Introduce about cnc router acrylic guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

A CNC router acrylic guide serves as a tool to provide information on the usage and benefits of using a CNC router for cutting and shaping acrylic materials. With its precision and efficiency, CNC routers are perfect for working with acrylic due to its smooth and clean cuts.

The quality of acrylic cut by a CNC router is superior as it ensures accurate measurements and precise cuts. This results in a professional finish, making it ideal for various applications in industries such as signage, fabrication, and woodworking.

While the cost of a CNC router may seem high initially, the long-term benefits outweigh the initial investment. The efficiency and accuracy of a CNC router save time and money in the long run, making it a cost-effective solution for businesses.

When looking for a supplier, it is important to choose one that offers high-quality machines and excellent customer service. Look for suppliers who have certifications and a good reputation in the industry.

Certifications such as ISO and CE are important factors to consider when choosing a CNC router supplier as they ensure quality and compliance with industry standards.

The market for CNC routers in the acrylic industry is growing rapidly, with increasing demand for precision cutting and shaping of acrylic materials.

Some tips for using a CNC router with acrylic include ensuring the proper settings and tooling for cutting acrylic, maintaining a clean work area, and using proper safety gear.

In conclusion, a CNC router acrylic guide provides valuable information on using CNC routers for acrylic materials, emphasizing quality, cost, suppliers, certifications, and market trends. By following the tips provided, users can maximize the potential of their CNC router for acrylic applications.

Types of cnc router acrylic

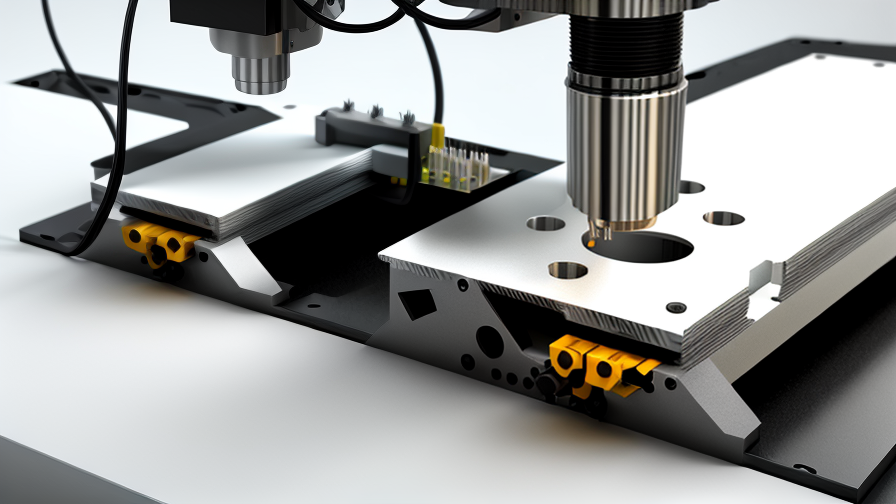

When it comes to CNC routers, there are different types of machines that are specifically designed for working with acrylic materials. These machines offer numerous advantages such as precision, speed, and efficiency in cutting, engraving, and shaping acrylic sheets. Here are some common types:

1. Entry-Level CNC Routers: These machines are ideal for small businesses or hobbyists who work with acrylic occasionally. They are usually affordable and user-friendly, with limited features and lower power. Entry-level routers can still produce good results for basic acrylic cutting and engraving tasks.

2. Mid-Range CNC Routers: These machines are suitable for medium-sized businesses or professionals who require higher precision and productivity. They offer more advanced features, better control systems, and increased power, enabling faster and more complex acrylic cutting, drilling, and engraving applications.

3. Industrial CNC Routers: These high-end machines are designed for large-scale production and heavy-duty use. Industrial routers provide excellent accuracy, speed, and versatility, offering a wide range of customization options. They can handle thicker acrylic sheets and perform complex cutting with multiple tools, making them ideal for demanding applications like signage, architectural elements, and furniture manufacturing.

4. Multi-Head CNC Routers: These machines are equipped with multiple cutting or engraving heads that can operate simultaneously, improving productivity by completing multiple tasks within a single operation. Multi-head routers are commonly used for mass production or when different cuts or engravings are required simultaneously on the same acrylic sheet.

5. ATC CNC Routers: Automatic Tool Change (ATC) routers possess a tool magazine that holds multiple tools, allowing for automatic tool changes during the cutting or engraving process. This feature eliminates the need for manual tool changeovers, saving time and increasing efficiency when working with acrylic materials.

Each type of CNC router is built differently to cater to various needs and budgets. It is essential to consider factors such as the preferred size of acrylic sheets, required precision, speed, and production volume before selecting the right CNC router for acrylic applications.

Pros and Cons of Using cnc router acrylic

One of the main advantages of using a CNC router for acrylic cutting is the precision and accuracy it offers. CNC routers are computer-controlled machines that can cut intricate designs with high levels of detail, making them ideal for creating complex shapes and patterns in acrylic materials. This level of precision can be difficult to achieve with traditional manual cutting methods.

Another advantage of using a CNC router for acrylic cutting is the speed and efficiency it offers. CNC routers can complete cutting tasks much faster than manual methods, making them ideal for large-scale production runs. This can help to reduce production times and costs, as well as improve overall efficiency in the manufacturing process.

Additionally, CNC routers offer flexibility in terms of design and customization. With a CNC router, it is easy to make adjustments to the design or dimensions of a part, allowing for greater customization and personalization. This can be particularly useful for creating unique or custom pieces for specific applications.

However, there are also some potential drawbacks to using a CNC router for acrylic cutting. One potential disadvantage is the initial cost of purchasing and setting up a CNC router, which can be relatively high compared to other cutting methods. Additionally, CNC routers require regular maintenance and upkeep to ensure optimal performance, which can add to the overall cost of operating the machine.

