Introduce about cnc machining prices guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

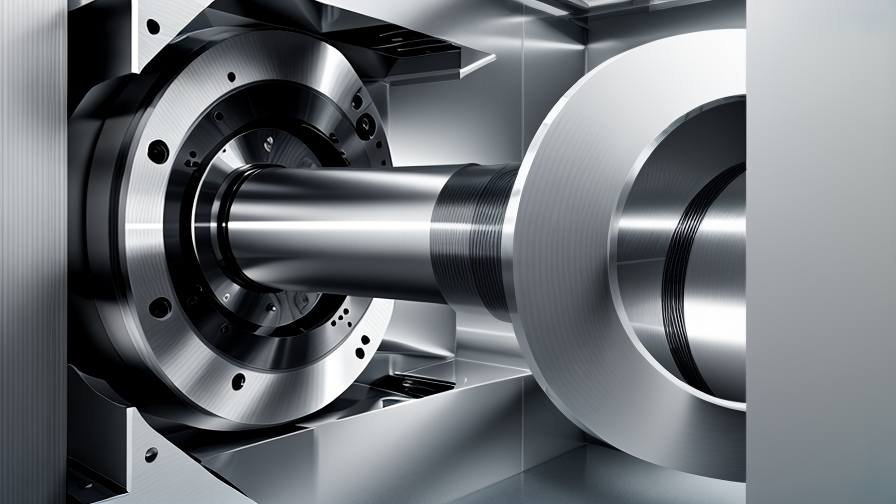

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilizes computerized controls to operate machine tools. It is widely used in various industries for precise and accurate production of parts and components. Understanding the factors that contribute to the pricing of CNC machining services is essential for both buyers and suppliers.

The quality of CNC machining can vary depending on the expertise of the supplier and the technology utilized. Higher quality machining typically involves advanced equipment, skilled operators, and stringent quality control measures, ensuring precise tolerances and surface finishes that meet client specifications.

The cost of CNC machining services can be influenced by several factors, including the complexity of the part design, material selection, machining time, and quantity required. More intricate designs and exotic materials may increase the overall cost. Furthermore, economies of scale can lead to cost reductions when large quantities of parts are ordered.

When selecting a CNC machining supplier, it is crucial to consider their experience, capabilities, and reputation. A reliable supplier should have a proven track record of delivering high-quality parts on time. Additionally, verifying their certifications, such as ISO 9001 for quality management systems, can provide assurance of their commitment to excellence.

The CNC machining market is highly competitive, with numerous suppliers worldwide offering their services. It is advisable to research and compare different suppliers to find the one that best meets your specific requirements. Obtaining quotes from multiple suppliers can help in evaluating the pricing and quality offered in the market.

Here are some tips for optimizing your CNC machining process: provide clear and accurate part specifications, communicate openly with your supplier, consider material alternatives for cost savings, and optimize your design to minimize complexity and machining time.

Frequently asked questions about CNC machining may include queries about turnaround times, material options, cost factors, customization capabilities, and finishing options. It is recommended to consult suppliers or refer to their websites to find answers to specific questions.

In conclusion, understanding the various aspects of CNC machining, including pricing, quality, suppliers, certifications, and the market, is essential to make informed decisions when sourcing machining services. By following the provided tips and referencing frequently asked questions, buyers can ensure a successful CNC machining experience.

Types of cnc machining prices

CNC (Computer Numerical Control) machining prices can vary depending on several factors. Here are some of the types of CNC machining prices you might encounter:

1. Hourly Rate: Some CNC machining services charge an hourly rate for their work. This rate can vary depending on the complexity of the job, the type of material being used, the precision required, and the machine involved. Hourly rates typically range from $50 to $100, or even higher for specialized services.

2. Material Costs: The type and quality of material used in CNC machining can greatly impact the price. Common materials include metals like aluminum, steel, brass, and titanium, as well as plastics and composites. Exotic or specialized materials will generally be more expensive.

3. Design Complexity: The complexity of the design or part being manufactured can affect pricing. Intricate components that require multiple machining operations or complex geometries may come at a higher cost due to the increased setup time and programming required.

4. Quantity and Batch Size: CNC machining prices can vary depending on the quantity ordered. Many service providers offer discounted rates for larger production runs or bulk orders. This is because the setup costs are distributed over a larger number of parts, improving efficiency and reducing the overall price per piece.

5. Additional Services: Certain additional services like CAD/CAM programming, tooling, finishing, assembly, and quality control inspections may incur extra charges. It is essential to consider these costs when calculating the final price.

6. Machine Capabilities: Different CNC machines and technologies have varying capabilities and precision levels. Highly precise machines that can accommodate complex designs usually come at a higher cost due to their advanced features and accuracy.

7. Turnaround Time: The requested turnaround time can affect the pricing. Urgent or rush orders may incur additional charges, as they require the service provider to allocate dedicated resources and prioritize the order over regular jobs.

It is important to note that these prices are just a general overview, and they can vary significantly depending on the specific factors involved in each project. It is recommended to obtain detailed quotes from CNC machining service providers to get a precise estimate for your particular requirements.

Pros and Cons of Using cnc machining prices

CNC machining, or Computer Numerical Control machining, has become increasingly popular in various industries for its ability to produce accurate, precise, and complex parts. However, like any manufacturing process, it has its pros and cons. Here are the key advantages and disadvantages of using CNC machining:

Pros:

1. Accuracy and precision: CNC machines can achieve exceptionally high levels of accuracy and precision, often within microns. This ensures consistent quality and eliminates human error, resulting in parts that meet tight tolerances.

2. Versatility: CNC machines can create parts from a wide range of materials, including metals, plastics, and composites. They can handle both simple and complex designs, allowing for the production of intricate and customized parts.

3. Efficiency and speed: CNC machining is a highly efficient process, as the programming and automation reduce production time. Additionally, multiple axes and simultaneous operations enable faster production rates compared to traditional machining methods.

4. Cost-effective for large quantities: Once the initial setup is complete, CNC machining can be cost-effective for large production runs. The automation reduces labor costs and minimizes material waste, making it economically viable for bulk production.

5. Repeatable and consistent quality: CNC machines can produce identical parts repeatedly, ensuring consistent quality throughout the production process. This is especially important for industries that require interchangeable or uniform parts.

Cons:

1. High initial setup cost: The purchase and installation of CNC machines can be expensive, which might be cost-prohibitive for small businesses or startups. Additional costs may include software, tooling, and maintenance.

2. Limited flexibility for small-scale production: CNC machining may not be cost-effective for small production runs or single-piece production due to the setup costs. It is more suited for large-scale or mass production.

3. Skilled operators required: While CNC machines eliminate the need for manual labor, they require skilled operators who can program and monitor the machines. Hiring and training experienced operators can add to the overall cost.

