Analysis of Manufacturing Expenses for cnc machining cost

CNC machining cost is a critical factor that can affect the profitability of manufacturing firms. The cost of CNC machining is influenced by various expenses that arise during the production process. These expenses may include raw material costs, labor costs, machine maintenance, tooling costs, electricity, and other miscellaneous expenses.

Raw material costs are a significant contributor to the CNC machining cost. The price of raw materials can have a massive impact on the overall cost of the finished product. Manufacturers must carefully monitor the cost of raw materials and search for cost-effective alternatives to minimize expenses.

Labor costs are another essential expense in CNC machining. The cost of labor represents the wages paid to machinists, CNC programmers, and other factory personnel. These costs can be lowered by reducing the time required to manufacture each component and improving the efficiency of workers.

Machine maintenance is also a crucial expense in CNC machining. The cost of maintaining CNC equipment can vary depending on the machine’s complexity and usage. Regular maintenance and replacement of worn-out parts can help minimize downtime and enhance the machines’ lifespan, which translates to reduced costs in the long run.

Tooling costs are a vital expense in CNC machining. The cost of tooling includes the purchase price of cutting tools, re-sharpening, and replacement of used tools. Tooling cost can be minimized by improving the tool life, investing in high-quality tools, and utilizing advanced tooling technologies.

Electricity and miscellaneous expenses are also a significant contributor to CNC machining cost. These costs include power consumption, water usage, and other overhead expenses like rent, insurance, and taxes. Manufacturers can minimize electricity expenses by investing in energy-efficient machines and equipment.

In conclusion, for firms dealing with CNC machining, it is essential to have a clear understanding of the various expenses affecting the CNC machining cost. By identifying these factors, manufacturers can optimize their manufacturing expenses and improve their overall profitability.

Understanding the Components that Contribute to the Price of cnc machining cost

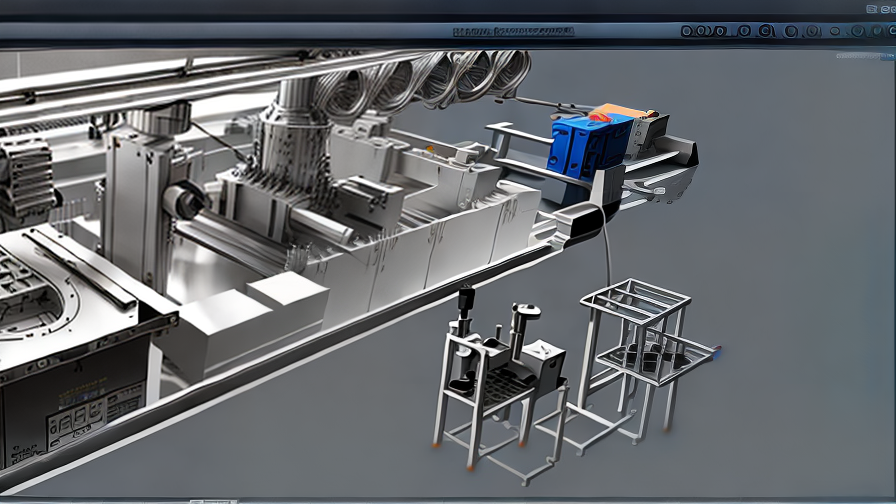

CNC machining is a complex process involving several components that contribute to its cost. Understanding these components is essential for determining the CNC machining cost accurately. Some of the key factors that affect the cost of CNC machining are:

1. Material costs: The cost of raw material is a significant factor in determining the CNC machining cost. The choice of material, its grade, and quantity required to produce the desired product all affect material costs.

2. Machine time: The amount of time taken to complete a CNC machining job is another important factor that determines the cost. This includes setup time, programming time, and actual machining time.

3. Labor costs: The cost of labor is another key determinant of CNC machining cost. The skill level and experience of the machinist impact the labor cost required for CNC machining.

4. Tooling costs: The cost of tooling, including cutting tools, fixturing and workholding, also affects the overall CNC machining cost. The complexity of the part and the need for specialized tools increases the tooling cost.

5. Design complexity: The complexity of the part being machined impacts the CNC machining cost. More complex geometries require additional setup time, programming time, and machining time.

6. Tolerance requirements: The level of precision required for the part being machined affects the CNC machining cost. Greater precision requires higher accuracy machines, specialized tooling, and increased setup time.

In conclusion, understanding the components that contribute to CNC machining cost is critical for accurately determining the overall cost of a project. Material costs, machine time, labor costs, tooling costs, design complexity, and tolerance requirements all affect the CNC machining cost, and must be considered carefully when estimating the cost of a job.

Comparing the Wholesale and Retail Prices of cnc machining cost in China

The cost of CNC machining services in China varies between wholesale and retail prices. Wholesale prices are usually charged to large-scale businesses or entities who require bulk orders, while retail prices are charged to small-scale businesses, individuals, or entities in need of small quantities.

The wholesale prices of CNC machining services in China are typically lower than the retail prices. This is due to the fact that wholesalers often make large orders, which translates to economies of scale. As a result, wholesalers can negotiate for better prices, lower production costs, and faster turnaround times. In many cases, wholesalers work directly with manufacturers, thereby cutting out intermediaries and further reducing costs.

On the other hand, retail prices of CNC machining services are higher than wholesale prices. This is because retailers are often purchasing smaller quantities and must pay for additional costs to make sure they meet the specific needs of their customers. Retailers may also have to pay more for shipping and handling costs, which can inflate the overall cost of the final product. Additionally, since retailers often purchase from wholesalers who mark up their prices, they will have to pay a premium for the convenience of getting CNC machining services in smaller quantities.

