Benefits of Chips Making Machine Price

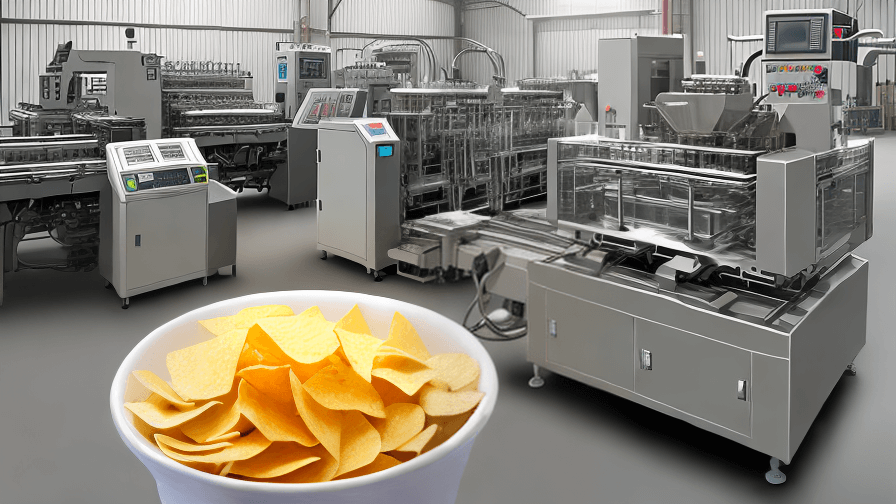

Chips making machine has become an essential equipment for many businesses in the food industry as it helps to boost production and streamline the process of making chips. With the increasing popularity of chips all over the world, chips making machine price has become important to consider for business owners who want to grow their production and increase profitability.

One of the benefits of chips making machine price is that it is affordable and can be a good investment for businesses that want to save money on labor and maximize production. With the rising cost of labor, investing in a chips making machine can help reduce the cost of hiring and training employees. This will also help to free up staff to work on other important tasks in the business.

Another benefit of chips making machine price is that it can help to improve the quality of the chips produced. These machines are designed to produce uniform and consistent chips, which are free from defects such as undercooked or overcooked chips. This not only helps to improve the taste and appearance of the chips but also increases customer satisfaction.

Chips making machines also help to increase productivity and efficiency in the production process. These machines are designed to work continuously for long periods, helping to save time and effort in the production process. They also require minimal supervision, which means that staff can focus on other tasks that require more attention.

Additionally, chips making machines are versatile and can be used for different types of chips such as potato chips, banana chips, and vegetable chips. This means that businesses can diversify their product offerings and cater to different customer preferences, which helps to increase sales and revenue.

In conclusion, chips making machine price can have numerous benefits for businesses in the food industry. These machines can help to save money on labor, improve the quality of chips produced, increase productivity and efficiency, and offer versatility in product offerings. Investing in a chips making machine can be a wise decision for businesses that want to grow their production and remain competitive in the market.

Features of Chips Making Machine Price

Chips making machine is a vital kitchen appliance that helps in the preparation of different types of snacks. The machine is designed to cut potatoes into thin slices that are fried to create chips. The device comes in various models, and the prices are determined by the features they have. Here are some features that affect the cost of chips making machines.

Firstly, the size of the machine is a significant determinant of its price. A smaller device may cost less than a bigger one. This is because more material is used to manufacture a larger machine, making it more expensive. Also, a bigger machine requires more energy to operate, which may make the cost higher.

Secondly, the power consumption of the machine affects its price. Machines with high power consumption are more expensive than those with low energy consumption. However, machines that consume more energy may be faster and produce more chips within a shorter time.

Thirdly, the material used to manufacture the machine may determine its price. Machines made of high-quality material may cost more. However, these machines are durable and can withstand frequent usage, saving the buyer from the cost of repairs or replacements.

