Knowledge about Clay Brick Making Machine

Clay Brick Making Machine is an economical tool that is used by many people for creating clay bricks. In order to use this machine, one must first have basic knowledge about it. This article will provide some basic information about Clay Brick Making Machine.

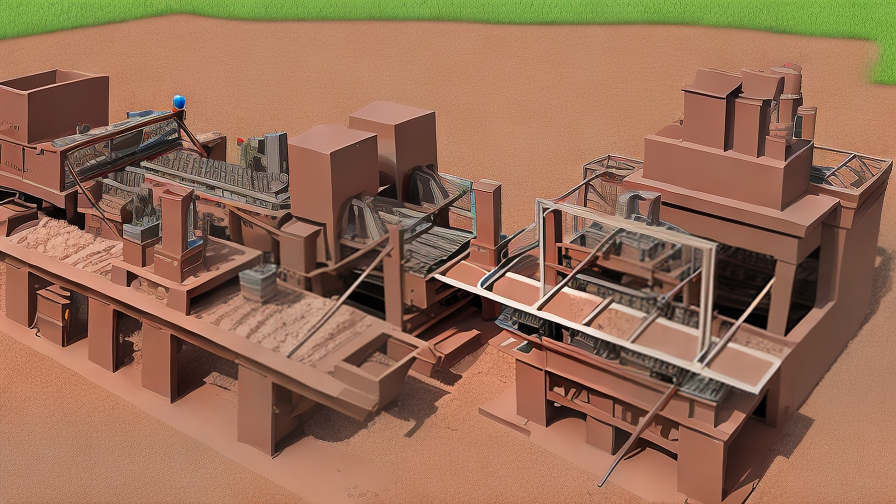

The Clay Brick Making Machine is a machine that takes clay and compresses it into bricks. The machine consists of a hopper where the clay is poured, followed by the compression chamber where the clay is pushed into a mold. The mold determines the shape of the brick. After the brick is molded, it is removed from the machine and allowed to dry.

The Clay Brick Making Machine comes in different sizes and types. Some models are small and can be operated manually while others are large and require electricity or gasoline to operate. The machine also differs in terms of capacity, speed, and quality of output.

When selecting a Clay Brick Making Machine, it is important to consider the quality of the bricks. Some machines are capable of producing high-quality bricks while others produce substandard bricks. It is important to consider the job’s requirements and budget to know which machine will meet expectations.

There are several factors to consider when using the Clay Brick Making Machine. The quality of clay used is important as it determines the quality of bricks produced. The moisture content of the clay should also be considered as it affects the molding process.

In conclusion, the Clay Brick Making Machine is a useful tool in the building industry. It is important to have some basic knowledge about the machine before using it to ensure that it is used correctly and effectively. A proper understanding of the machine’s capacity and operation will assist in selecting the appropriate model for the job.

