Knowledge about Cnc Manufacturing

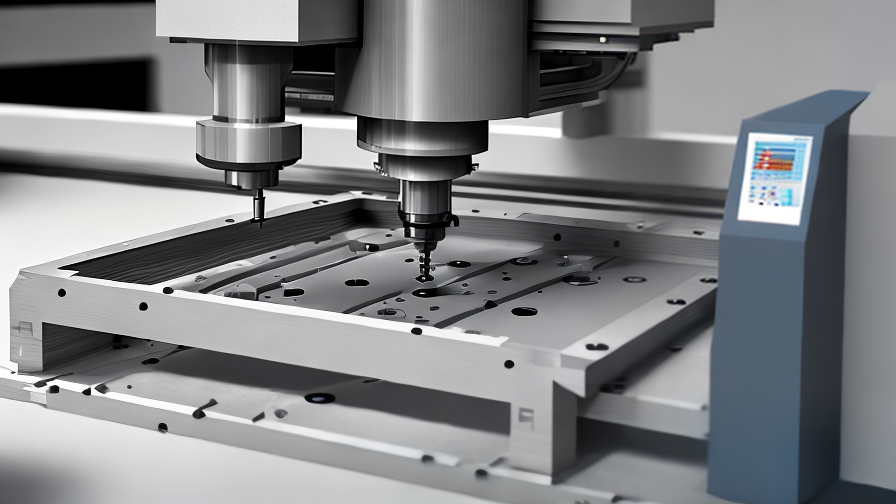

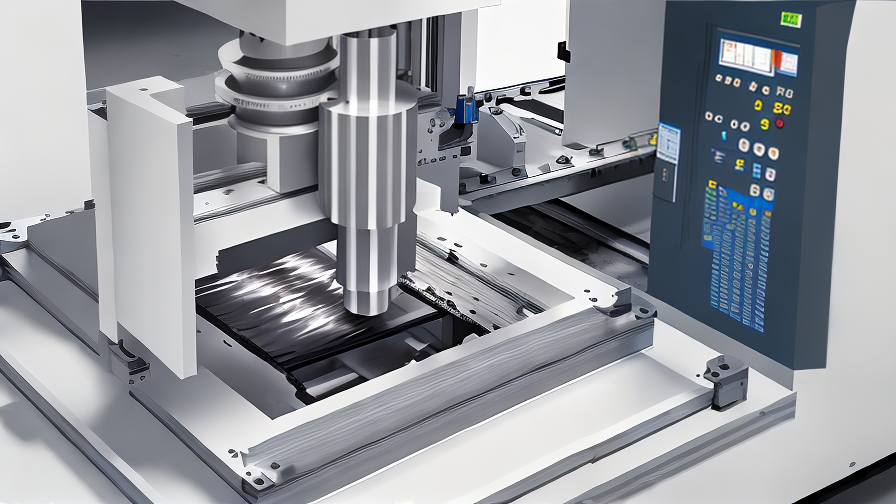

Computer Numerical Control (CNC) manufacturing is a process that uses automated machines to produce complex and intricate parts for various industries. It has revolutionized the manufacturing industry and has greatly improved the accuracy and efficiency of production.

CNC machines work by following programmed instructions that guide the cutting and shaping of a material. A CAD (Computer Aided Design) model is first created, and CNC software then converts the design into machine-readable code. This code is then used to control the operation of the machine, resulting in the precise cutting or shaping of the material.

Knowledge about CNC manufacturing is important for anyone involved in the production of parts or components. This includes engineers, designers, machinists, and operators. Understanding how CNC machines work, their capabilities and limitations, and best practices for programming and operating them is crucial to achieving optimal results.

One of the key advantages of CNC manufacturing is its ability to produce parts with a high level of accuracy and consistency. However, this requires an understanding of the various factors that can affect the machining process, such as tool selection, cutting speeds, and feed rates. Additionally, knowledge of the materials being machined is important, as different materials require different tooling and cutting strategies.

