Introduce about cnc cut guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

CNC (Computer Numerical Control) cut guide is a technology used in precision cutting of materials such as wood, metal, and plastic. It offers high quality and precision in cutting, making it ideal for industries that require intricate designs and shapes. The cost of CNC cut guides can vary depending on the complexity of the project, but overall they are cost-effective in the long run due to reduced waste and increased productivity.

There are many suppliers of CNC cut guides on the market, so it is important to choose a reputable and reliable supplier that offers quality products and excellent customer service. Look for suppliers that have certifications such as ISO 9001, which ensures quality control and compliance with industry standards.

The market for CNC cut guides is growing rapidly, with industries such as automotive, aerospace, and manufacturing utilizing this technology for cutting various materials. It is also popular among hobbyists and DIY enthusiasts for creating custom projects with precision.

Some tips for using CNC cut guides effectively include proper maintenance and calibration, using the right cutting tools, and selecting the appropriate materials for cutting. It is also important to ensure safety measures are in place when operating CNC machinery.

FAQ:

1. What materials can CNC cut guides cut?

CNC cut guides can cut a variety of materials including wood, metal, plastic, and composite materials.

2. How accurate is CNC cutting?

CNC cutting offers high precision and accuracy, with tolerances as low as 0.001 inches.

In conclusion, CNC cut guides offer high quality cutting, cost-effectiveness, and precision in various industries. Choosing the right supplier and following best practices for operation can ensure optimal results.

Types of cnc cut

CNC (Computer Numerical Control) cutting is a versatile and precise method of cutting various materials like wood, metal, plastic, and foam. There are several types of CNC cutting processes that are commonly used in different industries:

1. CNC Plasma Cutting: This process uses a high-velocity jet of ionized gas to cut through electrically conductive materials like steel and aluminum. Plasma cutting is ideal for cutting thick materials at high speeds and is widely used in industries like metal fabrication and automotive.

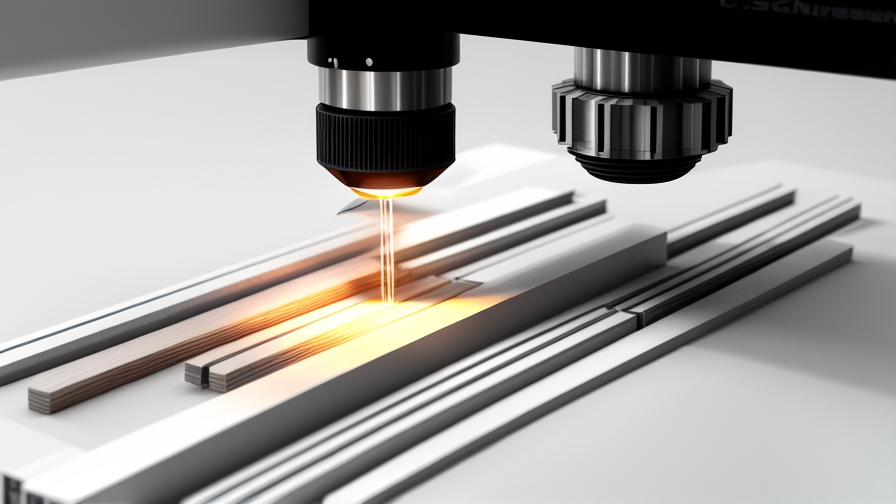

2. CNC Laser Cutting: Laser cutting uses a high-powered laser beam to cut through materials with extreme precision. It is commonly used for cutting flat sheet materials like acrylic, wood, and metal in industries such as signage, aerospace, and electronics.

3. CNC Waterjet Cutting: Waterjet cutting uses a high-pressure stream of water mixed with abrasive materials to cut through a wide range of materials, including metal, stone, glass, and composites. Waterjet cutting is known for its versatility and ability to produce clean and burr-free edges.

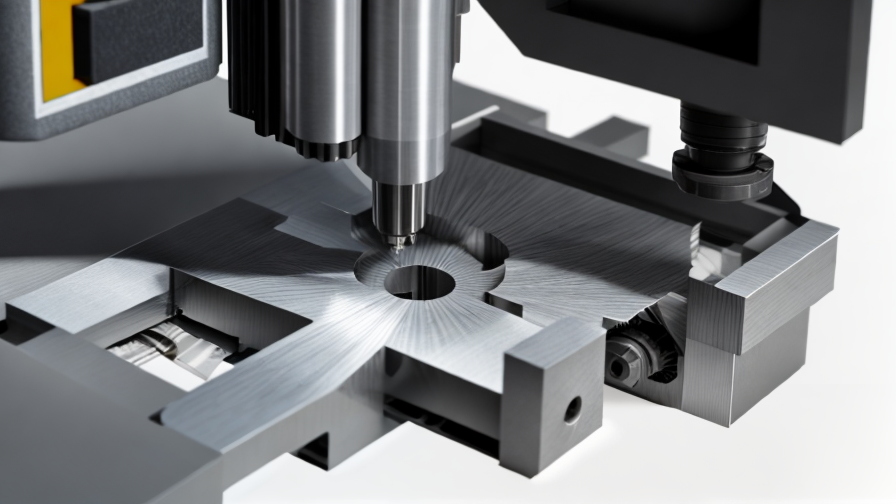

4. CNC Router Cutting: CNC routers use a rotating cutting tool to carve and shape materials like wood, plastic, and foam. Routers are commonly used in woodworking, cabinetry, and prototyping industries to create intricate designs and patterns.