4. Limited creativity and adaptability: CNC programming is based on pre-determined designs and instructions. This restricts creativity and adaptability in the production process, making it less suitable for industries that require constant design changes.

5. Lack of human touch: Some industries may prefer the human touch and craftsmanship that traditional machining methods offer. CNC machining, being automated, may lack the personal touch and artistry associated with traditional techniques.

In conclusion, CNC machining offers numerous advantages in terms of accuracy, efficiency, versatility, and repeatable quality. However, it also comes with some drawbacks, such as high initial setup costs, limited flexibility for small-scale production, skilled operator requirements, restricted creativity, and the absence of a human touch. Analyzing these pros and cons is essential for businesses to determine whether CNC machining is the right manufacturing process for their specific needs.

cnc machining prices Reference Specifications (varies for different product)

CNC machining prices vary depending on several factors such as the complexity of the product, the materials used, the quantity ordered, and the desired level of finishing. Here are some reference specifications and their corresponding price ranges.

Simple Parts: For basic parts with simple designs, the price can range from $20 to $100 per piece. These parts typically have few features and straightforward machining requirements.

Complex Parts: More intricate parts with multiple features, tight tolerances, and complex geometries will have higher prices. The cost for such parts can range from $100 to $500 per piece.

Material Selection: The type of material used also affects the pricing. Common materials like aluminum and mild steel are generally less expensive, whereas exotic materials such as titanium or Inconel would be more costly due to their higher machining difficulty. Material costs can add up to 30% to the final price.

Quantity and Batch Size: The price per part decreases as the quantity ordered increases due to economies of scale. For example, the price for a single part might be $100, but for a batch of 100 parts, the price could be reduced to $80 per piece.

Finishing Quality: Different levels of finishing, such as deburring, polishing, or anodizing, come with additional costs. Higher-quality finishes require more time and labor, which can increase the overall price. Prices for additional finishing operations typically range from $10 to $50 per piece.

Lead Time: Tight deadlines and expedited machining services might also incur additional costs due to the need for overtime work or rearrangement of the machining schedule.

It is important to note that these are just reference specifications, and prices can significantly vary depending on the specific requirements of the product. To obtain accurate pricing, it is recommended to contact CNC machining service providers with detailed specifications for an official quote.

Applications of cnc machining prices

CNC machining prices, referring to the cost associated with computer numerical control (CNC) machining processes, play a crucial role in various industries and applications. With the ability to automate and streamline manufacturing processes, CNC machining has become a preferred choice for many companies. Here are a few key applications where CNC machining prices are significant:

1. Automotive Industry: CNC machining is extensively used in the automotive industry for manufacturing various components, such as engine parts, transmission components, and chassis parts. The accuracy, precision, and versatility of CNC machining allow for the production of complex and customized parts with tight tolerances.

2. Aerospace Industry: The aerospace sector heavily relies on CNC machining for the production of intricate and critical components required in aircraft and spacecraft. CNC machines can efficiently manufacture turbine blades, housing, landing gear components, and other parts that require high accuracy, repeatability, and reliability.

3. Electronics Industry: In the electronics industry, CNC machining is utilized to manufacture circuit board enclosures, connectors, heat sinks, and other electronic components. The ability to produce complex shapes and intricate designs with tight tolerances ensures high-quality and reliable electronic products.

4. Medical and Dental Industry: CNC machining is indispensable for producing customized medical and dental implants, surgical instruments, orthopedic devices, and prosthetics. CNC machines can accurately create patient-specific implants based on medical imaging data, offering better fit and functionality.

5. Manufacturing and Prototyping: CNC machining is widely used in various manufacturing industries for prototyping and production purposes. It allows for the efficient production of prototypes and small to medium-sized production runs, reducing lead times and costs compared to traditional manufacturing methods.

6. Defense Industry: The defense sector utilizes CNC machining for manufacturing critical components and equipment required in defense systems. These include missile parts, weapon components, optical systems, and armored vehicle parts. Precision and reliability are paramount in the defense industry, making CNC machining an ideal choice.

The pricing associated with CNC machining can vary depending on factors such as material type, complexity of design, batch size, machine capabilities, and additional finishing processes. However, the upfront costs are often justified by the advantages offered, including improved quality, reduced errors, shorter production cycles, and the ability to create complex geometries.

The Work Process and how to use cnc machining prices

CNC machining, which stands for Computer Numerical Control machining, is a manufacturing process that uses computer-aided design (CAD) software to guide the movement of machinery and tools in order to produce precision parts and components. This process is widely used in various industries such as automotive, aerospace, electronics, and medical, to name a few.

The work process of CNC machining begins with the creation of a 3D CAD model of the desired part. This model is then converted into a computer program known as G-code, which contains the instructions that the CNC machine will use to produce the part. The G-code program determines the machine’s movements, tool changes, cutting speeds, and other parameters necessary for the machining operation.

Once the G-code program is created, it is loaded into the CNC machine’s controller. The machine operator sets up the workpiece by clamping it onto the machine’s table or fixture, ensuring proper alignment and stability. The operator also selects the appropriate cutting tools, inserts them into the machine’s spindle, and calibrates the tool offsets and workpiece position.

Once the setup is complete, the operator initiates the machining process. The CNC machine follows the instructions from the G-code program and executes a series of predefined movements, such as milling, drilling, turning, or grinding, to shape the workpiece according to the desired specifications. The machine continuously monitors the cutting parameters, adjusts them if necessary, and removes material with high precision and accuracy.

After the machining process is finished, the part is inspected to ensure it meets the required specifications. Additional finishing operations, such as deburring, polishing, or surface treatments, may be applied if needed. Finally, the finished part is ready for use or further assembly.

As for CNC machining prices, they are determined by various factors such as the complexity of the part, the materials used, the quantity ordered, and the machine setup time. More intricate parts with tight tolerances and exotic materials will typically cost more. Additionally, setup time and labor required for programming and tooling are also considered in the pricing.

In conclusion, CNC machining is a versatile and efficient manufacturing process that utilizes computer-controlled machinery to produce high-quality parts. By understanding the work process and considering the factors that influence prices, businesses can effectively utilize CNC machining for their manufacturing needs.

Quality Testing Methods for cnc machining prices and how to control the quality

When it comes to quality testing methods for CNC machining prices, there are several approaches that can be adopted to ensure the control of quality. Here are some key methods:

1. Dimensional Inspection: This method involves the use of precision measuring instruments such as calipers, micrometers, and coordinate measuring machines (CMMs) to verify the dimensions of the machined parts. By comparing the actual measurements with the specified tolerances, any deviations can be identified and addressed.

2. Visual Inspection: Visual inspection is a simple yet effective method to assess the overall quality of CNC machined parts. It involves visually examining the surface finish, presence of burrs or sharp edges, and any physical defects or abnormalities that may affect the part’s functionality or aesthetics.

