Benefits of Cnc Vacuum Pump

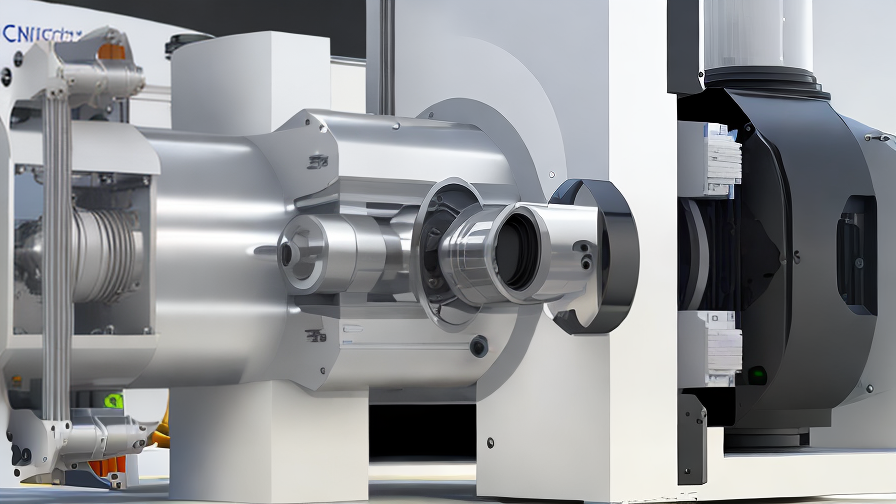

CNC vacuum pumps have been around for many years, offering a range of benefits to individuals and businesses in a variety of industries. These pumps use air pressure to create a vacuum that can be used to hold materials in place while cutting or engraving them using a CNC machine.

One of the main benefits of using a CNC vacuum pump is that it increases productivity. By holding materials securely in place, the machine can move more quickly and with greater precision, allowing for faster and more accurate cuts. Additionally, because the material is held in place, there is less chance of it moving or vibrating during the cutting process, which can cause problems with accuracy and quality.

Another benefit of a CNC vacuum pump is that it can be used with a variety of different materials, including wood, metal, plastic, and even stone. This makes it a versatile tool that can be used by many different types of businesses, from small woodworking shops to large industrial manufacturing facilities.

CNC vacuum pumps are also relatively low-maintenance, which is another benefit for businesses. They are designed to be durable and long-lasting, with regular cleaning and servicing required only every 3-4 months. This means that a business can continue to use the pump for many years without needing to spend a lot of time and money on maintenance.

Perhaps most importantly, a CNC vacuum pump can help to ensure the safety of employees. By holding materials in place securely, there is less chance of accidents and injuries occurring during the cutting or engraving process. This not only protects employees, but also reduces the risk of damage to the machine, which can cause costly downtime and repairs.

Overall, there are many benefits to using a CNC vacuum pump. They are a versatile and durable tool that can increase productivity, improve accuracy, and ensure the safety of workers. Whether you’re a small business owner or a large industrial manufacturer, a CNC vacuum pump is an investment that can pay off in the long run.

Features of Cnc Vacuum Pump

A CNC vacuum pump is an essential component of any CNC machine, as it is responsible for removing debris and dust created during the cutting process. There are various types of CNC vacuum pumps available in the market, each with unique features to suit different applications.

One of the key features of a CNC vacuum pump is its suction power, which determines the amount of debris and dust the pump can remove. High suction power is essential for CNC machines that cut hard and dense materials, such as metal and stone.

Another important feature of a CNC vacuum pump is its filtration system. A good filtration system ensures that the air released by the pump is clean and free of debris, preventing health hazards and ensuring the longevity of the pump.

CNC vacuum pumps are also designed with various safety features. For example, some models have built-in temperature sensors that prevent the pump from overheating and causing damage to the machine. Others have automatic shut-off systems that turn off the pump in case of a malfunction.

CNC vacuum pumps are also available in different sizes, depending on the size of the CNC machine or the size of the workpiece being cut. Larger pumps are used for machines that require a high volume of air flow, while smaller pumps are used for smaller machines or for more delicate workpieces.

Finally, some CNC vacuum pumps come equipped with accessories such as hoses, couplers, and clamps, facilitating easy installation and maintenance.

In conclusion, CNC vacuum pumps are crucial components of any CNC machine, ensuring the efficient removal of debris and dust during the cutting process. It is essential to choose the right vacuum pump with features tailored to the specific needs of the machine and the material being cut.

Various Types of Cnc Vacuum Pump

CNC vacuum pumps are an essential part of any CNC machine. They are used to create a vacuum that holds the workpiece securely in place during the machining process. There are various types of CNC vacuum pumps available in the market. This article will look at some of the most commonly used types.