Overall, the price difference between wholesale and retail prices for CNC machining services in China is significant. Wholesale prices are much lower due to lower production costs, while retail prices reflect the extra costs retailers must pay to meet the demands of their customers. Regardless of pricing differences, consumers are still able to take advantage of the competitive pricing of CNC machining services in China, since prices are still much lower than in other nations.

Understanding Shipping and Logistics for cnc machining cost from China

CNC machining cost from China involves not just the production and assembly of the parts but also the logistics of transportation. The process of shipping and logistics in CNC machining involves the movement of raw materials from the manufacturing site in China to the customer’s location.

There are several modes of transportation available for shipping the CNC machined parts, such as air, sea, and land. Typically, air freight is the fastest option but also the most expensive. Sea freight is a more cost-effective option, but it can take longer and may require additional transit times and customs clearance.

When considering logistics of shipping CNC machining from China, it is essential to plan and coordinate with various parties, including customs officers, freight forwarders, packaging and logistics companies, and carriers. Shipping and logistics companies can help in obtaining import and export permits, navigating customs, and selecting optimal transportation options.

The cost of shipping and logistics for CNC machining from China can vary based on several factors, including the size and weight of the items, distance, mode of transportation, and delivery time frame. Therefore, it is essential to work with experienced logistics providers that can help optimize shipping costs and manage all aspects of delivery.

In conclusion, shipping and logistics are critical factors to consider when estimating the overall cost of CNC machining from China. Companies that engage in CNC machining should work with experienced and reliable logistics providers to ensure timely and cost-effective delivery.

Potential Tariffs or Import Taxes on cnc machining cost Purchased from China

The US trade war with China has been a controversial topic in recent years. The Trump administration imposed tariffs on a range of goods from China, including CNC machining products. CNC machining is a process used to create complex and intricate parts for various industries, including aerospace, automotive, and defense. These parts are often sourced from China due to lower labor and production costs.

The potential tariffs or import taxes on CNC machining products could result in a significant increase in costs. This would discourage US companies from sourcing these parts from China and look for alternatives, such as domestic manufacturers or other low-cost countries. However, the cost of domestic manufacturing is comparatively higher, and the lead time could be longer. As a result, US companies may have to increase their prices, which could trickle down to the end consumer.

Moreover, the implementation of tariffs or import taxes could lead to trade retaliation from China, where they may impose similar trade barriers on US goods, adding further strain to the US-China trade relations. This could result in a reduction in overall trade and cause significant economic damage to both nations.

In conclusion, the imposition of tariffs or import taxes on CNC machining products sourced from China could result in a significant increase in cost, affect the US-China trade relations, and harm both nations’ economies in the long run. It would instead be beneficial for both nations to work towards a fair and balanced trade system.

Impact of Market Demand and Competitive Environment on cnc machining cost

Market demand and competitive environment have a significant impact on CNC machining costs. CNC machining is a subtractive manufacturing process that involves the use of computer-aided design (CAD) software and CNC machines. The cost of CNC machining is determined by several factors such as the complexity of the part, the quantity of parts required, and the machining time required to produce the part.

In a competitive market, CNC machining costs are likely to be lower due to increased competition among manufacturers. This is because manufacturers will be competing for business and will need to offer competitive prices to win customers. Additionally, manufacturers will be under pressure to reduce costs, which may lead to cost savings being passed on to customers.

Market demand also has an impact on CNC machining costs. If there is high demand for a particular part, manufacturers may be able to charge a higher price for their services. Conversely, if there is low demand for a particular part, manufacturers may need to lower their prices to attract business.

Another factor that can impact CNC machining costs is the availability of raw materials. If there is a shortage of raw materials, the cost of CNC machining may increase as manufacturers will need to pay more to acquire the materials they need.

In summary, market demand and competitive environment play a significant role in determining CNC machining costs. Manufacturers need to be aware of these factors and adjust their pricing strategies accordingly to remain competitive in the market.

FAQ about cnc machining cost with multiple answers

Q: What factors affect the cost of CNC machining?

A: The cost of CNC machining is affected by several factors such as the complexity of the design or part, the material used, the quantity of parts ordered, and the required finishing processes.

Q: What is the typical cost of CNC machining per hour?

A: The cost of CNC machining per hour varies depending on the machine used and the location. The hourly rate can range from $50 to $100 or more.

Q: Is CNC machining expensive?

A: CNC machining can be expensive, but it is a cost-effective option for producing complex and precise parts in large quantities.

Q: How much does it cost to produce a single CNC machined part?

A: The cost of producing a single CNC machined part depends on several factors such as the complexity of the part, the material used, and the required finishing processes. The cost can range from a few dollars to several hundred dollars or more.

Q: Can I save money by ordering large quantities of CNC machined parts?

A: Ordering larger quantities of CNC machined parts can often result in lower per-part costs due to economy of scale. However, it is important to consider the upfront cost of producing a large quantity of parts.

Q: How important is material selection in CNC machining cost?

A: Material selection is a crucial factor in the cost of CNC machining. More expensive materials such as exotic metals or composites will increase the overall cost of production.

Q: Can I save money on CNC machining by reducing part complexity?

A: Simplifying part design can potentially reduce CNC machining costs. However, this may not always be possible depending on the function and requirements of the part.

Q: Are there any additional costs associated with CNC machining?

A: Additional costs associated with CNC machining may include design or engineering fees, finishing processes such as painting or powder coating, and shipping or handling fees.