Benefits of Cnc Precision Machining

CNC precision machining has become an invaluable resource for manufacturers in several industries. CNC machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to control the cutting and shaping of raw materials, allowing for exact specifications in parts formation. The use of CNC technology provides numerous benefits to manufacturers.

One of the primary benefits of CNC precision machining is that it significantly enhances accuracy and repeatability. CNC machines can produce parts with very high tolerance levels and exact specifications, which ensures parts will fit correctly and function as intended. This is crucial for industries such as aerospace, defense, and medical, where even minor errors can have catastrophic consequences.

CNC machining also reduces the risk of errors, as the programming system ensures that every part is identical to the approved design. In addition, the system’s ability to start and stop quickly supports better efficiency and shorter lead times, allowing businesses to produce parts quickly, meet tight deadlines, and increase the overall productivity.

CNC machining saves a lot of labor time and cost due to a robot-controlled system that reduces manual labor costs, which makes it possible to produce parts much faster and at a lower cost. This brings us to the next benefit – cost-effectiveness. With the reduced cost of labor and shorter production times, businesses can save money, enabling them to offer more competitive prices to win over more customers.

Another significant benefit of CNC precision machining is its flexibility. CNC machines can manufacture parts with complex geometries, providing opportunities to create new and advanced solutions, thus complementing the manufacturer’s competitive edge.

In conclusion, CNC precision machining is an efficient, accurate, and flexible method for manufacturers looking to meet their clients’ needs while reducing cost, increasing productivity, and ensuring quality standards are met. Its adoption cements the businesses position among the leading manufacturers in various industries.

