Knowledge about Cnc Drilling Machine

CNC drilling machines are a crucial part of modern manufacturing plants, and being knowledgeable about their operations is essential for any manufacturing professional. Firstly, CNC drilling machines are designed to drill precise, accurate holes in a wide range of materials, including wood, metal, and plastic. These machines are controlled by computers, which means that they offer a high degree of accuracy and repeatability, making them ideal for producing large quantities of identical parts.

Moreover, there are two main types of CNC drilling machines: horizontal and vertical. Horizontal drilling machines are designed for drilling long, deep holes in large parts, while vertical drilling machines are ideal for smaller parts and drilling holes at different angles. Understanding the differences between these two machines and how they work is critical for achieving the desired results.

Furthermore, the cutting tools used in CNC drilling machines are specially designed to withstand the rigors of heavy-duty manufacturing operations. Choosing the right drill bit is crucial, as it can affect the quality of the hole and the lifespan of the machine itself. A good understanding of the different types of drill bits, including twist drills, center drills, and step drills, is essential for selecting the right tool for the job.

In addition, being knowledgeable about the programming language used in CNC drilling machines is essential for operating these machines effectively. CNC programming language is a set of commands used to control the machine’s movements, and being able to read and interpret these commands is essential for success.

In conclusion, understanding how CNC drilling machines work, the different types available, the cutting tools used, and the programming language is essential for anyone who is involved in manufacturing operations. With this knowledge, you can produce consistent, high-quality parts that meet your customers’ exacting standards.

Various Types of Cnc Drilling Machine

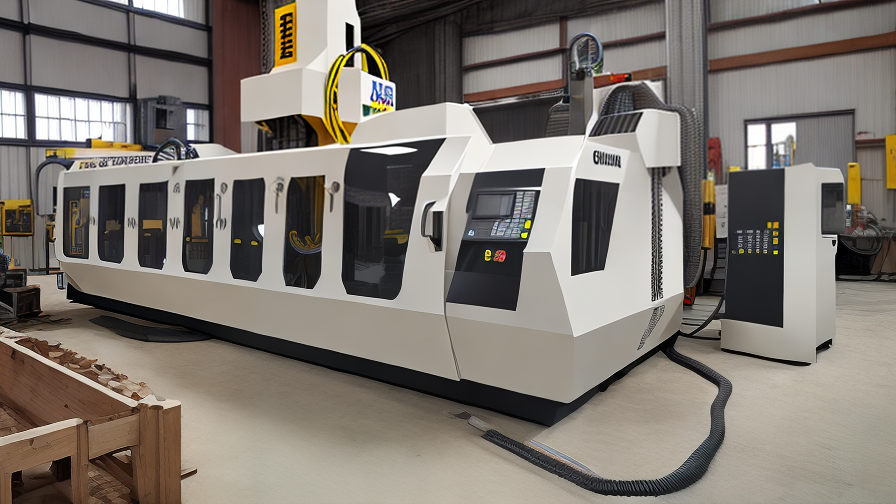

Computer numerical control (CNC) drilling machines are designed for precise hole drilling applications across different materials. These machines operate on software-driven programs that enable them to accomplish a wide range of drilling tasks accurately and with ease. Here are a few types of CNC drilling machines that you can find in the market today.

1. Benchtop CNC drilling machines: These machines are perfect for small-scale drilling tasks or home workshops. They are compact and easy to maneuver, making them perfect for hobbyists, DIY enthusiasts, or those with limited space.

2. Vertical CNC drilling machines: These machines use a vertical setup for drilling tasks. They are typically larger in size and can handle drilling tasks across a range of materials. Vertical CNC drilling machines are highly efficient and are perfect for industrial applications.

3. Horizontal CNC drilling machines: These machines utilize a horizontal setup and allow for a variety of drilling angles. They are highly efficient and can take on large and complex drilling tasks with ease.

4. Multi-spindle CNC drilling machines: As the name suggests, these machines have multiple spindle heads, which allow them to undertake multiple drilling tasks simultaneously. This makes them highly efficient and ideal for large-volume production.

5. Gantry CNC drilling machines: These machines have a large-scale gantry structure and allow for highly precise and efficient drilling tasks. They are ideal for large industrial applications that require high levels of accuracy and precision.

