Types and Applications of clow gate valve

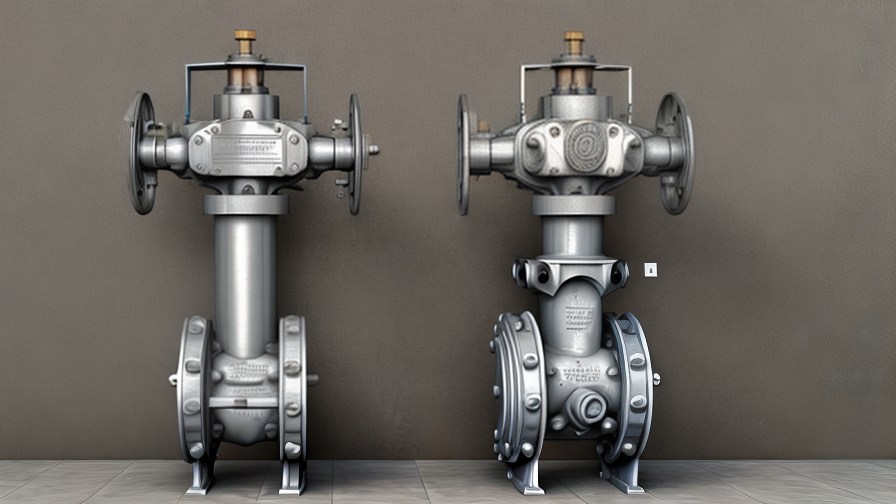

Clow gate valves have been in use for over a century and have gained popularity in various industries due to their ability to provide tight shutoff, low maintenance, and durability. Also known as a “knife gate” valve, the primary function of a gate valve is to regulate the flow of fluids in water and wastewater treatment plants, as well as in oil and gas, petrochemical, and mining applications. The following are the types of Clow gate valves and their applications:

1. Resilient Wedge Gate Valve: This type of gate valve is designed with a flexible wedge that allows the valve to adjust to any changes in the pipeline. It is commonly used in high-pressure water supply applications such as irrigation, fire protection, and HVAC systems.

2. Double-Disc Gate Valve: This type of gate valve features two flat gates that close and open simultaneously to provide a tight seal with minimal resistance. It is used in sewage treatment plants and other water/wastewater applications.

3. Slurry Gate Valve: This type of gate valve is designed for heavy-duty operations and is perfect for handling abrasive fluids and slurries. It is commonly used in the mining and chemical processing industries.

4. Knife Gate Valve: This type of valve is designed with a sharp-edged disc that slices through solids and fibers, preventing clogging and jamming in pipelines. It is commonly used in industries dealing with viscous fluids, such as pulp and paper mills, mining, and wastewater treatment plants.

In conclusion, Clow gate valves are utilized for a wide range of applications that require reliable operation, low maintenance, and tight shutoff. Different types of Clow gate valves are available depending on the specific use, ensuring efficiency and longevity in performance.

Benefits and Feature of Utilizing clow gate valve

A gate valve is a type of valve that uses a sliding gate to open and close the passage of fluid. The size and design of a gate valve can vary depending on the application, but one type of gate valve that has proven to be versatile and effective is the clow gate valve.

Benefits of Utilizing Clow Gate Valve

1. High Durability: The clow gate valve is made of high-quality materials that ensure its longevity and durability. This valve is resistant to wear, corrosion, and damage, making it a reliable choice for different settings.

2. Tight Shut-Off: The clow gate valve provides a powerful and tight shut-off that prevents any fluid or gas leakage. This feature is essential for applications where safety and efficiency are crucial.

3. Low Maintenance: The clow gate valve is a low maintenance device that requires very little attention once installed. This feature makes it an attractive option, as it saves on maintenance costs and time.

4. Smooth Flow Control: The clow gate valve has a streamlined and unobstructed design that allows it to regulate the flow of fluids smoothly and efficiently. This feature is ideal for applications that require accurate and precise flow control.

Features of Clow Gate Valve

1. Flanged or Mechanical Joint End Connections: The clow gate valve is available in either flanged or mechanical joint end connections. These options make it a versatile device that can be used in many different applications.

2. Solid Wedge Design: The clow gate valve has a solid wedge design that ensures a tight and reliable shut-off. This feature is critical in applications where safety and efficiency are essential.

