Knowledge about Concrete Planer

A concrete planer, also known as a concrete grinder or scarifier, is a tool used to level, smooth, or remove unwanted material from concrete surfaces. Knowledge about concrete planers is important because they can help you achieve a professional and clean finish on your concrete projects.

There are various types of concrete planers available in the market, each with its own unique features and capabilities. Some planers have single rotating heads while others have twin rotating heads to effectively remove material from large surfaces. They also come in different sizes, ranging from handheld models to larger machines that can be attached to vehicles.

When using a concrete planer, it is important to ensure that you have the right safety gear on, including safety goggles, earplugs, gloves, and protective clothing. Concrete planers can produce a lot of dust and debris, so a dust extraction system should also be used to avoid inhaling dust particles that can cause respiratory issues.

It is essential to have a good understanding of the grinding or scarifying process and techniques to achieve the desired finish. Many professionals recommend using diamond cutter heads, which produce a more consistent and smooth finish, reducing the need for additional surface finishing.

Knowledge about concrete planers also involves proper maintenance and cleaning practices. Blades need to be inspected regularly to avoid damage and the buildup of residue, which can affect the performance. It is also important to replace blades when they become worn out, as using old or damaged blades can lead to poor or inconsistent results.

In conclusion, knowledge about concrete planers is essential for achieving professional concrete surfaces, and proper safety precautions, techniques, and maintenance practices should be followed to ensure the best results.

Various Types of Concrete Planer

Concrete planers or scarifiers are machines that are used for removing rough surfaces on concrete floors. There are different types of concrete planers available in the market, each with unique features and benefits.

The first type of concrete planer is the walk-behind planer, which is used for large-scale concrete floor removal. These heavy-duty machines are powered by gas and feature rotating blades that are designed to grind down concrete surfaces. Walk-behind planers are suitable for warehouses, parking lots, and industrial floors.

The second type of concrete planer is the handheld planer, which is designed for smaller concrete surface areas. These compact machines are perfect for removing coatings, paint, and uneven surfaces on concrete floors. Handheld planers are lightweight and easy to operate, and they are suitable for DIY projects and small-scale commercial jobs.

The third type of concrete planer is the drum-type planer, which features a rotating drum that removes concrete surfaces in sections. These machines are perfect for removing high spots, trip hazards, and uneven surfaces on concrete floors. Drum-type planers are versatile and suitable for both commercial and residential applications.

The fourth type of concrete planer is the milling planer, which is designed for concrete leveling and restoration. Milling planers are equipped with multiple cutting heads that work together to remove concrete surfaces evenly. These machines are suitable for large-scale commercial projects and offer precise concrete surface preparation.

In summary, there are different types of concrete planers available in the market, each with unique features and benefits. Choosing the right concrete planer depends on the nature and scope of the project. Walk-behind planers are suitable for large-scale projects, handheld planers are perfect for DIY projects and small-scale commercial jobs, drum-type planers are versatile, and milling planers are designed for large-scale commercial projects.

FAQ sourcing Concrete Planer manufacturer from China

Concrete planers are machines used for grinding and planning rough or uneven concrete surfaces. If you are looking for a reliable Concrete Planer manufacturer from China, you might have several questions in mind. Here are some of the frequently asked questions (FAQ) you may have and the answers to help you better understand the sourcing process.

Q: What should I consider when choosing a Concrete Planer manufacturer from China?

A: You should consider factors such as the manufacturer’s reputation, industry experience, product quality, certifications and after-sales service.

Q: How can I verify the quality of the products supplied by a Chinese manufacturer?

A: You can request product samples, visit the manufacturer’s facilities in China, or conduct third-party quality tests.

Q: What is the average lead time for Concrete Planer orders from China?

A: The lead time may vary depending on the manufacturer’s production capacity, order quantity, and shipping arrangements. However, on average, it may take 30-60 days for the production and shipment of Concrete Planers from China.

Q: Can I get a customized Concrete Planer from a Chinese manufacturer?