5. CNC Milling: CNC milling uses a rotating cutting tool to remove material from a workpiece to create a desired shape or design. It is commonly used in industries like aerospace, automotive, and mold making to produce complex and precise parts.

Overall, CNC cutting processes offer a wide range of capabilities and applications for various industries, allowing for efficient and accurate production of parts and products. By utilizing CNC technology, manufacturers can achieve high-quality results with minimal waste and labor costs.

Pros and Cons of Using cnc cut

CNC cutting, or computer numerical control cutting, is a popular and efficient method for cutting various materials with precision and accuracy. There are several pros and cons to using CNC cutting that should be considered before deciding to use this technology.

One of the main advantages of CNC cutting is its precision and accuracy. CNC cutting machines are programmed to cut materials with exact specifications, resulting in clean and precise cuts every time. This level of precision is difficult to achieve with manual cutting methods, making CNC cutting ideal for complex designs and intricate patterns.

Another pro of using CNC cutting is its efficiency. CNC cutting machines can work continuously for long periods of time without any breaks, resulting in faster production times and increased productivity. This can be especially beneficial for large-scale manufacturing projects that require a high volume of cuts.

Additionally, CNC cutting is versatile and can be used to cut a wide range of materials, including metals, plastics, wood, and composites. This makes CNC cutting suitable for a variety of applications across different industries.

However, there are also some drawbacks to using CNC cutting. One of the main cons is the initial cost of purchasing and setting up a CNC cutting machine. These machines can be expensive to purchase and require training and expertise to operate effectively, which can be a barrier for some businesses.

Another con of CNC cutting is the maintenance and upkeep required to keep the machines running smoothly. Regular maintenance and calibration are essential to ensure the accuracy and precision of the cuts, which can be time-consuming and costly.

In conclusion, while CNC cutting offers many advantages, including precision, efficiency, and versatility, there are also some drawbacks to consider, such as the initial cost and ongoing maintenance requirements. Businesses should carefully weigh these pros and cons before deciding to invest in CNC cutting technology.

cnc cut Reference Specifications (varies for different product)

CNC (Computer Numerical Control) cutting is a versatile manufacturing process used to precisely cut various materials such as metal, wood, plastics, and composites. The reference specifications for CNC cut products can vary depending on the specific requirements of each product.

One of the primary considerations for CNC cutting is the material being used. Different materials have distinct characteristics that may affect the cutting process. For instance, metals may require specific cutting speeds, feeds, and tooling to achieve desired results, whereas wood may need different parameters to minimize burning or tear-out.

Another crucial factor is the desired tolerance or accuracy of the final product. CNC cutting can achieve highly accurate cuts, often within a few thousandths of an inch. The reference specifications for tolerance will depend on the application and may vary from product to product. Industries like aerospace or medical devices may require tighter tolerances compared to general fabrication applications.

The thickness of the material is also an important consideration. CNC machines have limitations on the maximum thickness they can cut efficiently. While thin materials can be easily cut, thicker materials may require multiple passes or specialized equipment to achieve the desired results. Reference specifications for maximum thickness should be provided to ensure the CNC machine is capable of accommodating the material.

Furthermore, the complexity of the design or shape being cut should be taken into account. CNC machines can cut intricate shapes and patterns, but the reference specifications should address any design limitations or requirements. This includes factors like minimum feature size, radius restrictions, or any other design considerations specific to the product.

Lastly, the production volume and time constraints need to be considered. CNC cutting can be a time-consuming process, especially for intricate or larger products. Reference specifications should communicate the desired lead time and production volume to ensure efficient scheduling and planning.

In conclusion, the reference specifications for CNC cut products can vary based on material, tolerance, thickness, design complexity, and production volume. Providing these specifications allows manufacturers to optimize the cutting process and deliver high-quality, accurate products within the desired timeframe.

Applications of cnc cut

CNC cutting technology is used in a wide range of industries for various applications. Some of the key applications include:

1. Manufacturing: CNC cutting is widely used in the manufacturing industry for cutting and shaping a variety of materials such as metal, wood, plastic, and composites. It allows for precise and accurate cutting of parts, resulting in high-quality products.

2. Aerospace: CNC cutting technology is used in the aerospace industry for cutting and shaping components such as aircraft parts, engine components, and structural elements. The accuracy and precision of CNC cutting machines make them ideal for creating complex and intricate parts used in aerospace applications.

3. Automotive: CNC cutting is commonly used in the automotive industry for cutting and shaping metal and plastic components such as body panels, interior trim, and engine parts. CNC cutting machines are able to produce high-quality parts with tight tolerances required for automotive applications.

4. Furniture making: CNC cutting technology is used in the furniture industry for cutting and shaping wood and other materials to create custom furniture pieces. CNC cutting allows for precise and intricate designs to be achieved, resulting in high-quality furniture pieces.

5. Signage: CNC cutting technology is widely used in the signage industry for cutting and shaping materials such as acrylic, aluminum, and PVC to create custom signs and displays. CNC cutting machines are able to produce intricate designs and lettering with precision and accuracy.