3. Non-Rising Stem: The clow gate valve has a non-rising stem that allows for easy and efficient operation. This design feature also reduces the overall size of the valve, making it a space-saving solution.

4. Fusion-Bonded Epoxy Coating: The clow gate valve has a fusion-bonded epoxy coating that provides superior protection against corrosion and damage. This feature is particularly useful in environments where the valve is exposed to harsh conditions.

In conclusion, the clow gate valve is an excellent choice for applications that require reliability, efficiency, and safety. Its durability, tight shut-off, low maintenance, and smooth flow control make it a valuable device in many industries.

The Process of clow gate valve

A clow gate valve is a type of valve used to regulate the flow of fluids through a piping system. It is typically used in water pipelines, irrigation systems, and other applications where a tight shut-off is required. The following is a brief overview of the process of the clow gate valve:

1. Valve Construction: Clow gate valves consist of a body, bonnet, gate, stem, and packing assembly. The body is typically made of cast iron or ductile iron, while the gate is made of brass or bronze. The stem is made of stainless steel or brass, and the packing assembly is made of either graphite or PTFE.

2. Operation: Clow gate valves are operated manually using a handwheel or chainwheel. When the handwheel is turned, the stem rotates and moves the gate up or down. This creates a path for fluid to flow through the valve or shuts off the flow of fluid completely.

3. Advantages: Clow gate valves have many advantages, including their ability to provide a tight shut-off, low pressure drop, and high flow capacity. They are also reliable, durable, and require little maintenance.

4. Applications: Clow gate valves are commonly used in water distribution systems, wastewater treatment plants, and industrial applications. They are also used for fire protection systems, irrigation systems, and mining operations.

5. Maintenance: Regular maintenance is essential for clow gate valves to ensure their performance and longevity. This includes cleaning the valve, replacing any damaged parts, and lubricating the stem and handwheel.

Overall, clow gate valves are an essential component of piping systems that require a reliable, durable, and effective valve for regulating flow. With proper maintenance, clow gate valves can provide trouble-free service for many years.

How to use clow gate valve

A Clow gate valve is a type of valve that is widely used in water supply systems, wastewater treatment plants, and other industrial applications. It is designed to control the flow of fluid through a piping system and is known for its durability and reliability. In this guide, we will discuss how to use a Clow gate valve.

Before we dive into the steps, it is important to understand the parts of a Clow gate valve. The valve consists of a body, a gate, a stem, and a handwheel. The gate is the moving part of the valve that controls the flow of fluid. The stem connects the gate to the handwheel, which is used to operate the valve.

Here are the steps for using a Clow gate valve:

1. Close the valve: Before performing any maintenance or repair work on the valve, you must close it completely. Turn the handwheel clockwise until it stops rotating. This will make sure that no fluid flows through the valve.

2. Open the valve: To open the valve, turn the handwheel counterclockwise. This will raise the gate, allowing fluid to flow through the valve.

3. Adjust the flow: You can adjust the flow of fluid through the valve by partially opening or closing the valve gate. Use the handwheel to rotate the stem and adjust the position of the gate accordingly.

4. Close the valve: To close the valve, turn the handwheel clockwise until the gate is fully closed. It is important to close the valve gently to prevent damage to the valve and the piping system.

5. Perform routine maintenance: Regular maintenance is important to ensure the proper functioning of the Clow gate valve. You should check the valve for signs of wear and tear, and lubricate the moving parts as needed.

In conclusion, Clow gate valves are essential components of water supply systems and other industrial applications. By following these simple steps, you can use a Clow gate valve safely and efficiently. Remember to perform routine maintenance to keep the valve in good working condition.

clow gate valve Manufacturer,Supplier and Wholesale

Clow Gate Valve is a widely recognized gate valve brand that has been providing high-quality products to various industries for over 130 years. As a leading manufacturer, supplier, and wholesale distributor of gate valves, Clow Gate Valve offers an extensive product range that includes resilient wedge gate valves, double-disc gate valves, solid wedge gate valves, and more.

Clow Gate Valve products are widely used in various industries, including water and wastewater treatment, oil and gas, HVAC, fire protection, and industrial applications. The products are designed and manufactured with precision to ensure that they meet industry standards and requirements.

One of the key features of Clow Gate Valve products is their durability. The valves are made of high-quality materials, such as ductile iron, which ensures that they can withstand harsh environmental conditions and heavy usage. Also, the products are built to last for decades, and they require minimal maintenance.