CNC drilling machines are highly versatile and can take on any drilling task efficiently and accurately. Their speed, precision, and efficiency make them a must-have for any manufacturing or industrial business. Whether you are looking for a small benchtop machine for your home workshop or a large-scale gantry machine for your industrial business, there is a CNC drilling machine that suits your needs.

FAQ sourcing Cnc Drilling Machine manufacturer from China

If you are planning to source a CNC drilling machine manufacturer from China, you might have several questions regarding the process. Here are some FAQs with multiple answers to help you with your sourcing decisions:

Q1. How to find a reliable CNC drilling machine manufacturer from China?

A1. You can search for suppliers on Alibaba, Made-in-China, or Global Sources. However, it’s always recommended to visit the supplier’s factory or office to ensure they are real and trustworthy.

Q2. What types of CNC drilling machines are available in China?

A2. You can find vertical and horizontal CNC drilling machines, as well as different drilling capacities and spindle speeds, depending on your specific requirements.

Q3. Can I customize my CNC drilling machine?

A3. Yes, most Chinese manufacturers offer customization options according to the customer’s needs, such as drilling diameter, distance between spindles, and worktable size.

Q4. What is the lead time for a CNC drilling machine?

A4. Lead time may vary from manufacturer to manufacturer, but it usually takes around 30-60 days from placing the order to delivery.

Q5. What is the manufacturing standard for CNC drilling machines in China?

A5. Chinese manufacturers comply with international standards, including CE, ISO, and SGS to ensure product quality and safety.

Q6. What is the warranty period for a CNC drilling machine?

A6. The warranty period may vary from supplier to supplier, but generally, it is one year, and some offer extended warranties with additional costs.

Q7. What are the shipping options for a CNC drilling machine from China?

A7. There are various shipping options available, including sea freight, air freight, and express delivery. The supplier can recommend the best shipping method based on your location and requirements.

In conclusion, sourcing a CNC drilling machine from China can be a cost-effective solution. However, it’s essential to find a reliable supplier, customize according to your needs, and ensure compliance with international

Applications of Cnc Drilling Machine

CNC drilling machines are widely used in various industries owing to their precise and accurate drilling capabilities. These machines provide automation for drilling processes, saving time and increasing efficiency.

One of the most significant applications of CNC drilling machines is in the manufacturing of printed circuit boards (PCBs). The drilling machine accurately drills holes in the boards, which are then used to mount electronic components. This process requires high precision and accuracy, which cannot be achieved manually.

CNC drilling machines are also used in the aerospace industry to drill holes in a variety of materials, including titanium and composites. These materials are challenging to drill due to their hardness and toughness, but the CNC drilling machine can drill precise holes without any damage to the material.

Another significant application of CNC drilling machines is in the manufacturing of furniture. These machines can drill holes for fixtures and fittings, such as hinges and drawer handles, with high precision, resulting in perfectly aligned and flush fixtures.

CNC drilling machines are also used in the automotive industry, where they aid in drilling holes for engine components and other parts. These machines ensure that the holes are drilled accurately, and the engine components fit perfectly, leading to enhanced performance.

In the construction industry, CNC drilling machines are used to drill precise holes in concrete and other materials for structural support. These machines can also drill holes for wiring and plumbing, resulting in an efficient and clean installation.

Overall, the applications of CNC drilling machines are diverse, making them incredibly versatile machines that can be used in several industries. Their precise and efficient drilling capabilities provide valuable advancements in various manufacturing processes, reducing cost and improving productivity, making them a crucial addition to modern industries.

Manufactured Products made of Cnc Drilling Machine

CNC drilling machines are widely used in the manufacturing of various products. The machines offer precise drilling and cutting capabilities that other machines may not have. CNC machines are used in a range of industries, from aerospace and automotive to consumer products and electronics. In this article, we will discuss the manufactured products that are made with a CNC drilling machine.

One product that is made using CNC drilling machines is metal parts. CNC machines are precise and can drill holes in metal parts with extreme accuracy. This degree of accuracy results in parts that fit together perfectly, which is essential in the manufacturing of products.

Another product produced by CNC drilling machines is printed circuit boards (PCBs). PCBs are used in all types of electronic devices, from smartphones to computers. CNC machines are ideal for drilling holes in PCBs because of their accuracy and speed. The holes must be drilled precisely to ensure the components fit correctly, and a CNC drilling machine can perform this task quickly and accurately.

