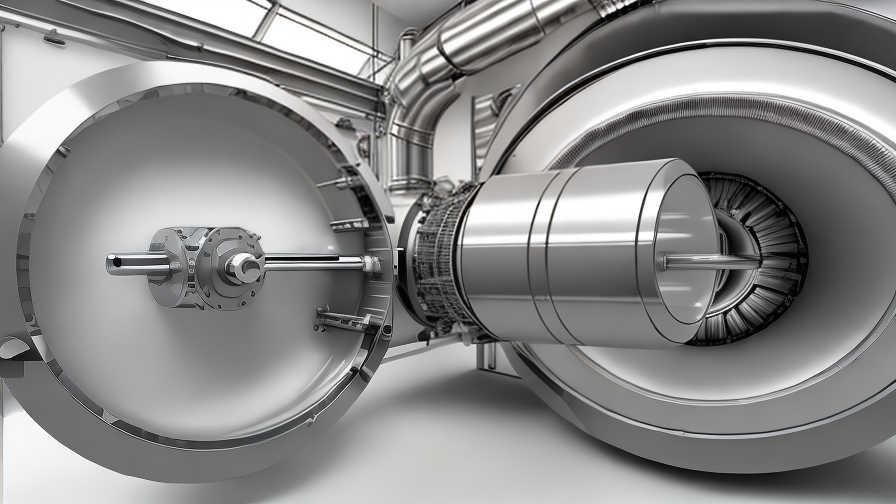

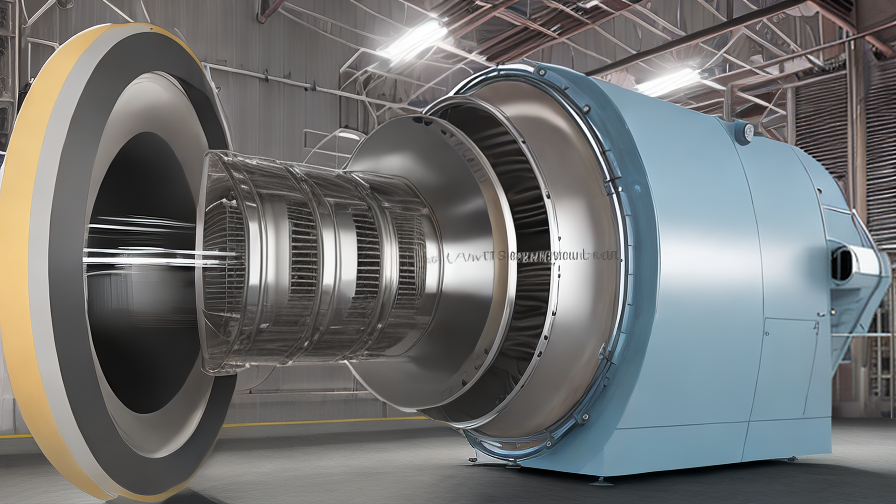

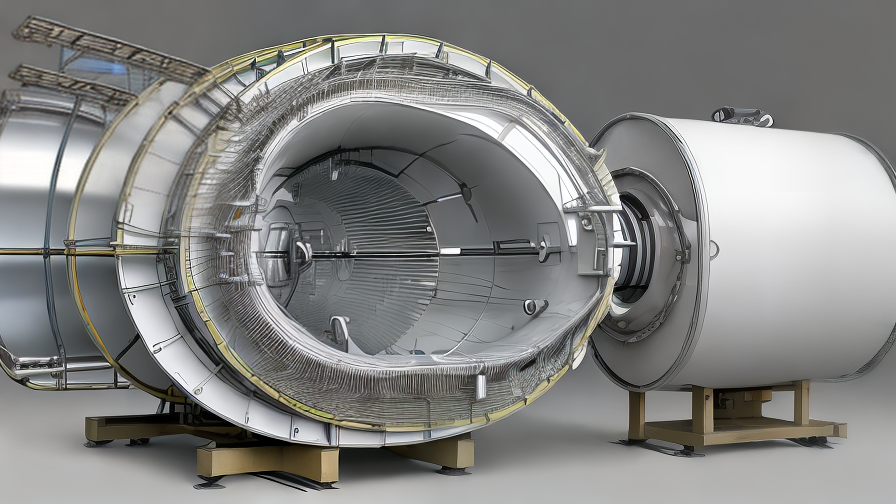

Centrifugal dryers are machines that are used to separate moisture from various materials such as plastics, metals, and paper products. They use a high-speed spinning action to force moisture out of the materials and onto a rotating drum before being discharged from the machine.