1. Rotary vane vacuum pump:

This type of pump is most commonly used in CNC machines. It consists of a rotor with vanes that rotates inside a cavity. As the rotor turns, the vanes sweep along the wall of the cavity, drawing in air and creating a vacuum. These pumps are efficient and have a high pumping speed.

2. Diaphragm vacuum pump:

This type of pump uses a flexible diaphragm that moves up and down to create a vacuum. It is commonly used in applications where oil contamination is a concern. Diaphragm pumps are quiet and have a low maintenance cost.

3. Scroll vacuum pump:

This pump uses two interlocking spirals that move against each other to create a vacuum. These pumps are oil-free and have a low noise level. They are commonly used in medical applications.

4. Liquid ring vacuum pump:

This type of pump uses a liquid to create a seal between the impeller and the casing. The liquid is typically water, oil, or a mixture of both. These pumps are very reliable and have a long life span. They are commonly used in applications where a high level of vacuum is required.

5. Turbomolecular vacuum pump:

This type of pump uses rapidly spinning blades to create a high vacuum. They are commonly used in scientific applications where a high level of precision is required. These pumps are very expensive and require a high level of maintenance.

In conclusion, there are various types of CNC vacuum pumps available in the market. The choice of pump will depend on the specific application and the level of vacuum required. It is important to choose the right pump to ensure the CNC machine operates efficiently and accurately.

Applications of Cnc Vacuum Pump

CNC vacuum pumps have revolutionized the way industries carry out their manufacturing processes. They have made work easier and faster while providing accuracy and precision in the production of various products. These pumps come in different types and sizes, with varying capabilities to handle different applications.

One application of CNC vacuum pumps is in the woodworking industry. They are used to hold wood pieces firmly in place during cutting, routing or carving. The vacuum pump creates suction that draws the wood pieces onto a cutting bed, ensuring they do not move during the cutting process. This results in accurate and straight cuts, which are essential in the production of quality furniture and wood products.

Another application of CNC vacuum pumps is in the glass industry. They are used to hold glass sheets firmly in place during processing. The vacuum pump creates suction that holds the glass sheet while it is cut, shaped or engraved. This ensures that the glass sheets remain intact throughout the process, reducing the possibility of breakage or damage.

CNC vacuum pumps are also used in the printing industry during the printing process. The vacuum pump creates suction that holds the printing substrate in place, preventing it from slipping during the printing process. This results in accurate and consistent printing, ensuring that the quality of the printed material is maintained.

In the packaging industry, CNC vacuum pumps are used to hold packaging materials in place during manufacturing. The pumps create suction that holds the packaging material steady, allowing for precise cutting and shaping. This ensures the production of uniform packaging materials that are crucial in the retail industry.

In conclusion, CNC vacuum pumps are versatile machines that have multiple applications in various industries. They offer accuracy, precision, and speed, making them an essential tool in modern manufacturing processes. Their use leads to the production of high-quality products, with minimal errors, and ensures that operations are carried out efficiently. Companies that use CNC vacuum pumps have a competitive advantage over those that do not, enabling them to run smoothly, and provide top-quality products to the market.

The Process of Cnc Vacuum Pump

CNC vacuum pumps are essential components of modern industrial and manufacturing processes. These devices are used to create a vacuum in various systems and machinery to ensure proper operation and precision.

The process of CNC vacuum pump involves removing air from a given environment or system to create a negative pressure. The pump creates a vacuum by removing air molecules from within an enclosed chamber or container. The high-powered suction force of the pump creates a pressure difference, which leads to a flow of air from high-pressure to low-pressure areas.

CNC vacuum pumps are used in a variety of industries such as woodworking, metalworking, glass blowing, and more. The pumps are used to hold objects in place, remove dust and debris during machining processes, and aid in the transportation of materials.

There are various types of CNC vacuum pumps available today, such as rotary vane pumps, liquid ring pumps, and scroll pumps. Each type of pump has its own unique features and advantages, making them suitable for different applications.

Overall, the process of CNC vacuum pump is crucial to the success of many industrial and manufacturing processes. Without these pumps, it would be challenging to achieve the level of precision and accuracy required in today’s complex manufacturing systems.

How to use Cnc Vacuum Pump

CNC (Computer Numerical Control) machines require a vacuum pump to hold the workpiece in place during the cutting process. The vacuum pump is an important part of the CNC system as it ensures accuracy, consistency and efficient production. Here is a brief guide on how to use a CNC vacuum pump:

1. Turn the machine on: Make sure the CNC machine is switched on and ready for operation.

2. Check the vacuum level: Before using the vacuum pump, check the vacuum level to ensure it is at the correct level for the size of workpiece you will be working with.