A: Yes, most Chinese manufacturers offer customization options for their products, including Concrete Planers. You can provide your specifications and requirements to the manufacturer and they will tailor-make the machine according to your needs.

Q: What are the payment terms when sourcing Concrete Planers from China?

A: The payment terms may vary depending on the manufacturer’s policies. However, most manufacturers require a deposit upfront and the balance payment before shipment.

In conclusion, sourcing a Concrete Planer manufacturer from China may seem daunting, but it can be made easier by doing thorough research, choosing reputable manufacturers, verifying product quality, and discussing customization and payment options with the supplier.

Applications of Concrete Planer

When it comes to smoothing and leveling concrete surfaces, one of the most useful tools is a concrete planer. These devices have become increasingly popular and are now commonly used in a variety of different applications.

One of the most common uses for concrete planers is in the construction industry. These tools are ideal for preparing concrete surfaces for new construction or renovation projects. They can help remove old coatings or adhesive residue, and can also level surfaces to make room for new flooring or other installations.

In addition to construction, concrete planers are also used in high-performance concrete repair applications. These tools are typically used to repair damaged concrete surfaces, such as highways or airport runways. With their high power, they can quickly remove damaged areas, leaving a smooth and even surface. This can then be finished with a specialized concrete product to complete the repair.

Another common use for concrete planers is in the preparation of concrete surfaces for polishing. Concrete polishing is a popular technique used to create a high gloss finish on concrete surfaces. To achieve this, the surface must first be leveled and smoothed. This is where a concrete planer comes in, allowing for a perfectly smooth surface to be prepared for the subsequent polishing process.

Finally, concrete planers are also commonly used for removing surface blemishes or stains. These tools can easily remove surface marks and finishes that have been applied to concrete surfaces, making it possible to achieve a clean and even surface.

In conclusion, concrete planers have become an essential tool for a wide range of different applications, from construction to concrete repair and polishing. With their high power and precision, they provide a perfect solution for preparing and leveling concrete surfaces regardless of the specific need.

Manufactured Products made of Concrete Planer

Concrete planers, also known as concrete grinders or scarifiers, are machines that are used to level and smooth concrete surfaces. These machines are used primarily in the construction industry and are used to prepare concrete surfaces for new installations or to repair damaged surfaces. In recent years, manufacturers have started to use concrete planers to make a range of manufactured products.

One of the most popular manufactured products made using concrete planers is decorative concrete tiles. These tiles are available in a range of colors and designs and can be used both indoors and outdoors. They are made by pouring a mix of Portland cement, water, and aggregate into molds, which are then smoothed using a concrete planer. Once they are dry, they are sealed to protect them from the elements.

Another popular product made using concrete planers is countertops. Concrete countertops are becoming more popular because they offer a unique and durable surface that can be customized to fit any design style. The countertops are made by pouring a mix of concrete into molds, which are then smoothed using a concrete planer. Once they are dry, they are sealed to protect them from staining and damage.

Concrete furniture is also becoming increasingly popular, and concrete planers are used to create the smooth finish on these pieces. Tables, chairs, and benches can all be made using concrete, and by using a concrete planer, the surface can be smoothed to create a polished look.

Finally, concrete planers can be used to create industrial products such as concrete pipes and precast concrete panels. These products are made on an industrial scale and are used in construction projects around the world.

In conclusion, concrete planers are essential to the manufacturing of a wide range of products. From decorative tiles to industrial pipes, these machines are used to create products that are durable, customizable, and long-lasting. As the demand for sustainable and eco-friendly building materials grows, it is likely that the use of concrete planers in manufacturing will only continue to increase.

The Evolution history of Concrete Planer

The concrete planer has come a long way in its evolution from its early beginnings as a simple tool used to smooth out surfaces. From the early development of hand-held planers to the advanced technology of today’s planers, the evolution of the concrete planer has been significant.