Another important aspect of CNC manufacturing is the ability to optimize the machining process for efficiency and cost-effectiveness. This can include strategies such as reducing waste material, minimizing tool wear, and optimizing cutting paths to reduce production time.

Overall, the knowledge and expertise required for CNC manufacturing are critical for achieving success in today’s competitive manufacturing environment. With continuous advancements in technology and automation, staying up-to-date with the latest trends and best practices will be essential for maintaining a competitive edge.

Various Types of Cnc Manufacturing

CNC manufacturing, which stands for computer numerical control, involves the use of automated machines to produce products. CNC manufacturing has revolutionized the manufacturing industry by improving the accuracy, precision, and speed of production.

There are several types of CNC manufacturing techniques, each with its specific advantages and limitations.

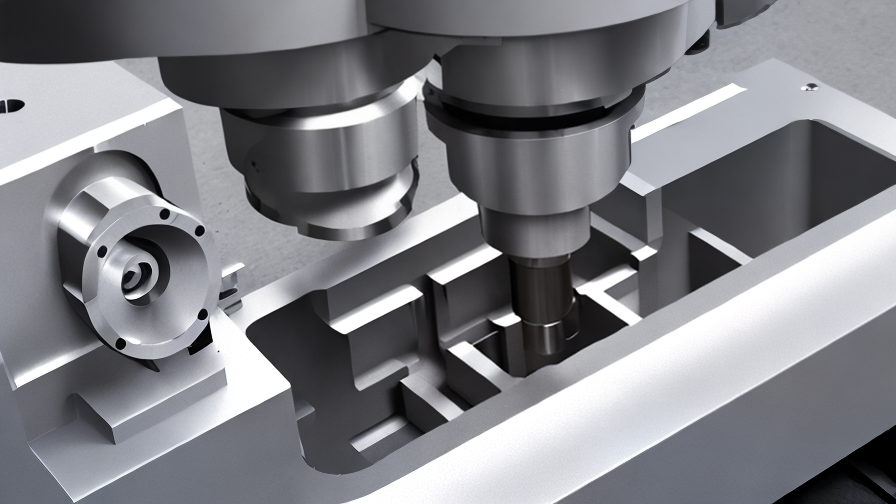

One type of CNC manufacturing is milling. This technique uses rotary cutters to remove material from a workpiece. It can produce parts with high accuracy and is ideal for creating parts with complex shapes. The other type is turning, where a workpiece rotates while a cutting tool shapes it. Turning is perfect for creating cylindrical parts like shafts, and it is faster than milling.

Another type of CNC machining is drilling, which creates holes in a material. This technique is perfect for creating a large number of holes in different sizes and shapes. Grinding is another technique that involves the use of abrasive wheels to remove material from a workpiece. It is suitable for creating precise shapes and finishes on hard materials like metals.

Wire EDM, which stands for electrical discharge machining, uses a thin wire to cut through a workpiece. It is suitable for creating precise parts with intricate shapes, such as aerospace components. Water jet cutting is also a CNC manufacturing technique that uses a high-pressure stream of water to cut through materials. It is ideal for creating parts from a wide range of materials, including metal, glass, and ceramics.

Lastly, 3D printing is a CNC manufacturing technique that uses a 3D printer to create objects by layering material on top of each other. It is ideal for creating complex, customized parts and prototypes quickly.

In conclusion, CNC manufacturing has revolutionized the manufacturing industry by improving the accuracy, precision, and speed of production. It is versatile, with various types of techniques suitable for different manufacturing needs. Whichever technique a manufacturer chooses, the important thing is to ensure that they have the right equipment and skilled personnel to use it effectively.

FAQ sourcing Cnc Manufacturing manufacturer from China

For businesses looking to source CNC manufacturing services from China, it’s essential to have a clear understanding of the process. This article will answer some of the most frequently asked questions about sourcing CNC manufacturing manufacturers from China.

Q: What is CNC manufacturing, and why should I consider sourcing from China?