Fourthly, the machine’s safety features may affect its price. Machines equipped with safety features like automatic shut off when the lid is opened or when the temperature gets too high may cost more. These safety features are crucial in preventing accidents while using the machine.

Lastly, the machine’s efficiency and speed may also determine its price. Machines that produce more chips within a shorter time may be more expensive than slower ones. However, this feature may be essential for commercial use, where more chips are required within a short time.

In conclusion, the cost of chips making machines is mainly determined by the features they have. When purchasing the machine, it is vital to consider the features that best suit one’s needs. However, it’s important to get the best machine that fits your budget and can meet your chips requirements effectively.

Various Types of Chips Making Machine Price

Chips making machines come in various types, designs, sizes, and prices. The prices differ based on the machine’s features, durability, and brand. Here is a breakdown of the various types of chips making machine prices.

The simplest and most common type of chips making machine is the manual potato slicer. This machine comprises a manual crank that rotates the slicer blade and a potato holder. The holder is where you place the potato to be sliced. The average price for a manual potato slicer is around $20.

The next type is the automatic potato slicer; these machines are more efficient than manual slicers as they can slice larger volumes of potatoes. Automatic slicers come in different sizes and have varying levels of automation. The price range for automatic potato slicers can be anywhere from $100 to $300.

The third type of machine is the industrial potato peeler. As the name suggests, this machine is designed for industrial use and can peel large batches of potatoes quickly. Industrial potato peelers come in varying sizes and capacities and can cost anywhere from $500 to $10,000.

The fourth type of chips making machine is the industrial fryer. Industrial fryers come in various sizes, with large fryers costing more money. The price range for industrial fryers can be anywhere from $500 to $6,000.

The final type of chips making machine is the combination machine. These machines come with both potato slicing and frying capabilities. The price range for combination machines skyrocket as they offer more functionalities. Combination machines can cost anywhere from $1,000 to $20,000.

In conclusion, the price of chips making machines varies greatly depending on the machine’s type, capacity, and features. Depending on your intended use, you can choose the most suitable and affordable machine for your needs. Make sure to consider factors such as the type of slicer, fryer, and peeler when purchasing a chips making machine.

Applications of Chips Making Machine Price

The chips making machine is a crucial apparatus in the food industry. The popularity of potato chips and other varieties of chips has led to a rise in demand for chips making machines across the world. These machines are ideal for businesses that produce a large number of chips and require speed and consistency in production. The machine helps businesses save time and provides a higher level of hygiene.

Chips making machine prices vary based on the machine’s capacity, features, and materials used in manufacturing. The machine price may range between $500 and $5000. However, the cost is worth the investment for small and large enterprises in the food industry.

The most significant applications of chips making machines include producing uniform shaped and sized chips within seconds. These machines allow for a faster processing rate, ensuring the production of a large quantity of chips daily, and with less effort. In addition, the machines enhance the quality control aspect of production, ensuring that chips’ flavor and texture remain constant, boosting customer satisfaction.

The chips making machine is versatile and can be used to produce a variety of chips, including potato chips, banana chips, plantain chips, Cassava chips, and even vegetable chips. This flexibility allows businesses to diversify their products and reach a wider audience.

The machine’s automated process ensures that there is less wastage, creating a considerable economic benefit to businesses. The chips making machine also has an efficient drying and frying process, which results in reduced oil absorption, reducing production costs and making chips healthier.

In conclusion, chips making machine is essential in the food industry, and it’s applications are numerous. The machine’s price may vary depending on various factors. However, the investment is worth it, as it results in increased productivity, cost reduction, and quality control. The versatility of the machine allows businesses to expand their product range, providing additional revenue streams. Hence, chips making machines are a valuable investment that can significantly enhance businesses’ profitability and efficiency in the food industry.

The Process of Chips Making Machine Price

The process of chips making machine price involves a number of factors and considerations that manufacturers and buyers need to take into account. With the growing demand for chips making machines, it is essential to understand how the prices are determined and what factors to consider when choosing a machine.