Furthermore, CNC routers may not be suitable for all types of acrylic cutting tasks. Some complex shapes or designs may be challenging to achieve with a CNC router, requiring additional time and resources to program and set up the machine for the desired cut.

Overall, using a CNC router for acrylic cutting offers numerous advantages in terms of precision, speed, and flexibility. However, it is important to weigh these benefits against the potential costs and limitations of using this technology for specific applications.

cnc router acrylic Reference Specifications (varies for different product)

CNC routers are versatile machines used to cut and carve various materials, including acrylic. When working with acrylic on a CNC router, it’s important to consider the following reference specifications to achieve optimal results:

– Feed Rate: The recommended feed rate for cutting acrylic on a CNC router is typically between 100-300 inches per minute. It’s essential to adjust the feed rate based on the thickness and type of acrylic being used to prevent melting or chipping.

– Spindle Speed: The spindle speed for cutting acrylic on a CNC router should be set between 10,000-18,000 RPM. Slower speeds may result in overheating and melting, while higher speeds can cause cracking or chipping.

– Tooling: It’s advisable to use a sharp, clean cutting tool specifically designed for acrylic to achieve clean and precise cuts. A single flute or up-cut spiral bit is commonly used for cutting acrylic to minimize heat buildup and ensure smooth edges.

– Depth of Cut: When cutting acrylic on a CNC router, it’s recommended to make shallow passes with a depth of cut between 0.125-0.25 inches. Cutting too deep in a single pass can lead to excessive heat generation and cause the material to melt or warp.

– Clamping: Properly secure the acrylic sheet to the router bed using clamps or tape to prevent vibration and ensure accurate cutting results.

By following these reference specifications and adjusting them according to the specific acrylic material and thickness, users can achieve precise and clean cuts when cutting acrylic on a CNC router. Remember to experiment and test different parameters to find the optimal settings for your specific application.

Applications of cnc router acrylic

CNC router acrylic is widely used in various industries for its versatility, precision, and efficiency. Some common applications include:

1. Signage and displays: Acrylic is a popular material for producing signage and displays due to its high transparency, durability, and ease of customization. CNC routers can accurately cut and engrave acrylic to create intricate designs and logos for advertising purposes.

2. Furniture manufacturing: Acrylic is increasingly being used in furniture manufacturing for its modern look and durability. CNC routers can carve, shape, and polish acrylic sheets to create unique furniture pieces such as tables, chairs, shelves, and decor items.

3. Prototyping and modeling: Acrylic is a popular choice for rapid prototyping and modeling due to its affordability and ease of machining. CNC routers can quickly turn digital designs into physical prototypes for testing and evaluation in various industries.

4. Architectural applications: CNC router acrylic is used in architectural applications such as interior decorations, lighting fixtures, and wall panels. Acrylic can be easily fabricated into complex shapes and designs to enhance the aesthetics of residential and commercial spaces.

5. Medical and scientific equipment: Acrylic is commonly used in the production of medical and scientific equipment due to its transparency, durability, and ease of sterilization. CNC routers can accurately cut and shape acrylic components for devices such as lab equipment, medical instruments, and protective barriers.

Overall, CNC router acrylic offers endless possibilities for creating custom, high-quality products in industries ranging from manufacturing and design to healthcare and architecture. Its versatility and precision make it a valuable tool for bringing digital designs to life in a wide range of applications.

The Work Process and how to use cnc router acrylic

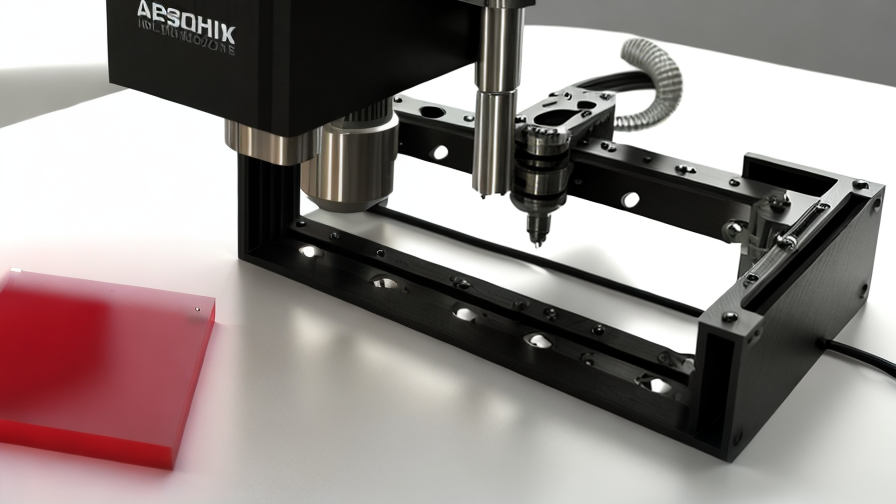

CNC routers are commonly used to cut and shape acrylic due to their precision and efficiency. The work process for using a CNC router to work with acrylic involves several steps:

1. Preparation: Secure the acrylic sheet to the CNC router’s work surface using clamps or double-sided tape. Ensure that the acrylic sheet is level and securely in place to prevent any movement during the cutting process.

2. Programming: Create a design file using CAD or CAM software that outlines the desired shapes and dimensions for the acrylic. The design file will serve as the instructions for the CNC router to follow.

3. Tool selection: Choose the appropriate cutting tool for acrylic, such as a spiral up-cut or compression bit. These tools are designed to minimize chipping and produce clean cuts in acrylic.

4. Set up the router: Install the selected cutting tool in the CNC router’s spindle. Adjust the router’s settings, such as cutting speed and depth, based on the type and thickness of the acrylic being used.

5. Cutting: Start the CNC router and run the program to begin cutting the acrylic sheet. Monitor the cutting process to ensure that the tool is cutting smoothly and accurately.

6. Finishing: Once the cutting is complete, remove the acrylic sheet from the CNC router and inspect the edges for any roughness or imperfections. Sand or polish the edges as needed to achieve a smooth and professional finish.