A: CNC manufacturing is a process in which computer-controlled machines are used to produce highly accurate and precise parts from metal, plastic, or other materials. Sourcing from China can be an attractive option due to lower labor and manufacturing costs, as well as access to a wide range of high-quality materials.

Q: How can I find a reliable CNC manufacturing manufacturer in China?

A: It’s crucial to do your research and vet potential manufacturers thoroughly. Look for reviews and testimonials online, ask for references, and ensure that the manufacturer has experience with your specific industry or product. It’s also essential to communicate clearly with the manufacturer to ensure they understand your requirements.

Q: What materials can be used in CNC manufacturing, and what are the benefits of each?

A: CNC manufacturing can work with a variety of materials, including metals such as aluminum, steel, and titanium, as well as plastics such as ABS and PVC. Each material has its benefits, such as aluminum’s lightweight and corrosion resistance, steel’s strength and durability, and ABS’s flexibility and versatility.

Q: What quality control measures should I expect from a CNC manufacturing manufacturer in China?

A: A reputable CNC manufacturing manufacturer should have a comprehensive quality control process in place, including using calibrated measuring tools, inspecting parts at various stages of production, and performing final inspections before shipping. They should also be willing to provide inspection reports and certifications as needed.

Q: What should I consider when choosing a shipping method?

A: The shipping method will depend on factors such as the size and weight of your order, the delivery timeline, and your budget. Options may include sea or air freight, courier services, or a combination of methods. It’s crucial to factor

Applications of Cnc Manufacturing

CNC manufacturing, which stands for Computer Numerical Control, is a manufacturing process that involves computer-controlled machines that can produce precise, high-quality products. The applications of CNC manufacturing are many and varied, and they include numerous industries, such as automotive, aerospace, and healthcare.

One of the main advantages of CNC manufacturing is that it allows for high precision and accuracy, which makes it particularly suitable for producing complex parts with very tight tolerances. This is especially important in the aerospace industry, where even the slightest mistake can have disastrous consequences. CNC machines can produce parts with a level of precision that is impossible to achieve with traditional manufacturing methods.

Another major advantage of CNC manufacturing is that it allows for high repeatability. Once the process has been set up, the same part can be produced over and over again with exactly the same dimensions and specifications. This makes CNC manufacturing ideal for mass production, where multiple identical components are needed.

CNC manufacturing also offers a high degree of flexibility. The program that controls the CNC machine can be easily modified to produce different parts, which makes it possible to switch from one product to another without having to retool the machine or make significant changes to the manufacturing process. This makes CNC manufacturing particularly suitable for small batch production, where the number of parts needed is relatively small.

CNC manufacturing has numerous applications in the healthcare industry as well. For example, it can be used to produce custom implants and prosthetics that are tailored to the individual patient’s requirements. CNC machines can produce these parts quickly and accurately, which makes them particularly useful in emergency situations where time is of the essence.

In conclusion, CNC manufacturing offers numerous advantages over traditional manufacturing methods, including high precision, repeatability, and flexibility. Its versatility makes it useful in a wide range of industries, from aerospace and automotive to healthcare and beyond.

Manufactured Products made of Cnc Manufacturing

Manufactured products made of CNC manufacturing have become very popular in recent times due to their high precision and accuracy levels. These products are made using Computer Numerical Control (CNC) machines that allow the manufacturing process to be automated, ensuring that the end products are of the best quality.