Features of Cnc Precision Machining

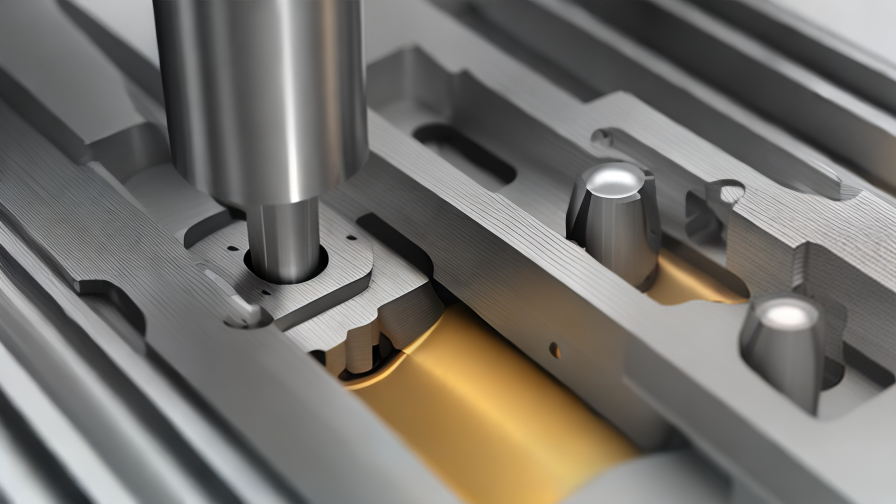

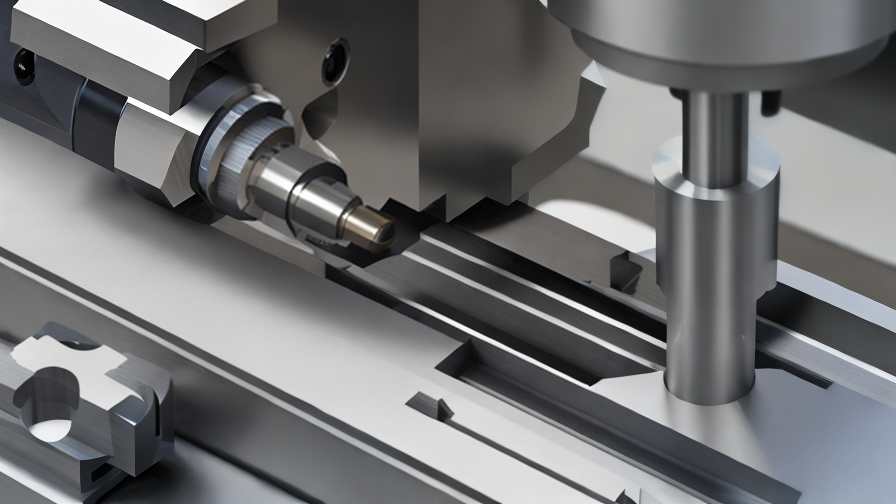

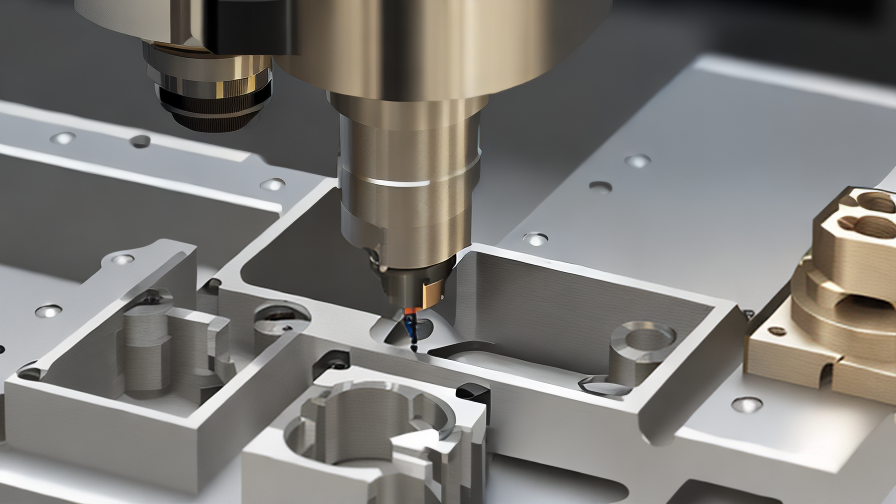

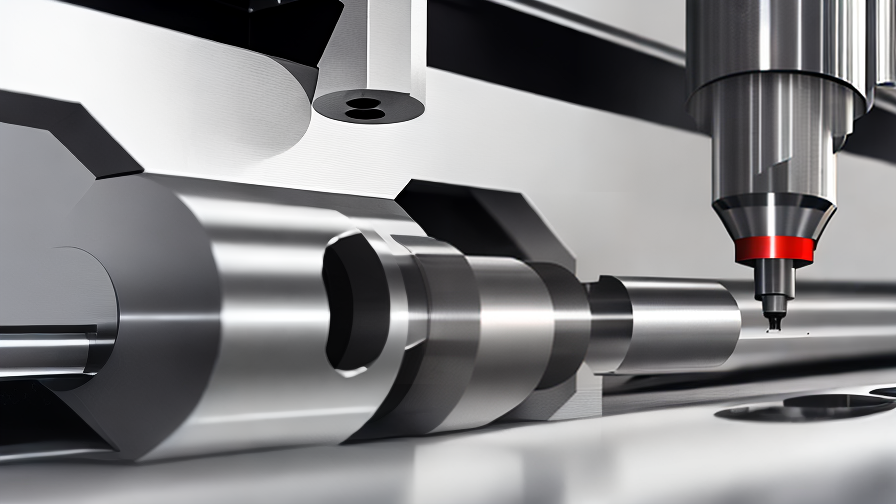

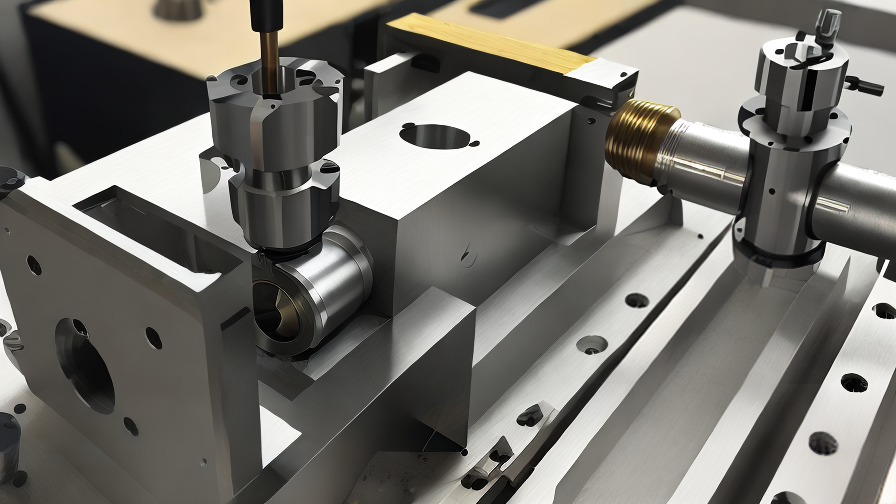

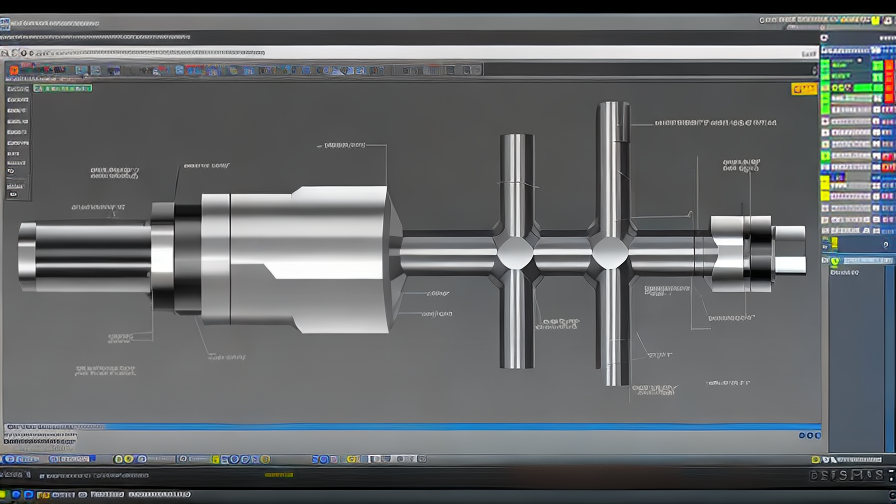

CNC Precision Machining is a manufacturing process which involves the use of computer numerical control to automatically operate machine tools such as lathes, mills, routers and grinders. This automated technology has revolutionized the manufacturing industry by providing precision, accuracy and speed in the production of complex and intricate parts. The following are some of the key features of CNC precision machining.

1. Automation – CNC machining is fully automated, meaning that the operation of the machine is controlled by a computer program. This ensures that the machining process is accurate, reliable and efficient, eliminating the need for human intervention in the manufacturing process.

2. Precision – CNC machining eliminates human error by providing precise and accurate cutting, milling and shaping of metals and other materials. This ensures that parts are produced to exact specifications, with high quality finishes and tight tolerances.

3. Versatility – CNC machines can be programmed to produce a variety of parts and components, from simple to complex shapes and sizes. This makes it ideal for manufacturing a wide range of products, from automotive parts to medical devices and aerospace components.

4. Speed – CNC machining is fast and efficient, allowing for the production of large quantities of parts quickly and efficiently. This reduces the production time and costs associated with traditional manufacturing methods.

5. Flexibility – CNC machines can be programmed to produce prototypes and small production runs, allowing for testing and quality assurance before mass production. This flexibility enables the manufacturing process to be more efficient and cost-effective.

6. Consistency – CNC machines provide consistent results with every part produced, ensuring that each part is identical in shape, size and quality. This is essential for maintaining product quality and meeting customer expectations.