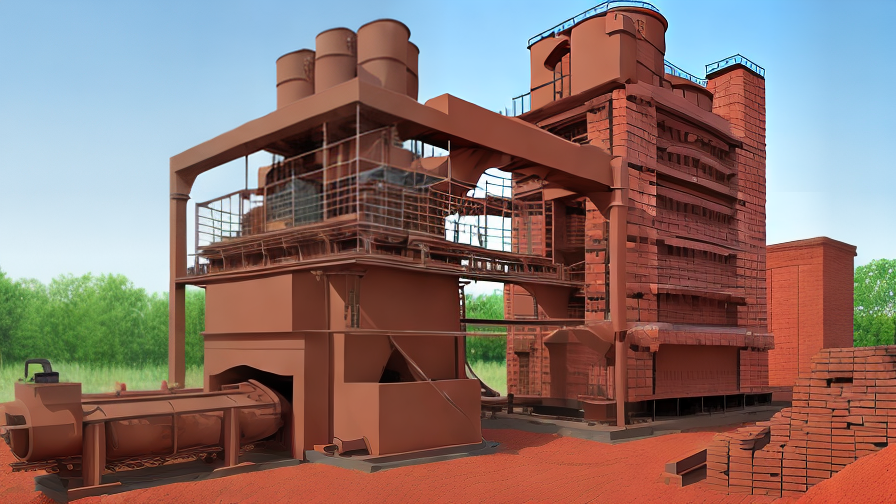

Various Types of Clay Brick Making Machine

Clay brick making machines have been in use for ages, and they are still prevalent in modern times. With technological advancements, the machines have been made to be efficient and cost-effective. The machines come in different types and are designed to cater to various needs. Here are some of the most common types.

Extruder: The extruder machine is used for making bricks using soft mud. It is efficient and can produce many bricks at once. The machine has a hopper where the clay is mixed with water to form a soft dough. The dough is then pushed out in long strips that are cut into bricks.

Dry press machine: Dry press machines are ideal for making bricks using hard clay. The machine uses a hydraulic system to compress the clay into a brick shape. The compressed bricks are then baked in a kiln to harden them.

Wet press machine: Wet press machines are used for making bricks from clay that has high water content. The machine uses a hydraulic system to compress the clay into a brick shape. The bricks are then dried and fired in a kiln.

Semi-automatic machine: Semi-automatic machines are designed for small-scale brick making. They are easy to operate and require minimal skills. The machine works by manually placing the clay in a mold, which is then compressed by a hydraulic system.

Fully automatic machine: Fully automatic machines are designed for large-scale brick making. They are efficient and can produce many bricks at once. The machine works by automatically feeding the clay into a mold, which is then compressed and released into a conveyor belt.

In conclusion, the various types of clay brick making machines are designed to cater to the different needs of brick makers. Depending on the scale of production and the type of clay used, one can choose the best machine for their business. With the right machine, brick making can be a profitable venture.

FAQ sourcing Clay Brick Making Machine manufacturer from China

Finding a reliable brick making machine manufacturer in China can be a daunting task. We understand the need to get accurate and relevant information before making a purchase. This is why we have compiled some frequently asked questions (FAQs) about sourcing clay brick making machine manufacturers from China, with multiple answers to help guide your purchasing decision.

Q: What should I consider when choosing a brick making machine manufacturer in China?

A: Before choosing a manufacturer, consider the following factors: reputation, experience, product quality, customer support, and price competitiveness.

Q: How can I verify the reputation of a brick making machine manufacturer in China?

A: You can verify the reputation of a manufacturer by researching online, checking their reviews and ratings, visiting their website, and reading feedback from other customers. You can also ask for referrals from friends or colleagues who have made similar purchases.

Q: What types of clay brick making machines are available in China?

A: China manufacturers offer various types of clay brick making machines that include manual, automatic, and semi-automatic machines. The machines have different production capacities, ranging from small-scale to large-scale production.

Q: How long is the delivery time for a brick making machine from China?

A: The delivery time depends on various factors such as the type of machine, production capacity, and shipping location. Generally, delivery time can range from a few days to several weeks.

Q: Can I get technical support and after-sales services from the manufacturer?

A: Yes, most of the brick-making machine manufacturers in China offer technical support and after-sales services to their customers. You can contact them and seek help with any issues or queries you may have.

Q: What is the estimated cost of a brick-making machine from China?

A: The cost of a brick-making machine varies depending on the type, size, and production capacity. Prices can range from a few hundred dollars to several thousand dollars.

In conclusion, choosing a reliable clay brick making machine manufacturer in China requires extensive research and due diligence.

Applications of Clay Brick Making Machine

The clay brick making machine is an efficient and reliable tool that is useful in several industries. From construction to agriculture, the machine has proven useful in providing high-quality and durable bricks for various purposes. Here are some of the applications of clay brick making machine.

1. Construction Industry: The brick making machine is widely used in the construction industry to create bricks for various purposes. The machine produces high-quality bricks that are strong and durable, making them ideal for building walls, homes, and other structures.