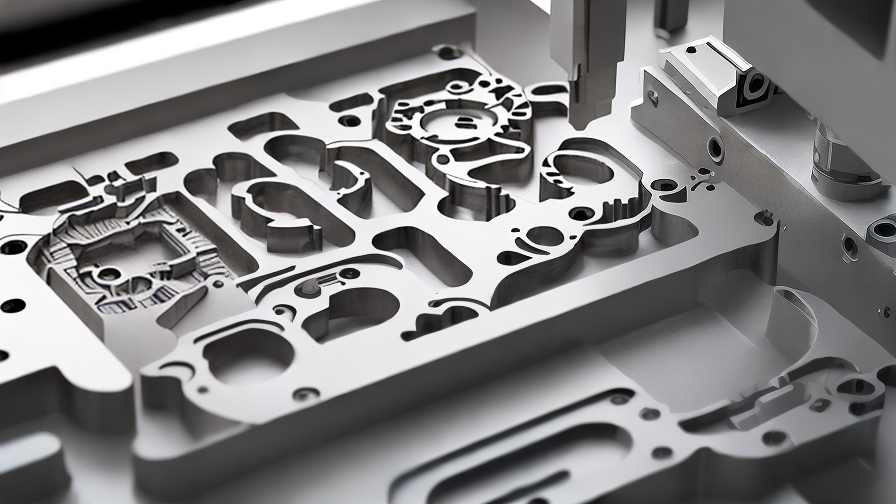

CNC manufacturing has revolutionized the manufacturing industry by making it possible to produce complex parts and components that were previously thought to be impossible. The machines are designed to work with a wide range of materials such as metals, plastics, and wood, ensuring that there are no limitations when it comes to manufacturing products using CNC machines.

One of the key benefits of CNC manufacturing is its ability to produce products with high accuracy levels. The machines can work with high precision, ensuring that the end products are of a consistent quality. This level of accuracy is not possible with traditional manufacturing methods such as manual machining, which rely on human operators.

Another benefit of using CNC manufacturing is the speed at which products can be produced. The machines are designed to work continuously, allowing large volumes of products to be produced in a short amount of time. This is particularly useful when there are tight deadlines to meet or when large volumes of products are needed.

Products made using CNC manufacturing can be found in a wide range of industries, including automotive, aerospace, medical, and electronics. The precision and accuracy of CNC manufacturing make it ideal for producing complex parts and components used in these industries.

In conclusion, products made using CNC manufacturing are of exceptionally high quality due to the precision and accuracy of the manufacturing process. As a result, these products have become increasingly popular in various industries due to the many benefits they offer. With the continued growth and developments in CNC manufacturing, we can expect to see more products being made using this technology in the future.

The Evolution history of Cnc Manufacturing

CNC (Computer Numerical Control) manufacturing has revolutionized the way products are made. The evolution of CNC manufacturing started in the late 1940s and early 1950s with the use of punch cards to control machine tools. From there, it evolved into using magnetic tape and then digital computer programs to control CNC machines.

By the 1970s, CNC manufacturing became more popular and accessible, leading to more widespread use. During this time, improvements were made in the accuracy and precision of CNC machines, making them more efficient and effective.

In the 1980s, the introduction of CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software made CNC manufacturing even more efficient. This software allowed manufacturers to design products on a computer and automatically generate the coding needed to control CNC machines. This reduced the human error involved in programming CNC machines, making the entire process more reliable and consistent.

In the 1990s, advancements were made in CNC technology, including the ability to create complex 3D shapes and surfaces. This change opened up new possibilities for manufacturing complex products with CNC machines.

Today, CNC manufacturing continues to evolve, with advancements in automation, robotics, and artificial intelligence. These advancements are allowing manufacturers to produce products faster, more efficiently, and with greater precision than ever before.

In conclusion, the evolution of CNC manufacturing has come a long way since its inception. Advancements in technology have made it more accurate and efficient, making it an important tool in the modern manufacturing process. The future of CNC manufacturing looks bright, with continued advancements and improvements to come.

The Process of Cnc Manufacturing

CNC (Computer Numerical Control) manufacturing is a process that involves the use of computer software programs to control the operation of machines in the production of complex parts and intricate designs. This manufacturing process has revolutionized the manufacturing industry by providing higher levels of accuracy, precision, consistency, and speed as compared to traditional manufacturing methods.