In conclusion, CNC Precision Machining provides several features that have made it an essential technology in today’s manufacturing industry. The technology has revolutionized manufacturing by providing accuracy, efficiency, speed, versatility, flexibility and consistency. These features ensure that manufacturers can produce high-quality, reliable products that meet the expectations of their customers.

Various Types of Cnc Precision Machining

CNC precision machining is a manufacturing process that involves the use of computer-controlled machines to make highly accurate and precise parts. These machines use advanced technology to produce custom parts that meet the exact specification of the client. Various types of CNC precision machining can be used to create a range of parts, from simple to complex with high precision levels.

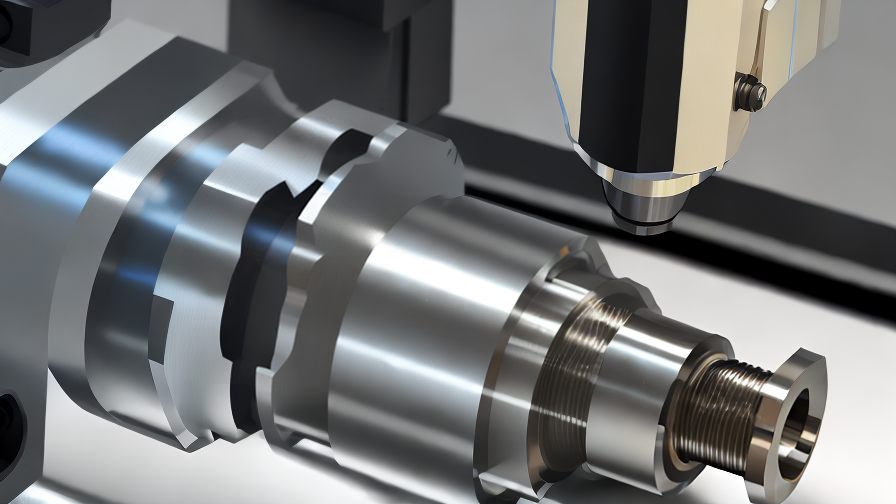

1) Turning: this CNC machining process involves a rotating workpiece that a machine tool cuts using a single-point cutting tool. Turning is used for creating cylindrical parts, such as shafts and tubes, and it can be used on metal, plastic, and other materials.

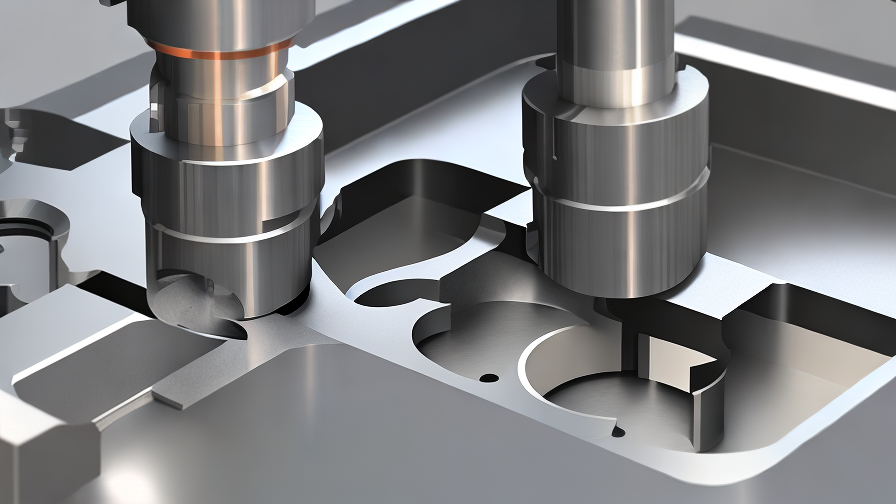

2) Milling: this CNC process removes material or chips from a workpiece by rotating cutting tools that are fed against the workpiece in different directions. Milling is used to create parts with complex shapes, such as those with curves, angles, and holes.

3) Drilling: this CNC process is used to make holes in workpieces using a rotating tool. Drilling can be done with various types of drills, including twist drills, flat bottom drills, and counterbore drills.