By following these steps, you can successfully use a CNC router to cut and shape acrylic with precision and efficiency. Remember to always follow safety guidelines when operating the CNC router and wear appropriate protective equipment, such as safety glasses and gloves.

Quality Testing Methods for cnc router acrylic and how to control the quality

Quality testing methods for CNC router acrylic involve various steps to ensure that the final product meets the desired specifications. These methods include:

1. Visual inspection: The first step is to visually inspect the acrylic pieces for any defects, such as scratches, cracks, or uneven edges. This can be done by trained personnel who perform a thorough examination of the acrylic parts.

2. Measurement: Accurate measurements are essential to ensure that the dimensions of the acrylic parts are within the required tolerance. This can be done using precision measuring instruments like calipers or micrometers to verify dimensions such as length, width, and thickness.

3. Surface finish evaluation: The surface finish of the acrylic parts is crucial, especially in applications where aesthetics are important. The quality can be evaluated by visually inspecting for any imperfections like roughness, unevenness, or waviness. Additionally, methods like gloss meters can also be used to measure the surface gloss and ensure it meets the desired specifications.

4. Functional testing: Depending on the application, functional testing may be necessary to ensure that the acrylic parts perform their intended purpose. For example, in a CNC router acrylic used for signage, the functionality can be tested by checking the accuracy and precision of the engraved letters or designs.

To control the quality of CNC router acrylic, several steps can be taken:

1. Process optimization: Ensuring that the CNC router is properly calibrated and programmed is crucial. Regular maintenance and calibration of the machine can minimize the occurrence of errors that might affect the quality of the acrylic parts.

2. Material selection: Using high-quality acrylic sheets that meet industry standards is essential. Choosing the appropriate grade and type of acrylic, such as cast or extruded, can significantly impact the overall quality of the final product.

3. Training and supervision: Trained operators who have a good understanding of the CNC router and its capabilities can greatly enhance quality control. Regular supervision and quality checks can help identify any potential issues at an early stage and take corrective actions.

4. Documentation and traceability: It is important to maintain comprehensive records of the production process, including the specifications, measurements, and inspection results of each acrylic part. This documentation allows for traceability and facilitates future analysis and improvement of the quality control process.

Implementing these testing methods and quality control measures can help ensure that the CNC router acrylic meets the desired quality standards and customer expectations.

cnc router acrylic Sample Policy and Post-Purchase Considerations for cnc router acrylic from China

Sample Policy:

When purchasing a CNC router acrylic from a supplier in China, it is important to consider their sample policy. It is advisable to request samples of the product before making a bulk purchase to ensure its quality and suitability for your needs. Most suppliers offer free or chargeable samples depending on the product’s value. It is crucial to clarify whether the supplier will refund the sample cost upon placing a bulk order.

Post-Purchase Considerations:

After purchasing a CNC router acrylic from China, there are several post-purchase considerations to keep in mind:

1. Quality Assurance: Verify the quality of the product received. Ensure that it matches the initial sample provided and meets your expectations. Check for any defects or damages and communicate them to the supplier for a resolution.

2. Replacement and Warranty: Understand the supplier’s policies regarding replacement and warranty. Enquire about the duration of the warranty, conditions for replacement, and the process for filing a claim. It is important to address any discrepancies quickly to avoid further complications.

3. Packaging and Shipping: Evaluate the packaging of the product. Look for sufficient protection to prevent damage during transit. If the packaging seems insufficient or compromised, report it to the supplier and request necessary improvements. Keep track of the shipping process to ensure timely delivery.

4. Communication with the Supplier: Maintain open communication with the supplier throughout the post-purchase process. Address any concerns promptly and clearly. Ensure that your expectations and requirements are clearly communicated to avoid any misunderstandings.

5. After-Sales Support: Inquire about after-sales support from the supplier. It is beneficial to establish a continuous relationship for future assistance, spare parts, or technical support. Evaluate their responsiveness and willingness to assist after the purchase.

Conclusion:

When purchasing a CNC router acrylic from China, requesting samples and understanding the supplier’s policies for post-purchase considerations are essential. Ensure the product’s quality, check warranty and replacement terms, evaluate packaging and shipping, maintain open communication with the supplier, and inquire about after-sales support. Following these guidelines will help ensure a satisfactory purchase experience.

Sourcing cnc router acrylic from China: Opportunities, Risks, and Key Players

Sourcing CNC router acrylic from China presents both opportunities and risks. China is known for its vast manufacturing capabilities and competitive pricing, making it an attractive option for businesses looking to source CNC router acrylic at lower costs. The Chinese market offers a wide range of options, allowing buyers to choose from various suppliers and manufacturers.

One of the main opportunities of sourcing CNC router acrylic from China is cost savings. Chinese manufacturers often offer products at lower prices compared to their counterparts in other countries. This pricing advantage enables businesses to lower production costs, increase profit margins, or offer more competitive prices in the market.

Another opportunity is the vast production capacity that China possesses. The country has well-established manufacturing infrastructure, advanced technology, and skilled labor force. This means that businesses can easily find Chinese suppliers who are capable of meeting their bulk production needs, ensuring a steady supply of CNC router acrylic.

However, there are also risks to consider when sourcing CNC router acrylic from China. Quality control can be a concern, as some Chinese manufacturers may prioritize lower costs over product quality. It is crucial for buyers to thoroughly research and vet potential suppliers, checking their reputation, certifications, and product quality standards to mitigate this risk.

Communication and language barriers can also pose challenges when sourcing from China. Effective communication is vital to ensure accurate product specifications, negotiate terms, and address any issues that may arise during the sourcing process. It is recommended to work with suppliers who have proficient English speakers or engage the services of a reliable sourcing agent to overcome these barriers.

Key players in the Chinese CNC router acrylic market include JINAN KUANGDA CNC MACHINERY CO., LTD., AUYU machinery CO., LTD., and Shenzhen Superwave Laser Technology Co., Ltd. These companies have established a strong presence in the industry and are recognized for their quality products and reliable services.