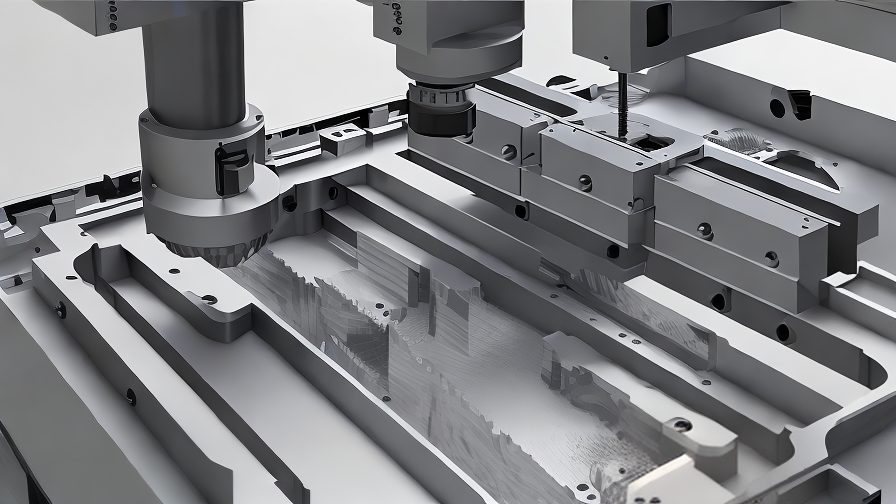

The CNC process starts with the creation of a digital design of the component or product to be manufactured. This design is created using computer-aided design (CAD) software or other similar design tools. Once the design is complete, it is then converted into a computer-readable format that can be used by the CNC machine.

The next step involves programming the CNC machine to execute the design. This is done by creating instructions that are written in a language that the machine can understand. These instructions are known as G-codes and are generated using computer-aided manufacturing (CAM) software.

After the programming is complete, the operator sets up the CNC machine by attaching the necessary tools and workpieces. The machine is then turned on, and the operator initiates the program to start the manufacturing process.

During the manufacturing process, the CNC machine cuts, shapes, drills, and finishes the workpiece according to the programmed instructions. The machine also monitors the process to ensure that the finished product meets the required specifications and tolerances.

Once the machining process is complete, the finished product is removed from the machine and inspected to ensure that it meets the desired quality standards. The product may undergo post-processing operations such as sandblasting, polishing, or painting, depending on the intended use.

In conclusion, the CNC manufacturing process is a highly efficient and precise method of producing complex parts and products. It involves the use of CAD and CAM software to create digital designs and G-code instructions that are executed by the CNC machine. CNC manufacturing offers numerous benefits such as faster production times, higher accuracy, and the ability to produce intricate designs that would otherwise be impossible using traditional manufacturing methods.

Benefits Advantages of Utilizing Cnc Manufacturing

CNC manufacturing, or Computer Numerical Control manufacturing, has become a popular method for producing goods across various industries. This technology enables the production of high-quality parts in a more efficient and cost-effective manner. Let’s take a closer look at the benefits and advantages of utilizing CNC manufacturing.

Precision and Accuracy:

CNC machines are designed to produce accurate and precise parts repeatedly. This level of accuracy reduces the need for human intervention, thus reducing the likelihood of errors. Additionally, CNC machines can produce complex shapes that would otherwise be impossible to create with conventional machines.

Increased Production Efficiency:

CNC machines can operate 24/7, which means that they can produce parts at a much faster rate than conventional machines. This is especially beneficial when producing large volumes of parts. Furthermore, the technology allows the user to make adjustments on the fly, without the need to shut down the machine completely.

Cost-Effective:

Although the initial investment in CNC machines may be high, it is a cost-effective solution in the long run. Because CNC machines are efficient and produce precise parts, there is less material waste, which reduces overall production costs. Additionally, reduced human intervention minimizes the likelihood of errors and accidents, which can be costly and time-consuming.

Flexibility:

CNC technology allows manufacturers to produce a wide range of parts in various shapes and sizes. CNC machines can be programmed to produce a variety of parts from metals, plastics, and other materials. This flexibility makes CNC manufacturing an attractive option for manufacturers looking to produce parts for a variety of applications.