3. Functional Testing: This method involves subjecting the CNC machined parts to real-world operating conditions to evaluate their performance and functionality. For example, assembled components can be tested to ensure proper fit, smooth operation, and adherence to functional requirements.

4. Material Property Testing: CNC machining often involves working with different materials, such as metals or plastics. Material property testing involves evaluating the mechanical, thermal, and chemical properties of these materials to ensure they meet the specified requirements and can withstand the intended operating conditions.

To effectively control the quality of CNC machining, several strategies can be employed:

1. Establishing Quality Standards: Clearly define the quality requirements, specifications, and tolerance limits for the CNC machined parts. This helps set the benchmark against which the manufactured parts will be evaluated.

2. Process Documentation: Maintain detailed documentation of the machining processes, including machine settings, tooling specifications, and cutting parameters. This enables consistent replication of successful processes and troubleshooting in case of any quality issues.

3. Regular Maintenance and Calibration: Ensure regular maintenance and calibration of CNC machines and measuring instruments to avoid any variations or deviations that may impact the quality of the machined parts.

4. Continuous Training and Skill Development: Provide training and development opportunities for operators and technicians to enhance their knowledge and skills in CNC machining. This can help ensure that they are well-equipped to deliver high-quality results consistently.

By implementing these quality testing methods and control measures, manufacturers can effectively monitor and improve the quality of CNC machining processes. Early detection of quality issues leads to timely corrective actions, minimizing defects and optimizing the overall production efficiency.

cnc machining prices Sample Policy and Post-Purchase Considerations for cnc machining prices from China

Sample Policy:

1. Quotation: Request a detailed quotation from the supplier, including unit price, quantity discounts (if applicable), and any other associated costs such as shipping and taxes.

2. Payment Terms: Clarify the payment terms with the supplier, such as the preferred mode of payment, down payment requirements, and the remaining balance. Determine if they offer any payment protection options, such as Trade Assurance or Escrow.

3. Production Time: Inquire about the estimated production time for your order. This will help you plan ahead and manage your delivery expectations.

4. Quality Assurance: Ask for information about the supplier’s quality control measures and certification. Request samples, if necessary, to inspect the product quality before placing a bulk order.

5. Packaging and Shipping: Discuss packaging requirements to ensure that your goods arrive safely. Inquire about shipping options, including cost, delivery time, and any customs or import duties that may apply.

Post-Purchase Considerations:

1. Delivery Time: Track your order closely and communicate with the supplier regarding the estimated delivery date. Follow up promptly in case of any delays or issues.

2. Quality Inspection: Inspect the received goods thoroughly upon arrival. Document any defects or discrepancies and discuss them with the supplier for possible solutions.

3. Warranty and After-Sales Service: Inquire about the warranty period and after-sales service offered by the supplier. Understand their procedure for handling any product defects or issues that may arise post-purchase.

4. Feedback and Reviews: Provide feedback to the supplier on the delivered goods and overall experience. Share your experience in online forums or review platforms to help other buyers make informed decisions.

5. Repetitive Orders: If satisfied with the supplier’s quality, pricing, and service, consider establishing a long-term relationship to benefit from discounts, loyalty programs, or customized solutions in future orders.

By following these sample policies and considerations, you can ensure a smoother purchasing experience and minimize any potential risks when dealing with CNC machining prices from China.

Sourcing cnc machining prices from China: Opportunities, Risks, and Key Players

China has become a major player in the global CNC machining market, offering competitive prices and a wide range of services. Sourcing CNC machining prices from China presents both opportunities and risks for buyers.

Opportunities:

1. Cost Savings: China’s CNC machining prices are often significantly lower compared to other countries. This is mainly due to lower labor costs and a highly competitive manufacturing industry, allowing buyers to save money on production.

2. Wide Range of Services: Chinese manufacturers offer a diverse range of CNC machining services, including milling, turning, drilling, and more. This enables buyers to find one-stop solutions for their machining needs, reducing the need for multiple suppliers.

3. Scalability: China has a large manufacturing capacity, allowing for scalability in production. Whether a buyer requires a small batch or a large volume of CNC machined parts, Chinese manufacturers can accommodate various order sizes.

Risks:

1. Quality Control: The quality of CNC machined parts can vary among Chinese manufacturers. Therefore, it is crucial for buyers to conduct thorough research and due diligence to ensure that they work with a reputable supplier that adheres to quality standards.

2. Communication and Language Barriers: Language differences and communication barriers can pose difficulties when sourcing from China. Misunderstandings during the negotiation and manufacturing process can lead to delays or quality issues. Engaging a proficient interpreter or working with manufacturers with English-speaking staff can mitigate this risk.

3. Intellectual Property Concerns: China has been associated with intellectual property infringement in the past. To protect proprietary designs and prevent unauthorized production, buyers should consider implementing non-disclosure agreements and other legal measures when working with Chinese manufacturers.

Key Players:

1. Foxconn Technology Group: One of the largest electronics manufacturers globally, Foxconn provides CNC machining services in addition to electronic assembly.

2. BYD Company Limited: A leading manufacturer of electric vehicles and batteries, BYD also offers CNC machining services for various industries.

3. Huizhou Foryou Medical Devices Co., Ltd: Specializing in medical device manufacturing, Foryou Medical provides CNC machining services for precision parts used in the healthcare sector.

In conclusion, sourcing CNC machining prices from China can be advantageous for buyers due to cost savings, a wide range of services, and scalability. However, certain risks like quality control, communication barriers, and intellectual property concerns should be carefully addressed. Key players such as Foxconn, BYD, and Foryou Medical are prominent in the Chinese CNC machining market.

How to find and select reliable cnc machining prices manufacturers in China,use google search manufacturers and suppliers

When it comes to finding and selecting reliable CNC machining prices manufacturers in China, utilizing Google search is an effective approach. Follow these steps to find the right manufacturer for your needs:

1. Begin by typing relevant keywords into the Google search bar, such as “CNC machining prices manufacturers in China” or “reliable CNC machining suppliers in China.” This will generate a list of potential manufacturers and suppliers.

2. Visit the websites of these manufacturers and suppliers to gather information such as company background, production capabilities, certifications, and client testimonials. Pay close attention to their experience in the industry and whether they specialize in the types of products you require.

3. Evaluate their pricing structure and whether they offer transparent pricing information on their website. Look for manufacturers that provide detailed quotes based on specific product requirements, quantities, and materials.

4. Check for any certifications or quality management systems, such as ISO 9001, that the manufacturer holds. These certifications demonstrate their commitment to maintaining quality standards.

5. Look for manufacturers that have experience working with international clients and provide support in your preferred language. This will help minimize language barriers and enhance communication during the production process.

6. Seek manufacturers that have a strong customer service team and are responsive to inquiries. Prompt and clear communication is crucial to avoid misunderstandings and ensure your requirements are met.