To best understand centrifugal dryers, you must first know the difference between a centrifugal dryer and a regular dryer. Centrifugal dryers use a different process to remove moisture from materials. Unlike regular dryers that use heat and air to evaporate moisture, centrifugal dryers rely on a spinning action to force water out of the materials, thus providing a more effective outcome in terms of drying efficiency.

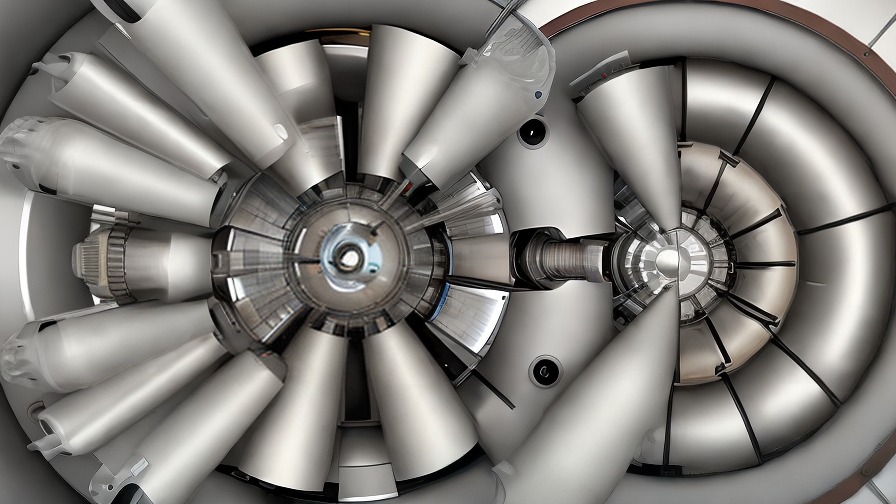

A centrifugal dryer works by loading the wet materials into its chamber, then it starts spinning, forcing the water outward from the material and onto the drum walls. Once the moisture level reaches a certain point, it is thrown off the drum by the spinning force, leaving behind the dry material.

Centrifugal dryers are used in various industries, including plastic recycling, metal finishing, and printed circuit board manufacturing. The type of centrifugal dryer used will depend on the specific materials being processed, and the amount of moisture that needs to be removed.

During the operation of a centrifugal dryer, various factors can affect its efficiency, including the speed of the drum, the load capacity, and the shape of the drum. It is, therefore, essential to understand how these factors impact the dryer’s performance and take necessary steps to optimize the process.

In conclusion, knowledge of centrifugal dryers is essential for industries that rely on drying efficiency to improve their products’ quality and production speed. With the right understanding of centrifugal dryers, organizations can select the right dryer for their application, optimize their drying process, and ensure maximum efficiency.

Various Types of Centrifugal Dryer

A centrifugal dryer is a type of industrial freezer or dryer that separates liquids from solids by the use of centrifugal force. They are available in many types and have several applications. Let’s take a look at some of the types of centrifugal dryers.

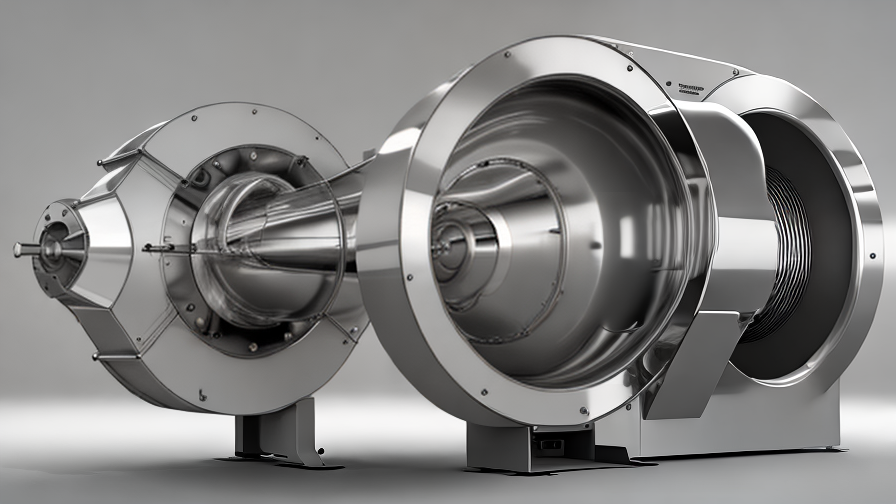

1. In-line centrifugal dryers: These types of dryers are used for continuous drying applications where a large quantity of product is processed.

