Benefits of Connector Manufacturer

Connector manufacturers are essential to the construction and development of modern industries. Their expertise in designing and producing connectors has made a significant impact on enhancing the overall productivity and efficiency of various industries. The benefits of connector manufacturers are relatively apparent, and they have proved to be a critical asset to many businesses. Below are the advantages of having a connector manufacturer on board.

Quality Products

Connector manufacturers are specialists in creating quality connectors used in various industries. Due to the high levels of expertise, the manufacturers can produce connectors that meet the specific needs of the industry. They understand how to design connectors that can withstand extreme environmental conditions and continuous usage. Therefore, clients only receive quality products that ensure safety and durability, which is crucial for an industry.

Cost-Effective

Connector manufacturers have the required expertise and technology to produce quality connectors at an affordable price. They have significant economies of scale, which means that they can produce more products with fewer resources, effectively reducing production costs. Furthermore, manufacturers have established relationships with suppliers, enabling them to acquire raw materials at an affordable price, thus reducing the overall manufacturing costs.

Customization

Innovative industries require customized connectors due to their unique applications. Connector manufacturers can develop connectors based on individual specifications and requirements. Therefore, clients can acquire connectors designed to meet specific industry needs, which positively impacts overall efficiency.

Technical Advice

Connector manufacturers’ expertise allows them to provide clients with technical advice on the best connectors to use for maximum efficiency. Manufacturers understand the precise requirements of each industry and can advise clients on connectors that will suit their individual need. In addition, they can provide technical support to help clients manage any issues that may arise with the connectors they produce.

In conclusion, connector manufacturers play a crucial role in various industries by producing quality connectors, customizing them to specific needs, providing technical advice, and reducing manufacturing costs. Therefore, industries that partner with connector manufacturers gain a competitive advantage over their rivals, as it allows them to concentrate on their core competencies with peace of mind.