4) Grinding: this process uses a grinding wheel to remove material from a workpiece, resulting in very tight tolerances and fine surface finishes. Grinding is commonly used in manufacturing parts with high precision, such as those used in the aerospace and medical industries.

5) Electrical discharge machining (EDM): this CNC process uses an electrode to remove material from a workpiece using electrical discharge. EDM is often used for making complex shapes that cannot be made using traditional machining processes like milling or turning.

In conclusion, CNC precision machining offers a wide range of processes that can create complex and precise parts. Each type of CNC machining has its own application and advantages, depending on the requirements of the final product. Clients should consider carefully the best process and machine for their needs when considering CNC precision machining services.

Applications of Cnc Precision Machining

CNC precision machining is a technology that has revolutionized the manufacturing industry. CNC, which stands for Computer Numerical Control, is a computer-controlled process that can produce complex and intricate parts with high precision and efficiency. This technology has brought about many applications in various industries.

One of the most common applications of CNC precision machining is in the aerospace industry. The aerospace industry requires parts that are lightweight, durable, and have high precision. CNC precision machining can produce these parts with ease, ensuring that they meet the industry’s stringent requirements. This has led to the production of aircraft engines, landing gears, and other components, which have significantly improved the safety and quality of air travel.

Another field that has benefited greatly from CNC precision machining is the medical industry. The production of medical devices and implants requires precision and accuracy to avoid any health risks. CNC precision machining has enabled the production of medical devices such as dental implants, prosthetic limbs, and surgical tools with high accuracy. This technology has greatly improved patients’ lives, allowing for faster recovery and better health.

CNC precision machining has also found applications in the automotive industry. As cars become more complex and advanced, the need for precision and accuracy has become paramount. CNC precision machining has enabled the production of complex parts such as transmission parts and engine blocks, which have improved the performance and efficiency of modern cars. Additionally, CNC precision machining has allowed for customization of cars, enabling customers to design and create unique parts tailored to their needs.

In conclusion, CNC precision machining has revolutionized various industries by enabling the production of high-precision and complex parts with ease. The applications of CNC precision machining are vast, ranging from the aerospace industry, medical industry, to the automotive industry. As technology advances, CNC precision machining will continue to play a critical role in the manufacturing industry, enabling the production of high-quality and efficient products.

The Process of Cnc Precision Machining

CNC (Computer Numerical Control) precision machining is a manufacturing process that utilizes computers to control the movement and operation of machinery tools. It is highly automated, highly accurate, and has revolutionized the manufacturing industry.

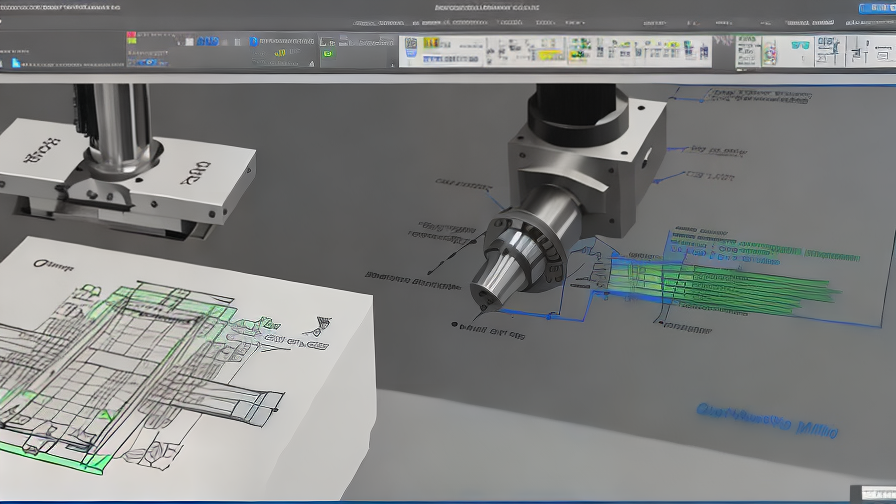

The process of CNC precision machining involves several steps, starting with the creation of a digital model or design. This design is then loaded into the CNC software and translated into machine code, which directs the machines to cut and shape the material according to the design.