Overall, CNC cutting technology offers a wide range of applications in various industries, allowing for precise and accurate cutting of a variety of materials to create high-quality products and components.

The Work Process and how to use cnc cut

CNC (Computer Numerical Control) cutting is a precise and efficient method of cutting various materials using a computer-controlled machine. The work process involves several steps:

1. Design: The first step is to create a design or drawing of the object that needs to be cut. This design is then converted into a digital format that can be read by the CNC machine.

2. Programming: The digital design is loaded into the CNC machine’s computer software. The software translates the design into a series of instructions that tell the machine how to move and cut the material.

3. Set up: The material to be cut is placed on the CNC machine’s cutting bed and secured in place. The machine’s cutting tools are then set up and calibrated for the specific job.

4. Cutting: Once everything is set up, the CNC machine is started and the cutting process begins. The machine uses its cutting tools to follow the programmed instructions and cut the material into the desired shape.

5. Quality control: After the cutting process is complete, the finished piece is inspected for quality and accuracy. Any necessary adjustments can be made before the final product is approved.

To use CNC cutting effectively, it is important to carefully follow the design and programming process to ensure accurate and precise cuts. It is also essential to regularly maintain and calibrate the CNC machine to ensure optimum performance. By following these steps, CNC cutting can be a highly effective and efficient method for cutting a wide range of materials.

Quality Testing Methods for cnc cut and how to control the quality

Quality testing methods for CNC cut parts can include visual inspection, dimensional measurement, surface roughness analysis, material analysis, and functional testing. Visual inspection involves examining the part for any defects such as burrs, dents, or scratches. Dimensional measurement ensures that the part meets the specified tolerances and dimensions. Surface roughness analysis checks the smoothness of the part’s surface. Material analysis can verify the material composition and properties. Functional testing involves testing the part’s performance in its intended application.

To control the quality of CNC cut parts, it is important to establish clear quality standards and procedures. This includes defining tolerances, inspecting parts at key stages of production, and implementing corrective actions when necessary. Using calibrated measuring equipment and ensuring proper maintenance of the CNC machine can also help to maintain quality. Regular training for operators on quality standards and techniques can improve consistency and accuracy in production. Additionally, establishing a quality management system such as ISO 9001 can provide a framework for continuous improvement and quality control. By following these methods and practices, manufacturers can ensure that CNC cut parts meet high-quality standards and customer expectations.

cnc cut Sample Policy and Post-Purchase Considerations for cnc cut from China

Sample Policy:

1. Returns: We accept returns within 7 days of delivery if the product is damaged or not as described. Customers must provide photo evidence of the issue before a return can be initiated.

2. Refunds: Refunds will be processed within 14 days of receiving the returned item. Shipping fees are non-refundable.

3. Exchanges: Exchanges are available for damaged or incorrect items. Customers are responsible for return shipping costs.

4. Custom Orders: Custom orders are final sale and non-refundable.

5. Warranty: Our products come with a 12-month warranty against manufacturing defects. Please contact us directly for warranty claims.

6. Shipping: We offer worldwide shipping with tracking numbers provided. Shipping times may vary depending on location.

Post-Purchase Considerations:

1. Inspection: Upon receiving your order, please inspect the items for any damage or defects. Contact us immediately if there are any issues.

2. Maintenance: Regularly clean and maintain your cnc cut products to ensure longevity and optimal performance.

3. Feedback: We value your feedback and suggestions for improvement. Please leave a review or contact us directly with your comments.

4. Recommendations: Share your experience with friends and family to help us grow our business.

5. Follow-up: We may reach out to you post-purchase to ensure your satisfaction and address any concerns you may have.

Sourcing cnc cut from China: Opportunities, Risks, and Key Players

Sourcing CNC cut services from China presents numerous opportunities for businesses looking to lower production costs while maintaining high quality standards. China has a well-developed manufacturing industry with a wide range of CNC cutting capabilities, offering a cost-effective solution for businesses looking to outsource their cutting needs. China also has a large pool of skilled and experienced workers who can provide high-quality CNC cutting services.

However, there are also risks associated with sourcing CNC cut services from China. Quality control and communication can be challenging, especially when dealing with overseas suppliers. Intellectual property concerns and supply chain disruptions are also common risks when sourcing from China. It is essential for businesses to conduct thorough due diligence when selecting a supplier to mitigate these risks.

Key players in the CNC cutting industry in China include companies such as Foxconn, BYD Precision Manufacturing Co., Ltd., and Suzhou Jiade Precision Machinery Co., Ltd. These companies have a strong reputation for providing high-quality CNC cutting services to both domestic and international clients. When sourcing CNC cutting services from China, businesses should consider working with established and reputable suppliers to ensure the quality and reliability of their products.

In conclusion, sourcing CNC cut services from China can provide significant cost savings and access to a wide range of cutting capabilities. However, businesses should be aware of the risks associated with sourcing from China and take steps to mitigate these risks. Working with established key players in the industry can help ensure the quality and reliability of CNC cutting services sourced from China.

How to find and select reliable cnc cut manufacturers in China,use google search manufacturers and suppliers

When searching for reliable CNC cut manufacturers in China, start by using Google to search for manufacturers and suppliers. You can use specific keywords such as “CNC cut manufacturers in China” to narrow down your search results.