2. Agriculture Industry: In the agriculture industry, bricks made by the clay brick making machine are used to line irrigation channels and create barriers to prevent soil erosion. By using these bricks, farmers can control the water flow in their fields and ensure that crops get the right amount of water.

3. Landscaping Industry: The clay brick making machine also finds its use in landscaping projects. Bricks can be used to create walkways, patios, and other structures that enhance the beauty of gardens and parks.

4. Environmental Industry: The clay brick making machine is also beneficial for the environment. Bricks made by this machine are eco-friendly and do not release harmful chemicals into the environment. They are also recyclable and can be used again for other purposes once they have reached the end of their lifespan.

In conclusion, the clay brick making machine is an essential tool that has several applications in different industries. Whether it’s building homes, lining irrigation channels, creating walkways, or protecting the environment, the machine produces high-quality and durable bricks that are useful for various purposes. If you are in any of these industries, you must invest in a quality clay brick making machine to ensure that you produce high-quality and durable bricks for your projects.

Manufactured Products made of Clay Brick Making Machine

Clay brick making machines have revolutionized the way that bricks are produced, making the process far more efficient and cost-effective. This has led to an increase in the number of manufactured products made of clay bricks, with a wide range of applications in both domestic and commercial settings.

One popular use of clay brick products is in home construction, where they are used to build walls, floors, and even entire houses. Clay bricks are prized for their durability and strength, and are able to withstand extreme weather conditions and natural disasters such as earthquakes and hurricanes.

Another common application of clay brick products is in landscaping and garden design. They can be used to build retaining walls, walkways, and patios, and can add a rustic and natural look to any outdoor space. Clay bricks are also popular in commercial construction, where they are used in the creation of office buildings, shopping centers, and other large-scale constructions.

In addition to these traditional applications, clay brick products have also found use in the creation of decorative and artistic installations. They can be used to create sculptures, murals, and other works of art, and can be molded and shaped in a variety of ways to suit the needs of the creator.

Overall, the increase in the use of manufactured products made of clay brick highlights the versatility and durability of this building material. As advancements in clay brick making technology continue to be made, it is likely that we will see even more innovative and interesting uses for this versatile substance in the future.

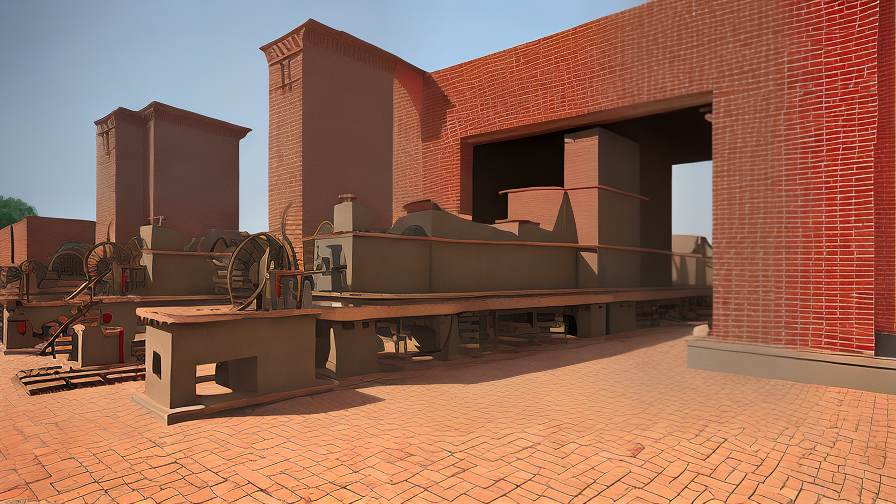

The Evolution history of Clay Brick Making Machine

The history of clay brick making machines dates back to ancient civilizations, where people used clay to build their homes and other structures. These machines have come a long way since their invention, and their evolution has been fascinating.

