Knowledge about Cnc Acrylic

CNC acrylic is a common material used in various industries. It is an acronym for Computer Numerical Control, and it refers to the process of using a computer to control machines that cut or create parts. The acronym acrylic means a type of plastic that is commonly used in manufacturing processes. In this article, we will discuss the knowledge required to use CNC acrylic.

One fundamental aspect of understanding CNC acrylic is knowing the different types of acrylic available. There are many types of acrylic, including clear, colored, opaque, and even mirrored. Knowing the attributes of each type will help select the right acrylic for specific projects.

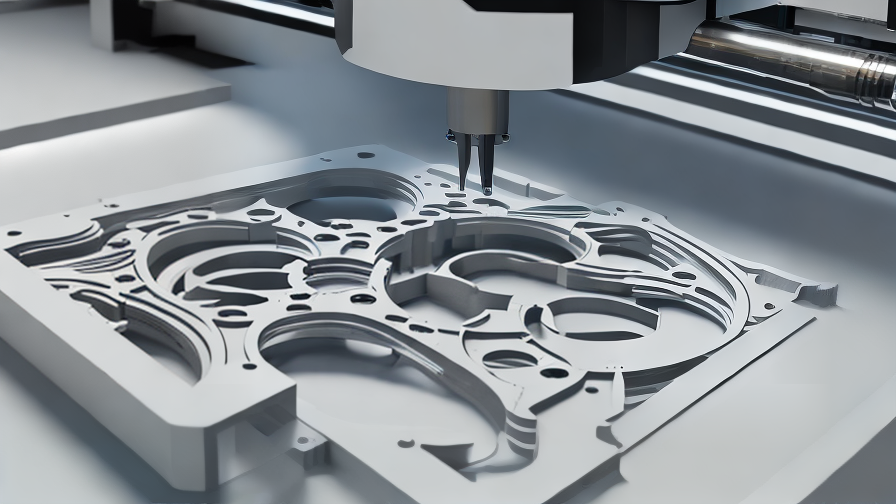

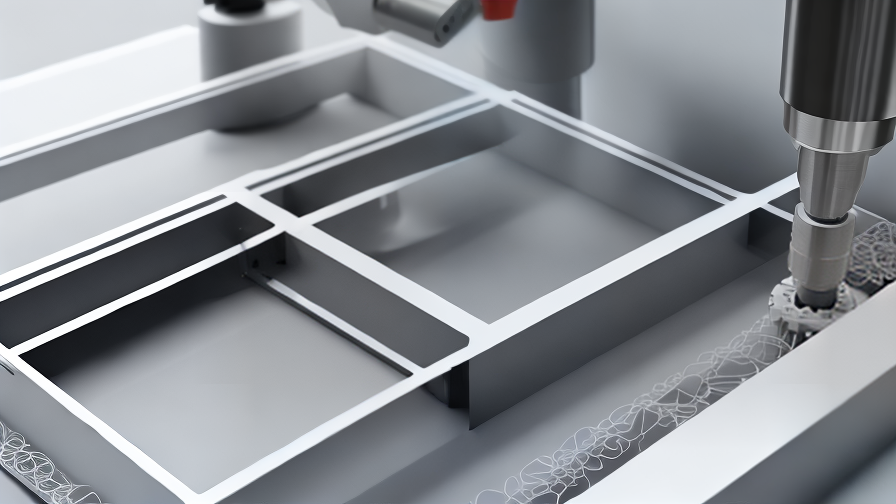

The second important aspect is to understand the cutting process. CNC machines create parts by cutting away plastic through a subtractive process. The part is designed using CAD (Computer-Aided Design) software, and the CNC machine cuts the plastic to the required shape. The cutter type used in the cutting process depends on the project’s complexity and thickness of the acrylic sheet.

The third aspect is the quality of the acrylic sheet. The quality of the sheet will determine the quality of the final product. High-quality sheets will have a consistent thickness, absence of bubbles, and the correct finish. On the other hand, low-quality sheets will produce inferior quality products.

Another crucial aspect is the maintenance of the CNC machine. Maintaining the CNC machine’s cleanliness and ensuring the cutting tools are sharp is critical. Dirty machines and blunt cutting tools may produce cracks on the acrylic sheet or lead to wastage of material.

In conclusion, understanding CNC acrylic requires knowledge of the types of acrylic available, the cutting process, quality of acrylic sheets, and machine maintenance. Mastering these concepts helps produce high-quality products and reduces operational costs.

Various Types of Cnc Acrylic

CNC acrylic, also known as polymethyl methacrylate (PMMA), is a highly versatile material that can be machined using Computer Numerical Control (CNC) technology. CNC acrylic can be used for a variety of applications, such as signage, trophies, retail displays, and protective screens.