In conclusion, sourcing CNC router acrylic from China offers cost savings and access to a vast manufacturing capacity. However, businesses need to be cautious about quality control and communication challenges. By conducting thorough research, vetting suppliers, and maintaining clear communication, businesses can leverage the opportunities presented by sourcing CNC router acrylic from China.

How to find and select reliable cnc router acrylic manufacturers in China,use google search manufacturers and suppliers

To find and select reliable CNC router acrylic manufacturers in China, the first step is to use Google search to look for manufacturers and suppliers. You can start by entering keywords such as “CNC router acrylic manufacturers China” or “acrylic cutting machine suppliers in China” to generate a list of potential companies.

Next, carefully review the websites of the manufacturers to gather information about their products, services, certifications, and customer reviews. Look for manufacturers with a good reputation, experience in the industry, and a history of producing high-quality acrylic products.

You can also consider reaching out to industry associations or trade shows to get recommendations for reliable manufacturers. Networking with other professionals in the industry can also lead you to reputable CNC router acrylic manufacturers in China.

When selecting a manufacturer, make sure to request samples of their work to assess quality. Additionally, ask for a list of their previous clients and contact them for references. It is important to communicate your specific requirements clearly and ensure that the manufacturer can meet your needs in terms of customization, quality, production capacity, and delivery times.

Overall, conducting thorough research, reviewing online resources, seeking recommendations, and evaluating samples are key steps in finding and selecting reliable CNC router acrylic manufacturers in China.

How to check cnc router acrylic manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

One way to check the reliability of a CNC router acrylic manufacturer’s website is to use Google Chrome SEOquake extension to see if the website is ranking in the top 10 search results for relevant keywords. This can give you an indication of the website’s popularity and credibility in the industry.

Additionally, you can look for customer reviews and testimonials on the website or on other review platforms to get a sense of the manufacturer’s reputation. A reliable manufacturer is likely to have positive feedback from satisfied customers who have purchased their products.

It’s also a good idea to check if the website provides detailed information about the products they offer, such as specifications, materials used, and pricing. This shows that the manufacturer is transparent and knowledgeable about their products.

Finally, look for contact information such as a physical address, phone number, and email address on the website. A reputable manufacturer will have clear and accessible ways for customers to get in touch with them if they have any questions or concerns.

In summary, to check if a CNC router acrylic manufacturer’s website is reliable, look for a top search engine ranking, positive customer reviews, detailed product information, and clear contact information. These factors can help you determine if the manufacturer is trustworthy and reputable in the industry.

Top 10 cnc router acrylic manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Jinan Blue Elephant CNC Machinery Co., Ltd: With over 10 years of experience in the field, Blue Elephant offers high-quality acrylic CNC routers. Their models like the ELECNC-1325 and ELECNC-1530 come equipped with a powerful spindle, advanced control system, and precise cutting abilities. These machines are ideal for sign making, display manufacturing, and precise engraving.

2. Shandong Baokun Machinery Co., Ltd: Baokun specializes in manufacturing professional-grade acrylic CNC routers. Their machines feature a sturdy frame, precision ball screw drive system, and easy-to-use control panel. Baokun CNC routers are widely used in industries like advertising, woodworking, and handicrafts for diverse acrylic cutting requirements.

3. Jinan Firm CNC Equipment Co., Ltd: Firm CNC offers a range of high-performance acrylic CNC routers for applications like acrylic fabrication, architectural modeling, and relief carving. Their machines are designed with precision linear guides, efficient dust collection systems, and compatible control software, ensuring unparalleled accuracy and efficiency.

4. Jinan Senke CNC Machine Co., Ltd: Senke provides acrylic CNC routers that are specifically designed for processing acrylic materials. Equipped with an advanced water cooling spindle, durable frame, and user-friendly interface, Senke CNC routers offer superior performance in precision cutting, engraving, and drilling of acrylic surfaces.

5. Jinan Dexian Machinery Co., Ltd: Dexian specializes in manufacturing heavy-duty CNC routers for acrylic processing. Their machines are known for their superior stability, precise cutting performance, and long service life. Dexian CNC routers are widely used in the manufacture of acrylic letters, signs, and displays.

6. Shandong Chencan Machinery Incorporated Company: Chencan offers a wide range of acrylic CNC routers suitable for various industries. Their machines feature a solid structure, high-speed spindle, and advanced control system for efficient and accurate acrylic cutting, milling, and engraving tasks.

7. Jinan iGolden CNC Equipment Co., Ltd: iGolden’s acrylic CNC routers are designed for high-precision cutting, engraving, and milling applications. These machines are equipped with a heavy-duty frame, air-cooled spindle, and user-friendly control panel for effortless operation and precise results.

8. Jinan Unistar Machinery Co., Ltd: Unistar specializes in the production of CNC routers for acrylic processing. Their machines are equipped with an advanced dust collection system, a high-speed spindle, and a sturdy frame for impeccable precision and efficiency in cutting and engraving acrylic materials.

9. Jinan Blue Elephant CNC Machinery Co., Ltd – Weihong: Blue Elephant offers a range of acrylic CNC routers integrated with Weihong control systems. These machines are suitable for cutting, engraving, and milling acrylic materials with high precision and efficiency, making them ideal for signage, advertising, and woodworking applications.

10. Jinan Sign CNC Equipment Co., Ltd: Sign CNC Equipment specializes in manufacturing CNC routers for acrylic processing. Their machines feature a rigid structure, high-performance spindle, and intuitive control system for precise cutting, engraving, and milling of acrylic materials.