2. Batch centrifugal dryers: These dryers are used for drying small batches of products such as food, plastics, and chemicals.

3. Direct drive centrifugal dryers: In this type of centrifugal dryer, the motor is directly attached to the impeller, which spins at high speeds to remove the moisture from the product.

4. Belt-driven centrifugal dryers: These dryers have a belt that drives the impeller. They can be used for drying a variety of products, including textiles, grains, and pharmaceuticals.

5. High-speed centrifugal dryers: These dryers operate at higher speeds than other types of centrifugal dryers, which increases the amount of moisture that can be removed from the product.

6. Low-end centrifugal dryers: These types of dryers are used for drying delicate products that cannot withstand high speeds or harsh forces.

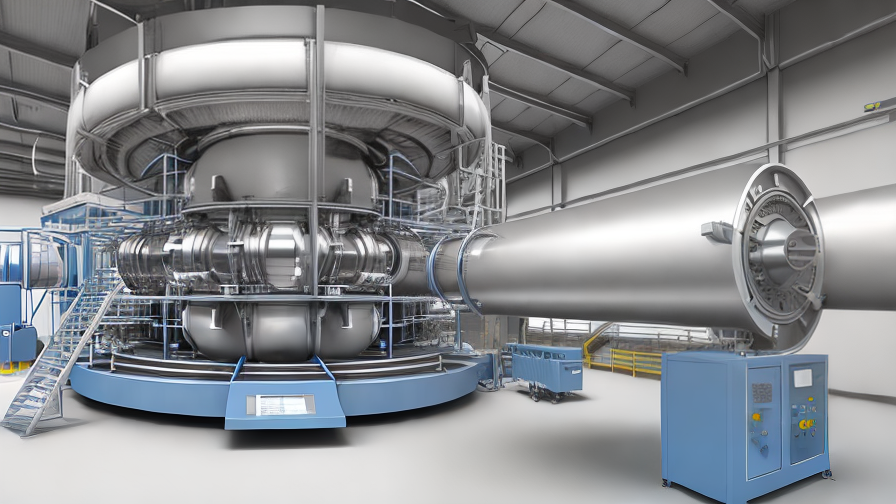

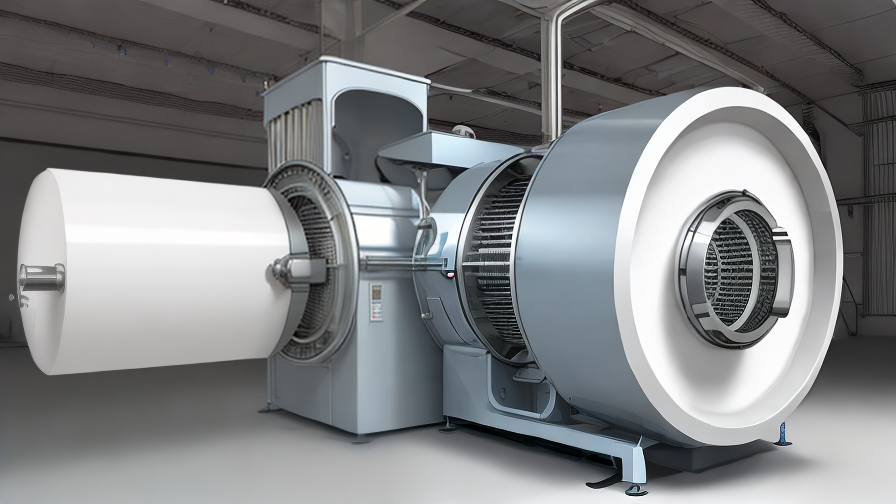

7. Industrial centrifugal dryers: These dryers are used in industrial settings and are designed for heavy-duty use.

Centrifugal dryers are used in a variety of industries, including food processing, chemical processing, and textiles. They are a popular choice for industrial applications because they are efficient and can handle large quantities of product. They are also easy to clean and maintain, making them a cost-effective choice for businesses. With so many types of centrifugal dryers available, it’s important to choose the right one for your product to ensure the best results.