Next, the material is loaded into the machine and secured securely in place. The machine then uses a variety of cutting tools to remove the material in a precise manner. This could include drilling, turning, milling, or any other type of machining operation.

Throughout the process, the CNC software constantly monitors the progress and makes adjustments to ensure the highest level of accuracy and precision. In addition, the software can also detect any errors or anomalies and make corrections in real-time.

Once the machining process is complete, the finished product is inspected to ensure it meets the required specifications. This may include checking for tolerance levels, surface finish, and overall quality.

CNC precision machining has numerous advantages over traditional manufacturing methods. It is highly automated, which means it requires minimal human intervention and reduces the likelihood of errors. It is also incredibly accurate, with tolerance levels as low as 0.0001 inches. This level of precision ensures that the finished product is of the highest quality and meets the strictest industry standards.

In conclusion, CNC precision machining is a highly efficient and sophisticated manufacturing process. Its ability to produce accurate and complex shapes has transformed various industries, including aerospace, medical, and automotive. As technology continues to advance, CNC precision machining will continue to play a critical role in the manufacturing industry.

How to use Cnc Precision Machining

CNC precision machining is a process of manufacturing that involves the use of computer-controlled machines to produce high-quality, precise parts. This technology has revolutionized the manufacturing industry by reducing the time and cost of production, while increasing accuracy and repeatability. Here are some tips on how to use CNC precision machining for your manufacturing needs.

1. Choose the Right Machine: There are various types of CNC machines available, including lathes, mills, routers, and grinders. Each machine has its own specific use, so it’s essential to choose the right one for your projects.

2. Program your Machine: To use a CNC machine, you will need to create a specific program using a computer-aided design (CAD) software. This program should include all the necessary details such as cutting depth, speed, and tooling to ensure that the machine produces accurate parts.

3. Use Suitable Tooling: The selection of cutting tools is crucial in CNC machining. Ensure the correct tool is being used for the specific task, and the tool is sharpened regularly.

4. Check the Material: Before starting the manufacturing process, check the material’s quality to ensure there are no defects or impurities. Choosing the right material grade is crucial to producing a quality part.

5. Monitor the Machine: Keep an eye on the machine while it’s running to avoid any issues that may result in defective parts. Regular maintenance of the machine is essential to ensure optimum performance.

In conclusion, CNC precision machining plays a significant role in the manufacturing industry. By following these tips, you can use CNC machines efficiently to produce high-quality, precise parts while saving time and cost.

Selecting the Ideal Manufacturer Cnc Precision Machining

CNC (Computer Numerical Control) precision machining has become a vital component in modern manufacturing processes. Selecting the ideal manufacturer for CNC precision machining can be a daunting task. The following tips can help you choose the right manufacturer for your manufacturing needs.

1. Experience: Look for a manufacturer with years of experience in CNC precision machining. A company with a proven track record shows that they have mastered the necessary skills and techniques to produce high-quality parts.

2. Quality Control: Look for a manufacturer with a robust quality control system in place. A good quality control system ensures that the parts manufactured meet the required specifications, reducing the risk of defects and scrap.

3. Machine Capabilities: Look for a manufacturer with the right machines and technology for your needs. Many manufacturers specialize in certain materials or types of parts, such as aerospace or medical components.

4. Communication: Look for a manufacturer that is easy to communicate with. It is crucial to work with a manufacturer who listens to your needs and can offer technical expertise and advice.

5. Pricing: Look for a manufacturer that offers competitive pricing. While the price should not be the only factor in considering a manufacturer, it is crucial to ensure that you get value for your money.