The earliest concrete planers were hand-held devices, developed in the early 1900s. These tools consisted of a blade attached to a handle that could be used to smooth out rough surfaces. Hand-held planers were used to prepare surfaces for cement and concrete finishes, and were an essential tool for workers in the construction industry.

As the construction industry continued to grow and develop, so did the demand for more efficient and effective tools. The early 1960s saw the introduction of power-driven concrete planers, which were able to significantly speed up the smoothing process. These early powered planers were heavy and cumbersome, but they paved the way for development of even more advanced models.

In the 1980s, the introduction of diamond blade technology revolutionized the concrete planer industry. Diamond blades were able to cut through concrete with much greater accuracy and efficiency, allowing for smoother finishes and more precise cuts. The introduction of diamond blades also reduced the amount of dust and debris produced during the cutting process, making it safer and healthier for workers.

Modern concrete planers continue to utilize diamond blade technology, but now incorporate additional features such as variable speed control, easy blade changes, and vacuum systems to collect dust and debris. These advancements in technology have allowed for more precise and efficient cuts, reducing the need for additional touch-up work.

In conclusion, the evolution of the concrete planer has been driven by the demand for higher efficiency and greater precision. From its early beginnings as a simple hand-held tool to today’s advanced models, the concrete planer continues to play an important role in the construction industry.

The Process of Concrete Planer

The process of concrete planer is a method of preparing a concrete surface for various purposes. A concrete planer is a machine that uses a rotating drum or blade with steel cutters to remove and level the top layer of a concrete slab. This process is also known as concrete milling or grinding.

The first step in the process of concrete planer is to prepare the surface by removing all obstacles like nails, bolts, or any other debris. Then, the machine is started, and the blade is adjusted to the depth required to remove the top layer of the concrete. The machine is then moved back and forth, systematically grinding away the old surface until the desired level is achieved.

There are many benefits to using a concrete planer. One primary advantage is that it creates a smooth surface, which is essential for a polished concrete finish or other decorative treatments. It also eliminates unevenness, damage, and imperfections on the concrete surface.

Concrete planer is commonly used in commercial, industrial, and residential settings. It is ideal for refurbishing concrete floors, parking lots, and pavements. It can also be used to level concrete surfaces for different purposes, such as installing carpet, tiles, or vinyl flooring.

Overall, the process of concrete planer is an essential method for preparing concrete surfaces for various purposes. It is a cost-effective and efficient way of creating a smooth, level surface that is suitable for a wide range of applications. As with all industrial equipment, it is important to hire an experienced professional with proper training and certification to operate the machine safely and effectively.

Benefits Advantages of Utilizing Concrete Planer

A concrete planer is a powerful tool that has revolutionized the concrete industry. It is a machine that is used to level, smooth, or remove concrete surfaces, making it an essential tool for anyone working with concrete surfaces. There are many benefits to utilizing a concrete planer, some of which include:

1. Versatile use

A concrete planer can be used for a wide range of concrete applications. It can be used for smoothing rough concrete surfaces to make them more even, removing old coatings or layers of concrete, or exposing aggregate to create a decorative finish. This versatility makes it a valuable tool for anyone working with concrete surfaces.

2. Saves Time

Concrete planers make quick work of leveling uneven surfaces and removing layers of concrete. This means that you can get more work done in less time. Because of their efficiency, they can save you a significant amount of time and labor.

3. Accurate Results

Concrete planers are a highly accurate tool that can level concrete surfaces to within a fraction of an inch. This accuracy ensures that the final finish is smooth and even, which is critical for high-quality concrete surfaces.

4. Cost-effective

Utilizing a concrete planer can help save money in the long run. Instead of having to remove and replace entire concrete slabs. This will save time and money on labor and material, as well as reducing the amount of waste generated.

5. Easy to Use

Concrete planers are easy to use, even for people with minimal experience with concrete surfaces. They are designed to be simple and straightforward, with clear instructions that make them easy to operate.

In conclusion, the benefits and advantages of using a concrete planer are numerous. From saving time and money to achieving accurate and smooth finishes, it is evident that this tool is an essential investment for anyone working with concrete surfaces.