When looking for a reliable manufacturer, consider the following factors:

1. Reputation: Look for manufacturers with a good reputation in the industry. Check for reviews and feedback from previous customers to gauge the quality of their products and services.

2. Experience: Choose manufacturers with years of experience in the CNC cutting industry. An experienced manufacturer is likely to have the expertise and resources to deliver high-quality products.

3. Quality Control: Make sure the manufacturer has stringent quality control measures in place to ensure the products meet your specifications and standards.

4. Production Capacity: Consider the production capacity of the manufacturer to ensure they can handle your order size and meet your deadline.

5. Communication: Choose a manufacturer that has clear communication channels and responds promptly to your inquiries. Good communication is essential for a smooth manufacturing process.

6. Price: While price is an important factor, do not compromise on quality for a cheaper price. Compare quotes from multiple manufacturers to find a balance between quality and cost.

By considering these factors and conducting thorough research, you can find and select a reliable CNC cut manufacturer in China to meet your needs.

How to check cnc cut manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

One way to determine the reliability of a CNC cut manufacturer’s website is to check its ranking using a tool like SEOquake in Google Chrome. This tool can show you where the website ranks in the top 10 million websites, giving you an indication of its popularity and credibility. A website that ranks highly is more likely to be reliable and trustworthy.

Additionally, you can look for other signs of a reputable website, such as a professional design, clear contact information, and customer reviews. A reliable CNC cut manufacturer will have a well-maintained website that provides detailed information about their products and services. They should also have a responsive customer service team that can address any questions or concerns you may have.

It’s important to do your research and read reviews from other customers before choosing a CNC cut manufacturer. By following these tips and using tools like SEOquake, you can ensure that you are working with a reputable and reliable company for your CNC cutting needs.

Top 10 cnc cut manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Suzhou Rico Machinery Co., Ltd.

Suzhou Rico Machinery specializes in manufacturing CNC cutting tools and accessories for a wide range of applications. Their products include CNC router bits, end mills, engraving tools, and cutting blades. These tools are designed to provide high precision and durability for various cutting tasks.

2. Jinan Penn CNC Machine Co., Ltd.

Jinan Penn CNC Machine offers a diverse range of CNC cutting machines, including CNC routers, laser cutters, plasma cutters, and waterjet cutters. Their machines are known for their efficiency, accuracy, and reliability in cutting a variety of materials such as wood, metal, and plastic.

3. Beijing Torch SMT Co., Ltd.

Beijing Torch SMT specializes in manufacturing CNC cutting equipment for the electronics industry. Their products include CNC routers, laser cutters, and PCB cutting machines. These machines are designed to provide high precision and efficiency in cutting circuit boards and other electronic components.

| Manufacturer | Products offered |

|———————–|—————————————–|

| Suzhou Rico Machinery | CNC router bits, end mills, engraving tools |

| Jinan Penn CNC Machine | CNC routers, laser cutters, plasma cutters, waterjet cutters |

| Beijing Torch SMT | CNC routers, laser cutters, PCB cutting machines |

Background Research for cnc cut manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to finding CNC cut manufacturers in China, there are several resources that can be accessed for background research. Let’s take a look at three platforms: qcc.com, archive.org, and importyeti.com.

Qcc.com is a business information search platform in China that provides detailed information on companies. It allows users to search for specific companies, including CNC cut manufacturers, and view their basic information, such as their registered location, business scope, and legal representative. This platform can give an initial understanding of the companies and their capabilities.

Archive.org is a popular online platform that allows users to access archived versions of websites. This can be useful for researching CNC cut manufacturers in China, as it may provide historical information about companies, such as their past products, services, and client portfolios. By reviewing these archived versions, a potential buyer can gain insight into the manufacturer’s experience and expertise.

Importyeti.com is a sourcing platform that specializes in helping businesses find suppliers in China. It provides a comprehensive directory of manufacturers, including CNC cut manufacturers, along with their company profiles and product information. Buyers can also view the ratings and reviews left by previous customers, which can help in evaluating the reliability and quality of the manufacturer.

By utilizing these platforms, potential buyers can gather valuable information about CNC cut manufacturers in China. They can assess the manufacturers’ business profiles, explore their past performance, and even find reviews and ratings from other customers. These resources can help buyers make informed decisions and select reliable and suitable manufacturers for their CNC cutting needs.

Leveraging Trade Shows and Expos for cnc cut Sourcing in China

Trade shows and expos are excellent opportunities for sourcing CNC cut products in China. These events bring together a wide range of suppliers and manufacturers, offering a one-stop-shop for sourcing CNC cut products. Here are some key tips for leveraging trade shows and expos for CNC cut sourcing in China:

1. Do your research: Before attending a trade show or expo, research the exhibitors to identify potential suppliers of CNC cut products. Make a list of the companies you want to visit and prioritize your time accordingly.

2. Network: Trade shows and expos provide a great opportunity to network with suppliers and manufacturers. Take the time to introduce yourself, learn about their products and capabilities, and establish a relationship for future business opportunities.

3. Ask questions: When meeting with suppliers at trade shows and expos, be sure to ask questions about their CNC cutting processes, materials used, lead times, pricing, and quality control measures. This will help you determine if they are a suitable partner for your sourcing needs.

4. Request samples: If possible, request samples of CNC cut products from potential suppliers. This will allow you to assess the quality of their workmanship and materials before making a purchasing decision.