FAQ sourcing Centrifugal Dryer manufacturer from China

Centrifugal dryers are widely used in various industries to dry and separate products. If you are looking for a reliable centrifugal dryer manufacturer from China, you may have some questions in mind. Here are some frequently asked questions (FAQ) and their answers that can help you source a centrifugal dryer manufacturer from China.

Question: How do I find a trustworthy centrifugal dryer manufacturer from China?

Answer: You can search online for centrifugal dryer manufacturers from China and check their reviews, certificates, and customer feedback. You can also attend industry events and exhibitions in China to meet with manufacturers face-to-face and inspect their products.

Question: What types of centrifugal dryers are available from Chinese manufacturers?

Answer: Chinese manufacturers offer a wide range of centrifugal dryers, including top-discharge, bottom-discharge, cone-shaped, and vertical centrifugal dryers. They can also customize a centrifugal dryer based on your specific needs.

Question: What materials are used to make centrifugal dryers from China?

Answer: Chinese centrifugal dryers are generally made of stainless steel, carbon steel, or other materials that are suitable for the product being dried.

Question: What is the lead time for centrifugal dryers from China?

Answer: The lead time may vary depending on the type and size of the centrifugal dryer and the manufacturer’s production capacity. Generally, the lead time can range from 30-60 days.

Question: What safety features are included in centrifugal dryers from China?

Answer: Chinese manufacturers usually include safety features such as emergency stop buttons, safety interlocks, and safety guarding to ensure the safety of operators.

In conclusion, sourcing a centrifugal dryer manufacturer from China can be a great way to get high-quality and cost-effective products. By asking the above questions, you can find a trustworthy manufacturer that meets your specific needs.

Applications of Centrifugal Dryer

Centrifugal dryers are special types of machines that are commonly used in industrial settings to remove excess moisture from various materials such as plastic pellets, textiles, and even food products. They are designed to rotate at high speeds, using centrifugal force to remove moisture and achieve a dry end product. With a wide range of applications across several industries, centrifugal dryers have proven to be essential in ensuring the quality and durability of products.

One of the most common applications of centrifugal dryers is in the plastic industry. Plastic pellets, which are used to create a variety of products such as water bottles, automotive parts, and toys, often require a strict level of moisture control to ensure optimal processing performance. Centrifugal dryers help to eliminate excess moisture from the pellets, which allows for better adhesion and strength of the final product.

Centrifugal dryers are also commonly used in the textile industry. Cotton, wool, and synthetic fibers must be dried thoroughly before processing to prevent mold formation and to ensure their ability to dye correctly. Centrifugal dryers can be used in various stages of the textile processing, from removing excess water after washing to drying yarn before weaving.

In the food industry, centrifugal dryers are used for the fast and efficient drying of products such as fruits and vegetables. This process helps to increase the shelf life of these products and, in some cases, improve their quality. In addition, the removal of excess water from fruits and vegetables can lead to a decrease in transportation and storage costs.

In conclusion, the applications of centrifugal dryers are vast and diverse. They are a crucial aspect of industrial manufacturing, allowing for the removal of excess moisture and the optimization of product quality. From plastic pellets to food products, they are used in many industries as a critical component of the manufacturing process.

Manufactured Products made of Centrifugal Dryer

Centrifugal dryers are machines used to remove moisture or water from wet solid materials. These dryers work by spinning a basket holding the wet materials, allowing the centrifugal force to separate the moisture from the solids. The result is dry materials that can now be used for their intended purposes.

One of the essential applications of centrifugal dryers is the manufacturing industry. Many products are made from centrifugal dryers, including plastic pellets, pills, and pharmaceuticals. In the manufacture of these products, the significance of centrifugal dryer cannot be overemphasized.

Centrifugal dryers are commonly used in food production, particularly for the preservation of fruits and vegetables. These materials, after being harvested, contain high water content, which can hasten spoilage. The drying process using centrifugal dryer eliminates the moisture and preserves the food for longer shelf life.

In the textile industry, centrifugal dryers are used for drying fibers like wool and cotton. In the process, the spinning helps to remove the water from the fibers, reducing the amount of time needed for drying.

Also, centrifugal dryers play an essential role in the recycling industry for the processing of used plastics. The plastics are shredded into smaller pieces, washed and rinsed, and then dried using the centrifugal dryer machine.

Another application of centrifugal dryers is in the production of ceramics. After molding, the wet ceramics are dried using centrifugal dryers, which help to remove the moisture and increase the strength of the material.