Disadvantages Concrete Planer

Concrete planer has been widely used in construction and renovation processes for its ability to level uneven surfaces, remove excess concrete, and prepare floors for coatings. However, it is important to know that this tool also comes with several disadvantages that cannot be ignored.

Firstly, concrete planers are loud and produce high levels of noise that can be disturbing and hazardous to the operator’s hearing. The noise level can range between 90-100 decibels, which is above the recommended safe sound level for prolonged exposure. It is essential to use hearing protection while operating this tool to avoid permanent damage to the ears.

Secondly, concrete planers generate a lot of dust as they grind and remove the concrete surface. The dust can cause respiratory problems and health hazards to the operator and anyone working in the area. The dust also settles on surrounding surfaces and can cause damage to nearby equipment and facilities, leading to maintenance costs.

Thirdly, concrete planers are heavy and challenging to maneuver, especially for extended periods. The weight of the machine can cause muscle strains, fatigue, and other physical injuries to the operator. The operator must take regular breaks to avoid over-exertion and ensure that they are physically fit to operate the tool.

Lastly, concrete planers are expensive, and not everyone can afford to purchase them or rent them for an extended period. Furthermore, the maintenance costs can be high, especially if there are frequent breakdowns or damages. It is important to evaluate the cost-benefit of using a concrete planer before investing or using it in a project.

In conclusion, Concrete planers are highly useful and have transformed the construction industry, but they come with several disadvantages that need to be considered. The noise level, health hazards, weight, and costs associated with concrete planers are factors that must be taken into account before using them to ensure safety, efficiency, and cost-effectiveness.

Selecting the Ideal Manufacturer Concrete Planer

Choosing the right concrete planer manufacturer can be a daunting task, as there are several manufacturers and models to pick from. However, making an informed decision about the ideal concrete planer is crucial to ensure a smooth and efficient concrete planning operation.

Firstly, it’s crucial to identify the purpose of the planer. Will it be for industrial, commercial, or residential usage? Based on this, you can shortlist the manufacturers that specialize in producing planers for your intended use.

Secondly, it’s imperative to consider the construction of a planer. Consider the quality of the materials and the technology used in designing it. Professional manufacturers use cutting-edge technology, ensuring their planers are durable and can withstand rigorous use.

The third aspect to consider is the frequency of usage of the concrete planer. If you only plan on using it occasionally, it’s better to opt for a lightweight and less powerful model, whereas if you plan on using it professionally, a more powerful and robust model would be ideal.

Next is the surface area that you need to cover. It’s essential to choose a concrete planer that can cover a larger surface area within a short period. Most manufacturers include this information in the specification of their products, thus making it easy for you to make an informed choice.

The fifth aspect to consider is the cost of purchasing a concrete planer. Choose a planer that offers value for money, one that is affordable, and can deliver high-quality performance.

Finally, choose a manufacturer that offers excellent customer service, including warranties, installation service, and technical support. This will give you peace of mind knowing that you have access to assistance when required.

In conclusion, choosing the ideal concrete planer manufacturer requires careful consideration of several factors, including the intended use, construction of the planer, frequency of use, surface area to be covered, cost, and customer service. Taking these factors into account will help you make an informed decision and select a planer that meets your specific needs.

Things to Consider When Purchasing Concrete Planer

Purchasing a concrete planer can be a significant investment, and therefore, it’s essential to consider a few factors to ensure you get the right tool for the job. Here are some things to keep in mind when buying a concrete planer:

1. Planer Size: Concrete planers come in various sizes, and the size you choose will depend on the size of the project you’re working on. For instance, if you’re planning to work on a small project, a compact planer model will be ideal. However, if you’re working on a large-scale project, a larger planer will be more efficient.

2. Cutting Depth: The depth of cut is an important consideration when selecting a planer. You’ll want to choose a planer that can cut deep enough to remove the unwanted layer effectively. It’s important to note that planers with larger cutting depths are more expensive.