Features of Connector Manufacturer

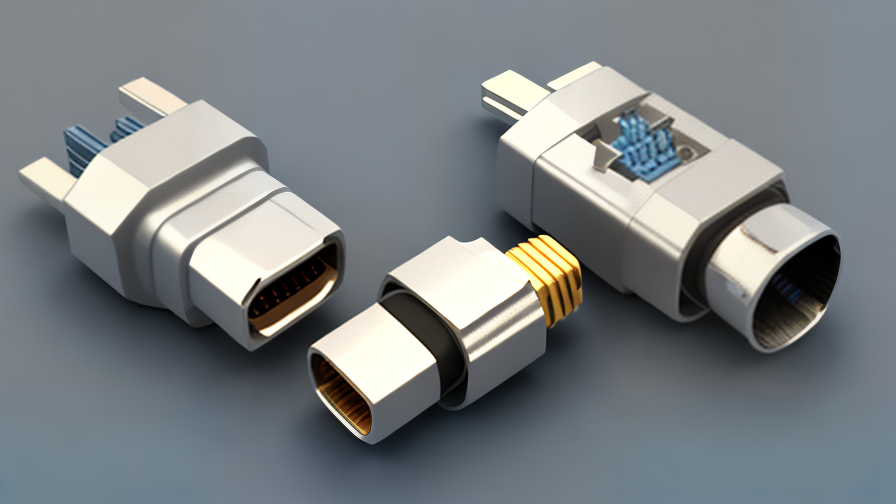

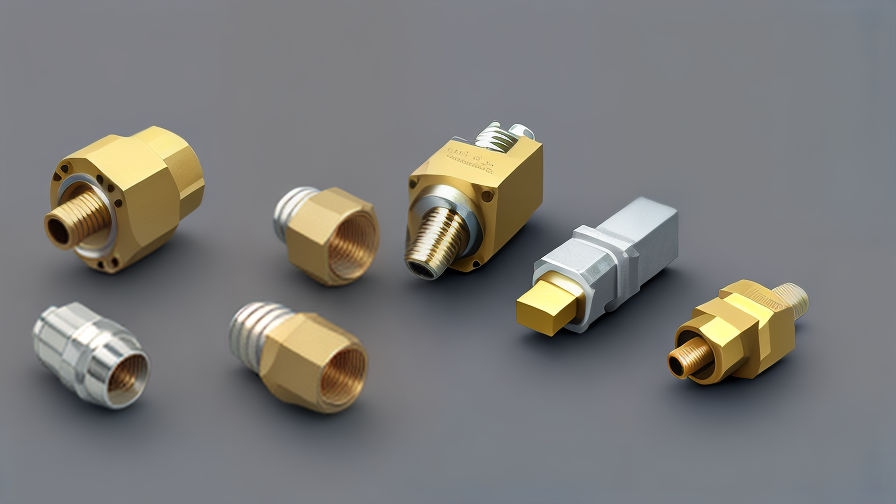

Connector manufacturers offer a wide range of products with varying features to cater to the needs of different industries. A good connector should achieve high levels of reliability, durability, and ease of use to create a dependable connection. Here are some of the main features that connector manufacturers offer.