5. Negotiate terms: Trade shows and expos are a great place to negotiate pricing, terms, and delivery schedules with suppliers. Be prepared to discuss your specific requirements and negotiate a mutually beneficial agreement.

By following these tips, you can effectively leverage trade shows and expos for CNC cut sourcing in China, and identify reliable suppliers for your business needs. Trade shows and expos are a valuable resource for connecting with suppliers, exploring new products, and expanding your network in the CNC cutting industry.

The Role of Agents and Sourcing Companies in Facilitating cnc cut Purchases from China

Agents and sourcing companies play a crucial role in facilitating CNC cut purchases from China. These entities act as intermediaries between the buyer and the Chinese manufacturers, helping to bridge the gap in language, cultural, and logistical barriers.

Firstly, agents and sourcing companies act as a liaison between the buyer and the seller. They have a deep understanding of the Chinese market and its suppliers, which enables them to identify and connect the buyer with reputable manufacturers capable of fulfilling their CNC cut requirements. By leveraging their network and industry knowledge, agents and sourcing companies can ensure that the buyer gets access to reliable suppliers who can meet their specific needs.

Secondly, agents and sourcing companies assist in negotiating the best terms and prices for the buyer. As experienced negotiators, they can help the buyer navigate the complexities of Chinese business practices and secure favorable deals. By assessing the market value, evaluating the product quality, and comparing multiple suppliers, these intermediaries can ensure that the buyer obtains competitive prices while maintaining the desired level of quality.

Additionally, agents and sourcing companies provide valuable quality control and inspection services. They can visit the manufacturers’ facilities and inspect the CNC cut products to ensure they meet the buyer’s specifications and quality standards. By conducting pre-shipment inspections, these intermediaries can help identify and address any potential issues before the products are shipped to the buyer, minimizing the risk of receiving defective or subpar goods.

Furthermore, agents and sourcing companies assist in navigating the complexities of shipping and logistics. They can handle the entire process, from arranging transportation to managing customs documentation, ensuring that the CNC cut products are delivered smoothly and on time. This expertise greatly simplifies the buying process for the buyer, who may otherwise encounter challenges related to shipping and import regulations.

In conclusion, agents and sourcing companies play a crucial role in facilitating CNC cut purchases from China. Their expertise in supplier identification, negotiation, quality control, and logistics management greatly simplifies the buying process for the buyer, ensuring smooth and successful transactions with Chinese manufacturers.

Price Cost Research for cnc cut manufacturers Companies in China, use temu.com and 1688.com

When it comes to finding competitively priced CNC cut manufacturers in China, two online platforms that can be particularly useful are temu.com and 1688.com. These platforms can provide valuable insight and help streamline the process of locating affordable manufacturers for CNC cutting services.

Temu.com is an online sourcing platform that connects global buyers with qualified Chinese suppliers. With a user-friendly interface, it allows users to browse through various categories, including CNC cutting, and find manufacturers that meet their specific requirements. One of the advantages of using temu.com is that it offers a wide selection of suppliers, allowing for a more comprehensive comparison of prices and services. This platform also provides information such as the supplier’s location, production capacity, and certification status, helping buyers make informed decisions.

1688.com, on the other hand, is a popular Chinese B2B platform owned by Alibaba Group. This platform is primarily designed for domestic buyers, giving it an edge for finding local manufacturers offering affordable CNC cutting services. Although the website is in Chinese, it can be translated using online tools such as Google Translate. 1688.com offers an extensive range of suppliers, with a focus on lower-priced products, making it a valuable resource for cost-conscious buyers.

To conduct effective price cost research on these platforms, several steps can be followed. Firstly, users should clearly define their requirements, such as the material type, quantity, and dimensions needed for the CNC cutting services. With these specifications in mind, buyers can search for relevant suppliers on temu.com and 1688.com. It is recommended to shortlist a few potential manufacturers based on their product portfolios, customer reviews, and pricing information.

Once a shortlist is created, buyers can initiate direct communication with the manufacturers, either through the platforms’ messaging systems or by contacting them directly. This allows for further negotiation and obtaining detailed quotations for the desired CNC cutting services. It is important to consider factors such as production time, shipping costs, payment terms, and quality assurance when evaluating the final price offers.

By utilizing temu.com and 1688.com, buyers can effectively research and compare prices of various CNC cut manufacturers in China, making it easier to find the most cost-effective option for their specific needs. However, it is recommended to exercise due diligence and thoroughly assess the manufacturers’ credibility, quality standards, and customer feedback before making a final decision to ensure a successful and economically viable partnership.

Shipping Cost for cnc cut import from China

The shipping cost for CNC cut imports from China can vary depending on several factors such as the size, weight, and type of the goods being shipped, as well as the shipping method and carrier chosen. Generally, the cost of shipping a CNC cut import from China to the United States can range from $500 to $2000, depending on the distance, speed, and mode of transportation.

When shipping CNC cut imports from China, it is important to consider factors such as the size and weight of the shipment, as these can affect the overall cost. Larger and heavier shipments will typically incur higher shipping costs, while smaller and lighter shipments may be more cost-effective to ship.

In addition to size and weight, the shipping method and carrier chosen can also impact the cost of shipping CNC cut imports from China. Air freight is typically faster but more expensive, while sea freight is slower but more cost-effective. It is important to compare different shipping options and carriers to find the most cost-effective solution for your specific needs.