Conclusion:

CNC manufacturing has many benefits and advantages, ranging from increased production efficiency, cost-effectiveness, and flexibility. As technology continues to evolve, CNC machines will become even more efficient and continue to provide manufacturers with a competitive edge in an increasingly competitive industry.

Disadvantages Cnc Manufacturing

CNC (Computer Numerical Control) manufacturing has revolutionized the way we produce and manufacture goods. However, despite improving efficiency and accuracy in production, CNC manufacturing also has drawbacks that limit its potential.

One major disadvantage is the high cost of initial investment. CNC machines are expensive and require a large amount of capital to set up. The cost of maintenance, power bills, and operator training also add up, making CNC manufacturing difficult for small businesses to afford.

Another challenge is the need for skilled workers. CNC machines require skilled operators to program, maintain and supervise their operations. The skills required entail a high level of technical knowledge, which might not always be available. The shortage of skilled workers in the market could result in downtime or high turnaround time.

Furthermore, CNC manufacturing is not suitable for producing complex designs or prototypes. While these machines are efficient when it comes to producing large orders or repetitive designs, they are not as effective in creating unique, complex designs. Often, the production of unique designs requires a lot of programming and setup, which makes the process slow and costly.

Finally, CNC machines have reduced human interaction in the manufacturing process. These machines automate a significant portion of the production, leading to job displacement. This can lead to an increase in unemployment rates, particularly in areas where there is a high concentration of manufacturing jobs.

In conclusion, the disadvantages of CNC manufacturing such as high costs, the need for skilled workers, limited scope for producing prototypes, and reduction in human interaction need to be taken into consideration when choosing to use CNC technology. However, with careful planning and a clear understanding of the potential risks, businesses can make the most of CNC manufacturing while mitigating the associated challenges.

Selecting the Ideal Manufacturer Cnc Manufacturing

Finding the right CNC manufacturer for your project is critical to achieving desired results. With so many options in the market, it can be overwhelming to select the ideal one. Here are some tips to help you select the ideal CNC manufacturer for your needs.

1. Experience and Expertise: Look for a company that has years of experience in CNC manufacturing. This will ensure that they have the knowledge and expertise necessary to handle your project with precision and accuracy.

2. Quality: Make sure that the manufacturer has a reputation for producing high-quality products. Check reviews and past projects to see the level of quality they are known for.

3. Technology: CNC machines are constantly evolving, so it’s important to choose a manufacturer that is equipped with the latest technology. This will help ensure that your project is completed with the most advanced tools and techniques available.

4. Customer Service: Look for a manufacturer that values customer service. It’s important to choose a company that is responsive during the manufacturing process and will work with you to achieve your goals.

5. Communication: Good communication is key to a successful project. Choose a manufacturer that has clear channels of communication and is transparent about the manufacturing process.

In conclusion, selecting the ideal manufacturer for CNC manufacturing requires research and careful consideration. By keeping these key factors in mind, you can find a manufacturer that will meet your needs and help you achieve successful project outcomes.

Things to Consider When Purchasing Cnc Manufacturing

When it comes to buying CNC manufacturing, there are a few key things to consider to ensure that you make the right choice for your business. Here are some of the most important factors to keep in mind:

Usage: First and foremost, you need to determine the purpose of the machine. Will it be used for mass production or for producing a few parts at a time? This will help you decide on the right size and capabilities of the machine.

Technology: CNC manufacturing has come a long way, and you should consider purchasing a machine with the latest technology. This will ensure that you are getting the most efficient and accurate machine available.

Support and Maintenance: Your CNC machine will need to be maintained and repaired regularly. Therefore, it’s important to choose a manufacturer who can provide good technical support, as well as easily accessible replacement parts.

Cost: Buying a CNC machine is a significant investment. Pricing can vary greatly depending on the size, specifications, and brand of the machine, so it’s important to set a budget beforehand and stick to it. You should also consider the added costs of installation, training, and any additional software that may be required.