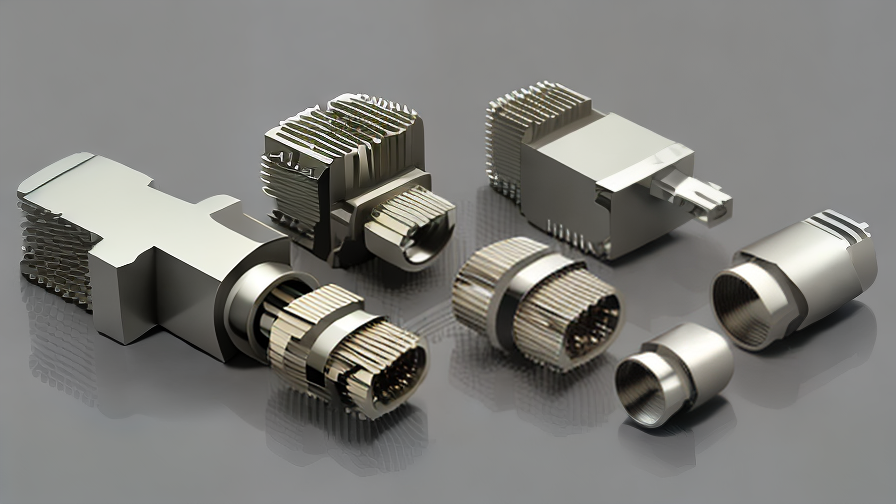

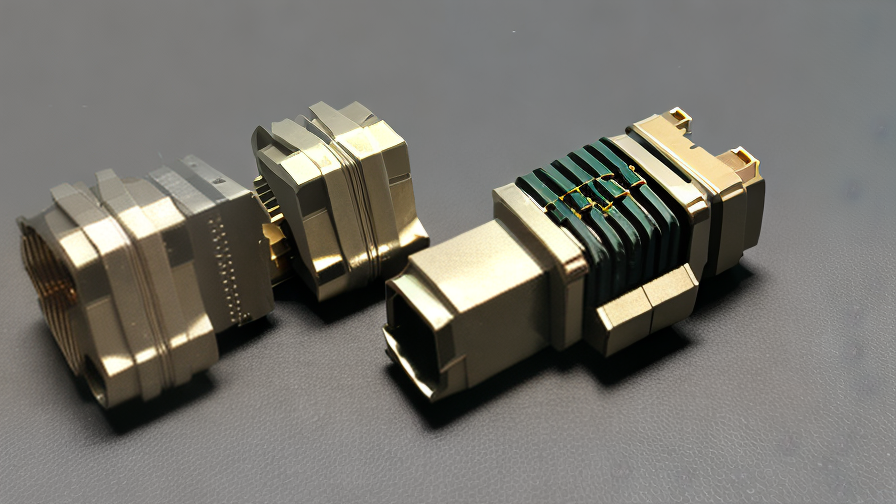

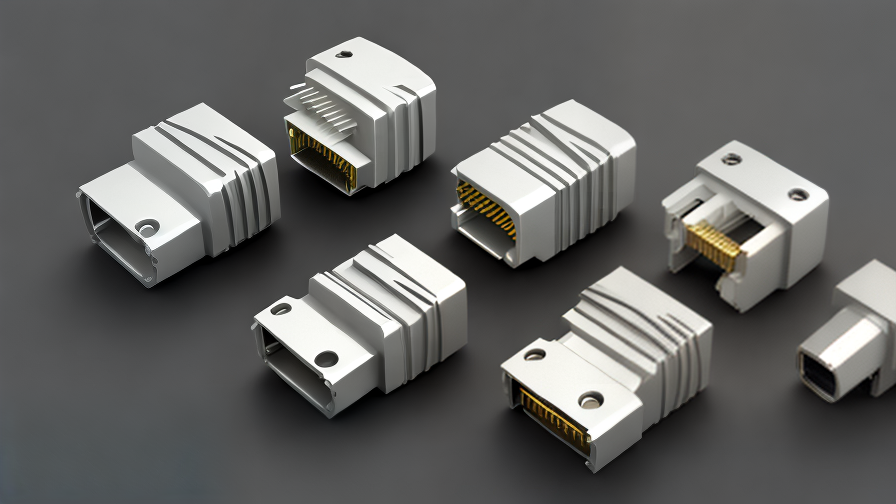

1. Connectors made from different materials – Connector manufacturers produce connectors made of different materials, including plastic, metal, and rubber. The choice of material depends on the application and environment in which the connector will be used.

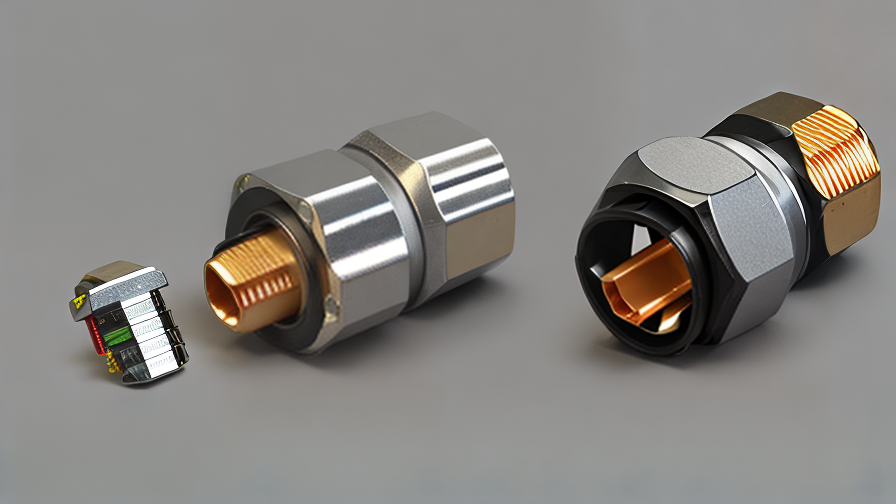

2. Waterproof connectors – Manufacturers offer waterproof connectors that can withstand moisture, dust, and other harsh environmental conditions. These connectors are mainly used in outdoor applications and for products that require submersion.

3. High-speed connectors – High-speed connectors support fast data transfer rates, making them ideal for applications such as digital cameras, video production, and streaming applications.

4. Shielded connectors – Shielded connectors protect against electromagnetic interference (EMI) and radio frequency interference (RFI). These connectors are ideal for use in areas with high electronic interference.

5. Circular connectors – Manufacturers produce circular connectors that offer a secure and reliable connection. These connectors are commonly used in military applications, aerospace, and in industrial control units.

6. PCB connectors – PCB connectors offer connections between printed circuit boards (PCBs) and are generally compact in size. They are ideal for high-density electronic designs, providing a durable and reliable connection.

7. Customization – Connector manufacturers offer customization to provide tailored solutions for different industrial applications. This flexibility ensures that customers only get the connectors that meet their unique needs.