Overall, when importing CNC cut products from China, it is important to factor in shipping costs as part of your overall budget. By considering factors such as size, weight, shipping method, and carrier, you can ensure that your shipping costs stay within a reasonable range and that your imports arrive in a timely manner.

Compare China and Other cnc cut Markets: Products Quality and Price,Visible and Hidden Costs

China is known globally for its dominance in the CNC (Computer Numerical Control) cut market. However, it is important to compare China with other CNC cut markets in terms of product quality and price, as well as visible and hidden costs.

In terms of product quality, China has a reputation for producing both good and poor quality products. While China offers a wide range of products, there can be certain variations in quality due to the large manufacturing industry and a diverse range of suppliers. On the other hand, other CNC cut markets may have a more specific focus on certain industries, resulting in higher quality products within their niche.

Price is another crucial factor when comparing CNC cut markets. China is often associated with low-cost manufacturing due to its low labor and production costs. This makes products manufactured in China more affordable compared to those from other markets. However, other CNC cut markets may offer higher prices due to factors such as higher labor costs or specialization in premium products.

Visible costs refer to the costs that are easily identifiable when purchasing CNC cut products. China generally offers competitive pricing due to economies of scale, making the visible costs lower compared to other markets. However, hidden costs, such as quality control, transportation, import duties, and compliance with safety regulations, can vary across different markets. It is important to consider these hidden costs to make an accurate cost comparison.

Ultimately, the choice between China and other CNC cut markets depends on the specific requirements of the products. If cost is the primary concern and a wider variety of products is desired, China may be the preferred option. However, if higher product quality is a priority or there is a need for specialized products within a specific industry, other CNC cut markets may offer more suitable options.

In summary, China stands out in the CNC cut market due to its low-cost manufacturing and wide range of products. However, comparing it to other markets in terms of product quality and price, as well as visible and hidden costs, is essential to make an informed decision. Each market has its own strengths and weaknesses, and the choice depends on the specific needs and preferences of the buyer.

Understanding Pricing and Payment Terms for cnc cut: A Comparative Guide to Get the Best Deal

When it comes to CNC (Computer Numerical Control) cut services, understanding pricing and payment terms is crucial to get the best deal. This comparative guide aims to provide essential insights into these aspects, helping you make informed decisions.

Pricing for CNC cut services can vary significantly depending on various factors. One crucial aspect is the material being used. Different materials have different costs and may require specific tools or techniques for cutting. For instance, cutting metal may be more expensive compared to wood or plastic. It’s essential to consider the material’s complexity, density, and thickness, as they may influence pricing.

The complexity of the design or pattern to be cut also affects pricing. A simple design may require less time and effort, resulting in a lower cost. On the other hand, intricate and detailed designs may require specialized equipment or skills, increasing the overall price. It’s recommended to consult with the CNC cut service provider to determine the impact of design complexity on pricing.

Batch size or quantity is another crucial factor influencing pricing. Some service providers offer volume discounts, where the cost per piece decreases as the quantity increases. Therefore, it’s advisable to consider the required quantity to leverage potential cost savings.

When it comes to payment terms, understanding the options offered by CNC cut service providers is essential. Most providers have different methods such as upfront payment, installments, or financing options. It’s crucial to carefully evaluate these options based on your financial capability and project requirements.

Additionally, it’s essential to inquire about additional costs or fees that may affect the overall pricing. These can include charges for design modifications, rush orders, or shipping. Clarifying such details beforehand will avoid any unexpected expenses.

To get the best deal, it’s recommended to research and compare multiple CNC cut service providers. Look for reliable and reputable companies with a proven track record of delivering high-quality work. Requesting quotes from different providers will help identify competitive pricing and negotiate better terms.

In conclusion, understanding pricing and payment terms for CNC cut services is essential to secure the best deal while ensuring cost-effectiveness and high-quality results. Considering factors like material, design complexity, batch size, and exploring payment options offered by service providers will lead to optimal decision-making. Researching and comparing multiple providers will empower you to make an informed choice and attain the desired CNC cut services.

Chinese Regulations and Industry Standards Certifications for cnc cut,Import Regulations and Customs for cnc cut from China

In China, CNC cutting machines are subject to various regulations and industry standards to ensure quality, safety, and compliance with local laws. Some of the key certifications for CNC cutting machines in China include ISO 9001 for quality management, CE for safety and environmental standards, and RoHS for restriction of hazardous substances. These certifications are often required for manufacturers to sell their products in domestic and international markets.

When importing CNC cutting machines from China, importers should be aware of the regulations and customs procedures that apply to their specific product. They should ensure that the products meet the necessary certifications and standards, as failure to do so can result in customs delays or rejection of the shipment. Importers may also need to provide documentation such as invoices, packing lists, and certificates of origin to clear customs and comply with import regulations.

It is important for importers to work with a reputable supplier who is familiar with export regulations and can provide the necessary documentation for customs clearance. Additionally, importers should be aware of any tariffs or duties that may apply to CNC cutting machines imported from China, and factor these costs into their pricing and logistics planning. By understanding the regulations and customs procedures for importing CNC cutting machines from China, importers can ensure a smooth and successful import process.