In conclusion, centrifugal dryers are critical machines in the manufacturing industry. They have a broad range of applications in the production of various products, including plastic pellets, pills, and textile fibers. The drying process using centrifugal dryer machines increases efficiency, reduces waste, and improves overall productivity.

The Evolution history of Centrifugal Dryer

Centrifugal dryers, also known as spin dryers, are devices that are used to remove moisture or liquids from solid materials using centrifugal force. The technology of centrifugal dryers can be traced back to the early 20th century when the basic concept was first introduced. The first centrifugal dryers were used in the textile industry to dry large quantities of spun yarn.

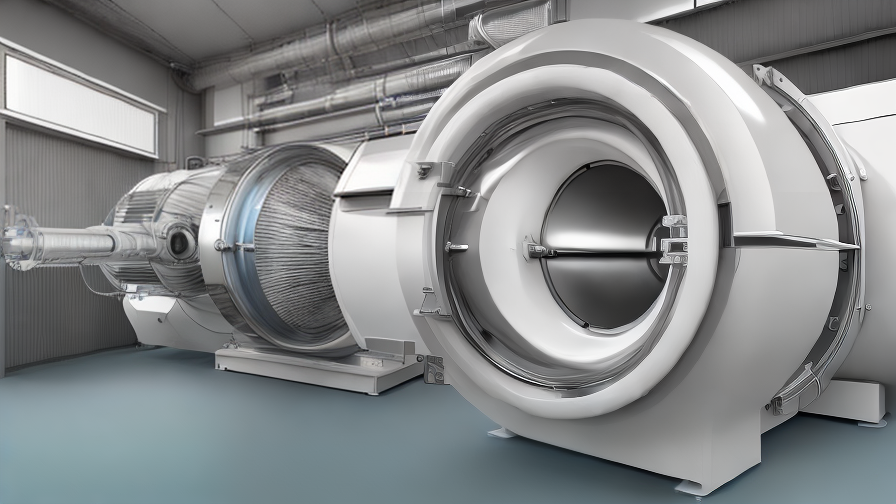

Over the years, as technology advanced, centrifugal dryers evolved to incorporate more advanced features and become more efficient in their operation. From the early models that operated at low speeds, the design of centrifugal dryers has developed to incorporate high-speed motors that can spin at high rates of speed, leading to faster drying times and increased productivity.

Today, centrifugal dryers are used in various industries, including the food and beverage, chemical, and pharmaceutical industries. Some of the latest models even come with advanced features such as programmable controls, automated loading and unloading systems, and even explosion-proof designs.

As the demand for centrifugal dryers continues to grow, manufacturers are constantly working to improve the design of these machines. Some of the latest innovations in centrifugal dryer technology include the use of improved materials to increase durability, the incorporation of energy-efficient motors to reduce operating costs, and the utilization of advanced sensors and control systems to improve overall efficiency.

In conclusion, the evolution history of centrifugal dryers has been marked by a steady progression in technology and design. From the early models that were designed for use in textile mills to the advanced machines of today, the journey has been marked by many milestones. As the demand for centrifugal dryers continues to grow, the future looks bright for these versatile and efficient machines.

The Process of Centrifugal Dryer

Centrifugal dryers are a type of machine that uses centrifugal force to remove moisture from materials. They are commonly used in manufacturing and production environments where materials need to be dried quickly and efficiently.

The process of a centrifugal dryer typically involves loading the material to be dried into the machine’s drum or basket. The drum is then rotated at high speeds, generating centrifugal force that causes the material to be pressed against the sides of the drum.

As the material is pressed against the sides of the drum, the moisture is squeezed out and forced to the outside of the drum. This moisture then collects in a separate chamber or is expelled from the machine, leaving the material dry and ready for further processing.

Centrifugal dryers can be used to dry a wide variety of materials, including plastics, metal parts, and textiles. They are often used in conjunction with other equipment, such as washing machines, to remove excess moisture from materials before they are further processed.

One of the key advantages of centrifugal dryers is their speed and efficiency. They can dry materials much faster than other types of dryers, and can often do so with less energy consumption. This makes them a cost-effective option for many manufacturing and production applications.

However, there are some limitations to using centrifugal dryers. They may not be suitable for all types of materials, and may not be able to remove all moisture in certain cases. Additionally, some materials may become damaged or distorted during the drying process if they are not handled properly.