Table:

| Manufacturer | Product Range |

|—————————————|——————————————————————————————–|

| Jinan Blue Elephant CNC Machinery Co. | ELECNC-1325, ELECNC-1530 |

| Shandong Baokun Machinery Co., Ltd | Professional-grade acrylic CNC routers |

| Jinan Firm CNC Equipment Co., Ltd | Precision linear guides, efficient dust collection systems |

| Jinan Senke CNC Machine Co., Ltd | Advanced water cooling spindle, superior performance in cutting and engraving |

| Jinan Dexian Machinery Co., Ltd | Heavy-duty CNC routers for acrylic letters, signs, and displays |

| Shandong Chencan Machinery Co. | Acrylic CNC routers for various industries, high-speed spindle, advanced control system |

| Jinan iGolden CNC Equipment Co., Ltd | High-precision cutting, milling, and engraving, air-cooled spindle |

| Jinan Unistar Machinery Co., Ltd | CNC routers equipped with advanced dust collection systems, high-speed spindle |

| Jinan Blue Elephant CNC Machinery Co. – Weihong | Integration with Weihong control systems, high precision and efficiency |

| Jinan Sign CNC Equipment Co., Ltd | CNC routers for acrylic processing, rigid structure, intuitive control system |

These top 10 CNC router acrylic manufacturers in China provide a diverse range of high-quality machines suitable for various acrylic cutting, engraving, and milling needs. Customers can choose based on their specific requirements, such as precision, spindle power, control system preferences, and applications.

Background Research for cnc router acrylic manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to searching for CNC router acrylic manufacturers in China, there are several online platforms and resources that can provide background research information. Websites such as qcc.com, archive.org, and importyeti.com can be valuable when exploring these manufacturers.

Qcc.com is a popular Chinese business information platform that offers comprehensive details about companies registered in China. This website provides information on a company’s registration details, financial status, management team, and other relevant details.

Archive.org is a digital library that allows users to access cached versions of websites from the past. This can be useful when researching the history or previous versions of a CNC router acrylic manufacturer’s website. By accessing archived web pages, one can gain insights into the company’s previous products, services, and any changes in their business strategies over time.

ImportYeti.com is a database that primarily focuses on import and export data. It provides information about the shipments made by various companies, giving insights into their trading activities. By using ImportYeti, one can track the imports of CNC router acrylic manufacturers, including details such as the quantity, origin, destination, and buyers.

These platforms can be beneficial for gathering background research on CNC router acrylic manufacturers in China. By utilizing qcc.com, archive.org, and importyeti.com, researchers can gain valuable insights into a manufacturer’s business history, financial stability, and import-export activities.

Leveraging Trade Shows and Expos for cnc router acrylic Sourcing in China

Trade shows and expos are excellent opportunities to source cnc router acrylic in China. These events bring together a wide range of suppliers, manufacturers, and industry professionals, making them ideal platforms for networking and discovering new products and suppliers.

When attending trade shows and expos for cnc router acrylic sourcing in China, it is crucial to plan ahead and identify the key exhibitors and manufacturers you want to connect with. Researching the event beforehand and creating a list of target suppliers will help you make the most of your time at the show.

Engaging with suppliers at trade shows allows you to establish personal connections, discuss your specific requirements, and negotiate pricing and terms face-to-face. This direct interaction can help you gauge the supplier’s reliability, product quality, and production capabilities, giving you confidence in your sourcing decision.

In addition to meeting potential suppliers, trade shows and expos also provide opportunities to stay current on industry trends, technologies, and innovations. Attending seminars, workshops, and product demonstrations can help you expand your knowledge and make informed decisions when sourcing cnc router acrylic in China.

Overall, leveraging trade shows and expos for cnc router acrylic sourcing in China can be a valuable strategy for connecting with suppliers, exploring new products, and staying competitive in the market. By taking advantage of these events, you can streamline your sourcing process, build relationships with reliable suppliers, and ultimately, enhance your business success.

The Role of Agents and Sourcing Companies in Facilitating cnc router acrylic Purchases from China

Agents and sourcing companies play a crucial role in facilitating cnc router acrylic purchases from China by acting as intermediaries between the buyer and the manufacturer. They are often based in China and have established relationships with a network of suppliers and manufacturers in the region.

These agents and sourcing companies assist buyers in finding the right cnc router acrylic manufacturer that meets their specific requirements in terms of quality, price, and delivery time. They have in-depth knowledge of the local market and can provide valuable insights and recommendations to help buyers make informed decisions.

Agents and sourcing companies also help buyers navigate the complexities of doing business in China, including language barriers, cultural differences, and logistics. They handle all the negotiations, contracts, payments, and shipping arrangements on behalf of the buyer, ensuring a smooth and efficient purchasing process.

Overall, agents and sourcing companies serve as a valuable resource for buyers looking to source cnc router acrylic from China. Their expertise and experience can help buyers save time, reduce costs, and mitigate risks associated with sourcing products internationally.

Price Cost Research for cnc router acrylic manufacturers Companies in China, use temu.com and 1688.com

When researching the prices and costs of CNC router acrylic manufacturers in China, two major platforms that can be utilized are temu.com and 1688.com.

Firstly, on temu.com, users can find a wide range of CNC router acrylic manufacturers with a variety of products and services. Prices for CNC routers on temu.com can vary depending on factors such as the size of the machine, the complexity of the design, and the quality of materials used. Additionally, users can compare prices from different manufacturers to find the best deal for their specific needs.

Secondly, 1688.com is another popular platform for sourcing CNC router acrylic manufacturers in China. Users can search for manufacturers based on specific criteria such as price range, production capacity, and location. On 1688.com, users can also find detailed information about each manufacturer, including their price list, production process, and customer reviews.

In conducting research on both temu.com and 1688.com, it is important to consider factors such as shipping costs, import taxes, and potential language barriers when dealing with manufacturers in China. By using these platforms, users can find the right CNC router acrylic manufacturer that meets their requirements and budget.

Shipping Cost for cnc router acrylic import from China

The shipping cost for importing a CNC router acrylic machine from China will vary depending on several factors such as the size and weight of the machine, the shipping method chosen, and the destination country.