Sustainability and Environmental Considerations in cnc cut Manufacturing

Sustainability and environmental considerations are increasingly important in the CNC cut manufacturing industry. CNC machines are known for their precision and efficiency in cutting materials, but they also have an impact on the environment.

One of the key sustainability considerations in CNC cut manufacturing is the choice of materials. Using sustainable and eco-friendly materials such as recycled plastics or wood from certified sustainable sources can help reduce the environmental impact of manufacturing processes. Additionally, optimizing the use of materials through efficient cutting patterns and minimizing waste can also contribute to sustainability efforts.

Energy consumption is another important aspect to consider in CNC cut manufacturing. Using energy-efficient CNC machines and optimizing their operation to reduce energy usage can help lower the carbon footprint of manufacturing processes. Implementing energy-saving practices such as scheduling production runs during off-peak hours or using renewable energy sources can further enhance sustainability efforts.

Reducing emissions and waste generation is also crucial in promoting environmental sustainability in CNC cut manufacturing. Proper disposal and recycling of waste materials, such as metal shavings or plastic scraps, can help reduce the impact on the environment. Additionally, implementing pollution control measures and adhering to environmental regulations can ensure that manufacturing processes are conducted in a responsible and sustainable manner.

Overall, integrating sustainability and environmental considerations into CNC cut manufacturing practices is essential for ensuring the long-term viability of the industry and minimizing its impact on the environment. By making conscious choices in material selection, energy usage, and waste management, manufacturers can contribute to a more sustainable future for the industry and the planet.

List The Evolution history of “cnc cut”

The evolution of CNC cut technology has spanned several decades, revolutionizing the field of manufacturing and shaping the way we produce various products. The timeline below highlights the key milestones in the history of CNC cut:

1. 1950s-1960s: Computer Numerical Control (CNC) emerged during this period as a means to automate machine tools. Early developments included punched-tape systems, where instructions were encoded on paper tape and read by the machine.

2. 1970s-1980s: CNC technology became more sophisticated, introducing direct numerical control (DNC) systems. These systems allowed multiple machines to be controlled by a single computer, improving efficiency and reducing human intervention.

3. 1980s-1990s: CNC cut technology advanced with the introduction of CAD-CAM systems. Computer-Aided Design (CAD) enabled engineers to design products digitally, while Computer-Aided Manufacturing (CAM) translated those designs into machine-readable code. This integration simplified the production process and improved accuracy.

4. 1990s-2000s: The introduction of 3-axis cutting machines brought greater versatility to CNC cut technology. These machines could move in three directions (x, y, and z axes), enabling complex cutting and shaping capabilities.

5. 2000s-present: CNC cut technology continued to evolve with the introduction of 4 and 5-axis machines. These advanced systems enabled even more intricate and precise cutting, allowing for the production of complex designs and geometries.

Additionally, the integration of various software advancements, such as simulation tools and optimization algorithms, improved efficiency, accuracy, and productivity in CNC cut processes.

In recent years, the CNC technology has also witnessed advancements in automation and robotics. Robotic CNC systems have been introduced, which integrate the capabilities of CNC machines with the flexibility and dexterity of robots. This allows for increased productivity, faster setup times, and the ability to perform complex tasks without human intervention.

As CNC cut technology continues to evolve, we can expect further advancements in areas such as artificial intelligence, machine learning, and additive manufacturing (3D printing). These technologies have the potential to further enhance the capabilities of CNC cut systems, enabling the production of even more complex and customized products.

The Evolution and Market Trends in cnc cut Industry

CNC (Computer Numerical Control) cutting has undergone significant evolution and advancements in recent years, with the market for CNC cutting services experiencing steady growth. The use of CNC technology has revolutionized the manufacturing and fabrication industries by offering increased precision, efficiency, and flexibility in cutting a wide range of materials such as metal, wood, plastic, and composites.

One of the key trends in the CNC cut industry is the increasing automation and integration of advanced software and technology. CNC machines are becoming more sophisticated and capable of executing complex cutting tasks with minimal human intervention. This trend has led to improved productivity, reduced production times, and higher quality finished products.

Another trend in the CNC cutting market is the growing demand for customization and personalized products. CNC cutting allows for the creation of intricate and unique designs, enabling manufacturers to cater to individual customer preferences and specific requirements. This trend is particularly evident in industries such as signage, automotive, aerospace, and furniture.

In addition, the adoption of CNC cutting technology in various industries, including automotive, aerospace, construction, and electronics, is driving the growth of the market. CNC cutting services are increasingly being utilized for prototyping, rapid manufacturing, and production of complex components and parts.

Overall, the evolution of CNC cutting technology and the growing demand for precision cutting solutions are driving market trends towards automation, customization, and diverse applications across industries. As CNC technology continues to advance, the market for CNC cutting services is expected to further expand and offer innovative solutions for manufacturing and fabrication needs.

Custom Private Labeling and Branding Opportunities with Chinese cnc cut Manufacturers

Chinese CNC cut manufacturers offer a great opportunity for custom private labeling and branding. With their advanced technology and expertise in CNC cutting, these manufacturers can create high-quality products with precision and accuracy.

Private labeling allows businesses to put their own branding and logo on the products they sell. This helps create brand recognition and increases brand loyalty among customers. Chinese CNC cut manufacturers are well-equipped to help businesses with private labeling by offering customizable options such as engraving or etching the brand name or logo onto the products.