The features offered by connector manufacturers differ depending on the application, industry, and product specifications. It is essential to work with a reputable connector manufacturer that can provide a product that meets all required standards, including durability, reliability, and ease of use.

Various Types of Connector Manufacturer

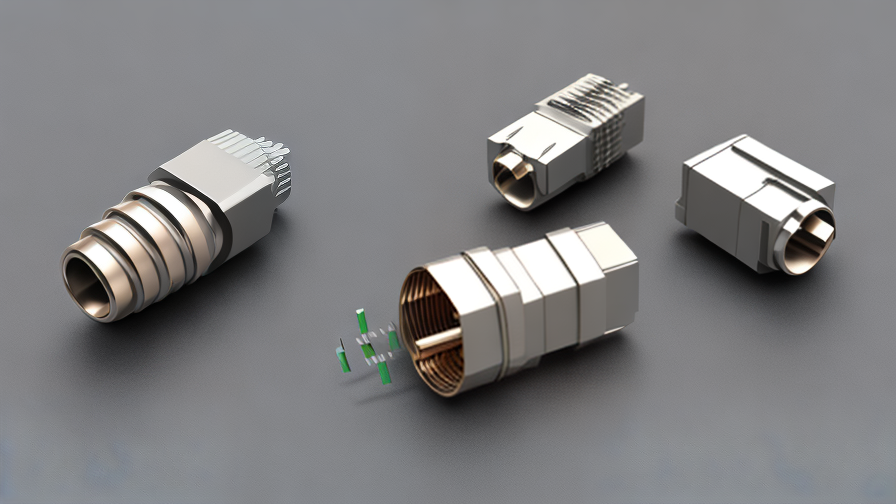

Connectors are essential components that facilitate the transfer of power or signals between different devices in electronic systems. There are various types of connector manufacturers that specialize in designing and producing connectors for specific applications. Here are some of the different types of connector manufacturers:

1. Standard Connector Manufacturers: Standard connector manufacturers produce connectors for general purposes that can be used in multiple applications. These connectors have a standardized design and features, making them easily available and affordable. They are commonly used in consumer electronics, industrial equipment, and telecommunications.

2. High-End Connector Manufacturers: High-end connector manufacturers produce connectors with advanced features and higher quality standards. These connectors are typically used in mission-critical applications like military equipment, medical devices, and aerospace. They have a higher price point and require specialized expertise to install and maintain.

3. Specialized Connector Manufacturers: Specialized connector manufacturers produce connectors for specific applications, such as automotive or audio equipment. They work closely with their clients to develop customized connectors that meet their specific needs. These connectors are typically more expensive and have longer lead times due to their customization.

4. Integrated Connector Manufacturers: Integrated connector manufacturers offer a comprehensive solution that combines connectors with other electronic components like sensors, cables, and circuit boards. These integrated connectors are used in applications that require high reliability, space-saving design, and complex functions. They are commonly used in industrial automation, automotive systems, and medical devices.

5. Regional Connector Manufacturers: Regional connector manufacturers cater to specific geographic regions and market segments. They focus on producing connectors that meet the unique requirements of their local customers, like language, environmental conditions, and regulatory compliance. These connectors are typically less expensive than branded products but can have lower quality and reliability standards.

In conclusion, choosing the right connector manufacturer is crucial for ensuring the performance, reliability, and cost-effectiveness of electronic systems. It is important to work with a manufacturer that has the expertise, resources, and experience that align with your specific application and requirements.