In conclusion, selecting the ideal manufacturer for CNC precision machining is a crucial step in ensuring the quality of your products. A manufacturer with experience, a robust quality control system, the right machine capabilities, good communication, and competitive pricing can make all the difference in your manufacturing process.

list FAQ with answer about Cnc Precision Machining

CNC Precision Machining is the advanced manufacturing process that uses computer-controlled machines to craft precise and complex parts. This process is widely used in various industries, including aerospace, automotive, medical devices, and more. Here are some frequently asked questions and answers about CNC Precision Machining.

1. What materials can be used in CNC Precision Machining?

CNC Precision Machining can work with various materials, such as metals like aluminum, steel, brass, and copper. It can also handle plastics, wood, and composite materials.

2. What is the accuracy of CNC Precision Machining?

The accuracy of CNC Precision Machining depends on various factors, such as the machine’s specifications, the quality of the CAD/CAM design, and the operator’s skills. However, CNC machines can achieve high accuracy and repeatability, with tolerances as tight as 0.001 inches.

3. What are the advantages of CNC Precision Machining?

CNC Precision Machining has several advantages over traditional machining methods, including higher accuracy, faster production, and lower labor costs. It also enables designers to create complex geometries and shapes that are difficult to achieve with traditional methods.

4. Can CNC Precision Machining handle large parts?

Yes, CNC Precision Machining can handle both small and large parts, depending on the machine’s size and the workpiece’s dimensions. CNC machines can also work with multiple axes to create more complex parts.

5. Is CNC Precision Machining environmentally friendly?

CNC Precision Machining can be environmentally friendly, depending on the materials used and the waste management practices in place. Many CNC machines use coolant fluids to reduce heat and friction during machining, which can be recycled and reused. Additionally, the precision of CNC machines reduces the scrap material generated during the manufacturing process.

In conclusion, CNC Precision Machining is an advanced manufacturing process that offers numerous benefits, including high accuracy, faster production, and greater design flexibility. With its wide range of applications and materials, it’s no surprise that CNC Precision Machining is becoming increasingly popular in today’s manufacturing world.

Things to Consider When Purchasing Cnc Precision Machining

CNC precision machining has become a vital component in modern industrial manufacturing. It offers precise, reliable and cost-effective solutions for producing high-quality products. Choosing the right CNC precision machining company to work with is a critical decision. Here are some things to consider when purchasing CNC precision machining.

1. Technology and Equipment: Look for a company that invests in state-of-the-art CNC machines and technology. These tools can provide greater precision, speed, and performance. They should also have a range of machines with varying capabilities to offer diverse machining solutions.

2. Quality control: Quality is a critical component of all machining processes. Check if the company has an efficient quality control system in place to ensure that all products are manufactured to the highest quality. This includes the use of detailed inspection records, machine maintenance, and adherence to industry-specific standards.

3. Experience: Always choose a company that has years of experience providing CNC precision machining services. Experienced companies have an in-depth knowledge of the industry, support employees with a wealth of skills, and can take on more complex projects.

4. Cost: Consider the cost of the machining process, including set-up costs, machine usage fees, and material costs. Choose a company with competitive pricing that can provide consistent, high-quality products without breaking the bank.

5. Turnaround time: The turnaround time of your project is crucial as it affects your ability to meet production schedules. Ensure the company you choose can deliver your projects timely without any quality compromise.

Conclusion

When purchasing CNC precision machining services, ensure you consider the technology and equipment used, quality control, experience, cost and turnaround time. By keeping these essential factors in mind, you can make a well-informed decision and choose a company that meets your production needs.

Properties of Cnc Precision Machining

CNC precision machining is an advanced method of manufacturing that involves using computer-controlled machines to make precise and accurate cuts on various materials. The properties of CNC precision machining include accuracy, efficiency, consistency, flexibility, and versatility.

Accuracy is a crucial property of CNC precision machining. Thanks to the precision of the computer controls, the machines can produce extremely precise cuts with tight tolerances, which is essential for creating complex and intricate parts.

Efficiency is another property of CNC precision machining. The machines can produce parts much faster and with greater consistency compared to traditional methods, which can manually take hours or even days to complete a single part.