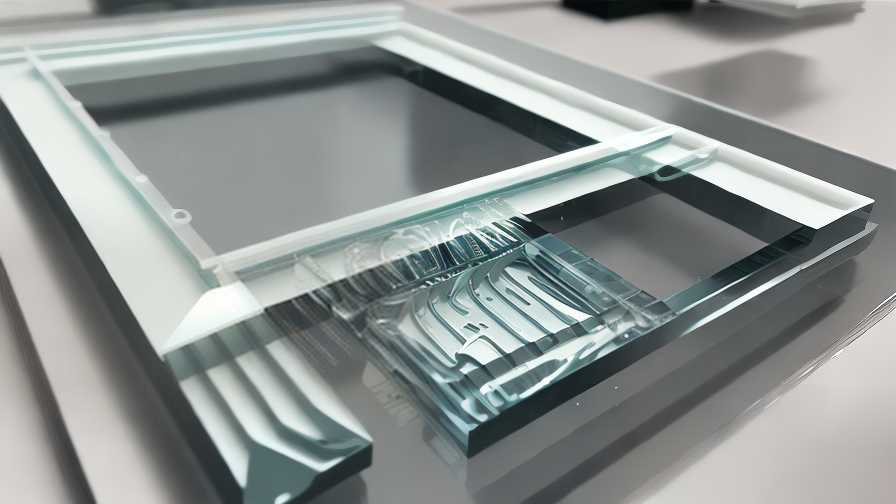

One popular type of CNC acrylic is extruded acrylic. Extruded acrylic is made by heating and melting acrylic pellets, then forcing the melted material through a die to create a continuous sheet. This type of CNC acrylic is highly versatile and can be easily cut, drilled, and milled.

Another type of CNC acrylic is cast acrylic. Cast acrylic is made by pouring liquid acrylic between two sheets of glass and allowing it to cure. This process results in a harder material than extruded acrylic, making it more scratch and impact-resistant. Cast acrylic is commonly used for high-end retail displays and architectural applications.

There are also different finishes available for CNC acrylic, such as matte, satin, and glossy. The finish will depend on the desired look and application of the final product.

When it comes to color, CNC acrylic can come in a variety of shades and tints. Clear acrylic is a popular option for signage, displays, and protective screens, while colored acrylic can be used for a variety of decorative purposes.

In conclusion, CNC acrylic is a highly versatile material that can be crafted into various shapes, sizes, and colors depending on the product’s purpose. Whether it’s for signage, decorative elements, or protective barriers, CNC acrylic is an excellent option for producing high-quality, attractive, and durable products.

FAQ sourcing Cnc Acrylic manufacturer from China

If you’re looking to source CNC acrylic manufacturers from China, you probably have many questions. Here are some of the most frequently asked questions:

1. What is CNC acrylic manufacturing?

CNC acrylic manufacturing involves using computer-aided machines to create precise shapes and designs out of acrylic materials.

2. Why should I source a CNC acrylic manufacturer from China?

China is a leading manufacturer of a wide variety of products, including acrylic materials. Sourcing from China can often result in lower costs and higher quality products.

3. How do I find a reliable CNC acrylic manufacturer in China?

Research reputable manufacturers on online platforms such as Alibaba or Global Sources, and ask for references or certificates to ensure quality and reliability.

4. Can I request samples before placing a large order?

Yes, most manufacturers offer sample orders for customers to test the quality of the product and verify if the manufacturer is a good fit.

5. What are the lead times for a CNC acrylic order?

Lead times vary depending on the complexity of the product and the quantity ordered. Most orders will take 2-4 weeks to manufacture and ship.

6. Is it possible to customize my CNC acrylic order?

Yes, most manufacturers offer customization options for size, shape, color, and design.

7. What are the payment terms for a CNC acrylic order?

Payment terms will depend on the manufacturer, but most will require a deposit before starting production and full payment before shipment.

By keeping these FAQs in mind, you can ensure a successful partnership with a CNC acrylic manufacturer in China.

Applications of Cnc Acrylic

CNC acrylic machining is the process of producing high-quality, precise and complex acrylic pieces using a computer program. It has numerous applications in industries such as signage, automotive, aerospace, and medical devices.

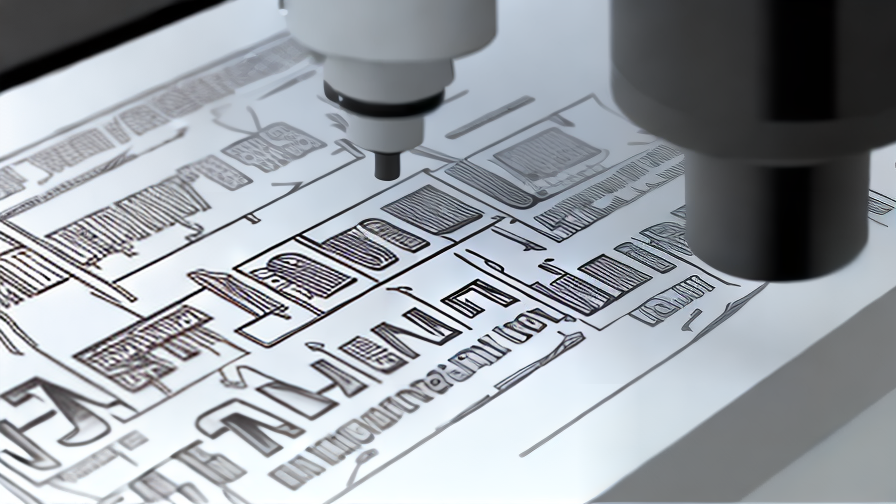

In the signage industry, CNC acrylic is used to create 3D signs, letters, and logos. This is possible due to the precision of CNC machining, which makes it easy to create intricate designs. Furthermore, acrylic has excellent light transmission properties, making it ideal for illuminated signs.