Despite these limitations, the process of centrifugal drying is an effective and widely used method for removing moisture from materials in a variety of industrial applications. By harnessing the power of centrifugal force, these machines can quickly and efficiently dry materials to a level of readiness for further work.

Benefits Advantages of Utilizing Centrifugal Dryer

Centrifugal dryer is a device that is used for quick drying of wet materials. It works by spinning the wet materials at high speed to remove excess moisture. Centrifugal dryer is commonly used in industrial and commercial settings because of its effectiveness and efficiency.

One of the main benefits of utilizing centrifugal dryer is that it saves time. It can dry materials in a matter of seconds, which makes it ideal for organizations that have a high volume of materials that need to be dried quickly. This saves time and allows organizations to increase their output.

Another advantage of using a centrifugal dryer is that it helps to maintain the quality of the material being dried. Since centrifugal dryer uses high speed spinning to remove moisture, there is little to no heat generated in the process. This ensures that the material being dried is not damaged in any way, which preserves its quality.

Centrifugal dryer is also cost-effective. Since it dries materials at a high speed, organizations can save on energy costs. They can also save on labor costs since the machine does not require a lot of attention. This makes it an ideal choice for organizations that want to reduce operational costs.

Lastly, centrifugal dryer is versatile. It can be used to dry a wide range of materials including vegetables, fruits, grains, and even fragile items such as glass bottles. This makes it a valuable investment for organizations that operate in different industries.

In conclusion, centrifugal dryer is a valuable investment for organizations that want to save time, preserve the quality of their materials, reduce operational costs, and increase output. Its effectiveness, efficiency, and versatility make it a must-have device for organizations that prioritize speed and quality in their operations.

Disadvantages Centrifugal Dryer

Centrifugal dryers are commonly used in industrial applications to remove moisture from various substances. While these machines are efficient and effective, they do have some disadvantages that users should be aware of.

One major disadvantage of centrifugal dryers is that they can be expensive to operate. These machines require a lot of energy to function, which can result in high energy bills. Additionally, they require regular maintenance to keep them operating at peak efficiency, which can increase maintenance costs.

Another major disadvantage is that centrifugal dryers can damage delicate materials. The high centrifugal force generated by these machines can cause items that are sensitive or fragile to become distorted or even break apart. This can result in a higher rate of damaged or unusable materials, which can be costly for businesses.

Additionally, centrifugal dryers can be noisy and create a lot of vibration, which can be a concern in certain settings. They may require specialized installation to minimize these effects or may need to be located in an isolated area away from other equipment or personnel.

Lastly, centrifugal dryers may not be suitable for all materials or processes. Some materials may not be able to withstand the high speed and force generated by these machines, while others may require a different drying method altogether. It may be necessary to use different equipment or methods for certain materials or processes.

Overall, while centrifugal dryers are efficient and effective for many industrial applications, they do have some significant disadvantages that should be considered before selecting them as a drying method. It’s important to carefully evaluate the needs of your process and materials to determine if a different drying method may be more suitable.

Selecting the Ideal Manufacturer Centrifugal Dryer

When it comes to selecting a manufacturer centrifugal dryer, there are several essential factors that one should consider before making a final choice.

First and foremost, it’s crucial to assess the manufacturing capacity of the dryer. This would include the drying time, drying capacity, and the type and volume of materials that the dryer can handle. Understanding this information will assist in determining the best machine for your drying needs.

Next, check the quality of the dryer’s construction. It’s important to have a machine that is both durable and efficient. Ensure that the materials used to manufacture the centrifugal dryer are of high quality, and all components are assembled with precision.

The dryer should also be user-friendly and easy to operate. You should choose a machine that comes with a simple and clear manual that guides the user through all the processes. It should also have a user-friendly control panel that makes it easier to adjust for different materials or drying settings.

Another vital factor to consider is the reliability and productivity of the manufacturer. Be sure to conduct thorough research and read reviews from previous customers to get a sense of the manufacturer’s reputation. It’s important to choose a manufacturer who can provide excellent after-sale support and customer service.

Finally, cost is an essential factor to keep in mind when selecting a manufacturer centrifugal dryer. You want to get the best deal while ensuring that you don’t compromise on quality. Compare offers from different manufacturers to get a sense of market prices.

In conclusion, choosing the right manufacturer centrifugal dryer involves careful consideration of the dryer’s manufacturing capacity, quality of construction, ease of operation, reliability and productivity of the manufacturer, and cost. With these factors in mind, you’ll be able to choose a solution that meets your unique drying needs.