The manufacturing of plastic parts is another area where CNC drilling machines excel. Plastic parts are used in a wide range of products, from household items such as containers and toys to automotive components. Using a CNC drilling machine, manufacturers can create plastic parts with extreme precision and speed.

In the woodworking industry, CNC drilling machines are used to produce furniture, cabinets, and other wooden products. With the help of a CNC machine, manufacturers can cut, drill, and carve wooden parts with high accuracy, creating furniture with precision and detail that would be challenging to achieve manually.

The food industry also benefits from the use of CNC drilling machines. Food manufacturers use CNC machines to produce molds for chocolates, candies, and other confectionery, ensuring that each piece is precisely the same size and shape.

In conclusion, CNC drilling machines are used to produce a wide range of products, including metal parts, PCBs, plastic parts, furniture, and moldings for the food industry. With their incredibly precise and fast drilling and cutting capabilities, CNC machines are the ideal choice for

The Evolution history of Cnc Drilling Machine

The history of CNC drilling machines dates back to the 1940s when the first numerical control (NC) machines were developed. These machines, which were the precursor to CNC machines, were designed to translate a set of instructions into specific movements and actions using coded instructions.

As technology progressed, the earliest CNC drilling machines were developed for industrial use in the 1960s. These machines used punch cards to store programs and instructions, which were later replaced by computer tapes and floppy disks.

The 1970s marked a significant shift in the evolution of CNC drilling machines, as microprocessors were introduced for use in manufacturing. These microprocessors allowed for greater versatility and accuracy in machining, which was crucial for industries such as aerospace and automotive that demanded high precision parts.

By the 1980s, the use of CAD/CAM (computer-aided design and manufacturing) software had become widespread in the machining industry. These advancements allowed for even greater precision and efficiency in drilling and allowed for the creation of complex shapes and forms.

In recent years, the development of 5-axis machining has revolutionized the CNC drilling machine industry. These machines can perform complex cutting motions in multiple directions, providing unparalleled precision and versatility.

Overall, the evolution of CNC drilling machines has been marked by a steady progression of advancements in technology and software. As manufacturing demands continue to grow, it’s likely that further innovations in CNC technology will continue to shape the industry for years to come.

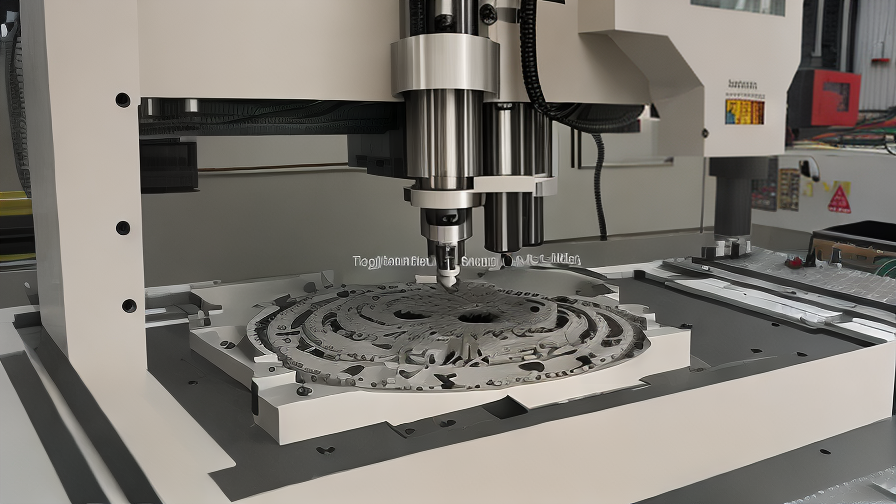

The Process of Cnc Drilling Machine

A CNC drilling machine is a computer-controlled machine used for drilling holes in various materials. The machine is equipped with a drill bit that can move in multiple directions, allowing it to bore holes in many different positions and angles.

The process of using a CNC drilling machine involves several steps. First, the operator creates a digital design of the piece they want to drill. This design is then fed into the computer of the CNC drilling machine.