7. Additionally, explore online directories and platforms like Alibaba, Made-in-China, or Global Sources. These platforms allow you to search for manufacturers by filtering for suppliers with good ratings, verified credentials, and positive customer feedback.

8. Connect and engage with potential manufacturers through email or other communication channels to inquire about their production processes, lead times, and any additional services they offer, such as logistics or packaging.

9. Before finalizing your decision, request samples of their previous work to assess the quality and precision of their CNC machined products.

10. Compare the pricing, capabilities, certifications, and overall professionalism of several manufacturers to make an informed decision. It is advisable not to solely focus on the lowest price, but instead, consider the overall value offered by the manufacturer.

By conducting thorough research, evaluating multiple options, and maintaining clear communication, you can find and select reliable CNC machining prices manufacturers in China that meet your specific requirements.

How to check cnc machining prices manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

When it comes to checking the reliability of CNC machining prices on a manufacturer’s website, there are a few steps you can follow. One effective method is using Google Chrome and the SEOquake extension to check if the website ranks within the top 10 million.

Here’s what you can do:

1. Use Google Chrome: Open the manufacturer’s website using Google Chrome browser. If you don’t have it installed, download and install it from the official website.

2. Install SEOquake: Once you have Google Chrome installed, go to the Chrome Web Store and search for “SEOquake.” Add this extension to your browser.

3. Activate SEOquake: Click on the SEOquake icon located on the top right corner of your browser’s toolbar. Ensure it is turned on by checking if it is highlighted in color.

4. Search Ranking: On the manufacturer’s website, go to the homepage or any relevant page with pricing information. Now, click on the SEOquake icon to display a drop-down menu. From this menu, select “Page Info.”

5. Analyze the Results: A new window will appear with various information about the website. Look for the “Google Index” section and note down the “Index Size” value. If the value is within the top 10 million, it indicates that the website is being recognized by Google and has a relatively high rank.

By following these steps, you can quickly determine if a manufacturer’s website is reliable in terms of its search engine optimization and visibility in Google’s search rankings. Remember to cross-reference other factors such as customer reviews, industry reputation, and the company’s overall credibility before making any final decisions.

Top 10 cnc machining prices manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Shenzhen JPT Precision Machinery Co., Ltd.

Shenzhen JPT Precision Machinery Co., Ltd. is a leading CNC machining manufacturer in China. They specialize in the production of high-precision CNC machined parts for various industries such as automotive, aerospace, and medical. Their product range includes automotive components, precision gears, medical implants, and electronic parts. With state-of-the-art facilities and a highly skilled team, they deliver superior quality products at competitive prices.

2. Dongguan Mingte Hardware Machinery Co., Ltd.

Dongguan Mingte Hardware Machinery Co., Ltd. is known for its extensive range of CNC machining services in China. They offer precision machining for diverse industries, including telecommunications, robotics, and electronics. Their product portfolio comprises CNC milled parts, turned parts, and custom-made components. They emphasize on meeting client requirements with strict quality control measures and cost-effective solutions.

3. Zhongshan City Precision Metal Products Co., Ltd.

Zhongshan City Precision Metal Products Co., Ltd. is a renowned CNC machining manufacturer catering to a broad spectrum of industries. Their product range includes CNC aluminum parts, stainless steel components, and custom-made machinery parts. Through advanced production equipment and rigorous quality control, they ensure the highest precision and durability of their products.

4. Suzhou Penglu Precision Machinery Co., Ltd.

Suzhou Penglu Precision Machinery Co., Ltd. specializes in CNC machining and provides comprehensive services from design to manufacturing. They offer precision-machined parts and components for the automotive, aerospace, and energy sectors. Their product line includes CNC turned parts, sheet metal components, and plastic parts.

5. Wuxi Qianqiao Precision Machinery Co., Ltd.

Wuxi Qianqiao Precision Machinery Co., Ltd. is a trusted name in CNC machining, providing cost-effective solutions for various industries. They offer a wide range of CNC machined products such as CNC milling parts, turned parts, and custom-made components. With a strong focus on quality assurance, they have earned a good reputation for their reliability.

6. Ningbo Champion Precision Parts Co., Ltd.

Ningbo Champion Precision Parts Co., Ltd. is a leading CNC machining manufacturer located in Ningbo, China. They specialize in providing precision machining services for industries like automotive, aerospace, and electronics. Their product range includes CNC machined parts, plastic injection molded parts, and stamping parts. With advanced technology and efficient production processes, they offer competitive prices and timely delivery.

7. Guangdong Eastern Precision Manufacturing Co., Ltd.

Guangdong Eastern Precision Manufacturing Co., Ltd. is a professional CNC machining manufacturer based in Guangdong, China. They offer a comprehensive range of CNC machined parts like aluminum extrusion, plastic injection molding, and sheet metal fabrication. With strict quality control and a customer-centric approach, they provide cost-effective solutions and timely delivery to meet client requirements.

8. Qingdao Shengkaiweijian Precision Machinery Co., Ltd.

Qingdao Shengkaiweijian Precision Machinery Co., Ltd. is a reputable CNC machining manufacturer in China. They provide precision machining services for various sectors, including automotive, aerospace, and energy. Their product range comprises CNC turned parts, CNC milling parts, and custom-made components. With a focus on quality, they ensure product excellence and competitive pricing.

9. Shenzhen Yijin Hardware Co., Ltd.

Shenzhen Yijin Hardware Co., Ltd. is a well-established CNC machining manufacturer located in Shenzhen, China. They offer high-quality precision machining services for industries like automotive, electronics, and telecommunications. Their product portfolio includes CNC milled parts, turned parts, and custom-made components. With strong engineering expertise, they deliver reliable products at competitive prices.

10. Xiamen Wondee Industries Co., Ltd.

Xiamen Wondee Industries Co., Ltd. is a leading CNC machining manufacturer based in Xiamen, China. They have extensive experience in producing CNC machined parts for industries such as automotive, aerospace, and medical. Their product range includes CNC milled parts, turned parts, and sheet metal components. With a focus on technological innovation and quality control, they offer competitive pricing and excellent customer service.