Things to Consider When Purchasing Centrifugal Dryer

When selecting a centrifugal dryer, there are a few important factors to consider. First, consider the type of material you will be using the dryer for. Different materials have different drying requirements. For example, delicate fabrics and materials like silk may require a gentler drying process than heavy-duty metal parts.

The size and capacity of the centrifugal dryer also play a crucial role in selecting the right one. The size of the dryer should match the volume of materials you need to dry. It is essential to note that oversizing the dryer may not only be a waste of resources, but it may also lead to poor drying performance.

Consider the drying speed of the centrifugal dryer. This factor determines the amount of time it will take to dry your materials. A faster drying speed may lead to quicker turnaround times, but it may also contribute to wear and tear of the dryer in the long run.

The ease of use is another vital factor to consider. Choose a centrifugal dryer that is easy to operate and maintain. Additionally, choose a dryer with user-friendly controls that are easy to understand and use.

When it comes to the cost of the centrifugal dryer, consider the initial cost, as well as the ongoing expenses. Determine the maintenance costs, energy usage costs, and spare parts costs. This will help you get a rough estimate of the total cost of owning and operating the dryer.

Lastly, choose a centrifugal dryer from a reputable manufacturer. This will ensure that you get a high-quality dryer that is reliable and durable. Additionally, choose a manufacturer that offers after-sales support, including installation, training, and repair services.

In conclusion, selecting the right centrifugal dryer is crucial to ensure efficient and effective drying of your materials. By considering the factors mentioned above, you can choose a dryer that meets your specific needs and requirements.

Properties of Centrifugal Dryer

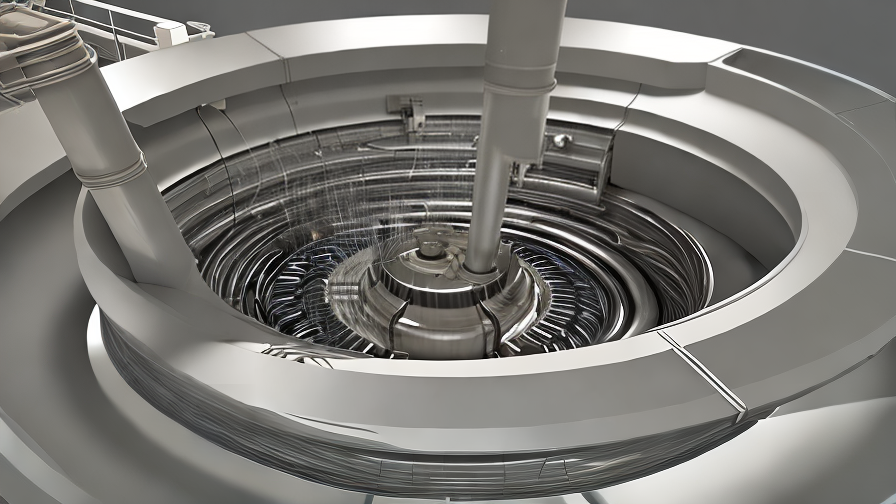

A centrifugal dryer is one of the most popular types of dryers used in various industries. It is a machine that uses centrifugal force to dry materials quickly and efficiently. The dryer consists of a drum that rotates at a high speed to separate moisture from the materials being dried.

There are several properties of centrifugal dryers that make them ideal for use in various industries. For instance, these types of dryers are very efficient in drying moisture from materials. Since the drum rotates at a high speed, it creates centrifugal force that helps to extract moisture from the materials, leaving them dry.

Another property of centrifugal dryers is that they can be used to dry a wide range of materials. They are particularly suitable for use in industries that deal with powders, granules, and other small-sized materials that require fast and efficient drying.

Furthermore, centrifugal dryers are very energy-efficient compared to other types of dryers such as tumble dryers. They can dry materials very quickly, which means they consume less energy, resulting in lower energy bills.

In addition, centrifugal dryers are very easy to maintain. They have very few moving parts, which means there is minimal wear and tear. This reduces the need for frequent maintenance, allowing the dryer to operate for long periods without any issues.

Finally, centrifugal dryers are very versatile machines. They can be configured to suit different drying requirements, including temperature and moisture level. This means they can be used to dry materials that require specific drying conditions, making them very useful in various industries.