The next step is setting up the machine. The operator will mount the material to be drilled onto the machine’s bed, ensuring that it is held securely in place. The drill bit is then positioned above the material.

Next, the operator initiates the drilling process. The machine will automatically begin to move the drill bit according to the preset design. The drill bit will move up and down, side to side, and in and out of the material, precisely following the design’s specifications.

During the drilling process, the CNC drilling machine’s computer monitors the machine’s position, making adjustments as necessary to ensure the drill bit’s accuracy. Once the drill bit has completed all the holes required in the design, the drill bit will retract, and the machine will stop.

The final step in the process is inspecting the holes to ensure they meet the design specifications. If the holes are not precise or do not meet the design’s requirements, the operator can make adjustments to the machine’s settings and try again.

In conclusion, the process of using a CNC drilling machine involves several steps, but it ultimately results in precise and accurate holes drilled in materials. The ability to program the machine to create complex designs makes it an essential tool in many industries, including manufacturing, automotive engineering, and aerospace. Overall, CNC drilling machines have revolutionized the drilling process, making it faster, more efficient, and more accurate than ever before.

Benefits Advantages of Utilizing Cnc Drilling Machine

CNC (Computer Numerical Control) drilling machines have revolutionized the world of manufacturing by offering a range of benefits and advantages. Here we will discuss some of the most significant benefits of using CNC drilling machines in the manufacturing process.

Firstly, CNC drilling machines are incredibly accurate and precise. Unlike traditional drilling machines that rely on human operators to achieve accuracy, CNC drilling machines have computerized controls that make precise and accurate movements every time. This eliminates any human error and ensures that the drilling process always produces accurate and uniform results.

Secondly, CNC drilling machines are incredibly efficient. They allow for faster drilling speeds, reduced setup times, and increased productivity. With the use of CNC drilling machines, companies are able to produce more products in less time, which leads to increased profits.

Another significant advantage of CNC drilling machines is their versatility. These machines can be used to drill a variety of materials, including wood, metal, plastic, and composites. This versatility makes them an ideal choice for a wide range of manufacturing applications.

CNC drilling machines are also very user friendly. They are easy to program and operate by anyone with basic computer skills, which reduces the need for skilled labor. This makes them an ideal choice for small and medium-sized manufacturers who may not have access to specialized operators.

Lastly, using CNC drilling machines can lead to reduced costs in the long run. While they may cost more initially, their efficiency and accuracy ultimately lead to lower production costs, reduced errors, and increased productivity. This also means that companies can produce higher-quality products at a lower price, making them more competitive in their respective markets.

In conclusion, there are many benefits and advantages to utilizing CNC drilling machines in the manufacturing process. These machines offer accuracy, efficiency, versatility, user-friendliness, and cost savings, making them an indispensable tool for any manufacturer looking to optimize their operations.

Disadvantages Cnc Drilling Machine

CNC (Computer Numerical Control) drilling machines are used for drilling holes in a wide variety of materials, including metal, plastic, and wood. While these machines have revolutionized the drilling process, they also come with some significant disadvantages.

Firstly, CNC drilling machines can be expensive. Even the most basic models can cost tens of thousands of dollars, and more advanced models can cost up to several hundred thousand dollars. This can be prohibitive for smaller companies or those on a tight budget.

Secondly, CNC drilling machines require significant maintenance. These machines have a lot of moving parts that need to be regularly maintained and serviced to ensure they are functioning correctly. Without proper maintenance, the machine may break down, leading to expensive repairs and downtime.

Thirdly, CNC drilling machines are not as flexible as manual drilling machines. While they can drill precise and accurate holes, they are designed for specific tasks and are not as versatile as manual machines. This means that they may not be suitable for drilling a wide range of hole sizes or shapes.

Fourthly, CNC drilling machines require specialized training. Operating these machines requires a high level of technical knowledge, and not everyone on a production team can easily operate them. Training and certification are required to ensure that operators can use the machines correctly and safely.

Lastly, CNC drilling machines can be time-consuming to set up. These machines require accurate programming, tool setups, and workpiece fixturing, which can take a lot of time and effort. This can be challenging for manufacturers who need to produce a high volume of parts quickly.

In conclusion, while CNC drilling machines offer precision and accuracy, they also come with notable disadvantages, including their high cost, requirements for maintenance and specialist training, limited flexibility, and time-consuming setup. As such, companies must weigh up their options before investing in a CNC drilling machine.