The automotive industry uses CNC acrylic for dashboards, instrument panels, and other interior parts. Acrylic has excellent durability, resistance to heat, and UV light. As a result, it can withstand harsh temperatures and conditions without cracking or fading.

Furthermore, the aerospace industry uses CNC acrylic to manufacture cockpit canopies, wingtips, and other aircraft parts. Due to its lightweight property, acrylic provides a suitable material for aircraft components that require both strength and durability.

The medical devices industry also utilizes CNC acrylic to create laboratory equipment such as Petri dishes, test tubes, and other surgical equipment. The clarity of acrylic makes it easy to examine samples without the need to open a container or get close to the sample.

In conclusion, CNC acrylic has numerous applications in various industries. It provides a cost-effective, easy to manipulate, and visually appealing material for producing complex designs that meet specific requirements in various industries.

Manufactured Products made of Cnc Acrylic

CNC Acrylic is a material that has become increasingly popular in recent years among manufacturers of various products. The material is a type of plastic that is cut using computer numerical control (CNC) machines to create a high level of precision and accuracy in the final product.

One of the primary benefits of using CNC Acrylic is its versatility. It can be used to create a wide range of products such as signs, displays, machine guards, industrial parts, and more. These products are popular in various industries, including the medical, automotive, and retail sectors due to their durability and resistance to wear and tear.

Another advantage of using CNC Acrylic is its transparency. The plastic has a clear and glossy appearance that allows it to be used in applications where optical clarity is essential. Due to this property, CNC Acrylic is a popular choice for creating high-quality lenses, windows, and light diffusers.

In addition to its transparency, CNC Acrylic is also a lightweight material, making it easy to machine, transport, and assemble. Its lightweight nature also makes it an ideal choice for transportation and aerospace applications. Moreover, the material is resistant to UV rays, making it ideal for outdoor applications such as signage, displays, and fixtures.

In conclusion, CNC Acrylic is a versatile material that can be used for various products. Its high level of precision and accuracy, transparency, lightweight nature, and UV resistance make it an ideal choice for manufacturers of signs, lenses, windows, displays, and other products. With its unique properties, CNC Acrylic is a must-have material in today’s manufacturing industries.

The Evolution history of Cnc Acrylic

The evolution history of CNC acrylic can be traced back to the 1960s when the first CNC machines were developed. At that time, the CNC machines were not as sophisticated as they are today and were mainly used for basic machining operations.

Over the years, advancements in technology led to the development of more complex CNC machines capable of machining acrylic with greater precision and accuracy. One of the most significant advancements in the history of CNC acrylic was the development of computer aided design software. This software allowed designers to create incredibly detailed 3D models of their acrylic designs, which could then be processed by CNC machines.

With the development of this technology, CNC acrylic became increasingly popular in many industries, including automotive, aerospace, and medical. Today, CNC acrylic is used to create a wide range of products, including prototypes, molds, and finished parts.

Another major advancement in the history of CNC acrylic is the development of multi-axis CNC machines. These machines are capable of machining acrylic in multiple directions, allowing for the creation of even more complex and detailed designs.

In recent years, there has been a growing trend towards the use of CNC acrylic in the field of architecture, where it is used to create unique and visually stunning facades for buildings. CNC acrylic is also used in the art world to create sculptures, installations, and other works of art.

Overall, the evolution of CNC acrylic has been a fascinating journey, marked by significant advancements in technology and the increasing use of this material in a wide range of industries. As technology continues to improve, it is likely that we will see even more exciting developments in the world of CNC acrylic in the years to come.