Applications of Connector Manufacturer

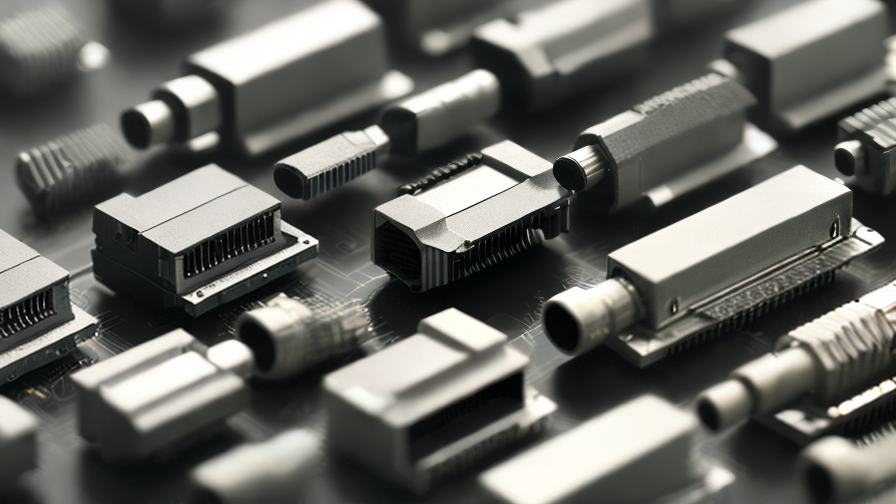

The importance of connectors in our everyday lives is often overlooked. However, connector manufacturers play a crucial role in designing and producing connectors for a wide range of applications. These connectors are used in various industries including automotive, aerospace, military, medical, telecommunications, and consumer electronics.

In the automotive industry, connectors are used in various applications such as engine control units, sensors, ignition systems, and power distribution. These connectors must be reliable and durable to withstand the harsh conditions of the automotive industry.

In the aerospace industry, connectors play a vital role in communication and control systems. Connectors must be able to withstand extremes of temperature, pressure, and vibration. The aerospace industry relies on high-quality connectors to ensure safe flight operations.

In the military, connectors are used in communication systems, radar, missiles, and other military equipment. These connectors must be rugged and able to withstand the extreme conditions of the battlefield.

The medical industry uses connectors in imaging and diagnostic equipment, monitoring devices, and electronic medical records. These connectors must be sterile and reliable to ensure the safety of patients.

In the telecommunications industry, connectors are used in fiber optic networks, cellular networks, and satellite communications. These connectors must be able to transmit signals with minimal loss and interference to ensure efficient and reliable communication.

In consumer electronics, connectors are used in smartphones, laptops, and gaming consoles. These connectors must be small and robust to withstand frequent use and transportation.

In conclusion, connector manufacturers are essential in designing and producing connectors for various applications in different industries. These connectors must meet specific requirements such as durability, reliability, and functionality to ensure the safety and efficiency of various systems. Advances in technology and further integration of devices will continue to drive the demand for high-quality connectors.

The Process of Connector Manufacturer

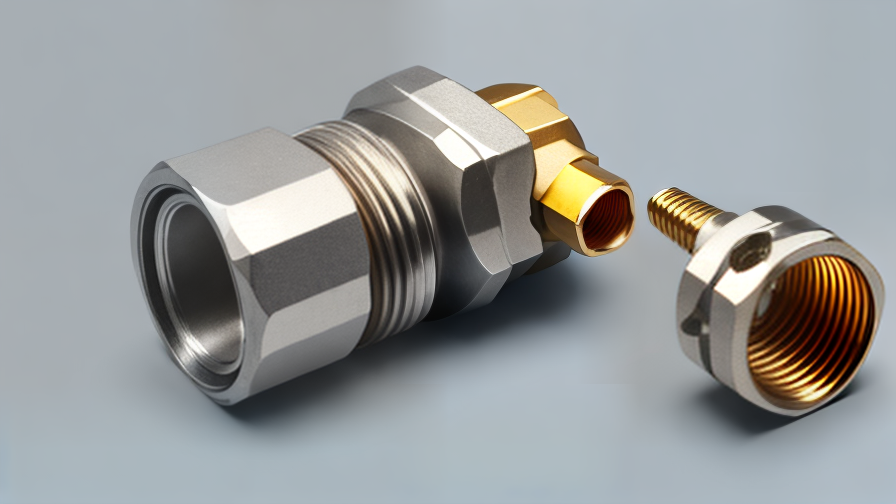

The process of connector manufacturer involves designing and producing electronic connectors that interface between different parts of an electronic system. Manufacturers design the connectors to enable easy installation and facilitate optimal electric transfer.