3. Connect the hose: Connect the vacuum hose to the vacuum pump and the machine.

4. Switch on the vacuum pump: Switch on the vacuum pump using the on/off switch on the pump. The pump will start working immediately and will create suction to hold the workpiece in place.

5. Secure the workpiece: Use the CNC machine’s clamps or other securing devices to ensure that the workpiece is held securely in place.

6. Monitor the vacuum level: Throughout the cutting process, monitor the vacuum level to ensure that it is maintained at the recommended level. If the level drops, it could affect the accuracy of the cutting and may need to be adjusted.

7. Turn off the vacuum pump: Once the cutting process is complete, switch off the vacuum pump and disconnect the hose.

In summary, using a CNC vacuum pump is a straightforward process that involves switching on the machine, connecting the vacuum hose, and monitoring the vacuum level. By following these steps, operators can ensure that the workpiece is held securely in place, resulting in precise, consistent and efficient production.

Selecting the Ideal Manufacturer Cnc Vacuum Pump

When it comes to selecting the ideal manufacturer CNC vacuum pump, there are a number of factors to consider. First, it is important to assess the specific needs of your CNC machine and determine what type of vacuum pump will be most effective for your operations. From there, it is important to research different manufacturers and compare their products in terms of quality, reliability, and cost.

One important factor to consider is the level of customization that a manufacturer can provide. Some vacuum pump manufacturers offer a range of customizable options, such as various sizes, flow rates, and materials to suit specific needs. It is important to choose a manufacturer that can create a vacuum pump that meets your exact specifications and requirements.

Another key consideration is the level of technical support and customer service provided by the manufacturer. It is important to choose a company that has a strong reputation for reliability and customer satisfaction, and that offers comprehensive technical support and assistance whenever necessary.

Ultimately, the ideal manufacturer CNC vacuum pump will be one that offers a combination of high-quality products, customizable options, competitive pricing, and excellent customer service and technical support. By carefully assessing your specific needs and researching your options, you can make an informed decision that will help you maximize the efficiency and productivity of your CNC machine.

list FAQ with answer about Cnc Vacuum Pump

What is a CNC Vacuum Pump?

A CNC vacuum pump is a device designed to extract air or gas molecules from a sealed chamber, creating a partial vacuum that can be used to hold workpieces in place during machining. CNC vacuum pumps are often used in computer numerical control (CNC) machines to ensure precise cutting and drilling without the need for additional clamps or fixtures.

What are the advantages of using a CNC vacuum pump?

Using a CNC vacuum pump has several advantages, including increased accuracy and efficiency during machining, the ability to hold irregularly shaped or delicate workpieces, and a reduction in material waste and damage caused by clamps or fixtures.

What types of CNC vacuum pumps are available on the market?

CNC vacuum pumps come in a variety of types, including oil-sealed rotary vane pumps, dry screw pumps, and liquid ring pumps. Each type has its unique strengths and weaknesses, so choosing the right one depends on individual needs and preferences.

How do I select the right CNC vacuum pump for my application?

Selecting the right CNC vacuum pump depends on several factors, including the size and weight of the workpiece, the material being machined, and the desired level of vacuum. Consulting with a qualified expert in the field can help determine which pump is best suited for a particular application.

How do I install and maintain my CNC vacuum pump?

Installation and maintenance of a CNC vacuum pump vary depending on the type and model of the pump. However, in general, it’s crucial to follow the manufacturer’s instructions carefully and perform regular maintenance, such as changing filters and cleaning the pump, to ensure optimal performance.

In conclusion, a CNC vacuum pump is a valuable piece of equipment in the machining industry, offering numerous benefits to improve accuracy, efficiency, and safety. By understanding these common FAQs, individuals can make informed decisions about selecting and maintaining their CNC vacuum pump for maximum performance and long-term reliability.

Things to Consider When Purchasing Cnc Vacuum Pump

When purchasing a CNC vacuum pump, there are several factors to consider before making a final decision.

Firstly, it is important to ensure that the pump has sufficient power to effectively hold down the material being processed. The strength of the vacuum pump must be sufficient to prevent materials from moving during processing.

Secondly, the size of the vacuum pump should be considered. The size of the pump will depend on the size of the CNC machine and the volume of material being processed. A larger machine will require a larger pump, and vice versa.

Thirdly, the maintenance requirements of the vacuum pump should be considered. Some pumps require regular cleaning, oiling, or servicing to maintain optimal performance. It is important to factor in the cost of maintenance when considering the overall cost of the pump.

Fourthly, the noise level of the pump should be considered. This is especially important for businesses that require a quiet working environment. Pumps with higher noise levels may be disruptive to the workplace, so quieter models should be considered in such cases.