The Process of Cnc Acrylic

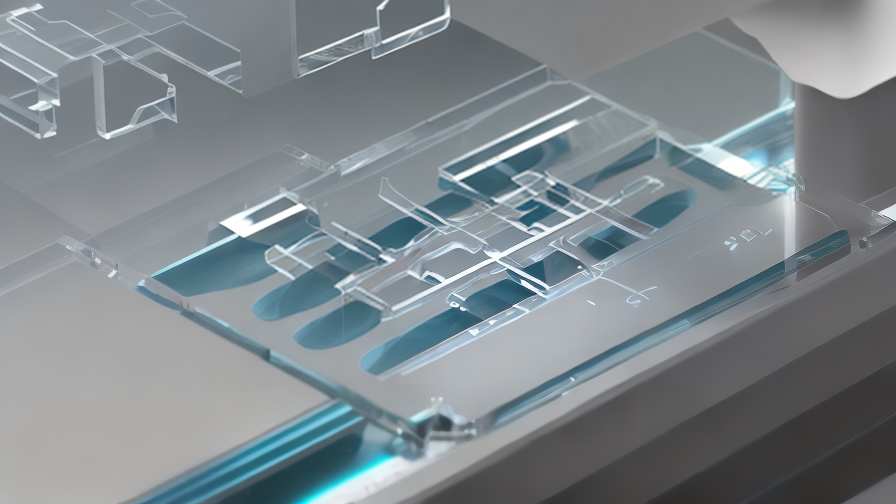

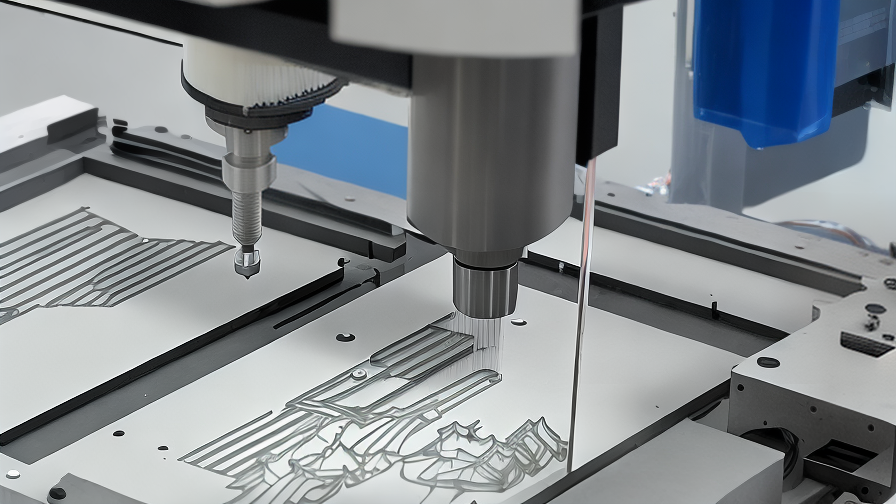

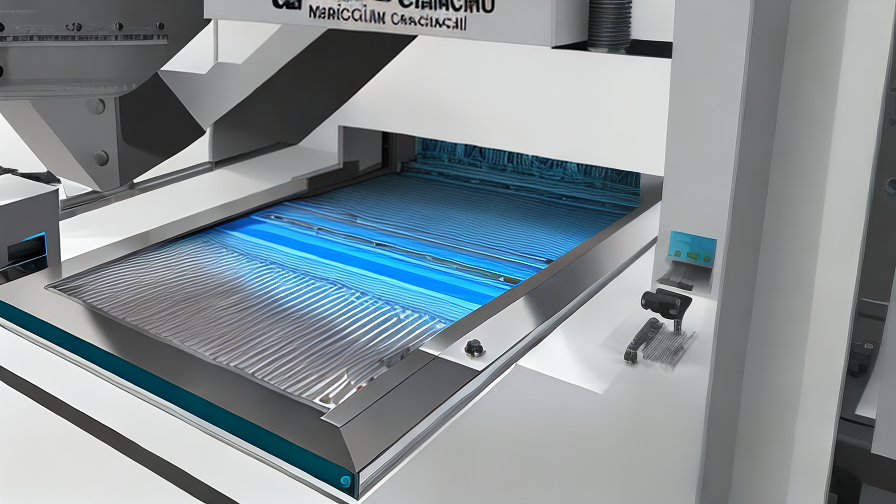

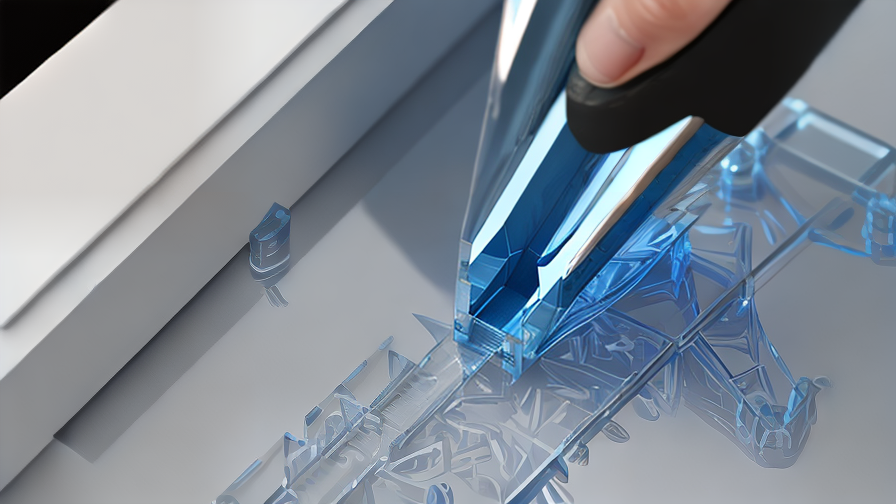

CNC acrylic, or computer numerical control acrylic, is a process that involves the use of computer-operated machines to cut, shape, and engrave acrylic material. The process involves several steps, from the design stage to the final product production.