Clow Gate Valve products offer excellent flow control and are designed to reduce pressure drop and turbulence. Additionally, the valves are easy to install and operate, making them ideal for various applications.

As a wholesale distributor, Clow Gate Valve offers competitive pricing for its products. The company has an extensive distribution network, which enables it to deliver products to customers worldwide. And with an experienced team of professionals, the company provides excellent customer service and technical support to ensure that customers get the best products and services.

In conclusion, Clow Gate Valve is a reliable gate valve manufacturer, supplier, and wholesale distributor that offers high-quality products to various industries. With its extensive product range, competitive pricing, and excellent customer service, Clow Gate Valve is a one-stop-shop for all your gate valve needs.

clow gate valve Price

Clow gate valve is a type of valve that is commonly used in water distribution systems, fire protection systems, and other industrial applications. This valve is designed to control the flow of water or other fluids by using a gate or wedge that moves up and down inside the valve body.

The price of a Clow gate valve can vary depending on several factors such as size, material, pressure rating, and end connection type. Generally, smaller sizes (2″-12″) are less expensive than larger sizes (14″-36″) due to the difference in manufacturing costs. The material of the valve body also plays a role in determining the price. Cast iron is usually the most cost-effective option, while ductile iron and stainless steel are more expensive due to their superior durability.

The pressure rating of the valve is another factor that impacts the price. Higher pressure ratings require thicker valve bodies and more robust construction, making them more expensive. Finally, the type of end connection (flanged or mechanical joint) can also affect the price.

In general, a Clow gate valve can range in price from a few hundred dollars to several thousand dollars. It’s important to remember that while price is a consideration, it’s not the only factor to consider when selecting a valve. Factors such as durability, reliability, and ease of maintenance are also essential to ensuring the proper functioning of a water distribution or fire protection system.

Overall, a Clow gate valve is a reliable and cost-effective solution that is widely used in water and wastewater treatment plants, fire protection systems, and other industrial applications. With proper selection, installation, and maintenance, these valves can provide excellent performance and long service life.

FAQ sourcing clow gate valve manufacturer from China with multiple answers

Q: How to find a reliable clow gate valve manufacturer in China?

A: There are several steps you should take to find a reliable manufacturer for clow gate valves:

1. Research: Start by researching different Chinese manufacturers of clow gate valves. Look for their reputation, history, certifications, customer reviews, and quality standards.

2. Contact: Contact different manufacturers and ask for quotes, product catalogs, and certifications. A reliable manufacturer should respond promptly with detailed information.

3. Check certifications: Look for manufacturers that have proper certifications like ISO 9001, CE, and UL. Certification shows that the manufacturer follows internationally recognized quality standards.

4. Visit the manufacturing facility: If possible, visit the manufacturer’s facility and see their manufacturing process. This will give you an idea of their production capacity, quality control, and production efficiency.

5. Check customer reviews: Look for customer reviews and feedback to get an insight into the manufacturer’s product quality and customer support.

Q: What is the average production capacity for a clow gate valve manufacturer in China?

A: The average production capacity of a clow gate valve manufacturer in China can vary based on the size of the factory and the type of machinery used. However, most manufacturers have a daily production capacity of 200-300 units, while others can produce up to 500-600 units per day.

Q: What materials are commonly used for manufacturing clow gate valves in China?

A: Clow gate valves can be made from a variety of materials, including cast iron, ductile iron, stainless steel, and bronze. However, the most commonly used material for manufacturing clow gate valves in China is ductile iron. This material is durable, corrosion-resistant, and reliable, making it an ideal choice for manufacturing gate valves.

Q: What are the common export markets for clow gate valve manufacturers in China?

A: Clow gate valve manufacturers in China export their products to different countries worldwide. Some of the most common export markets include the United States, Canada, Australia, Europe, and the Middle East. These countries have a high demand for clow gate valves due to their reliable performance, durability, and affordability.

Q: How long does it take to produce a clow gate valve in China?

A: The production time for a clow gate valve in China can vary based on the manufacturer’s production capacity, the size of the order, and the complexity of the product specifications. Typically, the production time can range from 20-40 days. However, some manufacturers can offer a faster turnaround time depending on their production capabilities and the urgency of the order.