The process starts with the design stage where manufacturers work with their clients to create custom connectors that meet specific needs or adapt existing ones to suit unique applications. Some of the features manufacturers consider when designing connectors include the number and type of contacts, current carrying capacity, and environmental factors such as temperature, radiation, and humidity.

The next stage involves sourcing the raw materials required to design connectors. Manufacturers source high-quality metal alloys, plastic composites, and other materials needed to create connectors that can withstand harsh environments, impacts, and electromagnetic interference.

Once the raw materials are ready, manufacturers proceed to the production stage, where they use advanced machines like CNC and molding techniques to fabricate connectors. The production process involves the stamping of pins and sockets and molding to create plastic insulators and shells.

After production, the connectors are subjected to rigorous quality control procedures to ensure performance and reliability. Manufacturers use sophisticated testing equipment to verify the contact resistance, insulation resistance, and dielectric strength of each connector. This guarantees that the connectors meet international standards such as D-Sub, USB, and HDMI protocols.

Finally, connectors are packaged and shipped to clients all over the world. Manufacturers work with logistics partners to handle storage and transport of their products to ensure they reach their destination safely.

In conclusion, the process of connector manufacturing involves several stages, including design, sourcing raw materials, production, quality control, and shipping. Manufacturers must employ high and continuous quality control measures to produce standardized connectors that meet client specifications and international standards.

How to use Connector Manufacturer

Connector manufacturers offer a wide variety of products to meet the needs of different industries. From high-performance connectors that can transmit data at high speeds to ruggedized connectors that are designed to withstand harsh environments, there is a connector for almost every application.

When selecting a connector manufacturer, it is important to consider a few key factors. First, you should look for a manufacturer that has a good reputation for quality and reliability. This can be determined by looking at online reviews and ratings, as well as the manufacturer’s track record in the industry.

Second, you should consider the manufacturer’s range of products. Does the manufacturer offer a wide variety of connectors that can meet your specific needs? Are the connectors customizable to fit your unique requirements? Answering these questions will help you find a manufacturer that can provide the right connector solution for your application.

Once you have selected a connector manufacturer, the next step is to learn how to use their products effectively. This involves understanding the specifications and features of the connectors, as well as how to properly install and maintain them.

Most connector manufacturers provide detailed datasheets and user manuals that outline the specifications and features of their products. Reading through these documents can help you gain a better understanding of the connectors and how they work.

In addition, many manufacturers offer technical support and training services to help their customers use their products effectively. This can be particularly helpful if you are new to working with connectors or if you are using a new type of connector for the first time.

Overall, using a connector manufacturer involves selecting the right manufacturer, understanding their products, and learning how to use their connectors effectively. By following these steps, you can ensure that you are getting the most out of your connectors and that they are working as intended in your application.

Selecting the Ideal Manufacturer Connector Manufacturer

When it comes to selecting the ideal connector manufacturer, there are a variety of factors that must be taken into account. Connectors are an essential part of any technology product, and therefore, selecting the right manufacturer can make a significant difference in the final product quality.

One of the primary factors to consider is the manufacturer’s experience in the field. The longer the manufacturer has been in business, the greater the likelihood that they have experience in a range of products and industries. Moreover, well-established manufacturers have a reputation for reliability and can be trusted to deliver high-quality products.

Another important factor to consider is the manufacturer’s product range. Manufacturers that offer a broad range of products typically have a more comprehensive understanding of the industry’s demands and requirements. Moreover, manufacturers who can offer a variety of products can provide more solutions to your technology’s unique needs.

The manufacturer’s location is another factor that must be taken into consideration. It is recommended selecting a manufacturer who is located near your production facilities. This can help reduce transport time and costs and enable prompt delivery of connectors when needed.

Lastly, it is essential to consider the manufacturer’s quality assurance. The ideal connector manufacturer should have ISO 9001:2015 certification, which is the international standard for quality management. Moreover, the manufacturer should have a rigorous quality control process in place to ensure the products’ consistency and reliability.