The first step in the process of CNC acrylic is designing the product. The design is created using software, and the final design is uploaded to the CNC machine. The machine will follow the design specifications to cut and shape the acrylic.

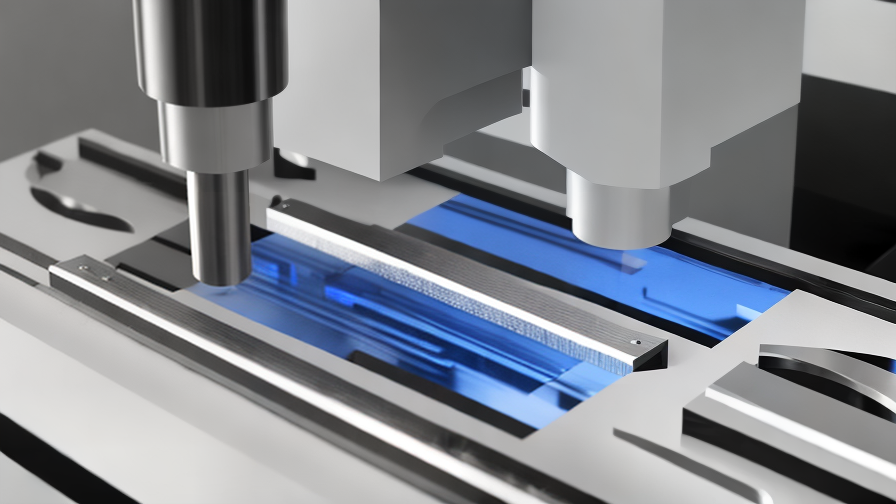

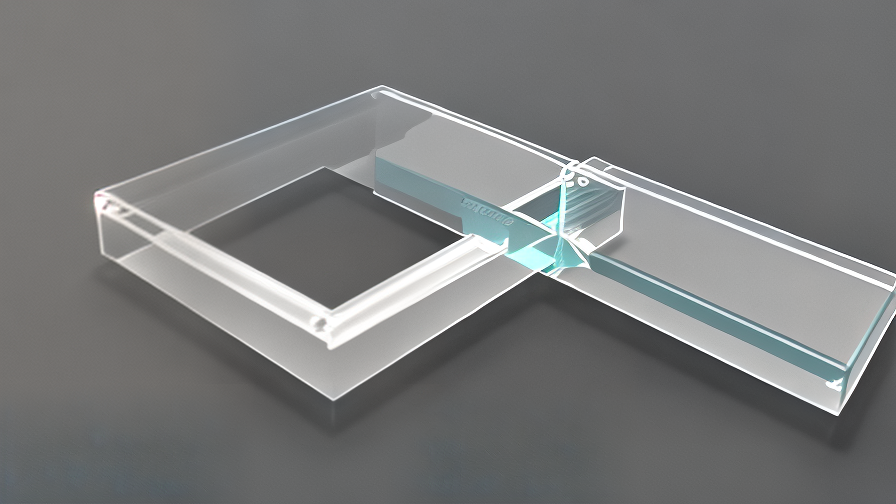

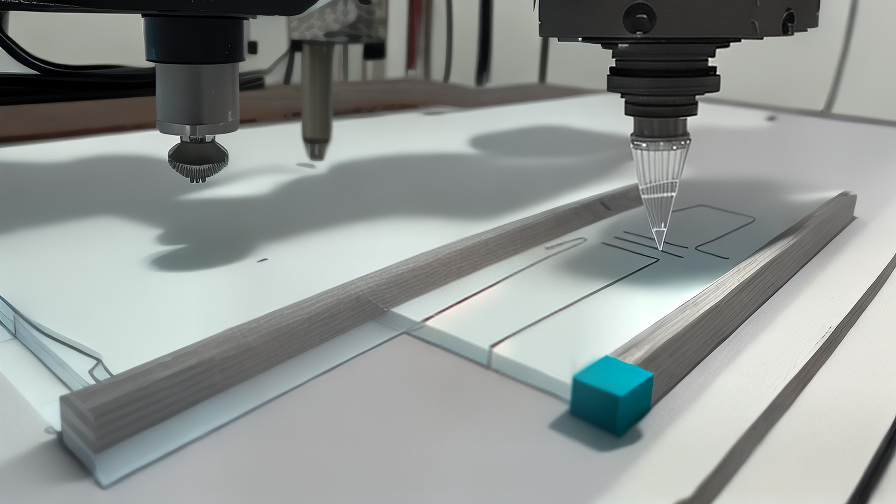

The next step is to prepare the acrylic material that will be used. The material is usually in the form of sheets, which are then clamped to a bed where it can be cut and shaped. The machine uses a cutting tool that is controlled by a computer to cut the acrylic with precise accuracy.