Selecting the Ideal Manufacturer Cnc Drilling Machine

When it comes to selecting the ideal manufacturer CNC drilling machine, there are several factors that need to be considered. The first and foremost factor is the quality of the machine, as any compromise on quality can lead to a decrease in productivity and profitability.

In addition to quality, it is also important to consider the features of the machine. While some basic models may be suitable for simple jobs, more complex jobs require machines with advanced features such as multi-axis control and automatic tool changers.

Another crucial factor to consider is the manufacturer’s reputation in the industry. It is always advisable to choose a reputable manufacturer with a proven track record of delivering high-quality products and excellent customer support.

The cost of the machine is also an important consideration. While it is important to choose a machine that fits within your budget, it is also important to ensure that you are getting good value for your money. A machine that is cheaply priced but lacks the necessary features or is of inferior quality is not a good investment in the long run.

Lastly, it is important to consider the after-sales support provided by the manufacturer. This includes technical support, maintenance, and repair services. A good manufacturer will offer comprehensive support to ensure that your machine is always operating at peak efficiency.

Overall, selecting the ideal manufacturer CNC drilling machine requires careful consideration of several factors, including quality, features, reputation, cost, and after-sales support. By taking these factors into account, you can ensure that you make a wise investment that will help to improve the efficiency and profitability of your operations.

Things to Consider When Purchasing Cnc Drilling Machine

When it comes to purchasing a CNC drilling machine, there are several things that you need to consider. Choosing the right machine will help you improve production speed and efficiency while reducing costs. Here are some of the factors that you should consider before purchasing a CNC drilling machine:

1. Machine Capacity: The first thing you need to consider is the machine capacity. You need to determine what size of material you will be drilling and the thickness of the material. This will help you determine the size of the machine that you need.

2. Machine Type: There are various types of CNC drilling machines, and you need to determine which one will be suitable for your business. Some of the popular types include gantry, vertical, horizontal, and multi-axis drilling machines.

3. Spindle Speed: The spindle speed is an important factor as it affects the cutting speed and quality of the material. You need to choose a machine with a spindle speed suitable for the materials you will be drilling.

4. Automation: The level of automation of the machine is another vital factor. Some machines are fully automated, while others require manual intervention. Choosing a machine with automation features will reduce human error and improve efficiency.

5. Cutting Tools: The type of cutting tools used with the machine will play a crucial role in productivity and efficiency. Choose a machine that is compatible with a range of cutting tools to increase versatility.

6. Software and Control System: The software and control system of the machine are essential. You need to choose a machine with a user-friendly interface to reduce training and operational time.

7. Maintenance and Support: Lastly, consider the reliability of the machine, maintenance requirements, and support options. Choose a machine with low maintenance requirements and available technical support.

In conclusion, purchasing a CNC drilling machine requires careful consideration of several factors. You need to choose a machine suitable for your business needs, with capabilities to improve efficiency and productivity while reducing costs.

Properties of Cnc Drilling Machine

A CNC drilling machine is a computer-controlled machine that is used to drill holes in various materials such as metal, wood, and plastic. This machine uses a tool that rotates at high speeds to drill holes of different sizes and shapes. The following are some of the properties of a CNC drilling machine.

Accuracy: CNC drilling machines are very accurate and precise. These machines use computer-controlled programming to ensure that the hole is drilled in the right place and to the correct size. This level of accuracy is essential in industries where precision is crucial.

Speed: CNC drilling machines are very fast. They can drill multiple holes in a short time, making them perfect for industries that require high production rates. The speed of the machine is determined by the type of material being drilled and the size of the hole.

Flexibility: CNC drilling machines are very flexible. They can drill holes of different sizes and shapes, making them ideal for industries that require variety. The programming of the machine can be adjusted to drill holes of different sizes and shapes as required.

Ease of use: CNC drilling machines are very easy to use. The user only needs to input the drilling instructions into the computer, and the machine does the rest. This makes the machine ideal for use in industries where skilled labor is scarce.

Safety: CNC drilling machines are very safe to use. They are fitted with safety features such as emergency stop buttons and safety guards to prevent accidents. This makes them ideal for use in industries where safety is a priority.