During the ancient times, people used their bare hands to make brick or sometimes used simple tools like wooden frames. The first brick-making machine was invented in the 1800s, by a man named Samuel Hall. His machine used a screw system to press clay into the mold, giving way to the modern brick-making process.

In 1884, Besser Brothers, a German company, introduced the first hollowed-out brick-making machine. This machine made it possible to create hollow bricks, saving time and materials, and lowering production costs. The first fully automated brick-making machine was invented in 1929, changing brick-making forever.

The evolution of these machines continued, and in the 1950s, the use of hydraulic pressure helped to transform brick-making machines. This produced bricks with a more consistent size, shape, and quality. Later, smoother processes were introduced, such as the use of computers in the process, resulting in a more efficient production process.

Today, modern brick-making machines have not only made the brick-making process faster and more efficient but also more environmentally friendly. Computer-controlled systems reduce waste and energy consumption, and the use of recycled materials for the production of bricks has become an essential factor in brick-making machines.

In conclusion, the evolution of clay brick-making machines is one of technological advancement and strategic planning. With the use of advanced technology, clay brick making machines have become more efficient, faster, and environmentally friendly. Thus, it is worth noting that these machines have a rich history and have come a long way from simple wooden frames to the highly automated machines used today.

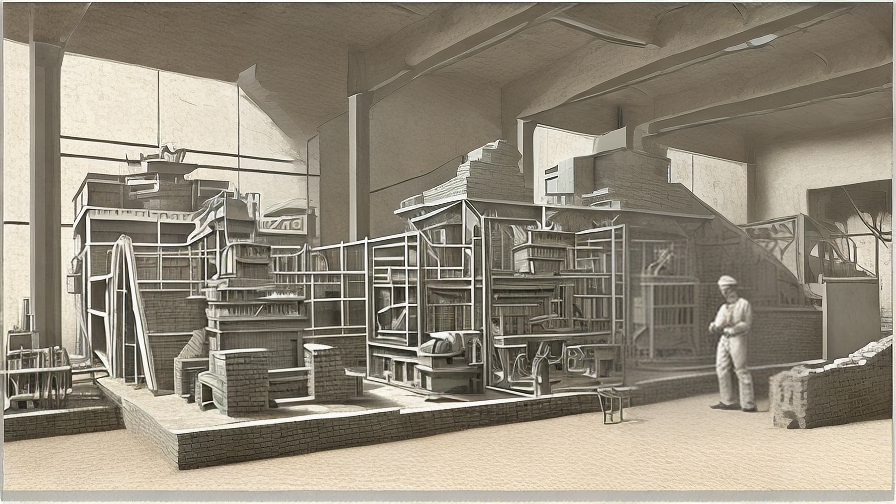

The Process of Clay Brick Making Machine

Clay brick making has been a traditional activity in many parts of the world. The process of making clay bricks involves various stages that transform the raw material into reliable and durable building materials. The process has been improved over the years, and now several machines have been developed to simplify the process.

The first stage involves the selection of the raw material, which is usually clay. The clay is then dug from the ground and left to dry for some time to improve its quality. Once the earth is collected, it is mixed with other materials such as sand and water to soften it.

The softened clay is then poured into a machine known as a clay brick making machine. The machine has various components that mix, shape, and compress the clay into a brick mold. Depending on the size of the machine, the process can either be automated, where the machine does most of the work, or manual, where human labor is required.

The next stage involves drying the bricks. The bricks are removed from the mold and laid on a dry surface in a sunny area to dry. The drying process can take several days, and during this time, the bricks need to be turned regularly to ensure they dry properly.

After the bricks have dried, they are then put through a firing process. The bricks are stacked in a kiln and fired at high temperatures to make them hard and durable. The firing process can take several hours, and once it is complete, the bricks are left to cool for several days.

The final stage involves testing the bricks to ensure they meet the required standard. The quality of the bricks is tested based on factors such as strength, density, and porosity. If the bricks meet the required standards, they are then packaged and sent to the market for use.