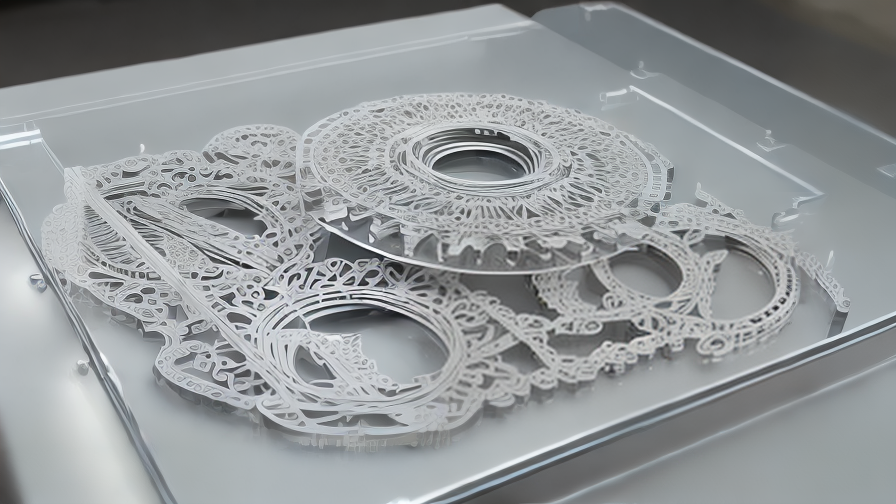

The third step in the CNC acrylic process is shaping the material. Depending on the design, different tools may be used to create the desired shape of the acrylic. The machine will also use high-precision lasers to engrave intricate designs on the material.

After the cutting and shaping process is complete, the final product is polished and finished to give it a high-quality look. This is done using a polishing compound that removes any rough edges or scratches on the surface of the acrylic.

CNC acrylic is preferred over traditional methods of cutting acrylic because it offers greater precision and accuracy. This is essential when creating intricate designs or working with large volumes of material. It also provides a faster and more cost-effective way of producing acrylic products.

Overall, the process of CNC acrylic involves designing the product, preparing the material for cutting, shaping the material, and finishing and polishing the final product. With the help of computer-operated machines, CNC acrylic offers businesses and individuals a reliable and efficient way of producing high-quality acrylic products.

Benefits Advantages of Utilizing Cnc Acrylic

CNC Acrylic machining has become very popular due to its numerous benefits and advantages. Acrylic is a versatile material that is used in various industries for its unique features such as transparency, lightweight, and durability. The use of CNC machines has made it easier to achieve precision and accuracy in acrylic fabrication. The following are some of the benefits and advantages of utilizing CNC Acrylic machining:

High Precision and Accuracy

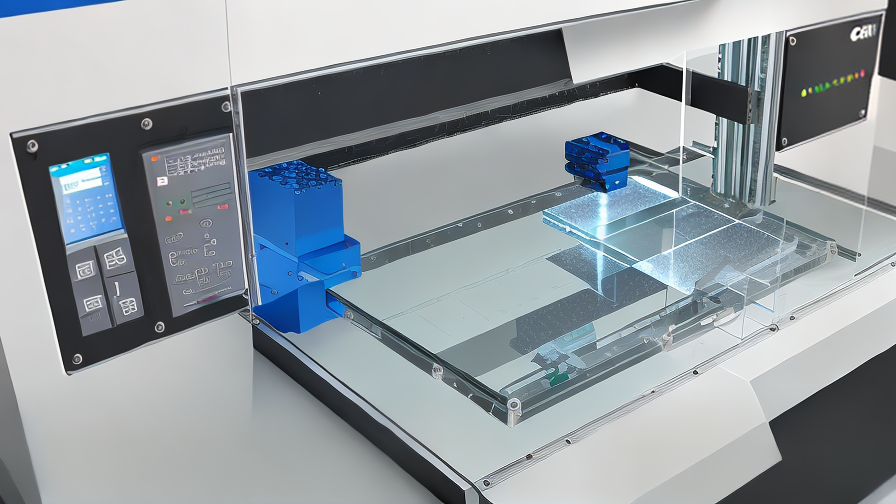

CNC Acrylic machining offers high precision and accuracy in the manufacturing process. These machines have superior technology that enables them to produce complex shapes and curves with minimal error margins. They can repeat the same exact process multiple times without any deviation, ensuring consistency in output quality.

Cost-effective

CNC Acrylic machining is cost-effective because it saves on material wastage and labor costs. These machines have a high level of automation that requires minimal staffing, meaning fewer labor costs. Additionally, the machines utilize CAD/CAM software that optimizes the use of raw materials, ensuring that there is minimal scrap or waste. This cost-saving approach makes CNC Acrylic machining an ideal choice for small and large production runs.

Versatility

CNC Acrylic machining is versatile and can fabricate any shape, size, or design, making it a perfect solution for complex or unique shapes. The machines can also work with different types of acrylic materials, such as opaque, translucent, and colored acrylics.

Quick Turnaround Time

CNC Acrylic machining provides quick turnaround time for production. The machines are highly efficient and can complete multiple processes, such as drilling, engraving and cutting, in a single setup. This means that the production of a large batch of acrylic parts can be completed quickly, saving time and increasing productivity.