To conclude, selecting the ideal connector manufacturer is critical to your technology’s success. Consider the manufacturer’s experience, product range, location, and quality control process when making your decision. By doing so, you can rest assured that your product will have the best connectors possible.

list FAQ with answer about Connector Manufacturer

A connector manufacturer is a company that produces electronic connectors for use in a wide range of applications. These connectors are used to link components in electronic devices, and they are essential for ensuring that complex systems perform reliably and efficiently.

Listed below are some frequently asked questions about connector manufacturers, along with their answers:

Q: What types of connectors do connector manufacturers produce?

A: Connector manufacturers produce a wide range of connectors, including power connectors, signal connectors, RF connectors, fiber optic connectors, and more. They also offer a range of accessories and tools to help users install and maintain these connectors.

Q: What are the most important factors to consider when choosing a connector manufacturer?

A: When choosing a connector manufacturer, it’s important to consider factors such as product quality, product performance, price, customer service, and delivery times. You should also look for a manufacturer with a strong reputation in the industry and a proven track record of supplying high-quality connectors to customers.

Q: How can I be sure that a connector manufacturer’s products are reliable and high-quality?

A: To ensure that a connector manufacturer’s products are reliable and high-quality, you should look for manufacturers that use advanced manufacturing processes and materials. You should also look for manufacturers that have a proven track record of producing reliable and effective connectors for a wide range of applications.

Q: How can I get in touch with a connector manufacturer to discuss my requirements?

A: Most connector manufacturers have websites that provide contact details for their sales and customer service teams. Alternatively, you can search for connector manufacturers using online directories or industry publications.

Q: Can connector manufacturers provide custom solutions for my specific needs?

A: Yes, many connector manufacturers offer custom solutions for specific requirements. Custom connector designs can be developed based on specific technical requirements or specific applications.

In conclusion, connector manufacturers produce a range of connectors to address different market needs. Factors to consider when choosing a connector manufacturer include product quality, product performance, price, customer service, and delivery times. It is important to verify the reliability and quality of manufacturers’ products before making a purchase. Customers can also seek custom solutions tailored to their specific requirements.

Things to Consider When Purchasing Connector Manufacturer

When it comes to purchasing a connector manufacturer, there are a few things you should keep in mind. These are essential to ensure that you get a trusted and reliable business partner that provides you with high-quality connector solutions that meet your specific needs. Here are some things to consider when purchasing a connector manufacturer.

Firstly, you need to consider the range of connectors and their capabilities. Look for a manufacturer that has a wide selection of connectors that can meet your needs. Ensure that they have connections for a variety of applications such as audio, video, data, power, and more. Also, look for manufacturers that design connectors that can tolerate extreme conditions to ensure they meet your needs.

Another thing to consider is quality. You will want to work with a connector manufacturer that values quality and produces connectors that are durable and reliable. Do they manufacture connectors that meet industry standards? You should also look into their testing processes to determine if they conduct thorough tests before releasing their connectors and products to the public.

Furthermore, you should consider the cost of their connectors. Check if the connector manufacturer has products that are within your budget. Choose a connector manufacturer that can give you discounts if you purchase their products in bulk. Also, it’s essential to factor in the overall cost of owning and using their connectors over time, such as maintenance and durability.

Lastly, research the manufacturer’s reputation and experience in the market. Look for a connector manufacturer that is established and has years of experience in the industry. Check their customers’ reviews to get insights into the quality of their connectors and services.

In conclusion, when purchasing a connector manufacturer, you should consider the range of connectors and their capabilities, quality, cost, and the manufacturer’s reputation and experience. By taking these factors into account, you can find a connector manufacturer that will provide you with reliable and quality connectors that meet your needs.

Properties of Connector Manufacturer

Connector manufacturers are responsible for designing and producing essential tools that are used to connect electronic circuits. These connectors can be found in a wide variety of electronic devices, including computers, smartphones, and even automobiles. The best connector manufacturers must possess certain qualities that set them apart from their competitors. In this article, we will discuss the properties of a reliable connector manufacturer.