| Manufacturer Name | Product Range | Quality Control | Pricing Advantage |

|———————————-|———————————————-|————————————|—————————-|

| Shenzhen JPT Precision Machinery Co., Ltd. | Automotive components, precision gears, medical implants, electronic parts | State-of-the-art facilities | Competitive |

| Dongguan Mingte Hardware Machinery Co., Ltd. | CNC milled parts, turned parts, custom-made components | Strict quality control | Cost-effective |

| Zhongshan City Precision Metal Products Co., Ltd. | CNC aluminum parts, stainless steel components, custom-made machinery parts | Rigorous quality control | High precision |

| Suzhou Penglu Precision Machinery Co., Ltd. | CNC turned parts, sheet metal components, plastic parts | Comprehensive services | Diverse industries |

| Wuxi Qianqiao Precision Machinery Co., Ltd. | CNC milling parts, turned parts, custom-made components | Strong focus on quality assurance | Reliability |

| Ningbo Champion Precision Parts Co., Ltd. | CNC machined parts, plastic injection molded parts, stamping parts | Advanced technology | Timely delivery |

| Guangdong Eastern Precision Manufacturing Co., Ltd. | Aluminum extrusion, plastic injection molding, sheet metal fabrication | Strict quality control | Customer-centric approach |

| Qingdao Shengkaiweijian Precision Machinery Co., Ltd. | CNC turned parts, CNC milling parts, custom-made components | Focus on quality | Competitive pricing |

| Shenzhen Yijin Hardware Co., Ltd. | CNC milled parts, turned parts, custom-made components | Strong engineering expertise | Competitive pricing |

| Xiamen Wondee Industries Co., Ltd. | CNC milled parts, turned parts, sheet metal components | Technological innovation | Excellent customer service |

This table provides an overview of the top 10 CNC machining manufacturers in China. The manufacturers are compared based on their product range, quality control measures, and pricing advantage. These companies are known for their precision machining services and cater to a wide range of industries. With their advanced technology, strict quality control, and competitive pricing, they ensure customer satisfaction and timely delivery of high-quality CNC machined parts.

Background Research for cnc machining prices manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to CNC machining prices, China is known for its competitive rates and extensive manufacturing capabilities. To conduct background research on CNC machining manufacturers in China, three useful platforms can be utilized: Qcc.com, Archive.org, and ImportYeti.com.

Qcc.com is a comprehensive business website in China that provides information on companies operating in various industries. It allows users to search for CNC machining manufacturers and obtain details such as company profiles, contact information, legal registrations, financial records, and more. This platform can help in verifying the credibility and legitimacy of potential manufacturers.

Archive.org is a digital library that provides access to archived web pages. By entering the websites of specific CNC machining manufacturers in China, one can view historical snapshots of their websites and gather information about the company’s history, products, services, and any changes they have undergone over time. This can give insights into a manufacturer’s experience and expertise in the CNC machining field.

ImportYeti.com is a platform that offers import-export data, particularly useful for identifying suppliers and manufacturers from various countries. By searching for CNC machining manufacturers in China, users can access data related to their shipments, customers, and pricing trends. This data can provide an understanding of a manufacturer’s export activities and their competitive pricing strategies.

In conclusion, utilizing Qcc.com, Archive.org, and ImportYeti.com can help in conducting background research on CNC machining manufacturers in China. These platforms provide information on company profiles, legal registrations, financial records, historical data, and import-export trends, giving insights into a manufacturer’s credibility, experience, capabilities, and pricing strategies.

Leveraging Trade Shows and Expos for cnc machining prices Sourcing in China

Trade shows and expos serve as valuable platforms for sourcing CNC machining prices in China. These events offer numerous advantages for businesses looking to connect with suppliers and compare pricing options.

One benefit of attending trade shows and expos is the opportunity to directly engage with suppliers. Exhibitors at these events are eager to showcase their products and services, making it easier for buyers to gather information and negotiate prices. By engaging in face-to-face conversations, buyers can gain a deeper understanding of the supplier’s capabilities, quality standards, and manufacturing processes, allowing for more accurate pricing estimates.

Moreover, trade shows and expos often feature a wide range of suppliers specializing in CNC machining. This concentration of industry professionals creates a competitive environment, motivating suppliers to offer attractive pricing packages to attract potential customers. Buyers can take advantage of this competition by leveraging their bargaining power to negotiate better prices and favorable terms.

Attending these events also enables buyers to compare different suppliers and their offerings side by side. This allows for a comprehensive evaluation of pricing structures, product quality, lead times, and after-sales services. Such comparisons help buyers make informed decisions and ensure they are receiving the best value for their money. Additionally, engaging with multiple suppliers enables buyers to build relationships and establish a network of reliable partners for future projects.

Furthermore, trade shows and expos provide opportunities for buyers to stay updated on the latest trends and technological advancements in the CNC machining industry. By attending seminars, workshops, and demonstrations, buyers can gain insights into cutting-edge manufacturing techniques, which may affect pricing and potential savings. Staying informed about industry developments can help buyers negotiate more effectively and identify cost-saving opportunities in the long run.

In summary, leveraging trade shows and expos for sourcing CNC machining prices in China offers several advantages. The ability to directly engage with suppliers, compare offerings, negotiate prices, and stay informed about industry trends ensures that buyers can find the best pricing options and establish partnerships with reliable suppliers.

The Role of Agents and Sourcing Companies in Facilitating cnc machining prices Purchases from China

When it comes to purchasing CNC machining products from China, agents and sourcing companies play a crucial role in facilitating the process. These entities act as intermediaries between buyers seeking CNC machining services and suppliers in China. Their primary purpose is to enhance efficiency, quality, and cost-effectiveness in the procurement process.

Agents are typically local representatives who have extensive knowledge of the Chinese market, language proficiency, and a comprehensive understanding of the CNC machining industry. They serve as a bridge between buyers and Chinese suppliers, assisting in communication, negotiation, and partner selection. Agents facilitate effective communication by removing language barriers and cultural misunderstandings, ensuring that buyers’ requirements are accurately conveyed and understood by the suppliers. Additionally, agents help buyers to identify and verify potential Chinese suppliers, examining their capabilities, certifications, manufacturing processes, and quality control systems. This evaluation process ensures that buyers are connected with reliable and reputable suppliers, minimizing the risk of fraud or subpar products.

On the other hand, sourcing companies specialize in helping buyers identify suitable suppliers and secure competitive prices for CNC machining products. These companies have in-depth knowledge of the Chinese market and provide a wide network of established supplier connections. By leveraging their sourcing expertise and relationships, they can negotiate favorable terms, including competitive pricing, flexible payment options, and shorter lead times. Sourcing companies also assist in managing the procurement process, ensuring timely delivery, quality control, and resolving any issues that may arise. Additionally, they offer assistance in logistics, customs clearance, and shipping, making the overall purchasing process smoother and less burdensome for buyers.

By utilizing the services of agents and sourcing companies, buyers can tap into the vast potential and benefits offered by the CNC machining industry in China. These entities help buyers navigate the complexities of international trade, overcome language and cultural barriers, and select the most suitable suppliers at the best possible prices. Ultimately, the involvement of agents and sourcing companies significantly simplifies and enhances the procurement process, ensuring that buyers achieve their desired outcomes efficiently and cost-effectively.

Price Cost Research for cnc machining prices manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for CNC machining prices in China, two reliable sources can be utilized: temu.com and 1688.com. These platforms provide comprehensive listings of manufacturers and their corresponding pricing information.

Temu.com is a leading online B2B platform that specializes in connecting buyers and sellers in various industries, including CNC machining. Users can search for manufacturers based on their specific requirements and obtain detailed information about their services, capabilities, and pricing. The platform also allows users to request quotes directly from manufacturers, facilitating easy price comparison.