Disadvantages Cnc Acrylic

CNC acrylic machining has many advantages but it also has some disadvantages that should be taken into consideration before deciding on using this material.

One of the main disadvantages of CNC acrylic is its susceptibility to scratches and cracks. Acrylic may look shiny and smooth, but even minor scratches can significantly mar its surface. This can be a problem in applications where the appearance of the final product is critical.

Acrylic also has a low resistance to heat, which can lead to warping and deformation during the machining process. The heat generated during the CNC process can cause the material to melt, resulting in poor quality cuts and poor surface finish. This can make it difficult to achieve the desired level of precision and accuracy.

Another disadvantage of acrylic is its low resistance to chemical exposure. It can be easily damaged by certain chemicals, such as solvents and cleaners, which can cause the surface of the material to become cloudy or discolored.

Finally, acrylic is also subject to yellowing over time when exposed to UV light. This can be a problem in applications where the material will be used outdoors, such as in signs or displays.

In conclusion, CNC machining of acrylic has many advantages, including easy machinability, excellent translucency, and a smooth surface finish. However, it also has some disadvantages, including low resistance to scratches and cracks, low resistance to heat and chemical exposure, and susceptibility to yellowing. These factors must be taken into account when deciding whether to use acrylic for CNC machining.

Selecting the Ideal Manufacturer Cnc Acrylic

When it comes to selecting the ideal manufacturer for CNC acrylic products, there are several factors to consider in order to ensure you end up with a high-quality product. Here are some tips to keep in mind:

1. Experience: Look for a manufacturer who has considerable experience in CNC acrylic manufacturing. This means they have the knowledge and expertise necessary to create high-quality products that meet your specific needs.

2. Capabilities: Make sure the manufacturer you choose has the necessary equipment and capabilities to produce the specific CNC acrylic product you need. This includes the ability to work with the size, thickness, and complexity of the product you require.

3. Quality control: The manufacturer you choose should have a robust quality control process in place to ensure that every product they produce meets rigorous standards. This can include regular inspections, testing, and documentation of their manufacturing process.

4. Material expertise: Not all acrylic materials are the same. Your manufacturer should have a deep knowledge of different types of acrylic material and how to work with them to create the best products possible.

5. Communication: Choose a manufacturer who is transparent and communicative throughout the manufacturing process. They should be able to provide regular updates on the progress of your project and be available to answer any questions or address any concerns you may have.

Overall, selecting the ideal manufacturer for your CNC acrylic needs requires careful consideration of a variety of factors. By taking the time to choose a manufacturer who has the necessary experience, capabilities, quality control, material expertise, and communication skills, you can be confident that you are getting the best possible product.

Things to Consider When Purchasing Cnc Acrylic

When it comes to purchasing CNC acrylic, there are certain things that you should consider to make sure that you get the best value for your money. Here are some of the things that you need to keep in mind:

1. Quality: When purchasing acrylic, always opt for high-quality materials. This ensures that the acrylic will remain stable over time, will not discolour, and will not crack if exposed to sunlight or changing temperatures.

2. Thickness: The thickness of CNC acrylic is an important consideration. Ensure that the thickness is appropriate for your application. Thinner acrylic sheets will not have the strength or rigidity of thicker sheets.

3. Colour: Choose the appropriate colour of the acrylic that will suit your project. Clear and coloured acrylic can be used in different applications, such as for signage, displays, and even for decoration purposes.

4. Precision: When buying CNC acrylic, it’s important to ensure that the machine used can produce precision cuts. This is essential in ensuring that your final product is of high quality, and that it’s produced according to the specified dimensions.

5. Compatibility: Consider whether the CNC acrylic you plan to buy is compatible with the other materials that you’ll be working with. If it’s not, you may need to look for other alternatives or switch to a different type of acrylic.

6. Supplier: Lastly, make sure that you select a reputable supplier to purchase your CNC acrylic from. This ensures that you receive high-quality materials, excellent customer service, and timely delivery.

In conclusion, CNC acrylic can be a versatile and effective material for many different applications. It is important to take the time to consider the above points before purchasing to ensure that you get the best value for your investment.

Properties of Cnc Acrylic

Cnc acrylic refers to the type of acrylic material that has been manipulated through Computer Numerical Control (CNC) technology. It is highly popular in the manufacturing industry because of its incredible properties, which make it ideal for various applications.

One of the notable properties of CNC acrylic is its durability. The material is sturdy and can withstand high temperatures, making it perfect for use in outdoor applications such as signs, displays, and lighting. It is also resistant to scratches and impact, ensuring that it can serve its purpose for an extended period.

CNC acrylic is highly transparent and has excellent light transmission capabilities, making it suitable for use in the lighting industry. It also maintains its clarity over time, even when exposed to harsh weather conditions or surface abrasion.

Moreover, CNC acrylic is highly versatile and can be cut and shaped into various forms and designs. This property, coupled with its high clarity, makes it the material of choice for designers and architects who require unique and intricate designs.