Brand: Finally, there are many CNC manufacturing brands available today. It’s important to choose a reputable brand that has a good track record in the industry. This will ensure that you are purchasing a quality machine with reliable customer service.

In conclusion, purchasing CNC manufacturing requires careful consideration of your business needs, a budget, the technology of the machine, maintenance and support, and reputation of the brand. By taking the time to evaluate these factors, you can be confident that you are making the right choice for your business.

Properties of Cnc Manufacturing

CNC manufacturing is a highly advanced process that has revolutionized the way products are produced. The properties of CNC manufacturing are numerous and highly beneficial.

One property of CNC manufacturing is precision. The machines are highly accurate and capable of producing exceptionally precise parts. This is made possible through the use of highly advanced software that allows the machines to produce parts with incredible accuracy.

Another property of CNC manufacturing is speed. The machines are highly efficient, producing parts at a much faster rate than traditional manufacturing methods. This makes CNC manufacturing a popular choice for high volume production runs.

CNC manufacturing is also highly flexible. It is possible to produce a wide range of parts using CNC manufacturing techniques. The machines can be quickly reprogrammed to produce different parts, making it an ideal choice for producing custom or specialized parts.

CNC manufacturing is also highly consistent. The machines are precise and reliable, ensuring that every part produced is consistent in terms of quality and dimensions. This is essential for industries such as aerospace and automotive where quality and consistency are paramount.

Another property of CNC manufacturing is reduced waste. The machines are highly efficient, using minimal material to produce parts. This reduces material waste and helps to lower costs.

In conclusion, the properties of CNC manufacturing make it a highly advanced and beneficial manufacturing method. With its precision, speed, flexibility, consistency, and reduced waste, CNC manufacturing is well suited to producing high-quality, accurate parts at a lower cost than traditional manufacturing methods.

How to use Cnc Manufacturing

CNC (Computer Numerical Control) manufacturing is a process that utilizes computer-controlled machines to produce high-precision components and parts. Due to its accuracy and efficiency, CNC manufacturing is currently used by different industries, including automotive, aerospace, medical, and many more. Here’s how to use CNC manufacturing.

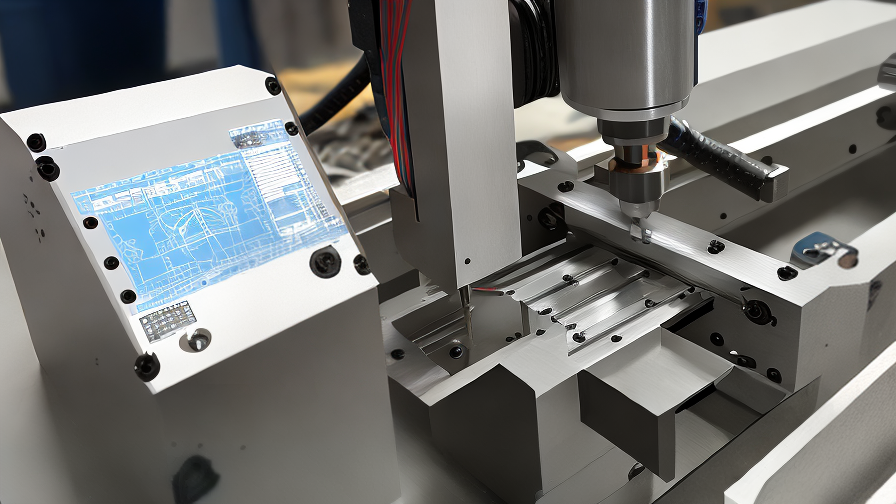

Firstly, you need to design your product using CAD (Computer-Aided Design) software. This software allows you to create a 3D model of your product, including all the necessary details, dimensions, and specifications. It’s essential to ensure your design is accurate and complete, as any mistakes will impact the quality of the final product.

After the design stage, you’ll need to transfer the CAD file to CAM (Computer-Aided Manufacturing) software. CAM software helps convert the design into a machine-readable program that can control the CNC machine’s movements. This step is vital, as the accuracy of the machine’s movements depends on the code generated by CAM software.