Similarly, 1688.com is also a popular online marketplace in China that offers a wide range of products and services, including CNC machining. It is particularly useful for conducting price research, as it provides access to a large number of suppliers and manufacturers. Users can browse through company profiles, product catalogs, and pricing information to determine the cost of CNC machining services.

When using these platforms for price cost research, it is important to focus on key factors that impact pricing. These include the complexity of the machining project, material requirements, quantity, tolerances, and any additional services required (such as surface finishing or assembly). By providing clear specifications and requirements, users can receive accurate quotes from manufacturers.

Furthermore, it is advisable to communicate with multiple manufacturers to obtain competitive pricing. By reaching out to different suppliers and comparing their quotes, users can ensure they are receiving a fair and reasonable price for CNC machining services in China.

In conclusion, temu.com and 1688.com are valuable resources for conducting price cost research for CNC machining services in China. By utilizing the features and functionalities offered by these platforms, users can access a large pool of manufacturers and obtain accurate quotes, ensuring they make informed decisions based on reliable and up-to-date pricing information.

Shipping Cost for cnc machining prices import from China

Shipping costs for CNC machining prices imported from China vary depending on several factors, including the size and weight of the shipment, the chosen shipping method and carrier, and the destination country.

In general, there are two main shipping methods for importing goods from China: air freight and sea freight. Air freight is generally faster but more expensive, while sea freight is slower but offers more affordable rates for large shipments.

For small and lightweight shipments, air freight is often the preferred choice. The cost is usually calculated based on the weight or volumetric weight (whichever is higher) of the package. Additionally, there might be additional charges for fuel surcharges, customs clearance fees, handling fees, and insurance. The shipping time for air freight can range from a few days to two weeks, depending on the destination and any potential customs delays.

On the other hand, sea freight is more suitable for larger and heavier shipments. The cost is typically calculated based on the volume or cubic meter of the cargo. Like air freight, there are additional charges for customs clearance, handling, and insurance. Sea freight shipping times can vary significantly, ranging from a few weeks to several months, depending on the distance and any unforeseen delays.

To get a more accurate estimate of shipping costs, it is advisable to contact shipping companies or freight forwarders that specialize in imports from China. They can provide detailed information and quotes based on the specific dimensions and weight of the CNC machining prices.

In conclusion, the shipping cost for imported CNC machining prices from China depends on various factors such as shipment size, chosen shipping method, carrier, and destination country. It is recommended to reach out to shipping companies for accurate quotes and information.

Compare China and Other cnc machining prices Markets: Products Quality and Price,Visible and Hidden Costs

China is known for being one of the largest and most competitive marketplaces for CNC machining. When comparing Chinese CNC machining prices with other markets, several factors need to be considered, including product quality and price, visible and hidden costs.

Product Quality and Price: China offers a wide range of CNC machining services, from low-cost options to high-end precision machining. The product quality can vary depending on the manufacturer and the price range. Chinese manufacturers often offer competitive prices due to their large-scale production capabilities and lower labor costs. However, the wide range of options available makes it essential for buyers to carefully choose the supplier to ensure the desired quality level.

Visible and Hidden Costs: Chinese CNC machining prices often have lower visible costs compared to other markets, thanks to factors such as lower labor and manufacturing expenses. Chinese manufacturers can typically offer products at lower prices due to economies of scale. However, it is crucial to consider other factors, such as shipping costs, import duties, taxes, and potential language barriers, which can add to the overall cost. These hidden costs may sometimes make other markets more cost-effective, especially for products that are bulky or require specialized expertise.

Factors Beyond Price: While price is an important consideration when comparing CNC machining markets, other factors should also be taken into account. These include lead times, customization options, communication capabilities, intellectual property protection, and quality assurance. Other markets may offer advantages in these areas, such as faster delivery times, specialized expertise, and stronger intellectual property rights.

In conclusion, China offers a highly competitive marketplace for CNC machining with a range of products at various price points. While Chinese manufacturers often provide cost advantages due to lower visible costs, potential hidden costs and other factors such as product quality, lead times, and communication capabilities should be carefully evaluated when comparing with other markets. Buyers should weigh the overall value rather than solely focusing on price to make informed decisions.

Understanding Pricing and Payment Terms for cnc machining prices: A Comparative Guide to Get the Best Deal

When it comes to pricing and payment terms for CNC machining services, it is essential to have a clear understanding to ensure you get the best deal. This comparative guide aims to shed light on the key factors to consider, enabling you to make informed decisions.

Pricing models: CNC machining prices can vary significantly based on different pricing models. The most commonly observed models include hourly rates, cost per part, and project-based pricing. Hourly rates are calculated based on the machine’s operating time, while cost per part considers factors such as material and machine setup. Project-based pricing involves a negotiated price for the entire project.

Factors influencing pricing: Several factors influence CNC machining prices. These include the complexity of the part, material selection, tolerances required, quantity of parts ordered, tooling requirements, surface finishes, and additional services like assembly or packaging. It is important to provide detailed part specifications to receive accurate quotes.

Comparing quotes: To get the best deal, it is crucial to compare quotes from multiple CNC machining suppliers. Look for transparent pricing that clearly breaks down costs for materials, machine time, tooling, and additional services. Consider the supplier’s reputation, experience, lead times, and quality assurance processes. Analyzing these factors alongside pricing will help you make an informed decision.

Payment terms: Payment terms vary among different CNC machining suppliers. Common payment options include advance payment, partial payment or milestone-based payments, and full payment upon completion. Some suppliers may also offer credit terms for long-term or repeat customers. Evaluating the payment terms is essential to understand the financial impact and plan your budget accordingly.

Other cost considerations: In addition to the quoted price, it is essential to consider other costs associated with CNC machining. These may include shipping, taxes, customs duties for international orders, and any additional fees for rush orders or expedited services. Factoring in these costs will give you a comprehensive understanding of the total project expenses.

In conclusion, understanding pricing models, factors influencing pricing, and payment terms is crucial to obtain the best deal for CNC machining services. Comparing quotes from different suppliers and considering additional costs will help you make an informed decision while ensuring the desired quality and timely delivery of your machined parts.

Chinese Regulations and Industry Standards Certifications for cnc machining prices,Import Regulations and Customs for cnc machining prices from China

In China, there are several regulations and industry standards certifications relevant to CNC machining prices. Firstly, the implementation of China Compulsory Certification (CCC) is mandatory for certain products, including CNC machines. This certification ensures that the products meet health, safety, and environmental protection requirements. Additionally, ISO 9001 certification is widely recognized in the CNC machining industry, indicating that the manufacturer has a quality management system in place.