One of the primary factors that influence chips making machine price is the level of automation and technology used in the machine. The more advanced and automated a machine is, the higher its price is likely to be. Machines with advanced features such as automatic slicing, peeling and frying, are usually expensive but more efficient and offer higher production capacity.

Another factor that affects the price of chips making machines is the quality of materials used. High-quality materials like stainless steel make machines durable and long-lasting hence increasing the price. On the other hand, low-quality materials like plastic make machines cheaper but less durable and less efficient.

The size of the machine is also a consideration when determining the price. Large capacity chips making machines are expensive as they are capable of producing large quantities of chips, while smaller machines are relatively cheaper.

Lastly, the brand name and location of the manufacturer also influence the price of a chips making machine. Well-known and established brands with a long-standing reputation in the industry tend to charge more for their machines as they offer better quality and efficient machines. Additionally, the location of the manufacturer also impacts the price, machines from countries with lower manufacturing costs tend to be cheaper.

In conclusion, the process of chips making machine price is dependent on several factors, including automation level, quality of materials, machine size, brand name and location of the manufacturer. Buyers need to consider these factors before settling on a machine that meets their specific needs and budget.

How to use Chips Making Machine Price

Are you looking for ways to simplify your potato chip-making process? Chips making machines offer an efficient and cost-effective solution for commercial or home use. Here is a guide on how to use a chips making machine price conveniently:

Step 1: Preheat your chips making machine. Make sure the oil temperature is ideal and consistent before you start cooking the potato chips. Also, confirm that the machine’s parts are assembled correctly.

Step 2: Clean and slice your potatoes. Use a potato slicer or a knife to cut the potatoes into uniform thickness. Rinse the slices with cold, running water, and then dry them thoroughly using paper towels.

Step 3: Start frying the chips. Place the potato slices in the frying basket and lower it into the oil. Fry for about 5 to 7 minutes until the chips turn golden brown.

Step 4: Remove the fried chips from the machine. After the chips are golden brown, lift the frying basket out of the oil and let the oil drain. Then, transfer the chips into a bowl coated with a paper towel to absorb the extra oil.

Step 5: Season the chips. Add your preferred seasoning to the chips while they are still warm. Some excellent seasoning options are salt, onion powder, garlic powder, and BBQ powder.

Step 6: Serve and enjoy your chips. Your crispy homemade potato chips are ready to serve, munch, and enjoy!

Conclusion

By following these six simple steps, you can produce a delicious batch of potato chips using a chips making machine easily. To maximize your investment, purchase a machine that fits your budget and meets your production capacity needs. Happy and safe chip-making!

Selecting the Ideal Manufacturer Chips Making Machine Price

Selecting the ideal manufacturer chips making machine price can be a challenging task for any business or individual. When determining the right machine, it’s essential to consider factors such as the quality of the machine, its durability, its efficiency, and of course, its price.

Before making a purchase, it’s essential to do some research and identify the manufacturers that offer chip-making machines that meet your specific needs. It’s also crucial to determine the affordability of the machine without sacrificing the quality and efficiency of the machine.

Additionally, it’s essential to consider the machine’s maintenance costs to avoid any unforeseen costs that may arise after the purchase. The ideal machine should be easy to operate and maintain, which will help reduce the machine downtime and increase the production rates.

Furthermore, the size of the machine is another critical factor to consider, as it determines how much space it will occupy and the amount of product it can produce. It would be best to consider the growth potential of your business and choose a machine that can accommodate the growth in production.

It’s also vital to consider the machine’s safety features, including emergency stop buttons, safety switches, and safety guards, to protect the operators from any possible accidents.