Consistency is important in industrial applications, and CNC precision machining excels at producing consistent, high-quality parts. The machines are programmed to repeat the same cut over and over again, resulting in identical parts that meet tight tolerances and specifications.

Flexibility is another property of CNC precision machining. The machines can handle a wide range of materials, including plastics, metals, and composites, making them ideal for manufacturing complex parts that require different materials.

Versatility is the final property of CNC precision machining. The machines can perform a wide range of operations, including drilling, milling, turning, and cutting. This versatility is essential for creating parts with different shapes, sizes, and dimensions.

In conclusion, CNC precision machining offers superior accuracy, efficiency, consistency, flexibility, and versatility, making it an ideal manufacturing method for producing high-quality parts with tight tolerances and specifications. With its advanced computer-controlled machines, CNC precision machining has become a critical part of modern manufacturing.

Technical Parameters Terms for Cnc Precision Machining

CNC Precision Machining is a critical industrial procedure that involves the production of custom parts and components. To achieve precision and accuracy in machining, it is essential to understand the technical parameters involved. Here are a few technical parameters for CNC Precision Machining that you should know:

1. Feed Rate – Feed rate refers to how fast the cutting tool moves through the material being machined. It is essential to have the right feed rate to achieve the desired result and avoid any damage to the tool.

2. Cutting Speed – Cutting speed is the velocity at which the cutting tool or workpiece moves during the machining process. It is critical in CNC Precision Machining to have the right cutting speed to get the desired surface finish and avoid overheating, which can damage the material being cut.

3. Depth of Cut – Depth of cut determines the thickness of the material that is removed in each pass of the cutting tool. The depth of cut should be precise to ensure that the desired dimensions and tolerances are met.

4. Tool Selection – The selection of the right cutting tool is critical to achieve precision in CNC Precision Machining. The tool should be chosen based on the material being machined, its hardness, and the desired surface finish.

5. Coolant Type and Flow Rate – In CNC Precision Machining, coolant is used to cool the cutting tool and remove the chips produced during the machining process. The type of coolant used and its flow rate should be adequate to ensure that the part being machined is not damaged, and the desired surface finish is achieved.

In conclusion, understanding the technical parameters involved in CNC Precision Machining is crucial to achieving the desired result. It is essential to have the right feed rate, cutting speed, depth of cut, tool selection, and coolant type and flow rate to attain precision and accuracy in machining.

Cnc Precision Machining Price

CNC Precision Machining Price is the rate charged for producing custom or mass-produced parts using computer numerical control (CNC) technology. CNC precision machining is a process where computer-controlled machines, such as lathes, mills, routers, and grinders, carve materials to high precision according to programmed instructions.

The price of CNC precision machining depends on various factors such as the complexity of the part, the type of material used, the machine’s capacity, and the desired finish. The cost of materials, labor, and machine maintenance also influences the pricing.

The complexity of the part is a major factor that affects the CNC precision machining price. Complex parts require more time and precision, and therefore, are charged higher prices than simple parts. The type of the material used also plays a significant role in the pricing. More expensive and challenging to work with materials such as titanium, carbon fiber, and aluminum alloys usually cost more than standard materials like brass or stainless steel.

The machine’s capacity is another important factor that influences the pricing of CNC precision machining. High-capacity machines require significantly more investment, maintenance, and specialist labor, thus commanding higher prices than lower capacity machines.

The desired finish plays an essential role in CNC precision machining price as well. Parts that require smooth or polished surfaces may need special sanding or polishing equipment or more precise machine work, which in turn, increases the price.

Overall, CNC precision machining providers usually offer standard pricing, but most customers receive a custom quote based on their individual needs. It is essential to choose your provider wisely and balance quality with cost as higher-priced machining options do not necessarily guarantee high quality, precision, or efficiency.

In conclusion, CNC precision machining price varies based on the complexity of the part, material used, machine capacity, and desired finish. As a result, it is crucial to choose your provider wisely and weigh your needs against cost to ensure that you receive high-quality precision machining at a fair price.