Furthermore, these manufacturers also offer branding opportunities. By working closely with businesses, they can create unique designs and patterns that align with the brand’s image and values. This allows for a distinctive brand identity and can help businesses stand out in the market.

Chinese CNC cut manufacturers have the capabilities to work with various materials including wood, acrylic, metal, and plastic. This versatility allows businesses to create a wide range of products such as signage, promotional items, custom furniture, and more. With the right design and branding, these products can become powerful marketing tools that effectively showcase the brand to customers.

In conclusion, Chinese CNC cut manufacturers provide an excellent opportunity for businesses looking for custom private labeling and branding options. With their advanced technology and expertise, they can create high-quality products that are tailored to a brand’s specific needs. Utilizing these services can greatly help businesses in creating a strong brand presence and standing out in the market.

Tips for Procurement and Considerations when Purchasing cnc cut

1. Determine your specific requirements: Before purchasing CNC cut products, clearly define your requirements and specifications. This includes the size, material type, thickness, and any specific design features. Knowing your specific needs will help you choose the right CNC cutting service provider.

2. Research potential suppliers: Conduct thorough research to identify potential CNC cutting suppliers. Look for companies with experience in your industry and positive customer reviews. Consider their capabilities, equipment, pricing, and turnaround times.

3. Request samples: Request samples from potential suppliers to assess the quality of their CNC cut products. This will help you determine if their capabilities align with your requirements.

4. Quality control measures: Inquire about the supplier’s quality control measures to ensure their CNC cuts meet your standards. Ask about their quality control processes, inspection equipment, and certifications.

5. Material options: Consider the types of materials the supplier can work with. CNC cutting can be performed on a variety of materials such as wood, plastics, metals, and composites. Ensure that the supplier has expertise in cutting the specific material you require.

6. Cutting precision and tolerances: Discuss the supplier’s cutting precision and tolerances to understand the accuracy and consistency they can achieve. This is especially important for intricate or precise designs.

7. Turnaround time: Consider the supplier’s turnaround time for producing CNC cut products. Delays in production can impact your project’s timeline, so choose a supplier who can meet your deadlines.

8. Pricing and cost-effectiveness: Obtain quotes from multiple suppliers to compare prices and ensure cost-effectiveness. However, keep in mind that quality should not be compromised for lower prices.

9. Communication and customer support: Evaluate the supplier’s communication skills and responsiveness. Good communication and customer support are vital to address any questions, concerns, or modifications throughout the procurement process.

10. Flexibility and scalability: Consider the supplier’s ability to handle varying quantities and adapt to changing demands. This is essential if you anticipate future growth or require varying quantities of CNC cut products.

By following these tips and considerations, you can make an informed decision when procuring CNC cut products.

FAQs on Sourcing and Manufacturing cnc cut in China

1. Why should I consider sourcing and manufacturing CNC cut products in China?

China is a global leader in CNC cutting technology and is known for its cost-effective manufacturing processes. By sourcing and manufacturing in China, you can benefit from competitive pricing, high-quality products, and access to a wide range of materials and finishing options.

2. How do I find a reliable CNC cutting manufacturer in China?

It is essential to do thorough research and due diligence before choosing a CNC cutting manufacturer in China. Look for companies with a proven track record, positive customer reviews, and certifications for quality control and production standards. You can also consider visiting trade shows or working with a sourcing agent to help you find a reputable manufacturer.

3. What materials can be used for CNC cutting in China?

China has a wide range of materials available for CNC cutting, including metals, plastics, wood, composites, and more. You can choose from standard materials like aluminum and stainless steel, or opt for specialty materials that suit your specific application.

4. How can I ensure the quality of CNC-cut products manufactured in China?

You can ensure the quality of CNC-cut products by specifying your requirements and standards clearly to the manufacturer, conducting regular inspections during production, and requesting samples for approval before mass production. Working with a trusted manufacturer with a quality assurance system in place can also help ensure the quality of your products.

5. What are the production lead times for CNC cutting in China?

Production lead times for CNC cutting in China will vary depending on factors such as complexity, quantity, and material availability. It is essential to communicate your timeline requirements with the manufacturer upfront to avoid delays and ensure timely delivery of your products.

Why contact sourcifychina.com get free quota from reliable cnc cut suppliers?

Contacting sourcifychina.com to get a free quota from reliable CNC cut suppliers is beneficial for several reasons. Firstly, sourcifychina.com has a network of trusted suppliers that have been carefully vetted to ensure quality and reliability. By obtaining a quota through sourcifychina.com, you can be confident that you are working with reputable suppliers who can meet your specific CNC cut requirements.

Additionally, sourcing through sourcifychina.com can save you time and effort in finding and vetting suppliers on your own. With sourcifychina.com’s extensive network of suppliers, you can easily compare quotes and choose the best option for your project without the hassle of conducting individual supplier searches.

Furthermore, by utilizing sourcifychina.com, you may also benefit from cost savings and competitive pricing. Sourcifychina.com works with a wide range of suppliers, allowing you to access a variety of options and negotiate the best price for your CNC cut needs.

Overall, contacting sourcifychina.com to get a free quota from reliable CNC cut suppliers is a smart decision that can help streamline your sourcing process, ensure quality and reliability, and potentially save you money.