3. Cutter Type: Concrete planers come with various cutter types, including diamond, tungsten carbide, and steel cutters. Diamond cutters are more expensive but are more effective in cutting through tough concrete surfaces. Tungsten carbide blades are durable and are ideal for cutting through soft and hard concrete surfaces. Steel blades are more affordable but are less effective than diamond and tungsten carbide cutters.

4. Dust Control: When planing concrete, dust is inevitable. You’ll want to choose a planer that comes with a dust collection system or one that allows you to attach a vacuum cleaner to collect the dust.

5. Power Source: Concrete planers are available in electric, pneumatic, and gas-powered models. Electric planers are the most common and less expensive. However, pneumatic and gas-powered models are more powerful and are ideal for larger projects.

In conclusion, when purchasing a concrete planer, it’s essential to consider the size of the planer, the cutting depth, cutter type, dust control, and power source. By taking these factors into consideration

Properties of Concrete Planer

A concrete planer, also known as a concrete grinder or scarifier, is an essential tool for smoothing and leveling concrete surfaces. It is used for a range of applications, from removing surface imperfections and coatings to preparing concrete for a new layer of coating or finishing.

The key properties of a concrete planer are its power, speed, and versatility. They are designed to remove thick coatings and uneven surfaces quickly and easily, resulting in a perfectly smooth finish. Some models are equipped with multiple cutting heads, allowing the operator to adjust the depth and speed of the cut.

In terms of power, concrete planers typically range from 5 to 20 horsepower. The higher the horsepower, the more powerful and efficient the machine is. However, the power of the machine must be matched to the job size, as a larger machine may be too powerful for smaller jobs.

The speed of a concrete planer is also a crucial factor. The faster the machine can operate, the more productive the operator can be. Some models are equipped with adjustable speed controls, allowing the operator to optimize the machine’s speed for the job they are working on.

Versatility is another important property of a concrete planer. They can be used to remove a variety of coatings, including epoxies, urethanes, and other protective coatings. Additionally, they are effective at removing uneven surfaces caused by spalling, cracking, or settling.

Overall, a concrete planer is an essential tool for any concrete professional. Its power, speed, and versatility make it the go-to tool for preparing concrete surfaces for a new layer of coating or finishing, resulting in a perfectly smooth and even surface every time.

How to use Concrete Planer

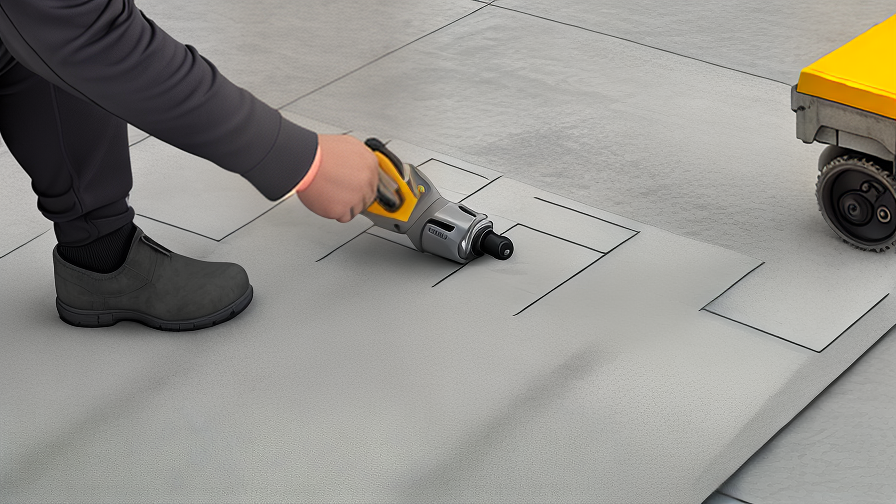

A concrete planer is a useful tool for creating a smooth finish on concrete surfaces. It can be used for a variety of applications from removing old coatings and paint to leveling uneven floors.