In conclusion, centrifugal dryers are very efficient, versatile, and easy to maintain machines that are ideal for use in various industries. They can dry materials quickly and effectively, making them an essential component of any manufacturing process that requires drying of materials.

How to use Centrifugal Dryer

Centrifugal dryer is a popular device used to remove moisture from wet substances. It is a simple and easy-to-use machine that works by spinning at high speeds to force out water from the material being dried.

To use a centrifugal dryer, follow these simple steps:

Step 1: Load the material to be dried into the machine’s drum. Make sure not to overload the drum as this can affect the drying process.

Step 2: Close the lid and switch on the machine. Set the timer and temperature according to the material being dried. It is important to follow the manufacturer’s instructions for optimal usage.

Step 3: As the machine spins, the moisture in the material is pushed out towards the walls of the drum. The water is then collected in the bottom of the machine and drained through a tube.

Step 4: Once the drying cycle is complete, switch off the machine and remove the dried material from the drum.

There are several benefits of using a centrifugal dryer. It is a fast and efficient method of drying, producing high-quality results in a short period of time. It is also a cost-effective way of drying large quantities of material and can be used in various industries such as food processing, textile manufacturing, and printing.

In conclusion, using a centrifugal dryer is a simple and effective method of removing moisture from substances. By following the above steps, you can achieve optimal drying results and maintain the efficiency of your machine.

Glossary Terminology Terms for Centrifugal Dryer

Centrifugal dryers are a critical part of many industries, from textile manufacturing to pharmaceuticals to food processing. As with any complex technology, though, there is a lot of complicated terminology associated with these machines. In this article, we’ll go over a few of the most important terms to know about centrifugal dryers.

First and foremost, it’s essential to understand the basic operating principles of a centrifugal dryer. These machines work by spinning the contents of a drum or basket at high speeds, using centrifugal force to remove moisture or other volatile materials. One of the key variables involved in this process is the “acceleration rate,” which determines the g-forces that the materials inside the drum will be subjected to.

Another important term to understand is “airflow rate.” Centrifugal dryers rely on a stream of hot air to evaporate moisture, and the airflow rate determines how much of this air is being directed through the drum. When choosing a centrifugal dryer for a particular application, it’s important to consider not just the airflow rate, but also the temperature and humidity of the air being used.

Other terms to be familiar with include “drying time,” which refers to the amount of time it takes for a given material to be fully dried in the centrifugal dryer; “humidity sensor,” which is a device that detects the amount of moisture in the air leaving the dryer; and “process control,” which refers to the various automated systems and controls that ensure the dryer is operating within specified parameters.

Of course, there are many other specialized terms associated with centrifugal dryers as well, including different types of dryers (such as direct or indirect heat dryers) and specific models or brands (such as “Turbo Dryer” or “Flash Dryer”). Ultimately, the most important thing is to find a dryer that meets the specific needs of your industry and application – and knowing the right terminology can help you do just that.

Centrifugal Dryer Price

A centrifugal dryer is a specialized drying equipment that uses centrifugal force to remove moisture or liquid from materials. It is commonly used in various industries such as food processing, chemical, pharmaceutical, and textile production, among others. The device works by spinning the material at high speed, causing the liquid or moisture to separate and move to the walls of the machine, creating a dry material.

When looking to purchase a centrifugal dryer, one of the most important considerations is the price. The cost of this equipment depends on several factors such as the size, material, and quality of the components. The average price for a centrifugal dryer ranges between $3,500 and $15,000, with larger or more specialized models costing up to $30,000 or more.

High-quality centrifugal dryers are generally more expensive than their lower-quality counterparts, but they offer better performance, durability, and safety. The material used in its construction also affects its price; dryers made with stainless steel or other high-grade metal are generally more expensive than those made with cheaper materials.

Another consideration that affects the price of centrifugal dryers is the manufacturer or supplier. Some manufacturers offer highly competitive prices for their products, while others may charge a premium for their brand reputation or superior quality.

When purchasing a centrifugal dryer, it is essential to consider the overall cost benefits. While a more expensive dryer may be an initial investment, it may offer greater benefits such as energy efficiency, lower maintenance costs, and increased productivity.

In conclusion, the price of a centrifugal dryer depends on several factors such as size, material, and quality of components, as well as the manufacturer or supplier. It is essential to consider the cost benefits when purchasing a centrifugal dryer to ensure that you get a high-quality and reliable machine that meets your drying needs at a reasonable cost.