In conclusion, the process of making clay bricks involves various stages that transform the raw material into reliable building materials. With the development of clay brick making machines, the process has become simpler and more efficient, providing a reliable source of affordable building materials

Benefits Advantages of Utilizing Clay Brick Making Machine

Clay brick making machine is an essential tool in construction. It produces bricks in varying shapes, sizes, and colors, which save time, money, and efforts. These machines offer several benefits and advantages, including:

1. Efficient production: Clay brick making machines are designed to automate brick production, resulting in faster and more efficient production rates. These machines can produce up to 20,000 bricks in a single day, which means it is easier to meet construction deadlines.

2. Quality bricks: The quality of bricks produced by a clay brick making machine is consistent and uniform. The machines’ automated process ensures that the bricks’ size, shape, and color are precise, making them perfect for construction purposes.

3. Cost savings: With clay brick making machines, construction companies can save money by producing bricks at a lower cost compared to purchasing bricks from external sources. Companies can also save money on labor costs because the machines are automated and require fewer people to operate.

4. Flexibility: Clay brick making machines come with different molds and tools, which means they can produce bricks in various shapes, sizes, and colors, making them very flexible for construction needs.

5. Durable equipment: Clay brick making machines are built to last for years, so they offer extended use that provides value for money. They require minimal maintenance and can continue functioning optimally for several years, providing value to the construction industry.

Finally, Clay brick making machines offer several benefits and advantages, including cost savings, quality bricks, flexibility, durability, and efficiency. Construction companies that utilize these machines in their operations can benefit from faster production, reduced labor costs, and increased quality control. Due to these benefits, clay brick making machines have become an essential tool in the construction industry.

Disadvantages Clay Brick Making Machine

Clay brick making machines have been widely used in the construction industry for many years. However, they come with their own set of disadvantages that are often overlooked. In this article, we will discuss some of the main disadvantages of using clay brick making machines.

Firstly, clay brick making machines require a lot of energy to operate. This means that they can be quite expensive to run, especially if they are used on a large scale. The machines also tend to produce a lot of waste and dust during the brick making process. This can be harmful to the environment and may pose health risks to workers who are exposed to the dust regularly.

Another disadvantage of clay brick making machines is that they are not very versatile. They can only be used to produce clay bricks, which means that they are not suitable for producing other types of building materials such as concrete blocks, AAC blocks, or fly ash bricks. This limits the range of construction projects in which they can be used, especially in modern construction, where innovative materials are widely used.

Furthermore, clay brick making machines are not very efficient. They require a lot of manual labor to operate, which can slow down the production process. This makes them unsuitable for large-scale construction projects that require high volumes of building materials. Additionally, the clay bricks produced by these machines tend to be inconsistent in size and shape, which can affect the overall quality of the building project.

In conclusion, while clay brick making machines are still widely used in the construction industry, there are several disadvantages that need to be considered. They require a lot of energy, produce a lot of waste, are not very versatile or efficient, and can be harmful to the environment and workers’ health. With the introduction of modern technologies like automated block making machines, it’s high time for the construction industry to adopt more efficient and sustainable machines that leave a positive impact on the environment and are easy to use.

Selecting the Ideal Manufacturer Clay Brick Making Machine

Selecting the Ideal Manufacturer Clay Brick Making Machine

Selecting the ideal manufacturer clay brick making machine is an important decision to make. Not only will it affect the quality of your bricks, but it can also have an impact on your production efficiency and overall profitability.

When choosing a manufacturer, you should consider several things. First, check the company’s reputation and experience in the industry. Look for reviews and testimonials from previous clients to determine if they deliver quality machines and have good customer service.

Second, consider the technical specifications of the machine. The ideal machine should be able to produce high-quality and durable bricks efficiently. Additionally, it should be easy to operate, maintain, and repair. A good manufacturer should be able to provide technical support and offer spare parts in case of breakdowns.