To use a concrete planer effectively, there are a few key steps to follow. First, ensure that you have the appropriate safety equipment, including ear protection, eye protection, and a dust mask.

Next, adjust the blade depth on the planer to the desired level. For removing a thin layer of material, a shallow depth setting is appropriate, while deeper levels can be used for more significant material removal. Be sure to keep the blade level as you work to avoid creating low spots in the concrete.

Start the planer and begin moving it in a straight line across the concrete surface. Be sure to maintain consistent pressure on the planer to ensure an even cut. For larger areas, it may be helpful to break the work into sections and work in parallel lines.

As you work, use a broom or vacuum to remove excess concrete dust and debris. This will prevent the particles from clogging the planer or damaging the motor.

Remember to take breaks as needed to rest your arms and give the planer a chance to cool down. When you’re finished, switch off the tool and carefully remove the blade for cleaning and storage.

Overall, using a concrete planer requires careful attention to safety and technique. With the right approach, however, it can be a valuable tool for achieving a smooth, even finish on concrete surfaces.

Glossary Terminology Terms for Concrete Planer

A concrete planer is a powerful tool that is used for smoothing and leveling concrete surfaces. It is an essential piece of equipment for anyone working in the construction or remodeling industry. But if you are new to this field, you might find some of the terminology associated with concrete planers confusing. Below, we have compiled a glossary of some of the commonly used terms associated with concrete planers to help you understand them better.

1. Concrete Planer: A tool used for smoothing and leveling concrete surfaces.

2. Cutter Drum: A rotating cylinder with blades or teeth that grinds the surface of the concrete.

3. Cutting Depth: The depth to which the cutter drum can make cuts into the concrete surface.

4. Flush Cut: A cut made by the cutter drum that results in a smooth, flat surface.

5. Dust Collection: The process of collecting dust generated during the planing process to minimize airborne dust.

6. Diamond Cutters: Cutters made with diamond particles for more effective and efficient cutting.

7. Drum Speed: The speed at which the cutter drum rotates.

8. Walk-Behind Planer: A planer that is pushed and guided by an operator.

9. Self-Propelled Planer: A planer that moves on its own without the need for an operator to push it.

10. Scarifier: A tool that uses a drum with steel teeth or blades for removing rough, uneven surfaces.

Understanding the terminology associated with concrete planers is crucial for ensuring that you use them correctly and efficiently. Whether you are a seasoned professional or new to the field, knowing these terms will help you communicate more effectively with your colleagues and clients. So, next time you work with a concrete planer, remember to use these terminologies accurately.

Concrete Planer Price

When it comes to removing or smoothing out uneven surfaces on concrete floors, walls, or curbs, a concrete planer is a must-have tool for any construction or renovation project. But just like any other construction equipment, the price for a concrete planer can vary depending on the features, specifications, and brand. In this article, we’ll explore the concrete planer price range and what factors affect the cost.

The average price for a concrete planer can range from $2,000 to $10,000, depending on the size and features. For example, smaller handheld planers are less expensive, usually costing around $2,000 to $3,000, while larger walk-behind models can cost upwards of $10,000. The power source can also impact the price, as electric planers are typically less expensive than gas-powered models.

Another factor that can affect the price is the cutting depth and width of the planer. Planers with a larger cutting width and depth are typically more expensive, but they can also complete the job much faster. Additional features such as adjustable handles, dust collection systems, and various cutting attachments can also increase the cost.

It’s important to note that buying a quality concrete planer is essential for ensuring the job is completed quickly and efficiently. Investing in a high-quality planer that is built to last can save you money in the long run, as cheaper models may need frequent repairs or replacements.

It’s also worth considering the cost of renting a concrete planer versus purchasing one. For smaller projects or occasional use, renting a planer may be more cost-effective. However, for larger or repeated jobs, buying a planer can ultimately save you money and provide convenience.

In conclusion, the price of a concrete planer can vary depending on several factors such as size, power source, cutting depth and width, and additional features. When considering a concrete planer, it’s important to take into account the quality and durability of the equipment to ensure