In conclusion, selecting the ideal manufacturer chips making machine price depends on various factors, including quality, efficiency, durability, affordability, and safety features. Therefore, businesses and individuals must do extensive research and compare different machines’ prices and features before making the final decision to ensure they get the best value for their investment.

list FAQ with answer about Chips Making Machine Price

If you are planning to start a chips-making business, one of the crucial things that you should consider is the price of the chips making machine. Here, we have compiled a list of Frequently Asked Questions about chips making machine price:

1. What factors influence the price of a chips making machine?

The factors that influence the price of a chips making machine include its capacity, brand, material, and functionality.

2. What is the average cost of a chips making machine?

The average cost of a chips making machine ranges from $200 to $5,000, depending on the machine’s size and capacity.

3. Where can I find the best-priced chips making machine?

The best-priced chips making machine can be found in several online stores, e-commerce sites, as well as physical stores that specialize in selling chips-making machines.

4. What is the minimum cost of a good-quality chips making machine?

The minimum cost of a good-quality chips making machine is around $700.

5. What is the standard capacity of a chips making machine?

The standard capacity of a chips making machine ranges from 50kg to 500kg per hour.

6. How long does a chips making machine last?

A good-quality chips making machine can last for up to 10 years, with proper maintenance and upkeep.

7. How can I maintain my chips making machine?

You can maintain your chips making machine by cleaning it after every use, lubricating it, and ensuring that it is stored in a cool and dry place.

In conclusion, the price of a chips making machine depends on several factors such as capacity, brand, material, and functionality. To find the best-priced chips making machine, you need to do thorough research and compare prices across several stores. As a business owner, you must invest in a good-quality chips making machine and ensure that you maintain it properly.

Things to Consider When Purchasing Chips Making Machine Price

When considering purchasing a chips making machine, you’ll need to take a number of factors into account, and one of the most important is price.

There are a number of factors that can influence the price of chips making machines, including the size of the machine, whether it’s new or used, and the quality of the components that are used in its construction.

When looking at the size of the machine, it’s important to consider the capacity that you need. If you’re running a small business or a home-based operation, you might be able to get by with a smaller machine. However, if you’re planning to produce chips commercially, you’ll likely need a larger machine that can handle high volumes of potatoes.

When considering whether to buy a new or used machine, it’s important to weigh the benefits of each. New machines often come with warranties and can be easier to maintain, but they are also generally more expensive. On the other hand, used machines can be more affordable, but they may not be as reliable as new machines and may require more maintenance.

Finally, it’s important to consider the quality of the components that are used in the machine’s construction. Higher quality components will generally result in a machine that is more durable and lasts longer, but they may also be more expensive. It’s important to strike a balance between cost and quality when considering which machine to purchase.

Overall, when considering the price of a chips making machine, it’s important to balance your budget with your needs. By taking into account factors like size, new vs. used, and component quality, you can make an informed decision that will benefit your business for years to come.

Properties of Chips Making Machine Price

A Chips Making Machine is an innovative and efficient machine that is specifically designed to produce various types of chips with ease. It is a multi-purpose machine that enables users to create customized potato chips, vegetable chips, and other snack items at home or within a commercial establishment. However, the machine’s price is a critical aspect that determines its affordability, quality, and effectiveness.

The price of a Chips Making Machine varies depending on the brand, model, features, and performance. The market offers different types of chips making machines at different prices to cater to the needs and budget of different clients. However, it is essential to understand the properties that determine the Chips Making Machine Price to make informed purchase decisions.

Firstly, the quality and design of the Chips Making Machine affect the price. High-quality chips making machines come with durable materials, efficient motors, stainless steel blades, and ergonomic designs that ensure long-lasting use and desirable results. Such machines are more expensive than their counterparts made of low-quality materials that often result in frequent breakdowns, loss of productivity, and maintenance costs.

Secondly, the machine’s capacity and speed significantly influence the Chips Making Machine Price. Machines with large capacities and high speeds can produce many chips within a short time, increasing productivity and profitability. Such machines are, therefore, pricier than those with smaller capacities and lower speeds.