Air freight is typically the fastest shipping method, but also the most expensive. The cost will depend on the weight of the machine, but on average, it can range from $500 to $2000.

Sea freight is a more cost-effective option for large and heavy machinery, but it takes longer for the shipment to arrive. The cost of sea freight can vary greatly depending on the size and weight of the machine, but it is generally lower than air freight.

Additional costs to consider when importing a CNC router acrylic machine from China include customs duties, import taxes, and insurance fees. These costs can add significantly to the total shipping cost, so it is important to factor them into your budget.

To ensure a smooth shipping process, it is recommended to work with a reputable freight forwarder or shipping company that has experience in importing machinery from China. They can help you navigate the complexities of international shipping, handle customs clearance, and provide you with a detailed quote that includes all the necessary costs.

Overall, while shipping costs for importing a CNC router acrylic machine from China can be significant, with careful planning and the right shipping partner, you can ensure a cost-effective and efficient process.

Compare China and Other cnc router acrylic Markets: Products Quality and Price,Visible and Hidden Costs

China has emerged as a major player in the CNC router acrylic market, offering products of varying quality and price to cater to different customer needs. While Chinese products may be competitively priced compared to other markets, the quality may not always be up to international standards.

In terms of product quality, China offers a wide range of CNC router acrylic products, spanning from entry-level machines to high-end models that can compete with products from other markets. However, the lower-priced Chinese products may suffer from inferior construction materials and lack of precision in cutting and engraving.

When it comes to price, China is often able to offer CNC router acrylic products at a lower cost compared to other markets such as Europe and the United States. This makes Chinese products attractive for budget-conscious customers looking to invest in CNC machinery.

However, there are also hidden costs associated with purchasing Chinese CNC router acrylic products. These may include additional expenses for shipping, customs duties, and potential maintenance or repair costs due to the lower quality of some Chinese products. Customers need to factor in these hidden costs when making a decision between purchasing from China or other markets.

Overall, while China offers a wide range of CNC router acrylic products at competitive prices, customers need to carefully consider the trade-offs in terms of product quality, visible and hidden costs before making a purchase decision. Other markets may offer higher quality products, but at a higher price point, making it essential for customers to weigh their options and priorities before choosing the right CNC router acrylic product for their needs.

Understanding Pricing and Payment Terms for cnc router acrylic: A Comparative Guide to Get the Best Deal

When it comes to purchasing a CNC router for acrylic work, understanding pricing and payment terms is crucial to ensure you get the best deal possible. This comparative guide aims to provide an overview of key factors to consider when making your purchase decision, all within a concise 300-word limit.

Firstly, researching the market is important to gauge the average pricing range for CNC routers specifically designed for acrylic work. Compare prices from multiple suppliers to identify any outliers. Be cautious of deals that seem too good to be true, as they may indicate low-quality equipment.

Payment terms also play a significant role. Some suppliers may offer financing options to ease the burden of upfront costs. Before committing to any payment plan, carefully review the terms and conditions, including interest rates, repayment periods, and any associated fees.

Another important aspect to consider is the warranty and after-sales support provided by the manufacturer or supplier. Ensure that they offer a comprehensive warranty package to protect your investment. Also, inquire about technical support availability, as this can save you time and money in case of machine malfunctions or troubleshooting needs.

Consider the machine specifications in relation to its pricing. Different routers come with varying features, power capacities, and cutting speeds, all of which can affect the price. Assess your specific requirements and budget to determine the optimal balance between cost and performance.

Do not overlook hidden costs such as shipping, taxes, or customs duties. These can significantly impact the final price of your CNC router. Clarify with the supplier whether these costs are included or if you will need to bear them separately.

Lastly, don’t hesitate to negotiate the price. Many suppliers are open to negotiating, especially if you have gathered quotes from multiple sources. While price negotiation may not always be possible, it’s worth exploring to secure the best deal.

To summarize, researching the market, understanding payment terms, considering warranties and after-sales support, evaluating machine specifications, accounting for hidden costs, and negotiating the price are key steps to ensure you get the best deal when purchasing a CNC router for acrylic work.

Chinese Regulations and Industry Standards Certifications for cnc router acrylic,Import Regulations and Customs for cnc router acrylic from China

In China, cnc router acrylic machines are subject to specific industry standards and regulations set by the government. Manufacturers of such machines must comply with these standards to ensure the quality and safety of their products. Some of the key standards certifications that cnc router acrylic machines may need to comply with in China include ISO 9001 for quality management, CE for safety requirements, and RoHS for restrictions on hazardous substances.

When importing cnc router acrylic machines from China, it is important to be aware of the country’s import regulations and customs procedures. The import of such machinery may require certain permits or licenses, and the products must meet the relevant standards and certifications as outlined by the Chinese authorities. Additionally, customs duties, tariffs, and taxes may apply to the import of cnc router acrylic machines, so it is essential to factor in these additional costs when planning the import process.

Overall, understanding Chinese regulations and industry standards certifications for cnc router acrylic machines is crucial for ensuring compliance and quality control. Importers should also be aware of the import regulations and customs procedures in China to facilitate a smooth and successful import process.

Sustainability and Environmental Considerations in cnc router acrylic Manufacturing

Sustainability and environmental considerations in CNC router acrylic manufacturing are crucial for minimizing the negative impact of the process on the environment and promoting long-term sustainability.

To start, the choice of raw materials is essential. Opting for eco-friendly and recycled acrylic sheets helps reduce the extraction of new resources and minimizes waste generation. Additionally, manufacturers should seek out suppliers who adhere to sustainable practices and have credible certifications.

Efficient use of resources is another important aspect. CNC router machines should be programmed to optimize material utilization, reducing waste and maximizing product output. Utilizing nesting software can help arrange parts more efficiently on the acrylic sheets, minimizing material offcuts.

Furthermore, energy consumption during the manufacturing process should be minimized. Employing energy-efficient CNC machines and optimizing production schedules can result in substantial energy savings. Making use of renewable energy sources, such as solar or wind power, is also a sustainable option.