Finally, the durability and reliability of the pump should also be considered. A high-quality pump will last longer and require less maintenance than a lower quality model. It is important to purchase a pump that will withstand the rigors of the operation and provide long-term value.

In conclusion, when purchasing a CNC vacuum pump, it is important to consider the power, size, maintenance requirements, noise level, and durability of the pump to ensure optimal performance and long-term value.

Properties of Cnc Vacuum Pump

CNC vacuum pumps are fundamental components of CNC machines. Without these pumps, CNC machines would not be able to function properly. These vacuum pumps work by sucking air from within the CNC machine, which creates a vacuum that holds material in place during the machining process.

One of the key properties of CNC vacuum pumps is their ability to create a strong and stable vacuum. This vacuum can hold materials securely in place, even during high-intensity machining processes. This is important because a weak vacuum could lead to movement of the material during the machining process, resulting in less precision and accuracy of output.

Another property of CNC vacuum pumps is their reliability. These pumps are designed to operate for long periods without needing maintenance or repair. This is essential as CNC machines typically operate for extended periods, and any breakdown would lead to a significant loss of productivity.

CNC vacuum pumps are also highly efficient, consuming minimal energy while providing high suction power. This is crucial as CNC machines consume a lot of power, and any additional energy consumption could add up to significant costs over time.

In conclusion, CNC vacuum pumps are essential components of CNC machines. Their strong vacuum, reliability, and efficiency make them indispensable for the successful operation of these machines. It is critical to select a vacuum pump that is designed to meet the specific requirements of the CNC machine in use to ensure optimum performance and durability.

Technical Parameters Terms for Cnc Vacuum Pump

A CNC vacuum pump is a vital component in most CNC machines used in manufacturing processes. It ensures the machine’s suction system works optimally and supports the safe and efficient movement of materials during processing. To understand how a CNC vacuum pump works, it’s crucial to grasp the technical parameters or terms used to describe it.

One crucial parameter is the airflow capacity of the pump, measured in cubic feet per minute (CFM). This capacity determines the maximum amount of air that the pump can move. A high CFM rating means the pump can work faster and support larger machining volumes. Another critical parameter is the vacuum level or pressure, defined in inches of mercury (Hg), that the pump can achieve. This level is critical to ensure proper material holding capacity, and a higher vacuum level indicates a stronger holding force.

The pump’s motor power is another important parameter that determines its ability to suck up debris and handle heavier materials. Motor power is measured in horsepower (HP) and varies, depending on the pump model. A higher horsepower rating means the pump can move more material or debris with ease. In addition, the suction port diameter is also considered. The port diameter is the size of the opening where the materials are drawn up, measured in inches. A larger port means more substantial equipment can be moved and supported.

The last critical parameter in CNC vacuum pumps is noise level or decibel (dB) rating. While all motors make some noise, a noisy pump can be a significant disruption in the workspace. Manufacturers aim to reduce noise as much as possible for a better working environment.

In conclusion, understanding these technical parameters when buying a CNC vacuum pump can ensure you get the right product for your needs. It’s also important to note that these parameters vary depending on the pump model and brand. Before making any purchase, ensure you study the parameters, plus other features that may be relevant to your specific manufacturing needs.

Cnc Vacuum Pump Price

CNC vacuum pumps are an essential part of any CNC machine. They help to hold down workpieces during the cutting and milling process, ensuring precision and accuracy. However, one of the major concerns for anyone looking to purchase a CNC vacuum pump is the price.

CNC vacuum pumps can vary in price depending on the brand, size, and capabilities. On average, the cost of a standard CNC vacuum pump ranges between $500 and $1500. However, high-end models with more advanced features can cost upwards of $3000-$5000.

It’s essential to consider the type of pump best suited for your CNC machine, taking into account the size of the bed and the weight of the material you want to hold down. A smaller CNC machine with a smaller bed and lightweight materials will require a smaller pump, which will be less expensive than a larger machine.

Factors such as vacuum level, noise level, and power efficiency can also affect the price of a CNC vacuum pump. Some models may include additional features such as built-in filtration systems, easy maintenance, and safety features, which can add to the cost.

It’s crucial to weigh the cost against the benefits of owning a CNC vacuum pump. Investing in a high-quality vacuum pump can save you time, increase efficiency, and reduce material waste, resulting in a faster return on investment. Additionally, choosing an energy-efficient model can save you money in utility costs over time.

In conclusion, when considering the cost of a CNC vacuum pump, it’s essential to take into account the machine’s size, material size and weight, and specific features required. While pump prices can vary greatly, investing in a quality unit can offer significant benefits and savings in the long run.