Thirdly, the technology incorporated in the Chips Making Machine determines its price. The latest technology machines come with innovative features such as automatic feeding systems, oil draining, and temperature control systems, and precise cutting systems that enhance the machine’s efficiency, ease of use and productivity. Machines with advanced technology are set at higher prices than those with conventional features.

Fourthly, the brand and reputation of the manufacturer affect the Chips Making Machine’s Price. Renowned and reputable brands offer high-quality, reliable, and durable machines at reasonable prices that ensure customer satisfaction and loyalty. In contrast, unknown brands may offer cheaper machines, but their quality and performance may be questionable, costing the users in the long run.

In conclusion, the Chips Making Machine Price is determined by several properties that include quality and design, capacity and speed, technology, and the manufacturer’s brand and reputation. A buyer’s knowledge of these critical properties when shopping for a chips making machine ensures efficient and profitable use. It is always advisable to purchase a machine that matches your needs, budget, and preferred features to optimize its use and value.

Technical Parameters Terms for Chips Making Machine Price

When it comes to purchasing a chips making machine, it’s important to know the technical parameters terms that determine its price. Understanding these terms can help you make an informed decision that meets your needs and budget.

First, one of the most important technical parameters is the capacity of the machine. Capacity refers to how much chips the machine can produce per hour. The higher the capacity, the more expensive the machine will be. However, it’s important to determine your production needs to ensure that you’re not paying for more capacity than you require.

Second, the power consumption of the machine is another technical parameter that affects its price. Higher power consumption means higher electricity bills, and thus a higher cost for the machine. Choose a machine that balances power consumption with efficiency in order to save on operating costs in the long run.

Third, the size of the machine also affects its price. A larger machine will have a higher material cost for manufacturing and transportation, which will add to its overall price. However, a larger machine may also have a higher production capacity, so it may be worth the extra cost in some cases.

Fourth, the material of the machine also plays a role in determining its price. A machine made of high-quality, durable materials will cost more, but it will also last longer and require fewer repairs. Look for a machine that is made of materials that can withstand long-term use in a production environment.

Finally, features such as automation, programmability, and durability also affect the price of a chips making machine. While machines with more features may come with a higher price tag, they can also increase efficiency and reduce labor costs in the long run.

In conclusion, understanding the technical parameters that go into determining the price of a chips making machine is crucial when making a purchase. Capacity, power consumption, size, material, and features all play a role in determining the price, so it’s important to choose a machine that meets both your production needs and budget.

Chips Making Machine Price Price

A chips making machine is a crucial equipment for any business that focuses on food service. Whether you run a small snack bar, a fast food chain, or a large restaurant, a chips making machine is an efficient tool that can help to simplify the process of making chips.

If you are planning to invest in a chips making machine, one of the most important factors you have to consider is the price. The price of a chips making machine varies depending on the brand, model, and features. In India, the price of a chips making machine ranges between INR 15,000 to INR 3,00,000 depending on the specifications and capacity.

The cheapest chips making machines are those that are manual and require human effort to operate. These machines have a simple design and require little maintenance, but they have low production capacity and are ideal for small businesses. Electric chips making machines, on the other hand, have higher production capacity, are more efficient and faster, but are more expensive.

When shopping for a chips making machine, you need to identify your unique business needs and inquire about the various features that are available. For instance, consider the processing speed, production capacity, and material of the machine, as well as the warranty and after-sales support offered by the manufacturer.

It is also essential to consider the cost of maintenance and upkeep of the machine. Some machines require regular cleaning and lubrication, so you will need to factor in the cost of hiring a technician or doing it yourself. Similarly, the cost of raw materials and energy consumption should also be taken into account.

In conclusion, a chips making machine is an essential investment for any business in the food industry. While the price of the machines may vary, it is crucial to find one that fits your budget and business needs adequately. Ensure that you research and compare different brands and models before making a purchase to get the best value for your money.