Proper waste management is crucial to mitigate the environmental impact. Recycling or reusing acrylic scraps generated during the CNC routing process is an effective method to minimize waste. Additionally, manufacturers should implement appropriate disposal methods for any hazardous waste generated, ensuring compliance with local regulations.

Transportation and logistics also play a role in sustainability. Minimizing transportation distances by establishing manufacturing facilities near the raw material sources or customer base can significantly reduce carbon emissions.

Lastly, companies should adopt environmentally-friendly practices such as implementing water-saving measures, supporting reforestation projects, and promoting recycling initiatives within their manufacturing facilities. Encouraging employee engagement in sustainability programs can also foster a culture of environmental responsibility.

In conclusion, sustainability and environmental considerations in CNC router acrylic manufacturing are crucial for minimizing the negative impact on the environment. By focusing on raw material choices, resource efficiency, energy consumption, waste management, transportation logistics, and adopting environmentally-friendly practices, manufacturers can contribute to a more sustainable and environmentally conscious manufacturing industry.

List The Evolution history of “cnc router acrylic”

CNC (Computer Numerical Control) router machines have revolutionized the precision and efficiency of cutting, carving, and shaping materials, including acrylic. The evolution of CNC router acrylic can be summarized through the following key milestones:

1. Early Developments: The concept of CNC machining originated in the 1950s. However, it was not until the 1970s and 1980s that computerized control systems started to be integrated into router machines. Early CNC routers used basic programming languages and limited cutting capabilities.

2. Advancements in Control Systems: In the 1990s, the introduction of more advanced control systems, such as proprietary software and CAD/CAM integration, greatly improved the accuracy and versatility of CNC router acrylic machines. These systems allowed for more complex designs and the ability to process various materials, including acrylic.

3. Improved Precision and Speed: Throughout the 2000s, CNC router acrylic machines experienced significant advancements in terms of precision and speed. These developments were made possible by the integration of servo motors and ball screws, which enhanced the movement and positioning accuracy of the routers. The use of improved tooling and cutting techniques also contributed to the efficiency of acrylic processing.

4. Enhanced Safety and Automation: In recent years, safety features and automation have become increasingly important aspects of CNC router acrylic machines. Manufacturers have introduced safety measures, such as integrated sensors and emergency stop buttons, to ensure the protection of operators. Additionally, advancements in robotic automation have allowed for increased productivity and reduced human error in the acrylic cutting process.

5. Integration of Advanced Technology: The evolution of CNC router acrylic is ongoing, with the integration of advanced technologies such as artificial intelligence (AI) and machine learning. These technologies enable CNC routers to automatically adjust cutting parameters based on real-time feedback, further enhancing precision and efficiency.

In summary, the evolution of CNC router acrylic can be traced from the basic control systems of the 1970s to the advanced technologies of today. Each milestone brought improvements in precision, speed, safety, and automation, transforming the way acrylic materials are processed and shaped.

The Evolution and Market Trends in cnc router acrylic Industry

The CNC router acrylic industry has witnessed significant evolution and market trends in recent years. CNC (Computer Numerical Control) routers have become indispensable tools for cutting, shaping, and engraving acrylic materials with precision and efficiency.

One major trend in the CNC router acrylic industry is the increased adoption of advanced technology. CNC routers equipped with advanced software and hardware have enabled manufacturers to enhance productivity and accuracy in acrylic cutting and carving processes. These technological advancements provide better control over speed, depth, and routing patterns, allowing for the creation of intricate designs and complex shapes.

Another notable trend in the industry is the growing demand for customization. CNC routers offer the flexibility to create custom acrylic pieces, which has gained popularity in various sectors such as interior design, signage, and advertising. Customers are increasingly seeking unique and personalized acrylic products, ranging from furniture to decorative items. The CNC router acrylic industry has responded by offering tailored services and designs to meet these demands.

Furthermore, sustainability has emerged as a significant market trend in the CNC router acrylic industry. As environmental concerns continue to rise, manufacturers are adopting eco-friendly practices and materials. Acrylic itself is a recyclable material, and CNC routers aid in reducing waste by optimizing the use of acrylic sheets during the production process. Additionally, advancements in cutting techniques have reduced the energy consumption of CNC routers, making them more environmentally friendly.

There is also a visible shift towards automation in the industry. CNC routers can now be integrated with other robotic systems, such as automated material handling and tool changing. This automation enables a seamless production process, reducing human error and increasing overall efficiency. The integration of CNC routers with robotics has played a vital role in streamlining the manufacturing process and reducing operating costs.

In conclusion, the CNC router acrylic industry has witnessed substantial evolution and market trends, driven by technological advancements, customization demands, sustainability concerns, and automation integration. These trends have led to increased productivity, higher precision, and the ability to create unique and personalized acrylic products. As the industry continues to evolve, it is expected to further embrace technological innovations, cater to diverse customization needs, and prioritize sustainability practices.

Custom Private Labeling and Branding Opportunities with Chinese cnc router acrylic Manufacturers

Chinese CNC router acrylic manufacturers offer custom private labeling and branding opportunities for businesses looking to customize their products. By working with these manufacturers, companies can create unique designs and branding for their acrylic products, helping them stand out in the market.

Manufacturers typically offer services such as custom color options, engraving, laser cutting, and printing, allowing businesses to fully customize their products to meet their specific needs. This ensures that companies can create products that align with their brand image and messaging, effectively establishing a strong brand presence in the market.

In addition, working with Chinese CNC router acrylic manufacturers allows businesses to take advantage of cost-effective production and fast turnaround times. These manufacturers have the expertise and technology to efficiently produce high-quality acrylic products, helping businesses meet their production deadlines and keep up with market demand.