Third, consider the price of the machine. Look for a manufacturer that offers reasonably priced machines without compromising on quality. Additionally, check the warranty and after-sales services offered by the manufacturer to ensure that you get value for your money.

Finally, consider the availability of training and support. A good manufacturer should provide training to help you and your staff operate the machine effectively. Additionally, they should offer customer support and troubleshooting to help resolve any issues that may arise.

In conclusion, selecting the ideal manufacturer clay brick making machine requires careful consideration of various factors. With the right machine, you can improve your brick quality, increase production efficiency, and boost profitability. Therefore, it is important to invest in high-quality equipment from a reputable manufacturer with good after-sales support.

Things to Consider When Purchasing Clay Brick Making Machine

If you are planning to buy a clay brick making machine, then you must consider a few essential things before making your purchase. One significant factor is the quality of the machine, which must be dependable and efficient. Here are a few things to consider when buying a clay brick making machine.

1. Quality: The quality of the machine is the most important thing to consider. The machine should be durable and reliable. If you are planning to buy a used machine, make sure it is well maintained and checked for any damages.

2. Production capacity: Brick making machines come in different production capacities. Choose the one that fits your needs. If you have a small-scale business, you may require a machine with a lower production capacity. However, if you have a large-scale business, go for a machine with a higher production capacity.

3. Energy efficiency: The machine should be energy-efficient to save on operational costs. Look for a machine that consumes less energy to produce as many bricks as possible.

4. Ease of operation: The machine should be easy to use with simple and clear instructions. It should also come with all the necessary tools and accessories.

5. Maintenance: The machine should be easy to maintain, with spare parts readily available, and simple preventive maintenance procedures.

6. Price: The price of the machine is an essential consideration. However, do not compromise on quality for a lower price. Consider your budget and prioritize quality over price.

In conclusion, always do your research before purchasing a clay brick making machine. Consider the factors mentioned above, and choose a reliable and efficient machine that meets your production needs. A good quality brick making machine will last long and help you grow your business.

Properties of Clay Brick Making Machine

Clay brick making machines are equipment used for making bricks by shaping clay and firing them in a kiln to increase their strength. The properties of these machines make the process of brick making easier and more efficient.

Strength and Durability: Clay brick making machines are built with high-quality materials that enable them to produce strong and durable bricks. They are designed to handle the high-pressure requirements involved in shaping clay into bricks.

Automation: The machines are equipped with automation features that make the process of brick making more efficient. They have automatic feeding systems, which reduce the time and labor required in manually feeding the machine.

Versatility: Clay brick making machines are designed to produce different types of bricks. They can make standard bricks, hollow bricks, and perforated bricks, among others. This versatility enables manufacturers to make bricks that meet the specific requirements of their customers.

Production Capacity: Clay brick making machines are built to handle large production volumes. They can produce hundreds or thousands of bricks per hour, depending on the specific machine’s capacity. This high production capacity enables manufacturers to meet their orders in a timely manner.

Ease of Maintenance: Clay brick making machines are designed with ease of maintenance in mind, reducing the downtime required for maintenance problems. Their maintenance requirements are minimal and do not require much technical knowledge, making them a suitable option for brick manufacturers.

In conclusion, clay brick making machines are essential equipment in the brick manufacturing industry. They are designed with properties that make the brick-making process more efficient, cost-effective, and less time-consuming. They are also customizable, so manufacturers can create bricks that meet different specifications. The versatility, strength, durability, production capacity, and ease of maintenance of clay brick making machines make them an ideal choice for brick manufacturers worldwide.

How to use Clay Brick Making Machine

Clay brick making machines have been around for decades, but with modern improvements, they have become more efficient and easier to use. These machines use clay, sand, and water to create bricks that are then baked or cured in a kiln. Here are some steps on how to use a clay brick making machine.

First, gather your materials. You will need clay, sand, water, a mixing machine, and a brick making machine. Make sure all the equipment is clean and free of debris, as this can affect the quality of the bricks.