Another significant property of CNC acrylic is its ease of maintenance. The material requires minimal cleaning and is not susceptible to staining or discoloration. This quality makes it ideal for use in areas that require strict sanitary conditions such as hospitals, laboratories, and kitchens.

Lastly, CNC acrylic is lightweight and easy to handle. The material can be transported and installed without requiring expensive equipment, making it a cost-effective solution for various applications.

In conclusion, CNC acrylic is a material that possesses several properties that make it ideal for various manufacturing applications. Its durability, transparency, versatility, ease of maintenance, and lightweight make it a popular choice amongst designers, architects, and manufacturers alike.

How to use Cnc Acrylic

CNC Acrylic is a type of material that has become increasingly popular in recent years. It is versatile, lightweight, and easy to work with when creating various projects. Here is a brief guide on how to use CNC Acrylic:

1. Choose the Right Type of Acrylic

Before you start working with CNC Acrylic, it’s essential to choose the correct type of acrylic for your project. Different types of acrylic such as cast, extruded, or impact-resistant have different properties and should be chosen carefully based on your needs.

2. Prepare Your Equipment

To work with CNC Acrylic, you’ll need some equipment such as a router, drill press, and saw. It’s essential to ensure that all equipment is in good working condition, and the blades are sharp to ensure a smooth cut through the material.

3. Create the Design of Your Project

The next step is to create the design of your project. You can use various software programs such as Adobe Illustrator or Autodesk to create a vector design file, which will guide the CNC machine to cut and shape the acrylic.

4. Secure the Acrylic Sheet

Once you have the design ready, you’ll need to secure the acrylic sheet to the CNC machine’s table with clamps or tape. It’s vital to ensure that the sheet is level and well-positioned so that the cutter does not damage it.

5. Customize Your Settings and Cut

It’s crucial to customize your CNC machine’s settings to ensure the best results. This includes adjusting spindle speed, feed rate, and depth of cut. Once you have customized the settings, start the machine, and let it cut according to the design specifications.

6. Finishing Touches

After the acrylic has been cut according to the design, it’s time to remove it from the machine and perform the finishing steps. The edges can be sanded with sandpaper to remove any rough edges or burrs. Also, the acrylic can be cleaned with a gentle soap and water solution

Glossary Terminology Terms for Cnc Acrylic

A Glossary of Terminology Terms for CNC Acrylic

Acrylic is a versatile material that can be transformed into various shapes and designs. With the use of CNC technology, acrylic can be cut, drilled and etched with precision and accuracy. Here are some commonly used terminology terms for CNC acrylic:

1. CNC: Computer Numerical Control is a computerized technology that controls the movements of the machine tool. It operates on preprogrammed codes that guide the machinery movement.

2. Acrylic: A transparent thermoplastic that has a glossy surface and is known for its durability, resistance to impact, and weathering.

3. Router: A cutting tool that uses a spinning bit to cut through materials. Routers can create designs and shapes with precision and accuracy.

4. CAD: Computer-Aided Design is software that allows designers to create designs and drawings using a computer.

5. CAM: Computer-Aided Manufacturing is software that creates a program that tells the CNC machine what to do.

6. Laser Cutting: A process where a beam of light is used to cut through acrylic, producing a clean and precise cut.

7. Engraving: A process used to etch designs and lettering onto acrylic using a router or laser.

8. Thermoforming: A process where acrylic is heated and molded into a specific shape using a mold.

9. Tolerance: The acceptable range of deviation from a specific measurement. CNC acrylic manufacturing requires a tight tolerance to ensure that the end product meets the required specifications.

10. Edge Finish: The final treatment applied to the edge of the acrylic after cutting to ensure a smooth and polished edge.

By familiarizing yourself with these terminology terms, you can effectively communicate with CNC acrylic manufacturers, ensuring that you get the product that meets your specific requirements.

Cnc Acrylic Price

CNC acrylic is a popular material used in a variety of industries for its durability and versatility. Whether you are looking to create displays, signs, or prototypes, CNC acrylic can be a cost-effective and attractive solution. When it comes to CNC acrylic prices, there are several factors to consider.

One of the biggest factors affecting the price of CNC acrylic is the thickness of the material. Thicker acrylic sheets will generally cost more than thinner ones. Additionally, the size of the sheet can also impact the cost. Larger sheets of acrylic will typically be more expensive than smaller ones.

Another factor to consider when looking at CNC acrylic prices is the type of acrylic being used. There are several different types of acrylic available, each with their own unique properties and benefits. For example, some types of acrylic are more resistant to impact or UV damage, while others are more scratch-resistant.

Finally, the complexity of the design being created with CNC acrylic will also impact the price. More intricate designs or shapes will require more time and expertise to produce, which can drive up the cost.

Overall, when looking at CNC acrylic prices, it is important to remember that the cost will vary depending on several factors. It is important to work with a trusted supplier who can help you choose the right type and thickness of acrylic for your needs while staying within your budget. With the right approach, CNC acrylic can be a cost-effective and high-quality solution for your manufacturing needs.