Overall, partnering with Chinese CNC router acrylic manufacturers for custom private labeling and branding opportunities can help businesses differentiate themselves in the market and create products that resonate with their target audience. With a range of customization options available, companies can create unique and eye-catching acrylic products that leave a lasting impression on their customers.

Tips for Procurement and Considerations when Purchasing cnc router acrylic

When purchasing a CNC router for working with acrylic, there are several factors to consider. First and foremost, make sure to choose a machine with the appropriate size and cutting capabilities for your specific needs. This includes considerations such as the bed size, spindle power, and cutting speed.

It is also important to ensure that the CNC router is compatible with acrylic materials. Look for a machine that features a high-quality cutting tool, such as a diamond or carbide bit, which is specifically designed for working with acrylic. Additionally, consider the machine’s capability for precision cutting and smooth edges, as these are important factors when working with acrylic.

Another important consideration when purchasing a CNC router for acrylic is the machine’s software and programming capabilities. Look for a machine that offers user-friendly software with easy programming options, as this will help streamline the cutting process and optimize efficiency.

Additionally, consider the level of technical support and training offered by the manufacturer. It is important to choose a reputable company that provides excellent customer support and training resources to help you maximize the capabilities of your CNC router.

Finally, consider your budget when purchasing a CNC router for acrylic. While it is important to invest in a high-quality machine that meets your specific needs, it is also important to find a balance between cost and features. Compare different options and prices to find the best value for your investment.

Overall, when purchasing a CNC router for acrylic, it is important to consider factors such as size, cutting capabilities, compatibility with acrylic materials, software and programming capabilities, technical support, and budget. By carefully evaluating these factors, you can make an informed decision and choose a CNC router that will meet your needs and deliver high-quality results.

FAQs on Sourcing and Manufacturing cnc router acrylic in China

1. What is a CNC router acrylic?

A CNC router acrylic refers to a machine that uses computer numerical control (CNC) technology to accurately cut, engrave, and shape acrylic sheets. Acrylic, also known as Plexiglas or Perspex, is a transparent thermoplastic material commonly used in various industries for its versatility and durability.

2. Why source and manufacture CNC router acrylic in China?

China has become a global leader in manufacturing due to its low labor costs, advanced technology, and large-scale production capabilities. Sourcing and manufacturing CNC router acrylic in China offers several benefits, including cost-effectiveness, high-quality products, and quick turnaround times.

3. How to source CNC router acrylic from China?

To source CNC router acrylic from China, you can follow these steps:

– Research and identify reliable manufacturers or suppliers through online directories, industry trade shows, or referrals.

– Request quotes and samples from multiple suppliers to compare prices, quality, and services.

– Conduct thorough background checks and assess their manufacturing capabilities, certifications, and customer feedback.

– Negotiate terms and place an order with the chosen supplier, ensuring clear communication regarding specifications, quantities, lead times, and payment conditions.

– Arrange shipping and logistics, considering factors such as customs regulations, transportation modes, and insurance.

4. What factors should be considered when selecting a supplier?

When selecting a supplier for CNC router acrylic in China, it is important to consider the following factors:

– Manufacturing capabilities and equipment: Ensure that the supplier has the required machinery, technology, and expertise to produce high-quality CNC router acrylic.

– Quality control measures: Check if the supplier adheres to international quality standards and has implemented stringent quality control processes.

– Pricing and payment terms: Compare prices from different suppliers and negotiate favorable terms, including payment methods, currency, and any additional costs.

– Communication and language proficiency: Effective communication is crucial; confirm if the supplier has proficient English speakers or consider hiring a translator if necessary.

– Delivery and lead times: Discuss shipping options, production lead times, and any potential delays to ensure timely delivery of the CNC router acrylic.

5. How can quality control be ensured during manufacturing?

To ensure quality control during the manufacturing process, you can:

– Define clear quality standards, specifications, and requirements before production begins.

– Conduct regular inspections and quality checks throughout the manufacturing process.

– Request product samples at different stages to assess and verify quality.

– Establish a good line of communication with the supplier, addressing any issues or concerns promptly.

– Consider hiring third-party quality inspection services to provide an unbiased assessment of the products.

In summary, sourcing and manufacturing CNC router acrylic in China offers cost-effectiveness, high-quality products, and quick turnaround times. When sourcing from China, it is crucial to thoroughly research suppliers, consider various factors like manufacturing capabilities and quality control, and maintain clear communication to ensure successful production and delivery.

Why contact sourcifychina.com get free quota from reliable cnc router acrylic suppliers?

Sourcifychina.com may be able to get a free quota from reliable CNC router acrylic suppliers for several reasons:

1. Long-standing relationship: Sourcifychina.com may have developed a strong and reliable partnership with the CNC router acrylic suppliers over time. This relationship is built on trust, mutual understanding, and successful past collaborations. As a result, the suppliers may be willing to offer free quotas as a gesture of goodwill and to maintain a long-term business partnership.

2. Large order volumes: Sourcifychina.com may consistently place substantial orders with the CNC router acrylic suppliers, making them a valuable and consistent customer. By providing a free quota, suppliers can incentivize Sourcifychina.com to continue placing bulk orders in the future, ensuring a steady stream of business for the suppliers.

3. Supplier benefits: Offering a free quota to Sourcifychina.com can benefit the suppliers in various ways. It can help them showcase their product quality and capabilities to other potential customers or the wider market. Additionally, if Sourcifychina.com is a well-known and reputable sourcing platform, being associated with them as a reliable supplier can enhance the supplier’s credibility and attract more clients.

4. Competitive advantage: In a competitive market, suppliers may be willing to provide free quotas to Sourcifychina.com as a strategy to gain a competitive edge over their rivals. By offering this added benefit, the supplier distinguishes themselves from others, making Sourcifychina.com more likely to choose them as their preferred supplier in the future.

Overall, free quotas from reliable CNC router acrylic suppliers can be seen as a strategic move to foster a strong business relationship, incentivize bulk orders, showcase product quality, gain credibility, and obtain a competitive advantage.