Import regulations and customs procedures for CNC machining prices from China vary depending on the importing country. Generally, it is advisable to thoroughly research and comply with the import regulations of the target market before importing CNC machines. This typically includes acquiring proper documentation, such as commercial invoices, packing lists, and certificates of origin, and ensuring compliance with customs declaration procedures.

It is also important to consider any applicable customs duties and taxes that may be levied on imported CNC machines. Import duties vary depending on the product and its classification under the Harmonized System (HS) code. Importers may be required to pay value-added tax (VAT) and customs fees, which can further impact the final price of CNC machining equipment imported from China.

To ensure a smooth import process, it is crucial to work with reputable suppliers in China who are experienced in exporting CNC machines. They can provide guidance on product certifications, assist with necessary documentation, and may even have experience in dealing with specific importing countries’ regulations and customs procedures. Additionally, engaging the services of a customs broker or freight forwarder can help navigate the complexities of customs clearance, ensuring compliance with import regulations and maximizing cost-efficiency.

In conclusion, understanding Chinese regulations and industry standards certifications for CNC machining prices is necessary when sourcing from China. Equally important is conducting thorough research on import regulations and customs procedures of the target market, as well as working with experienced suppliers and customs service providers in order to ensure a smooth and compliant import process.

Sustainability and Environmental Considerations in cnc machining prices Manufacturing

Sustainability and environmental considerations are important aspects in CNC machining manufacturing processes. CNC machining is a precise manufacturing method that utilizes computer-controlled machines to produce various parts and components. While this method offers efficiency and accuracy, it also has potential environmental impacts that need to be addressed.

One of the primary concerns is the energy consumption of CNC machines. These machines require a significant amount of power to operate, and this can contribute to greenhouse gas emissions and other environmental issues. Implementing energy-efficient strategies such as using high-performance motors, optimizing cutting parameters, and adopting machine tool designs that minimize energy waste can help reduce the environmental impact of CNC machining.

Another significant environmental concern in CNC machining is the generation of waste. This waste includes metal shavings, coolant residues, and packaging materials. Proper handling and disposal of these waste materials is crucial to prevent pollution and minimize the environmental footprint of CNC machining. Implementing recycling and waste management programs, such as reusing metal shavings or recycling coolant, can help reduce waste generation and promote sustainability.

Furthermore, the choice of materials used in CNC machining can also impact sustainability. Opting for environmentally friendly materials such as recycled metals or biodegradable plastics can help reduce the use of virgin resources and minimize the environmental impact of CNC machining. Additionally, selecting materials with low toxicity levels can prevent the release of harmful substances during machining processes.

In conclusion, sustainability and environmental considerations play a vital role in CNC machining manufacturing. Addressing energy consumption, waste management, and material choices can help minimize the environmental impact of CNC machining. Implementing energy-efficient practices, recycling and waste management programs, and using environmentally friendly materials are important steps toward achieving sustainability in CNC machining processes.

List The Evolution history of “cnc machining prices”

CNC machining prices have evolved significantly over the years, reflecting advancements in technology, changes in market demands, and various economic factors.

In the early days of computer numerical control (CNC) machining, prices were relatively high due to the limited availability of CNC machines and their complex operation. These machines were typically large and expensive, requiring significant technical expertise to operate, resulting in high production costs.

As CNC technology advanced and became more widespread in the 1980s and 1990s, prices gradually began to decline. The growing competition in the market, combined with increased automation and improved machine efficiency, led to a reduction in production costs. This allowed manufacturers to offer CNC machining services at more affordable prices.

The 2000s marked a turning point in the evolution of CNC machining prices. The rapid development of computer-aided design (CAD) and computer-aided manufacturing (CAM) software, combined with the availability of low-cost overseas manufacturing, led to a further drop in prices. This trend, commonly known as global manufacturing outsourcing, allowed manufacturers to source CNC machining services from countries with lower labor costs, significantly impacting pricing dynamics.

In recent years, advancements in CNC machining technologies, such as multi-axis machining and high-speed cutting, have increased productivity and efficiency even further. These advancements have resulted in shorter machining times, reduced material waste, and enhanced part accuracy. As a consequence, CNC machining prices have continued to decline, making it more accessible to a broader range of industries and businesses.

Another key factor influencing CNC machining prices is the availability and cost of raw materials. Fluctuations in material costs, influenced by factors like supply and demand, geopolitical events, and market speculation, can impact the overall pricing of CNC machining services. Additionally, environmental regulations affecting the extraction and processing of materials can introduce cost fluctuations.

In conclusion, the evolution of CNC machining prices has been shaped by technological advancements, global outsourcing, market competition, and fluctuating raw material costs. As CNC technology continues to advance, prices are expected to maintain a downward trajectory, making CNC machining a more economical and widely adopted manufacturing option.

The Evolution and Market Trends in cnc machining prices Industry

The CNC machining industry has seen significant evolution over the years, driven by advancements in technology, market demand, and changing customer preferences. These changes have also influenced the pricing trends within the industry.

One of the major developments in the CNC machining industry has been the introduction of advanced computer numerical control (CNC) technology. This technology has revolutionized the machining process, allowing for higher precision, faster production, and reduced operator errors. As a result, the demand for CNC machining services has increased significantly, leading to a more competitive market.

The increased competition in the market has had an impact on pricing trends. Earlier, CNC machining was a highly specialized field, and the prices were relatively high due to limited competition. However, with the entry of new players and the increased availability of CNC machines, prices have become more affordable.

Additionally, with the evolution of technology, the cost of CNC machines has decreased. This, in turn, has helped in reducing the overall production costs. As a result, CNC machining prices have become more competitive, making it more accessible to a wider customer base.

Another trend in the CNC machining industry is the focus on customization and quick turnaround times. Customers are increasingly looking for personalized and unique products, and CNC machining allows for easy customization. This has led to the emergence of smaller-scale CNC machining shops that specialize in providing quick and customized solutions. These shops often offer competitive prices to attract customers in this niche market.

Moreover, the growing demand for CNC machining in various industries, such as aerospace, automotive, and electronics, has also influenced pricing trends. As these industries seek precision and high-quality components, the demand for CNC machining services has increased. Consequently, some specialized CNC machining shops catering to these industries may charge higher prices due to the complexity and precision required for their products.

In conclusion, the evolution of CNC machining technology, increased competition, and changing customer preferences have all contributed to the changing pricing trends in the industry. While the overall prices have become more affordable due to advancements in technology and increased competition, specialized CNC machining services for specific industries may still command higher prices.

Custom Private Labeling and Branding Opportunities with Chinese cnc machining prices Manufacturers

Chinese CNC machining manufacturers offer custom private labeling and branding opportunities for businesses looking to create their own unique products. With their expertise in CNC machining technology, these manufacturers can produce high-quality products that meet specific design requirements.

One of the main advantages of working with Chinese CNC machining manufacturers is the ability to customize products with private labels and branding. This allows businesses to create a distinct identity and differentiate themselves in the market. Manufacturers can help with logo design, product labeling, and packaging, ensuring that the final product represents the brand’s image and values.