Next, mix the clay and sand together in the mixing machine. Gradually add water until you have a smooth, workable consistency. The right mixture will depend on the type of clay and sand you are using, as well as the climate and humidity of your workspace.

Once your mixture is ready, load it into the brick making machine. The machine will compress the mix into molds, and eject them onto a conveyor belt. From there, the bricks will be transported to a curing chamber or kiln.

It is important to note that some brick making machines may require you to manually feed the mix into the molds, while others are fully automated. Be sure to read the instructions carefully and follow the manufacturer’s recommendations.

The curing process is crucial to the strength and durability of your bricks. Depending on the type of clay and sand used, this can take anywhere from a few days to several weeks. Once cured, the bricks can be used for construction or other projects.

In summary, using a clay brick making machine requires basic knowledge of mixing and handling clay and sand, the use of a mixing machine, and operating the brick making machine. It is important to follow manufacturer instructions and to properly cure the bricks before use. With practice and experience, you can produce high-quality, durable bricks that will stand the test of time.

Glossary Terminology Terms for Clay Brick Making Machine

Clay brick making machines have become one of the essential pieces of equipment in the construction industry. However, understanding the terminologies used in the machines can be challenging for beginners. Here is a glossary guide of the basic terms and their meanings used in clay brick making machines.

Clay Extruder: A clay extruder is a device used to shape the clay to the desired form. It is the primary component of a clay brick making machine, which is responsible for extruding the clay.

Auger: An auger is a screw-like part that is attached to the clay extruder. The auger pulls in the clay and pushes it through the extruder to form the desired shape.

Pug Mill: A pug mill is a machine that mixes clay and other materials to produce clay bricks. It resembles a huge mixer that facilities a thorough mixing of the clay.

Die: The die is a mold or form that is used to shape the clay into various shapes and sizes.

Firing: Firing is a process that involves exposing the clay bricks to high temperatures in a kiln to make them hard and durable.

Green Brick: Green brick refers to the clay bricks that have not yet been fired in a kiln. They are still in the wet and soft state and can be easily molded into different shapes.

Kiln: A kiln is an oven that is used to fire the clay bricks at high temperatures to make them durable.

Mould: A mold is a device that is used to shape the green brick into the desired form. Molds can be of different shapes and sizes, depending on the desired end product.

Slip: Slip is a mixture of clay and water that is used in the making of clay bricks. It is used to moisten the clay and facilitate the molding process.

In conclusion, understanding the terminologies used in clay brick making machines is crucial for successful brick making. It helps in carrying out the entire process effectively and efficiently.

Clay Brick Making Machine Price

Clay brick making machine price varies greatly depending on the type of machine required. The capacity and production output of the machine also determine the price.

The simplest manual machines cost around 50,000 to 70,000 Indian Rupees, which is around $700 to $1000. These machines can produce a small number of bricks per hour and require the brickmakers to perform most of the work manually.

Semi-automatic machines, which have a higher production output, but still need some manual intervention during the process, can cost around 200,000 to 400,000 Indian Rupees. This is around $2800 to $5500.

Fully automatic machines, which can be operated with minimal input from the operator, are the most expensive type of machine, with prices starting from 1,000,000 Indian Rupees, up to 4,000,000 Indian Rupees. This is around $14,000 to $55,000.

The clay brick making machine price can also vary depending on the materials used to build the machine. Machines built with high-quality materials such as stainless steel or aluminum, which have a longer lifespan and require less maintenance, usually come with a higher price tag.

It is important to consider the cost of maintenance and repair when purchasing a machine, as this can significantly impact the total cost of ownership. Investing in a high-quality machine that requires fewer repairs and replacements can ultimately save money in the long run.

In summary, the prices of clay brick making machines range from $700 to $55,000, depending on the type of machine, its production output, and the materials used to build it. It is important to carefully evaluate the needs of the business before making a purchase and to consider the long-term costs of maintenance and repair.