In conclusion, CNC drilling machines have various properties that make them an essential tool in various industries. Their accuracy, speed, flexibility, ease of use, and safety make them ideal for use in industries that require high precision and productivity.

How to use Cnc Drilling Machine

CNC drilling machines are commonly used in manufacturing plants as they automate the drilling processes. These machines are capable of drilling slots, holes, and pockets with precision, and they are widely used because of their high accuracy and speed.

Here are the steps to use a CNC drilling machine:

1. First off, start by preparing the material you intend to drill. Ensure that it is clamped on the machine bed tightly to avoid movement during the drilling process. This allows the machine to make accurate cuts and prevent any damage to the material.

2. The next step is to power up the machine and initialize the system by loading the software program. Ensure that the operating system and software program are up-to-date for optimal functioning.

3. Once you have initialized the machine, use the control panel or touchscreen to select the right drilling parameters. These include the spindle speed, feed rate, depth of cut, and coolant flow.

4. The machine will then begin to drill holes, slots or pockets according to your specifications. Always monitor the drilling process to ensure that everything is running smoothly and that the material is not being damaged.

5. Once the drilling process is complete, switch off the CNC drilling machine, and remove the material from the bed. Inspect your workpiece to ensure that it is accurate and precise. If there are any errors, make the necessary adjustments and repeat the drilling process.

In conclusion, CNC drilling machines are sophisticated pieces of equipment that require proper handling, and given their high accuracy and speed, they can help boost productivity and efficiency in manufacturing plants. By following the above steps, you can achieve the best results when using a CNC drilling machine.

Glossary Terminology Terms for Cnc Drilling Machine

A CNC drilling machine is a machine that utilizes computer numeric control (CNC) technology to drill holes in various materials using different types of drills. When working with a CNC drilling machine, it is essential to know several terminologies, including:

1. Feed rate: The speed at which the drilling machine moves during the drilling process.

2. Spindle speed: The speed of the spindle that rotates the drill.

3. Drill point angle: The angle between the surface of the drill and the centerline of the drill.

4. Depth of cut: the distance from the surface of the material to the bottom of the hole that the drill makes.

5. Tool offset: The distance between the center of the drill and the center of the spindle.

6. Peck drilling: A process where the drill is lifted to avoid clogs and chips, which can cause damage to the machine.

7. Spot drilling: A process that involves drilling a small hole to serve as a guide for larger drilling.

8. Drilling cycle: The sequence of movements and actions of the drilling process.

9. G-codes: A language used by the CNC controller to program the machine.

10. Workholding: The method of holding the material in place to prevent movement during drilling.

11. Coolant: A fluid that cools the bit and flushes away debris during the drilling process.

In conclusion, understanding the terminology of a CNC drilling machine enhances efficiency, output quality, and safe operations. It allows operators to better communicate with each other and discuss drilling processes more effectively. Furthermore, with a better understanding of CNC drilling terminology, users of this machinery can troubleshoot problems and incorporate precision in their drilling abilities.

Cnc Drilling Machine Price

The use of CNC drilling machines in various manufacturing industries has made work easier and more efficient. These machines are highly accurate and can perform precise drilling operations with excellent speed. The cost of CNC drilling machines varies depending on a number of factors.

One of the main factors that affect the price of CNC drilling machines is the size and capacity of the machine. Larger machines with a higher drilling capacity are more expensive than smaller, less-capacity machines. The complexity of the machine’s design and function is also an important factor that affects its price. More complex machines that can perform a wide range of functions are more expensive than simpler ones.

Brands also play a role in determining the price of CNC drilling machines. Popular brands with a solid reputation for quality usually cost more than lesser-known brands with a weaker reputation. This is because consumers are typically willing to pay for quality and trust brands that have proven themselves to be reliable.

The source of a CNC drilling machine can also affect its price. Machines sourced from overseas or imported from other countries might be cheaper, but they may not meet the same high-quality standards as machines manufactured locally. Additionally, the cost of shipping and customs fees needed to import machines adds to their overall cost.

In conclusion, there are multiple factors that influence the cost of CNC drilling machines. However, it is important to note that price should not be the only determining factor when choosing a machine. Other factors such as quality, warranty, and technical support should also be considered when making a purchase.