Chinese CNC machining manufacturers often offer competitive prices, making it an attractive option for businesses looking to keep manufacturing costs low. With their advanced technology and efficient production processes, manufacturers can produce products at a lower cost without compromising on quality. This can lead to higher profit margins for businesses, allowing them to invest in other areas of their operations.

Furthermore, Chinese manufacturers have a wide range of CNC machining capabilities, including milling, drilling, turning, and precision machining. This versatility enables businesses to create a diverse range of products, from simple components to intricate parts. Manufacturers can work with various materials, such as metals, plastics, and composites, providing flexibility in product design.

When collaborating with Chinese CNC machining manufacturers, businesses can also benefit from their experience in international trade. These manufacturers are familiar with export regulations and logistics, making the process smoother for businesses looking to sell their custom products globally.

In conclusion, partnering with Chinese CNC machining manufacturers offers businesses custom private labeling and branding opportunities at competitive prices. With their advanced technology, expertise, and flexible capabilities, these manufacturers can help businesses create high-quality, customized products that effectively represent their brand identity.

Tips for Procurement and Considerations when Purchasing cnc machining prices

When it comes to procurement and purchasing CNC machining, there are several important tips and considerations to keep in mind. These factors will help ensure that you make informed decisions and get the best value for your money. Here are some essential tips:

1. Define your requirements: Clearly define the specifications, tolerances, and quality standards you expect from a CNC machining service. This will enable you to communicate your needs effectively to potential suppliers.

2. Quality assurance: Check if the supplier has quality certifications such as ISO 9001, which ensures they have implemented effective quality management systems. Quality control measures are crucial to avoid costly reworks or rejects.

3. Experience and expertise: Assess the supplier’s experience in handling similar projects or components. Verified customer references can give you an idea of their competence and reliability.

4. Cost vs. quality: While price is important, avoid solely choosing the least expensive option. Evaluate the quality of the supplier’s products and services to ensure they meet your requirements.

5. Request for samples: Ask suppliers for samples to check the accuracy and precision of their CNC machining capabilities. Evaluate the surface finish, dimensional accuracy, and overall quality to ensure it matches your needs.

6. Lead time: Inquire about the supplier’s lead times and capacity to handle your specific quantity and delivery requirements. Ensure their production schedule aligns with your project timeline.

7. Communication and responsiveness: Prompt and effective communication is key to smooth procurement. Assess their responsiveness in providing quotes, answering queries, and addressing concerns.

8. Supplier location: Consider the supplier’s geographic location in relation to your facility. Close proximity can lead to faster turnaround times and lower shipping costs.

9. Intellectual property protection: If you have design-sensitive or patent-pending parts, discuss intellectual property protection with potential suppliers. Ensure they have suitable measures in place to safeguard your designs.

10. Post-sale support: Inquire about their warranty, return policy, and technical support after delivery. A supplier that stands behind their products can provide peace of mind and assurance.

By keeping these factors in mind, you can navigate the procurement process and make informed decisions when it comes to purchasing CNC machining services. Remember, it’s crucial to balance cost with quality and consider other important factors like supplier experience and responsiveness to ensure a successful procurement experience.

FAQs on Sourcing and Manufacturing cnc machining prices in China

Q: What is the cost of CNC machining in China?

A: CNC machining prices in China vary depending on various factors such as the complexity of the design, the materials used, the quantity ordered, and the manufacturing method. Generally, Chinese manufacturers offer competitive prices compared to other countries due to their low labor costs and large-scale production capabilities. However, it is essential to request quotations from multiple suppliers to get a better idea of the pricing range and negotiate the best deal for your specific project.

Q: How can I find reliable CNC machining suppliers in China?

A: To find reliable CNC machining suppliers in China, you can start by conducting thorough research online, consulting industry directories, and utilizing online marketplaces that connect buyers with suppliers. It is crucial to evaluate the supplier’s credentials, such as their certifications, years of experience, and customer reviews. Additionally, requesting samples and conducting factory visits can help assess the supplier’s capabilities and quality standards.

Q: Can I negotiate the price with Chinese CNC machining suppliers?

A: Yes, negotiation is a common practice when dealing with Chinese CNC machining suppliers. It is recommended to compare quotes from multiple suppliers and leverage the competitive market to negotiate better prices. Chinese suppliers are usually open to negotiations, especially for larger order volumes or long-term partnerships. However, it is crucial to maintain a professional and respectful approach during negotiations to build a mutually beneficial business relationship.

Q: Are there any additional costs associated with sourcing CNC machining in China?

A: Along with the CNC machining prices, it is important to consider additional costs such as shipping, import duties, taxes, and any potential customs clearance fees. These costs may vary depending on the destination country’s regulations and the shipping method chosen. It is advisable to discuss these aspects with the supplier and consider using a freight forwarder or customs consultant to ensure a smooth and cost-effective shipping process.

Q: What are the lead times for CNC machining production in China?

A: The lead times for CNC machining production in China can vary depending on the complexity of the design, the quantity ordered, and the supplier’s current workload. Generally, Chinese manufacturers can offer relatively short lead times due to their efficient production processes and large production capacities. However, it is recommended to discuss the expected lead times with the supplier before placing an order to ensure alignment with your project timeline.

In conclusion, CNC machining prices in China can be competitive, and it is essential to research and compare multiple suppliers for the best deal. Finding reliable suppliers, negotiating prices, considering additional costs, and discussing lead times are crucial aspects to consider when sourcing and manufacturing CNC machining in China.

Why contact sourcifychina.com get free quota from reliable cnc machining prices suppliers?

Sourcifychina.com is able to provide free quota from reliable CNC machining prices suppliers because of its established network and reputation in the industry.

As a platform that connects buyers with manufacturers in China, Sourcifychina.com has built relationships with a wide range of suppliers over the years. These suppliers have been carefully vetted to ensure their reliability and adherence to high standards of quality.

By offering a free quota service, Sourcifychina.com aims to simplify the process for buyers who are looking for CNC machining services. Instead of reaching out to different suppliers individually and negotiating prices, buyers can conveniently submit their requirements to Sourcifychina.com and receive multiple quotations from trusted suppliers.

The platform’s ability to negotiate discounted prices is based on the volume of orders it generates for the suppliers. As Sourcifychina.com consistently brings business to these suppliers, they are willing to offer competitive prices that can be passed on to buyers.

Furthermore, Sourcifychina.com acts as a mediator between the buyers and the suppliers, ensuring clear communication and understanding of requirements. This eliminates the need for buyers to directly negotiate with the suppliers, minimizing potential language barriers and other challenges.

Overall, the free quota service offered by Sourcifychina.com provides buyers with a convenient and reliable way to access competitively priced CNC machining services from trusted suppliers in China.