Next, you need to set up the CNC machine. The machine’s configuration will vary depending on the product and the material you’re using. You’ll need to select the right cutting or milling tools, as well as the speed and temperature settings. Proper calibration ensures that the machine follows the code precisely and cuts the material accurately.

The last step is to run the machine. You should always monitor the process to ensure that everything is running smoothly. Once the machine is finished, you need to inspect the product for any defects or errors. After inspection, you can then utilize the product.

To summarize, CNC manufacturing is a high-precision process that requires careful planning, design, and execution. By following the steps outlined above, you can produce high-quality products quickly and efficiently using a CNC machine.

Glossary Terminology Terms for Cnc Manufacturing

CNC manufacturing is a process that involves the use of computer-controlled machines to create complex parts and components. It’s an essential technology that has revolutionized the manufacturing process. Understanding the terminology used in CNC manufacturing is crucial for professionals in the field to communicate effectively and avoid confusion with industry-specific terms. Below are some essential glossary terminology terms for CNC manufacturing.

1. CNC Machine – This machine is designed to read programmed commands and controls the movement of cutting tools and other moving parts.

2. Axis – Axis refers to the direction of movement of the CNC machine. The most common axes are X, Y, and Z, representing the horizontal, vertical, and depth movements, respectively.

3. CAD – Computer-Aided Design (CAD) is a software that helps to create digital models of parts and components of CnC manufacturing.

4. CAM – Computer-Aided Manufacturing (CAM) is a software that converts digital models of parts and components into code for CNC machines.

5. G-code – It is a standardized language used to program the CNC machine. The code tells the machine what to do regarding speed, positioning, and tool selection.

6. Fixture – A fixture is a device used to hold parts securely in place during machining operations.

7. Cutting Tool – A cutting tool is a device used to remove material from a workpiece during the machining process.

8. Workpiece – A workpiece is an object that undergoes a machining process to produce the desired shape or form.

9. Tolerance – Tolerance refers to the allowable variation in the dimensions or characteristics of a part or component during the manufacturing process.

10. Machining – Machining is a process whereby material is removed from a workpiece using cutting tools on a CNC machine.

In conclusion, understanding the terminology used in CNC manufacturing is of utmost importance in effective communication as well for the production of precise parts and components. The list of terms highlighted above is not exhaustive, but it serves as a starting point to acquire knowledge of the

Cnc Manufacturing Price

CNC manufacturing, or Computer Numerical Control manufacturing, is a process that has revolutionized the manufacturing industry. This process involves the use of computer-controlled machines to produce high-quality products in a quick and efficient manner. However, when it comes to CNC manufacturing price, many people wonder if this technology is affordable.

The cost of CNC manufacturing can vary depending on various factors such as the complexity and precision of the product, the material used, and the size of the production run. Typically, CNC manufacturing is more expensive compared to traditional methods of manufacturing, such as manual or mass production. This is due to the high cost of the machines and the specialized skills that are required to operate them.

However, the benefits of CNC manufacturing are worth the cost. CNC machines offer unmatched precision and accuracy, which results in a better quality of the final product. These machines can also produce complex and intricate designs that can’t be achieved with traditional methods. Additionally, CNC manufacturing can reduce production time and enhance efficiency, which can save a company money in the long run.

That being said, the cost of CNC manufacturing can be reduced by optimizing the design and production process. This includes using the most cost-effective materials and designing products that can be produced with minimal waste. Additionally, finding the right CNC manufacturing service provider can also help reduce costs. It’s essential to choose a service provider that has experience working with CNC machines and can provide efficient services at a reasonable price.

In conclusion, CNC manufacturing is an innovative and cost-effective manufacturing method that has transformed the industry. While it may be more expensive than traditional methods, the benefits it offers in terms of quality, precision, and efficiency are priceless. By optimizing the design and production process and finding the right service provider, the cost of CNC manufacturing can be made more manageable for businesses of all sizes.