Quality Control: A reputable connector manufacturer must have a quality control system in place to ensure that all connectors produced are consistently reliable and meet the required specifications. Quality control measures such as testing and inspecting connectors at various stages of production are critical in achieving high-quality connectors.

Innovation: A good connector manufacturer must be innovative to keep up with the changing technology landscape. The company must constantly develop new connectors to meet the demands of emerging technologies, such as the Internet of Things(IoT), Artificial Intelligence, wearables, and virtual reality.

Technical Expertise: The manufacturer must have a team of technical experts with a deep understanding of the electronic industry. The team should be familiar with new technologies and other significant trends in the industry to enable them to design and produce connectors that are compatible with various applications.

Service and Support: A reliable connector manufacturer must provide excellent support to its customers, including technical support, after-sales services, and customer care. The manufacturer must be available to advise customers on the best connectors for their specific applications, and should make it easy for them to order and receive their orders promptly.

Customization: Customization is a critical aspect for some customers who require a specific type of connector for their applications. A reputable connector manufacturer must be capable of designing connectors to meet the unique needs of their customers.

In conclusion, the properties of a reliable connector manufacturer include quality control systems, innovation, technical expertise, support, and customization. These qualities set a good connector manufacturer apart from its competitors and are essential to producing connectors of the highest quality that meet the specific needs of different customers.

Technical Parameters Terms for Connector Manufacturer

As a connector manufacturer, it is important to have a strong understanding of technical parameters terms that are used in the industry. Technical parameters are the values and specifications that determine the performance of a connector. Understanding these terms is vital to ensuring that the right connector is chosen for a specific application.

One of the most important technical parameters is current rating. Current rating refers to the amount of electrical current that a connector can safely carry without causing damage or overheating. This parameter is essential in selecting connectors for power applications.

Another essential technical parameter is contact resistance. Contact resistance refers to the amount of resistance in the electrical connection between the mating parts of a connector. A low contact resistance ensures a stable and reliable connection.

Insertion and withdrawal forces are important technical parameters that determine the ease of connection and disconnection of the connector. High forces can make it difficult to connect and disconnect while low forces may result in a loose connection.

Dielectric withstanding voltage is a crucial parameter that determines how well the connector can withstand high voltage levels without breaking down. This parameter is especially important for applications where high voltage levels are present.

Finally, another technical parameter that is critical in selecting the right connector is mating cycles. This parameter refers to the number of times a connector can be mated and unmated without damage. Understanding this parameter is vital in selecting connectors for applications that require frequent connections and disconnections.

In conclusion, technical parameters are vital in the design and selection of connectors. As a connector manufacturer, it is important to have a strong understanding of these terms to ensure that the right connector is chosen for each specific application. By considering technical parameters such as current rating, contact resistance, insertion and withdrawal forces, dielectric withstanding voltage and mating cycles, manufacturers can design and supply connectors that meet the needs of their customers.

Connector Manufacturer Price

When it comes to purchasing connectors for your electronic devices or machinery, price is often a key factor to consider. Connector manufacturers offer a wide range of products, and it can be challenging to determine the best option for your needs while keeping costs in check.

The price of connectors can vary depending on several factors, including the materials used, the complexity and size of the connector, and the volume of units ordered. Furthermore, different manufacturers price their connectors differently, making it vital to compare options before making a purchase decision.

If you’re looking for the best deal, it’s essential to consider factors beyond the quoted price, such as delivery times, return and exchange policies, and customer service. Additionally, you should consider the quality of the connectors and choose a manufacturer with a good reputation for producing reliable, robust products.

Another way to save money on connector purchases is to look for opportunities to buy in bulk. Many connector manufacturers offer discounts for large volume orders, so it’s worth considering this option for your more extensive projects.

Overall, determining the best connector manufacturer price requires thorough research, comparisons, and a good understanding of your specific needs. By finding a balance between quality, price, and other factors, you can make an informed decision and get the most out of your connector purchases.